Ceramic material with multi-stage duct structure and manufacture method thereof

A technology of ceramic materials and pore structure, applied in the production of ceramic materials, ceramic products, clay products, etc., can solve problems such as the impact of living environment, and achieve the effect of less cracks, good water permeability, excellent water absorption and water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

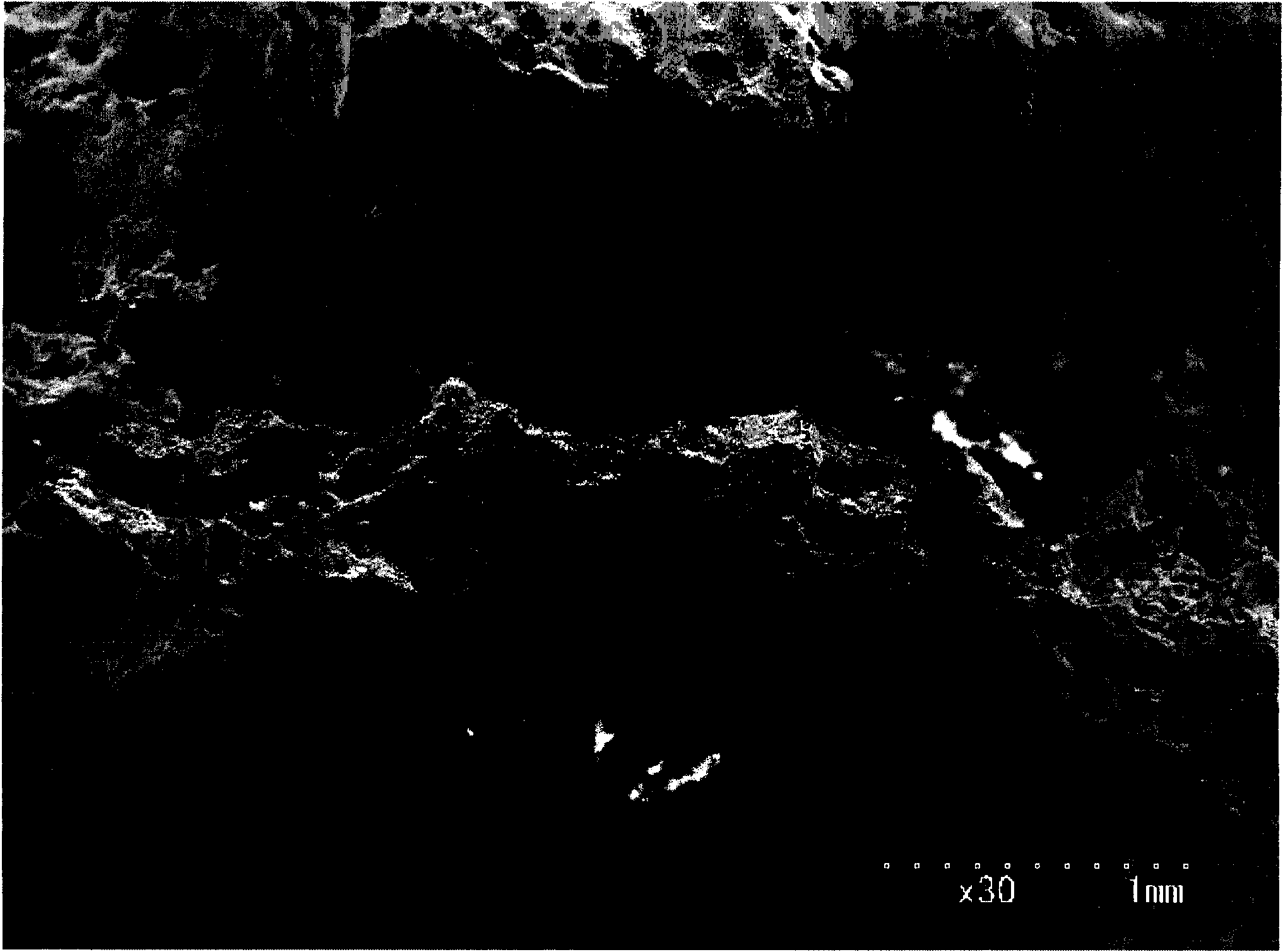

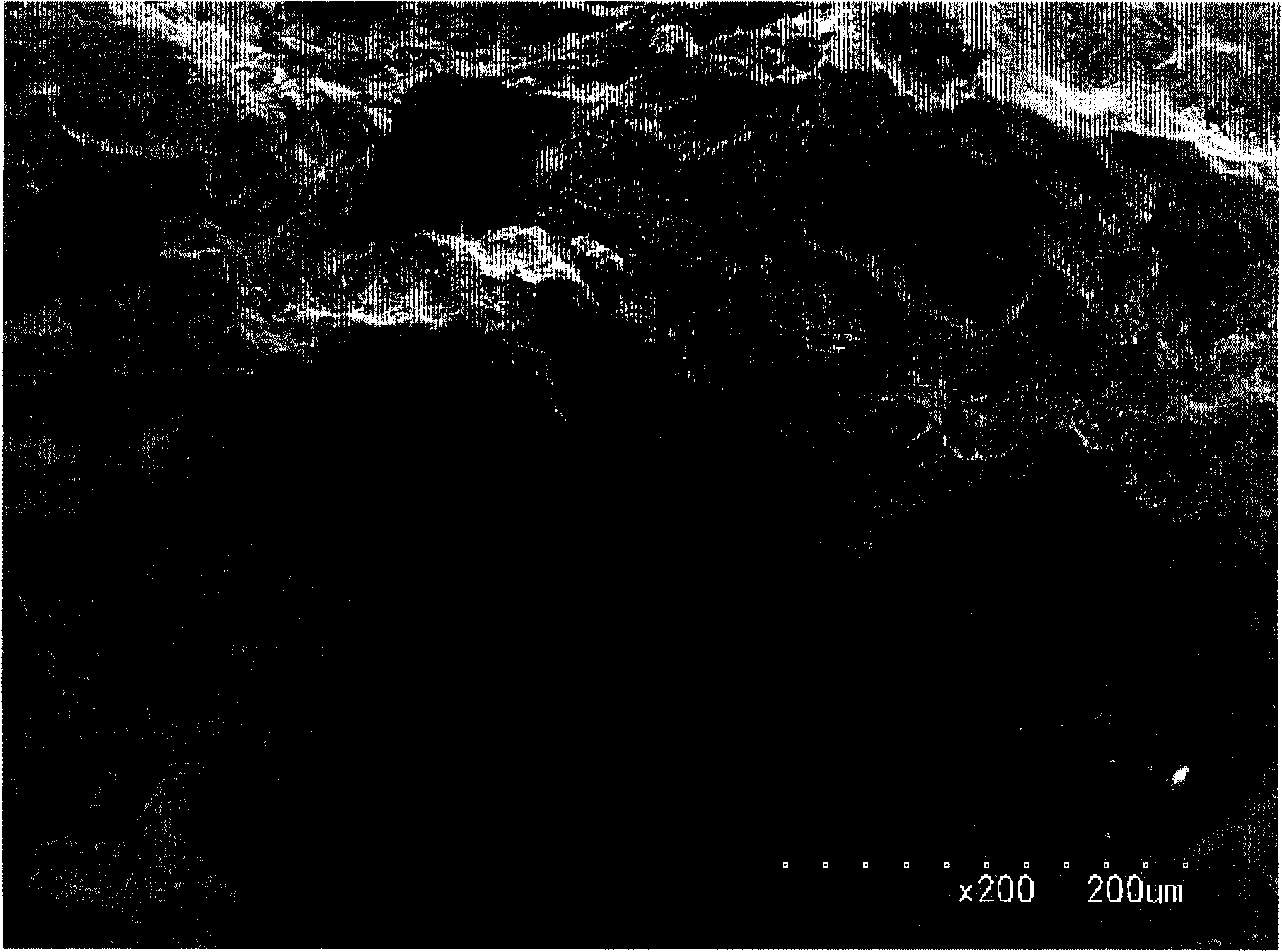

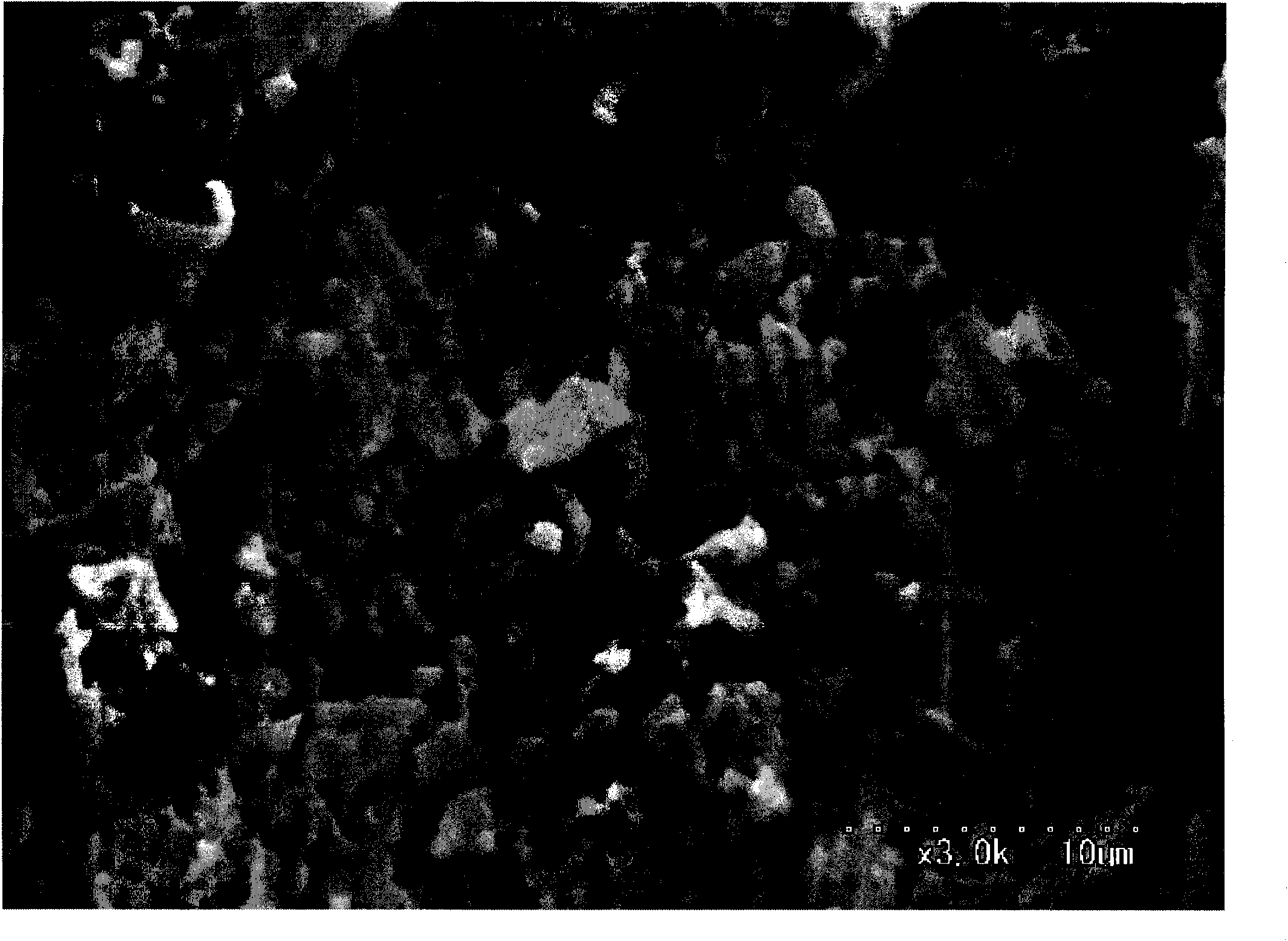

Image

Examples

Embodiment 1

[0064] 1. Raw material formula

[0065] (1) Water-quenched slag: the particle size is in the range of 0.5-1mm, and the mass percentage is 50%.

[0066] (2) Zeolite used as an adsorbent eliminated in the water treatment industry: the average particle size is 20 μm, and the mass percentage is 5%.

[0067] (3) Diatomaceous earth eliminated from the brewery as an adsorbent: the average particle size is 30 μm, and the mass percentage is 15%.

