Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235results about "Ceramic article drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

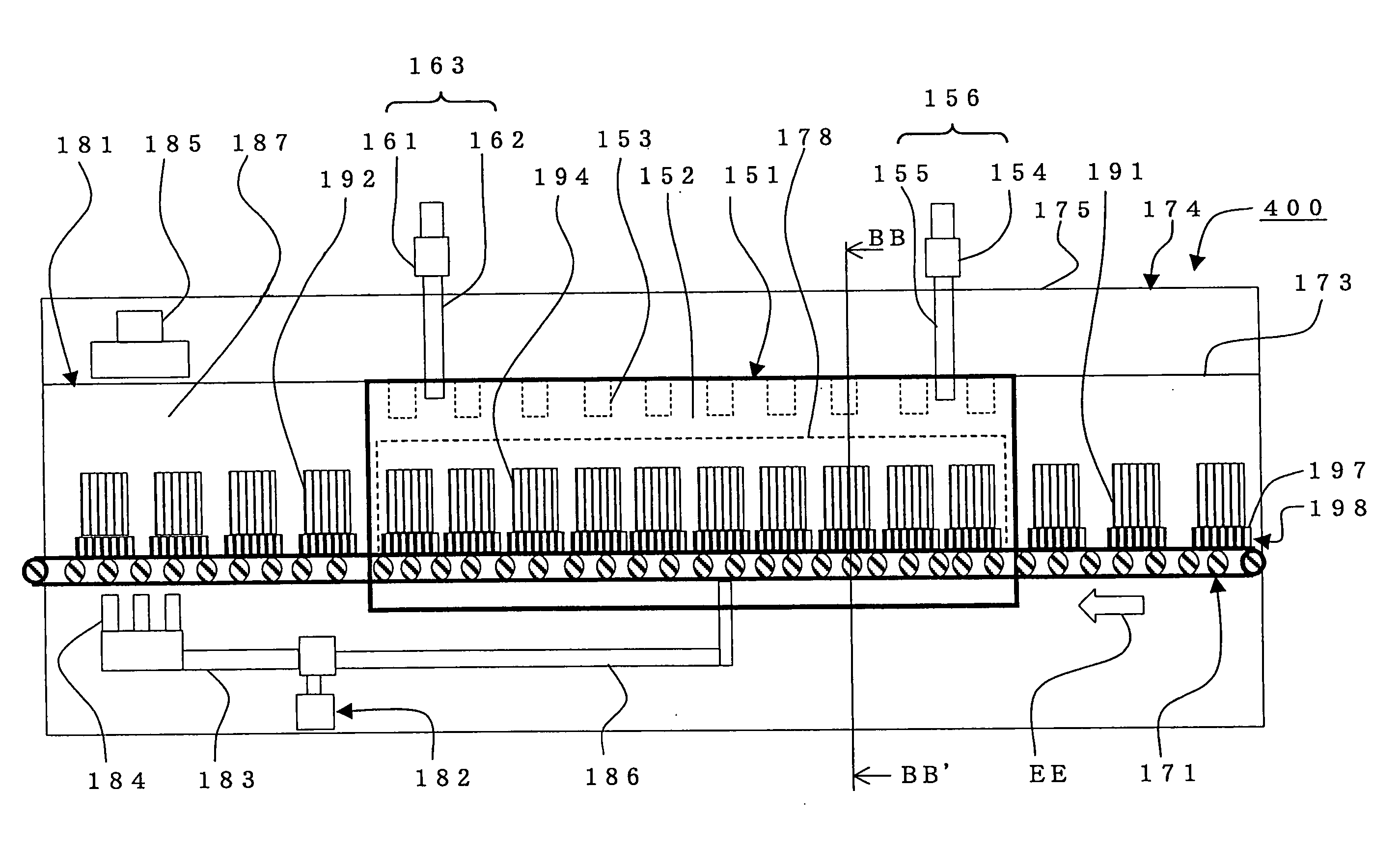

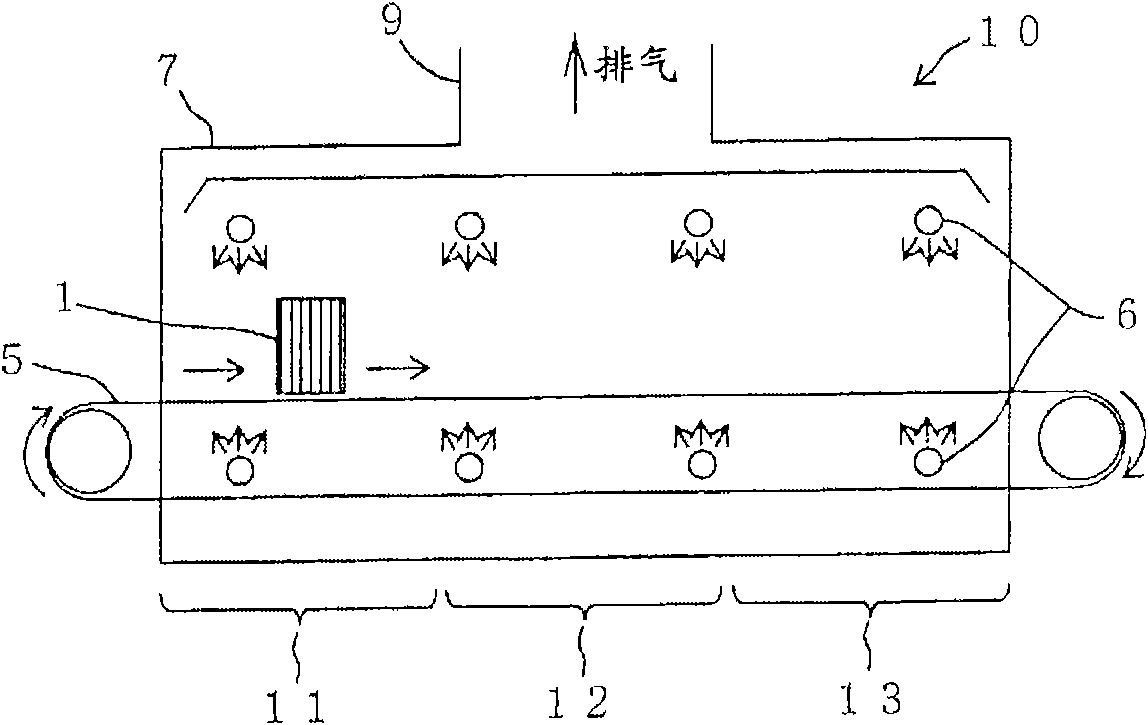

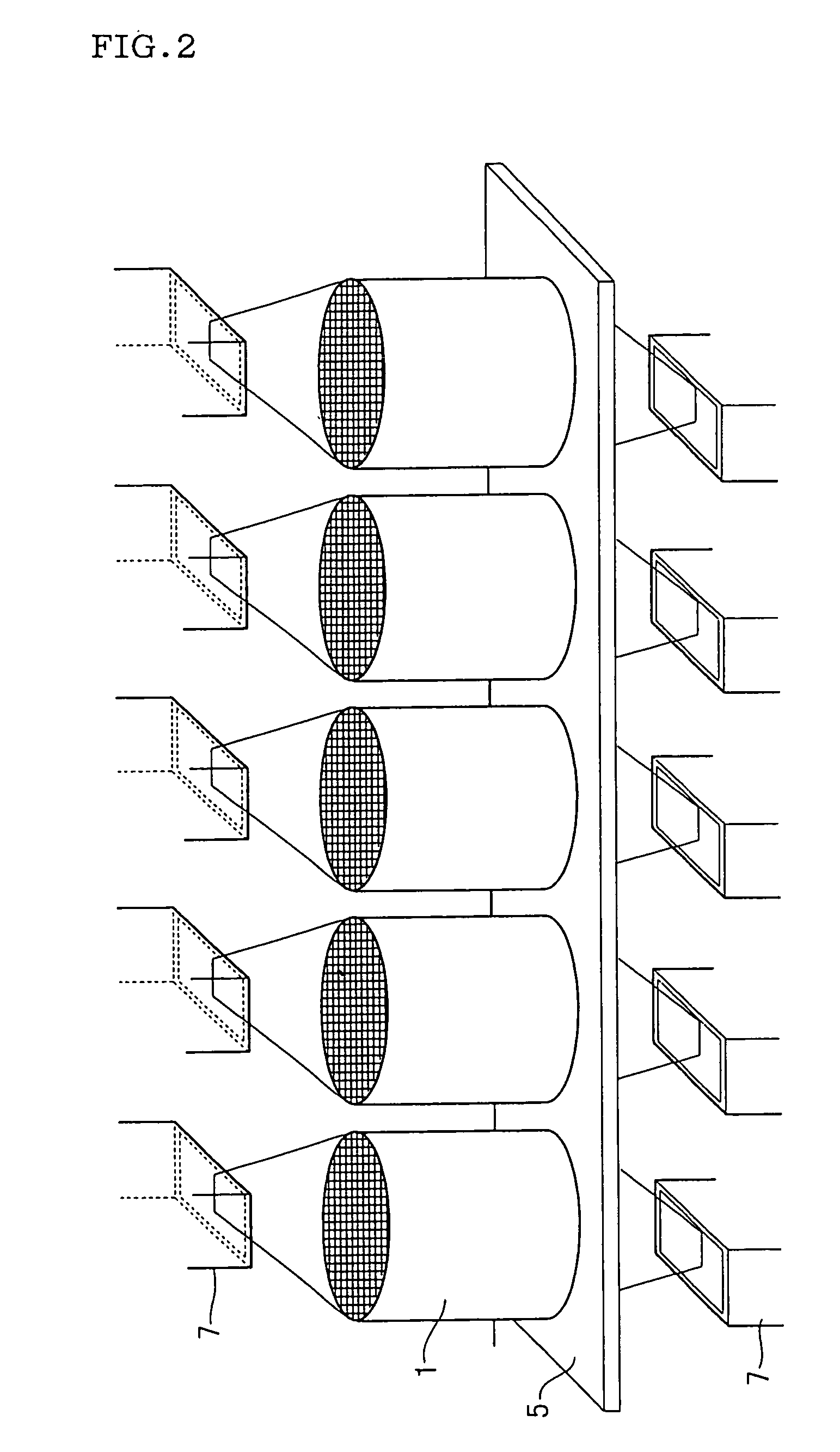

Drying apparatus, method for drying ceramic molded body, and method for manufacturing honeycomb structure

InactiveUS20080136062A1Remove moistureDrying solid materials with heatDrying gas arrangementsCeramic moldingIrradiation

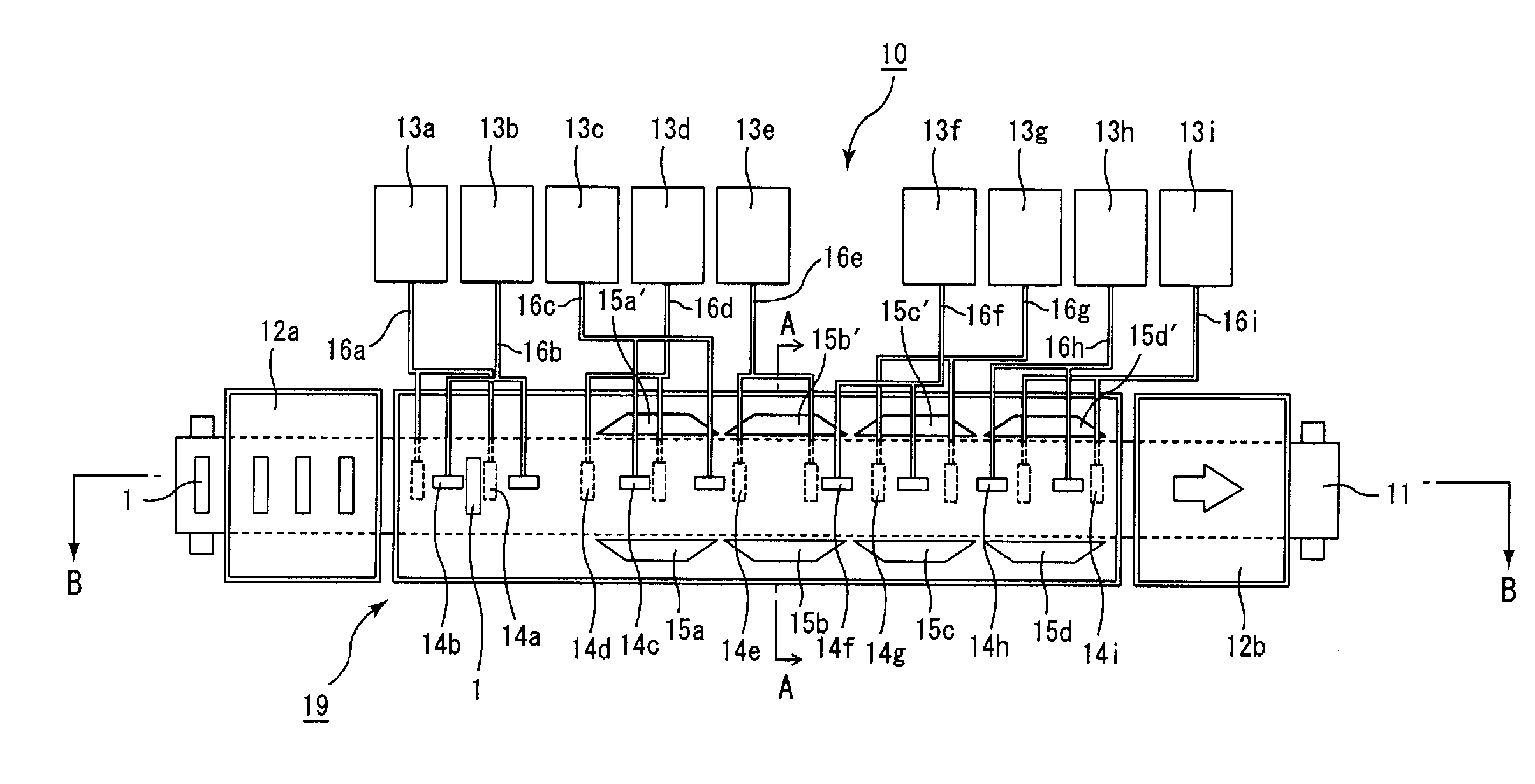

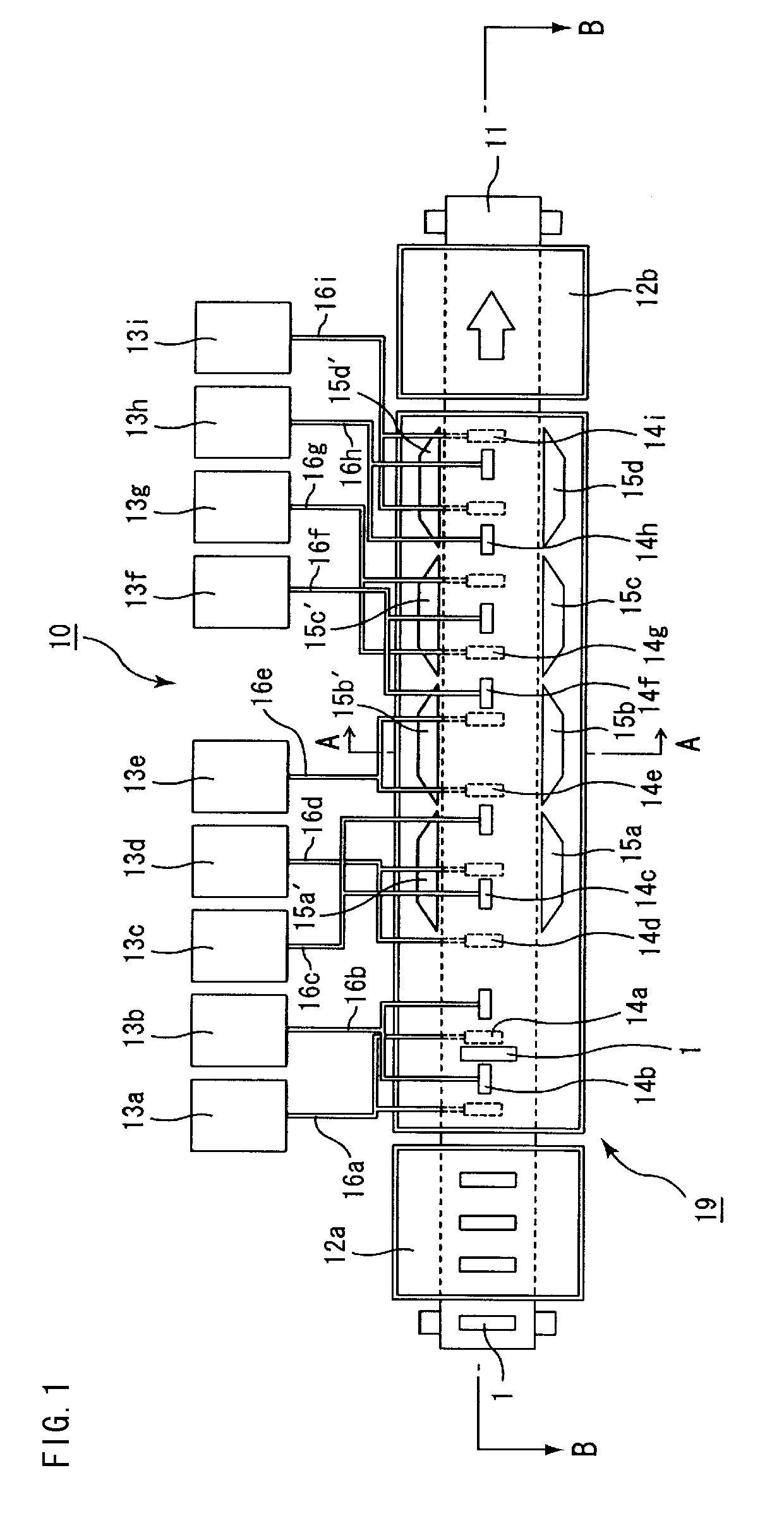

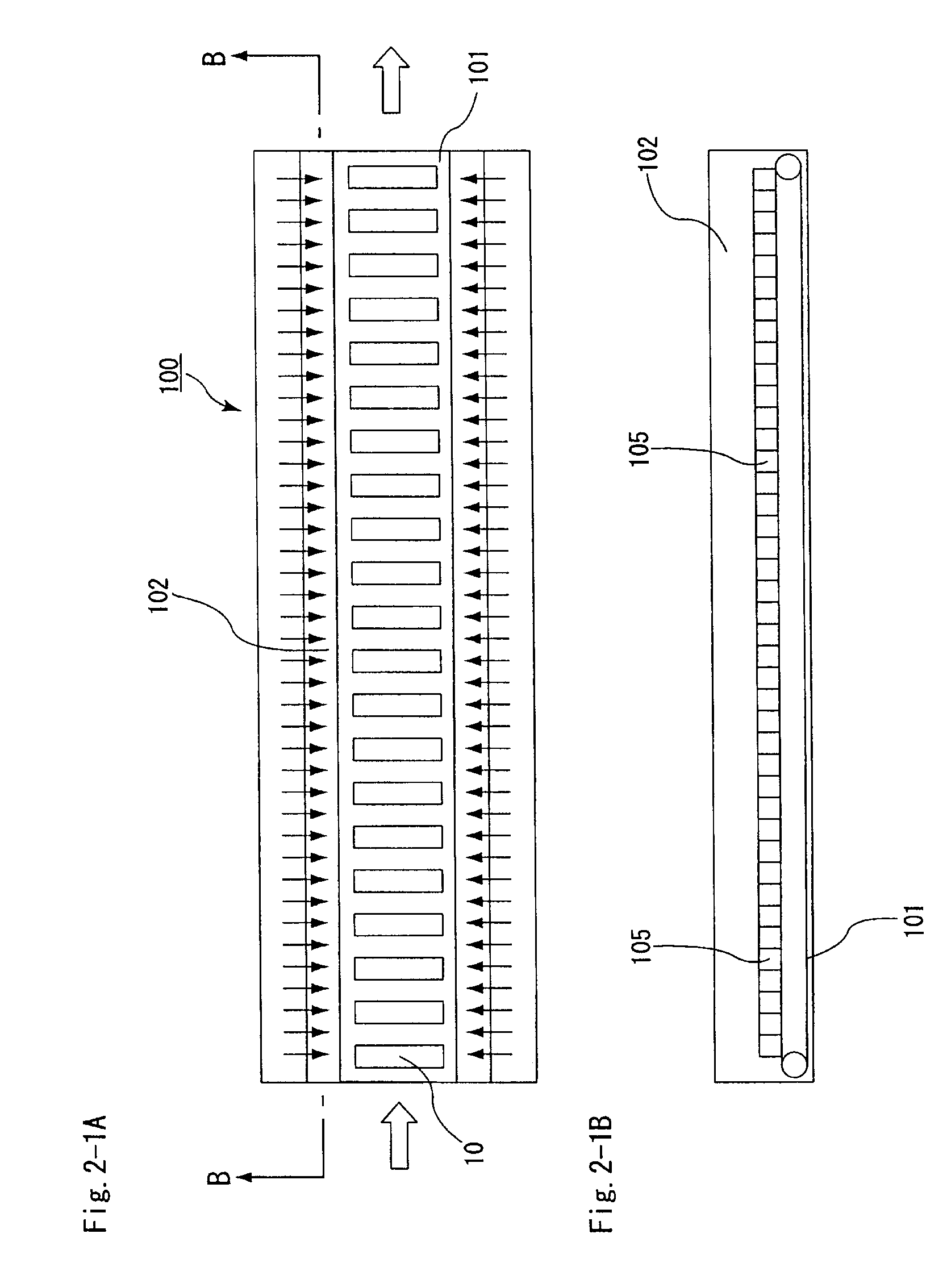

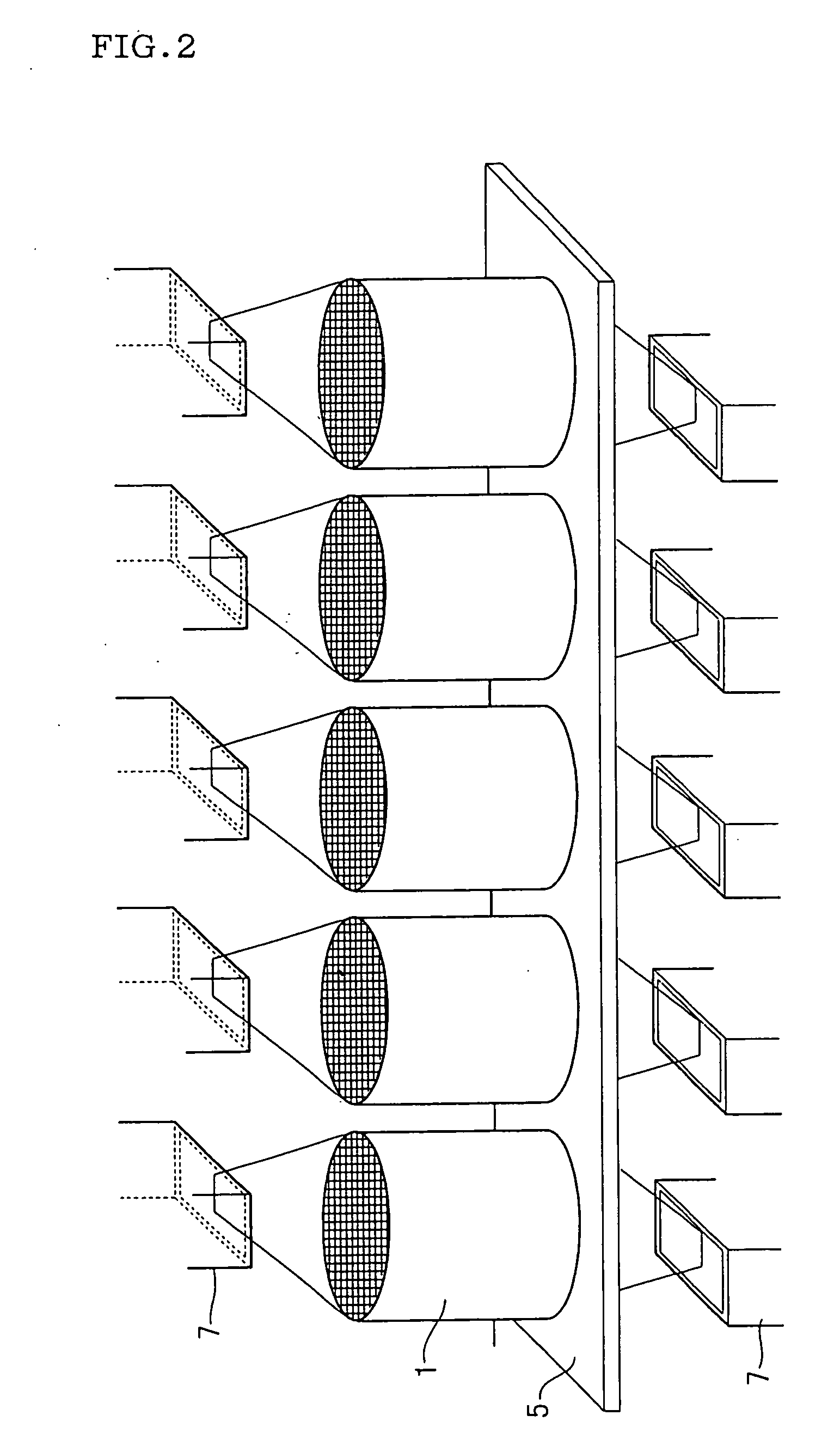

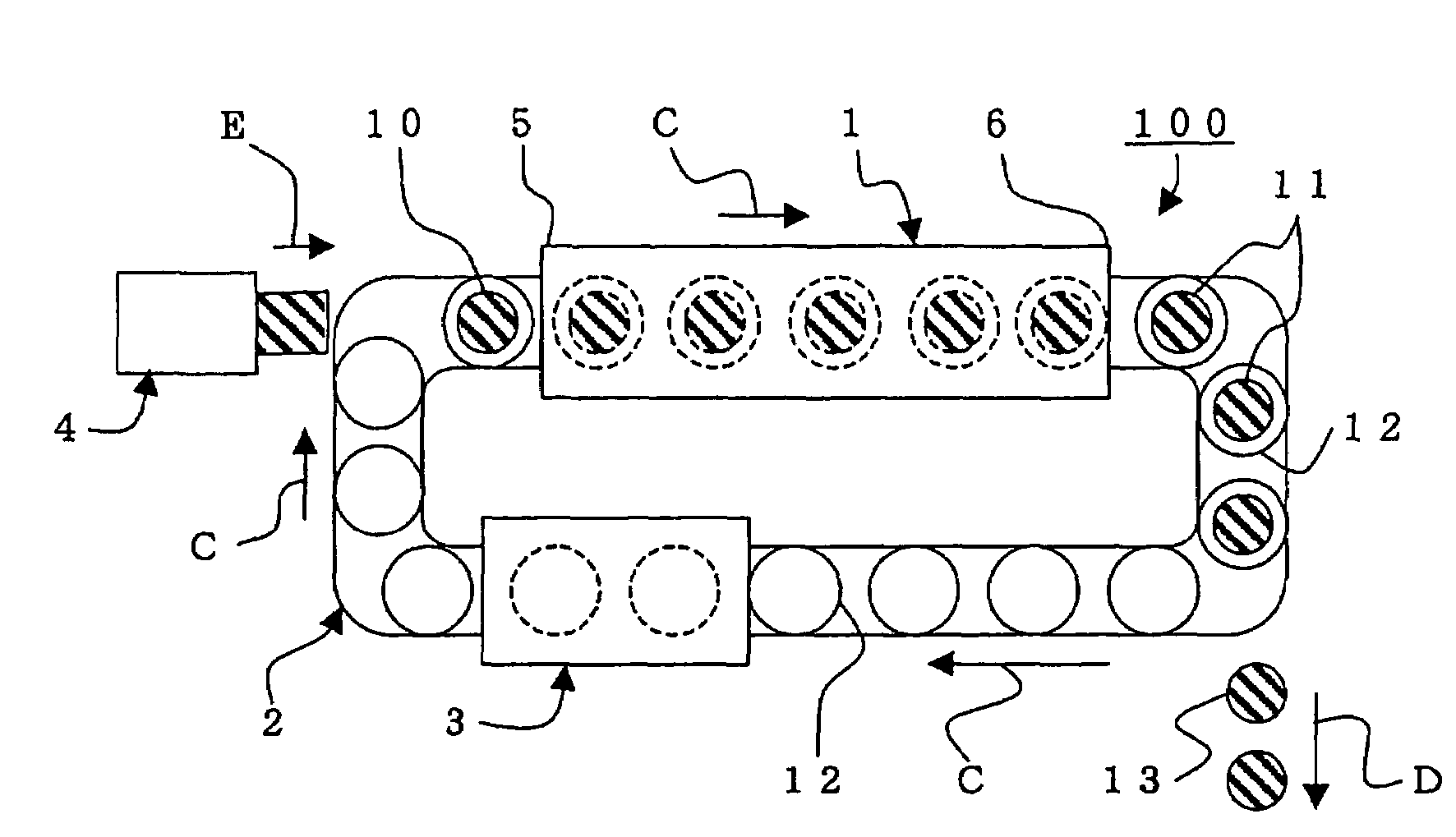

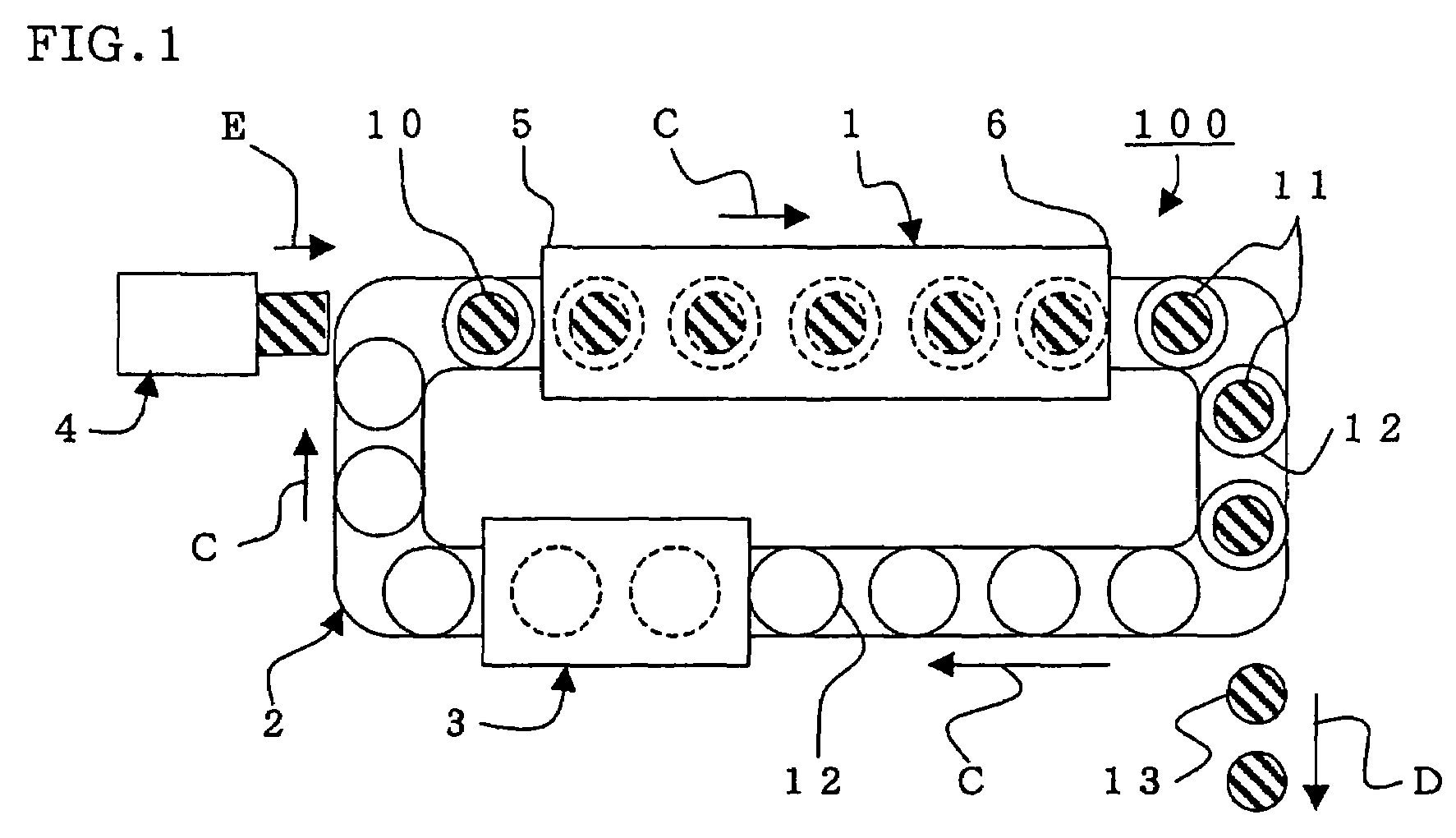

A drying apparatus including a conveying member configured to convey an item to be dried, a plurality of microwave irradiation portions disposed alternately at an upper side and a lower side of the conveying member, and a plurality of hot air blowing portions. The microwave irradiation portions are configured to irradiate the item to be dried with microwaves in an alternating manner from the upper side and the lower side. The hot air blowing portions are configured to apply hot air to the item to be dried in parallel with irradiation of the microwaves by the microwave irradiation portions.