[0068] (4) Kaolinite clay: the average particle size is 100 μm, and the mass percentage is 30%.

[0069] 2. Manufacturing process

[0070] (1) Mixing and adjustment of raw materials: Mix the above-mentioned raw materials according to the proportion, add appropriate amount of water and stir evenly in the concrete mixer for 30 minutes, and adjust the water content of the slurry between 7% and 10%.

[0071] (2) Compression molding: Pour the slurry into a metal mold, and use 10kgf / cm 2 The pressure was molded to obtain a 16cm×8cm×3.5cm brick-...

Embodiment 2、 Embodiment 3、 comparative example 1 and comparative example 2

[0078] All adopt the same raw materials as in Example 1, namely, water-quenched slag, zeolite as adsorbent eliminated in the water treatment industry, diatomite and kaolin clay eliminated as adsorbent in breweries, and the specific ingredients are as follows: Table 1 shows. A brick-shaped porous ceramic body was sintered using the same manufacturing process as in Example 1. The results of the sintered compact and the properties of the porous ceramics are shown in Table 1.

Embodiment 4

[0080] 1. Raw material formula

[0081] (1) Vitreous residue remaining after sewage sludge is incinerated and melted: After crushing and screening, the particle size is controlled within the range of 0.5-1mm, and the mass percentage added is 35%.

[0082] (2) Zeolite used as an adsorbent eliminated in the water treatment industry: the average particle size is 20 μm, and the mass percentage is 10%.

[0083] (3) Diatomaceous earth eliminated from the brewery as an adsorbent: the average particle size is 30 μm, and the mass percentage is 35%.

[0084] (4) Kaolinite clay: the average particle size is 100 μm, and the mass percentage is 20%.

[0085] 2. Manufacturing process

[0086] (1) Mixing and adjustment of raw materials: Mix the above-mentioned raw materials according to the proportion, add appropriate amount of water and stir evenly in the concrete mixer for 30 minutes, and adjust the water content of the slurry between 7% and 10%.

[0087] (2) Compression molding: Pour the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com