Owner:IBIDEN CO LTD

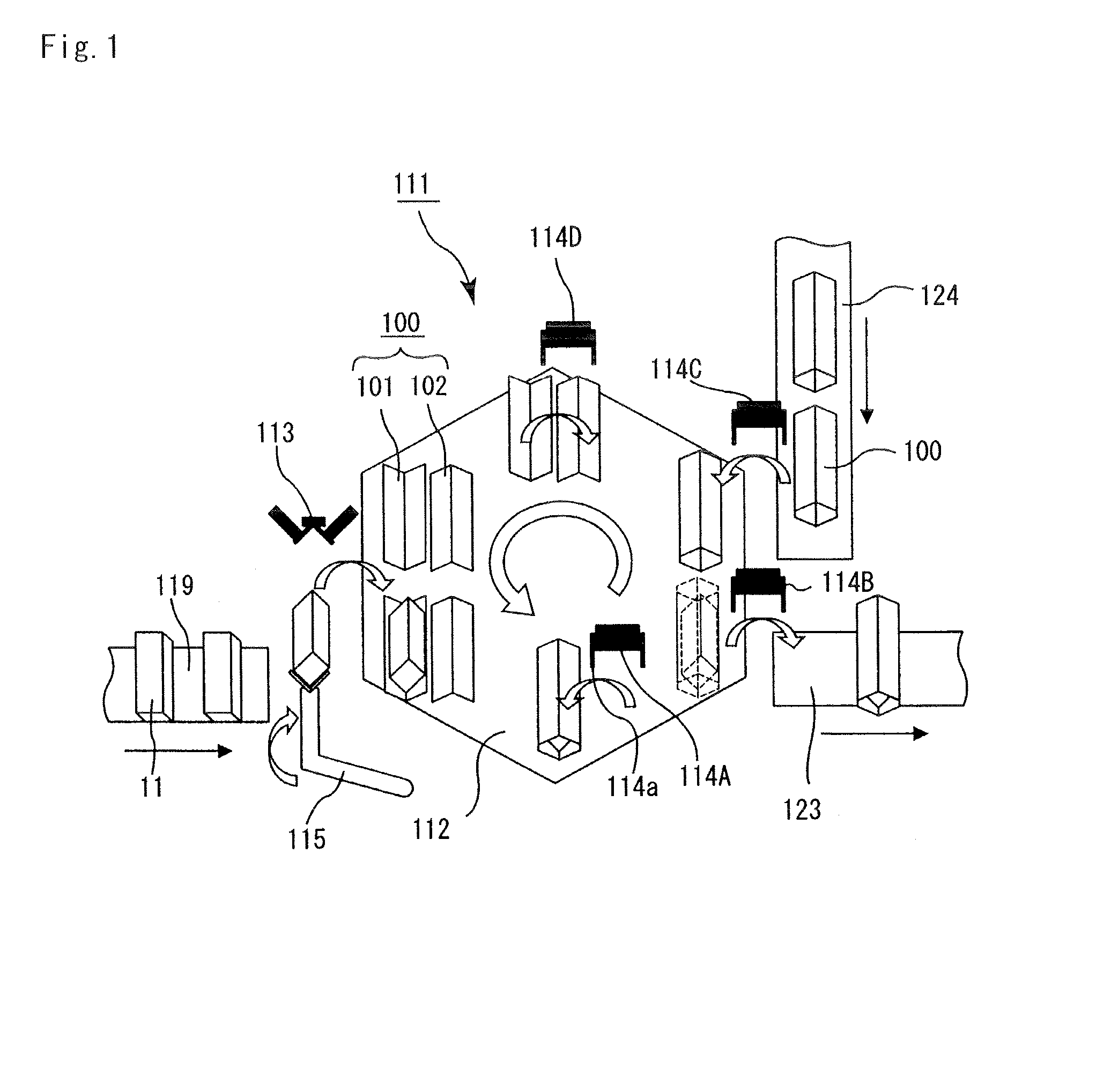

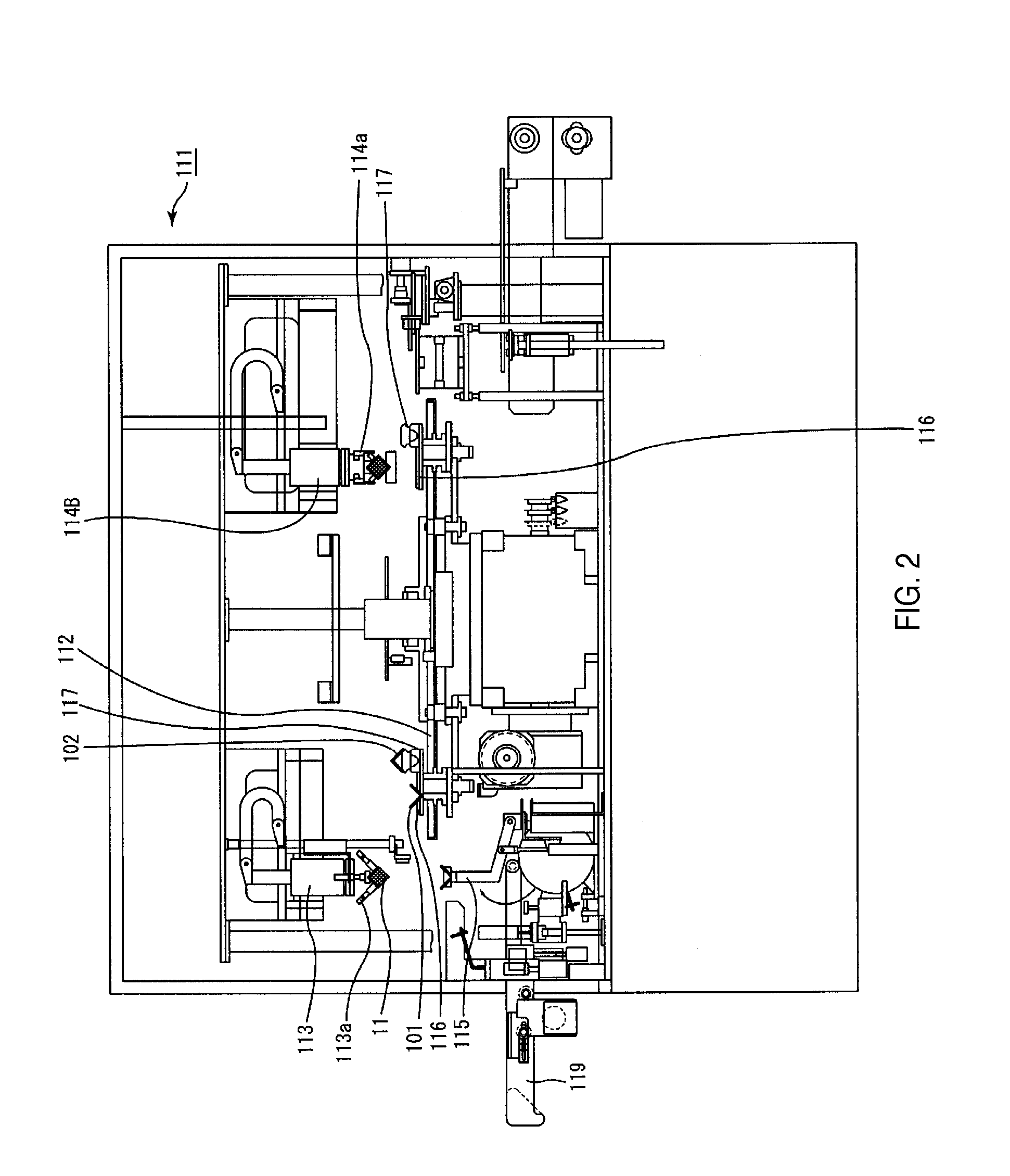

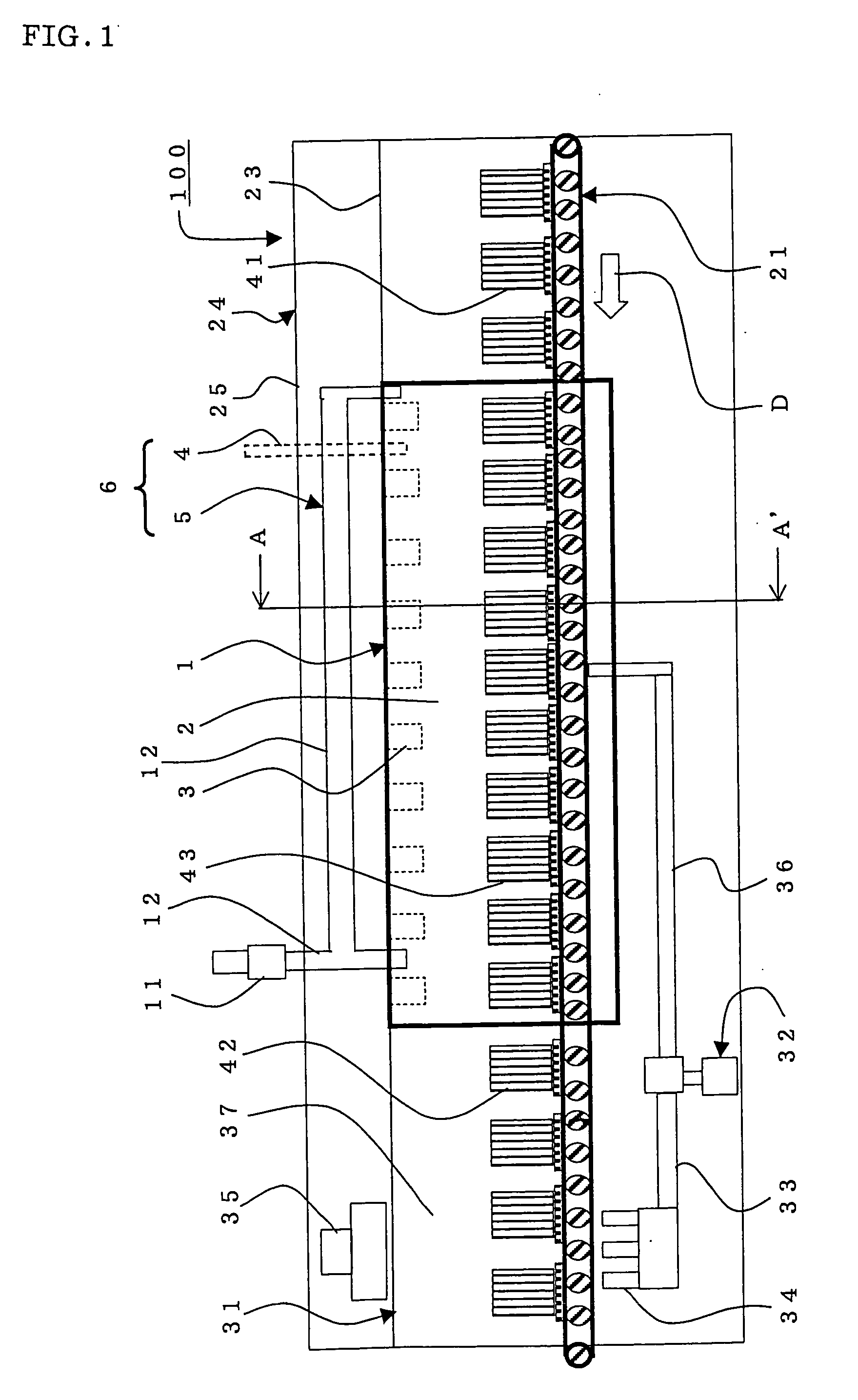

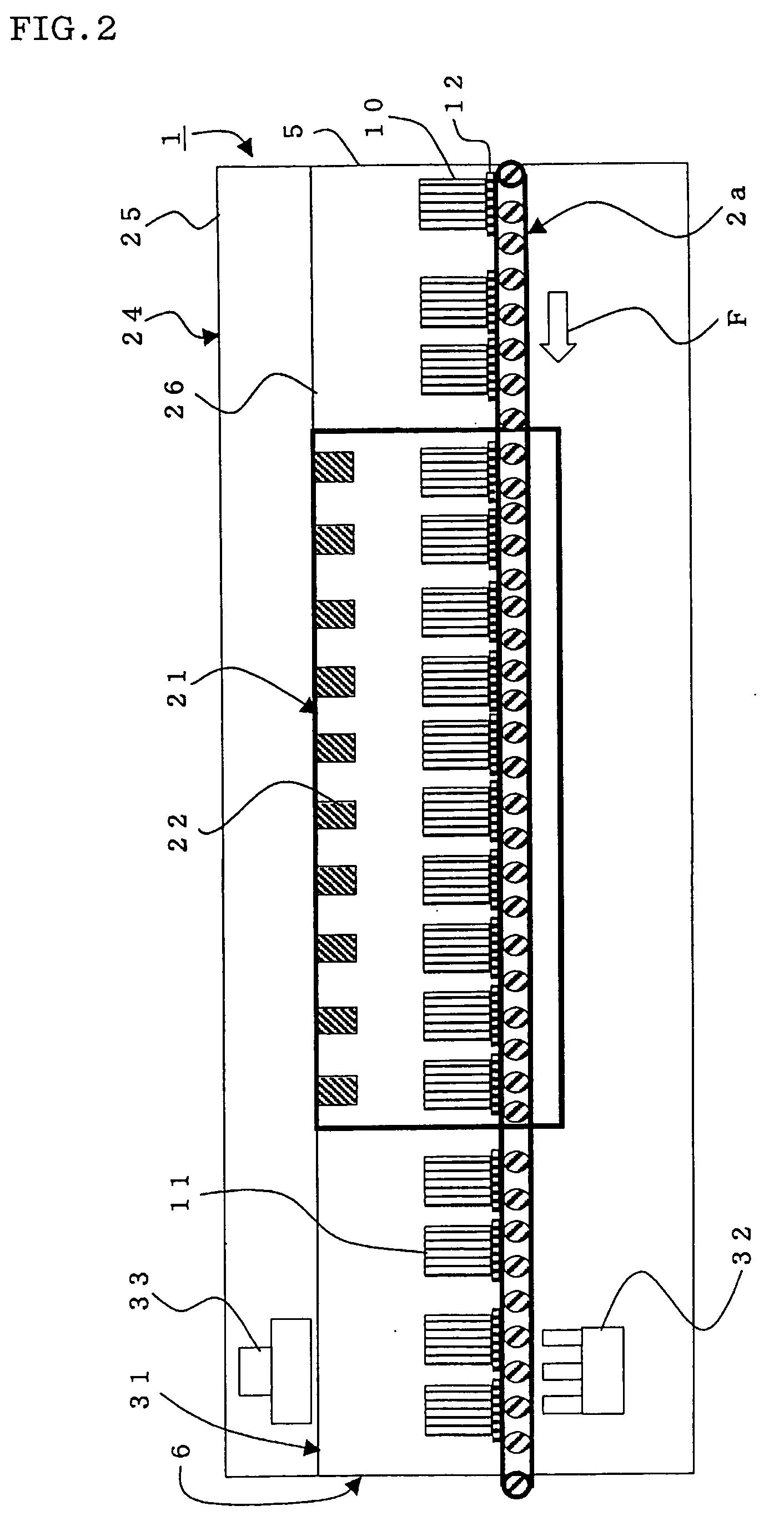

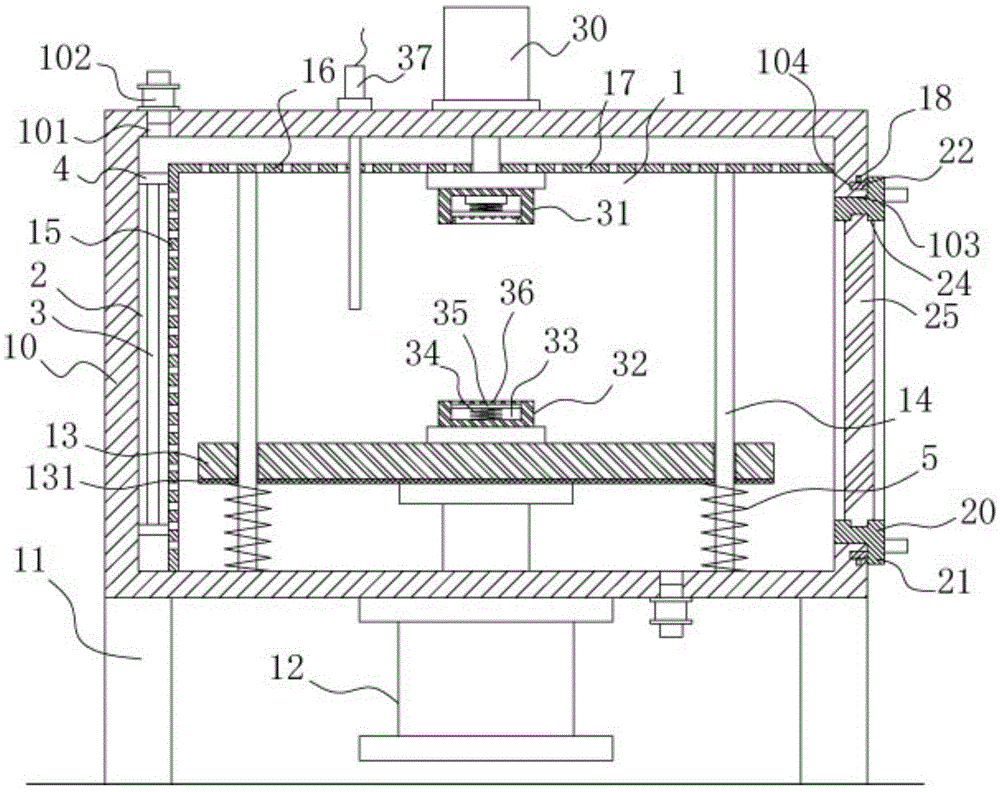

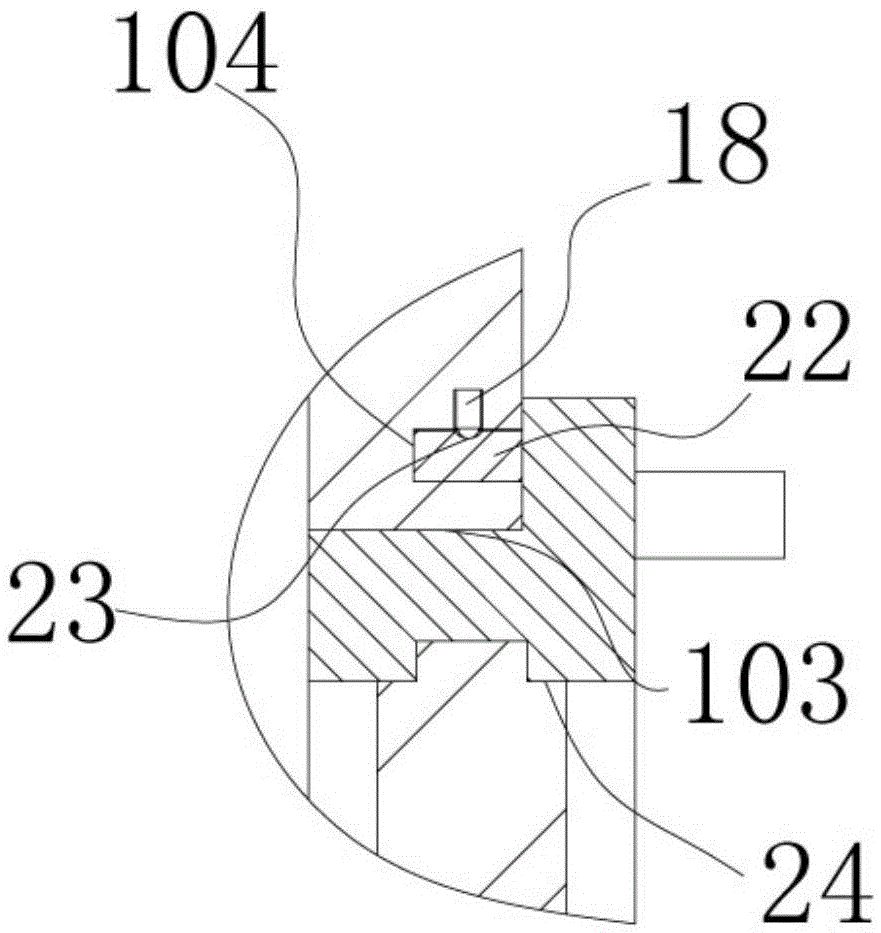

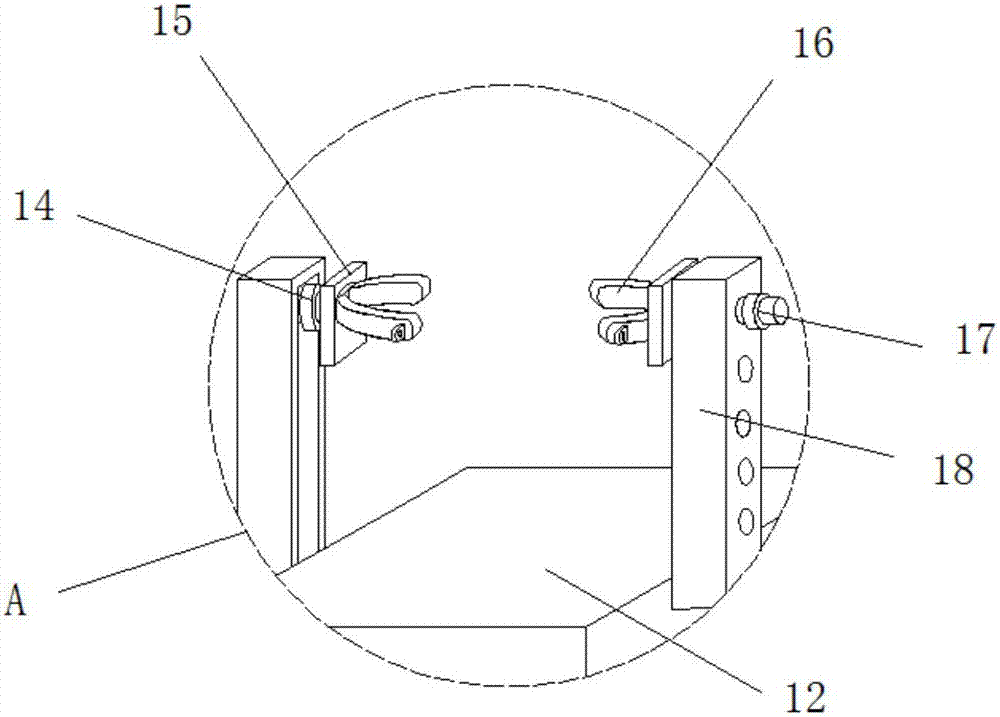

Drying jig assembling apparatus, drying jig disassembling apparatus, drying jig circulating apparatus, drying method of ceramic molded body, and method for manufacturing honeycomb structure

InactiveUS20080106008A1Drying using combination processesAuxillary shaping apparatusHoneycomb structureClosed state

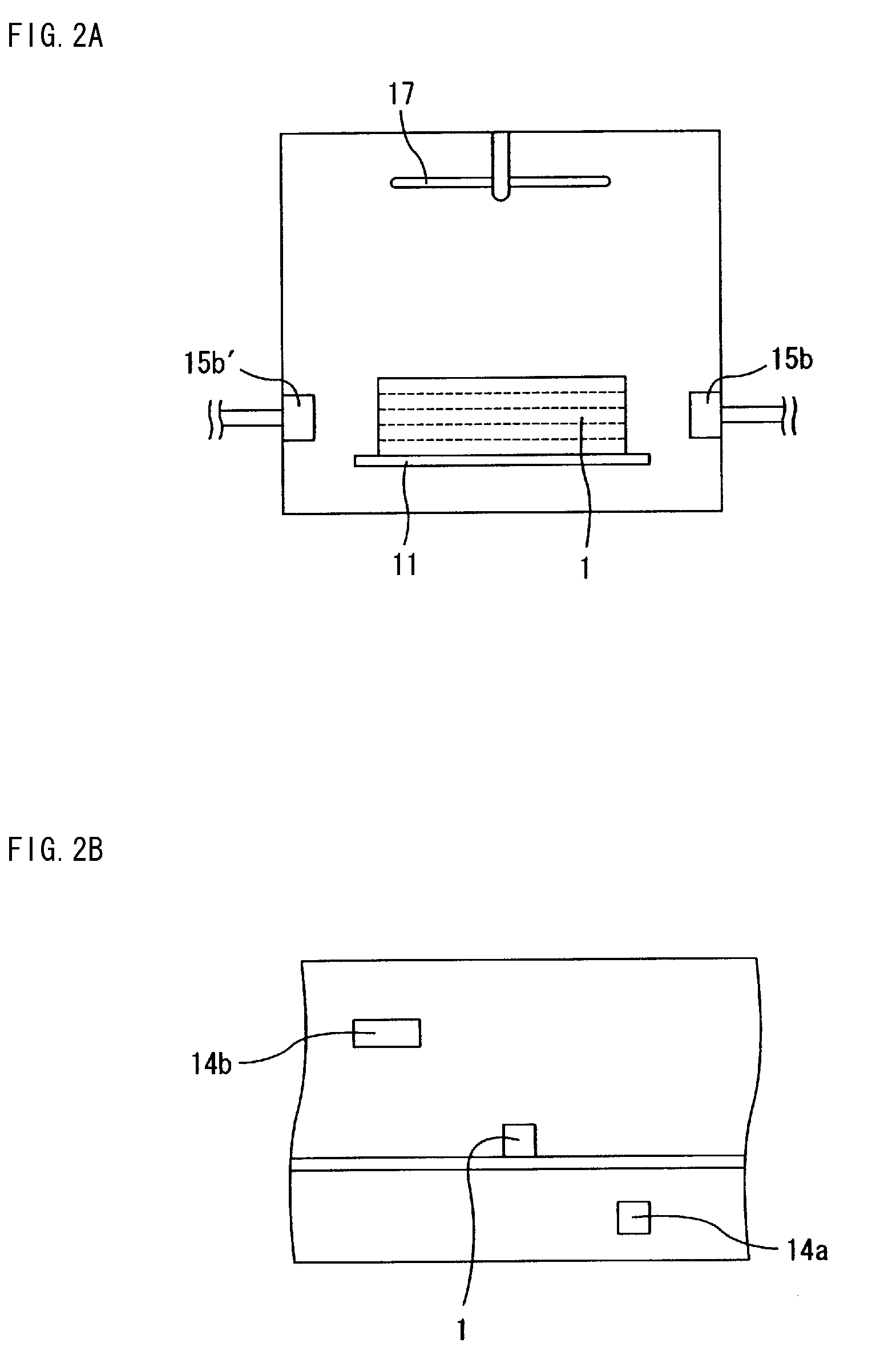

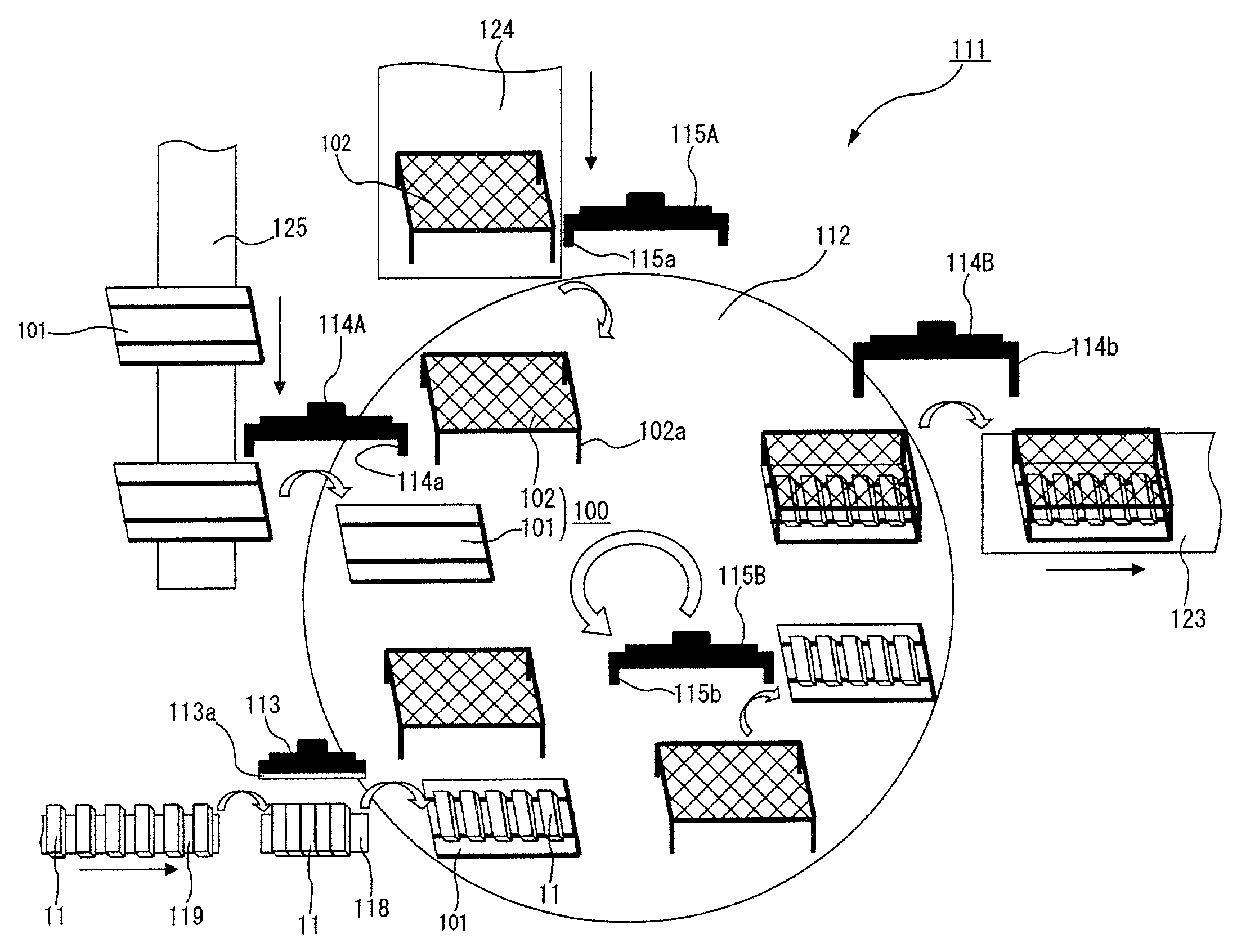

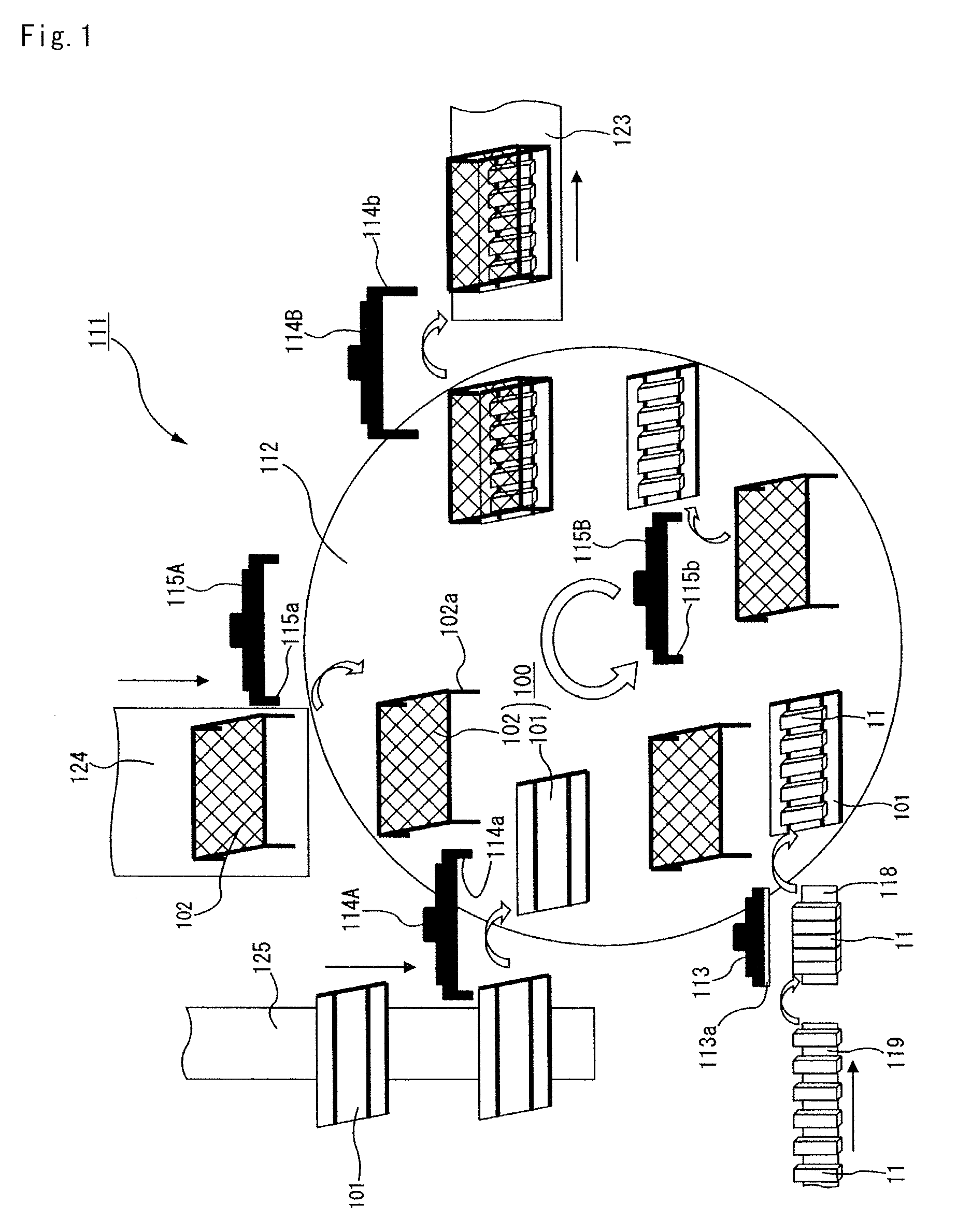

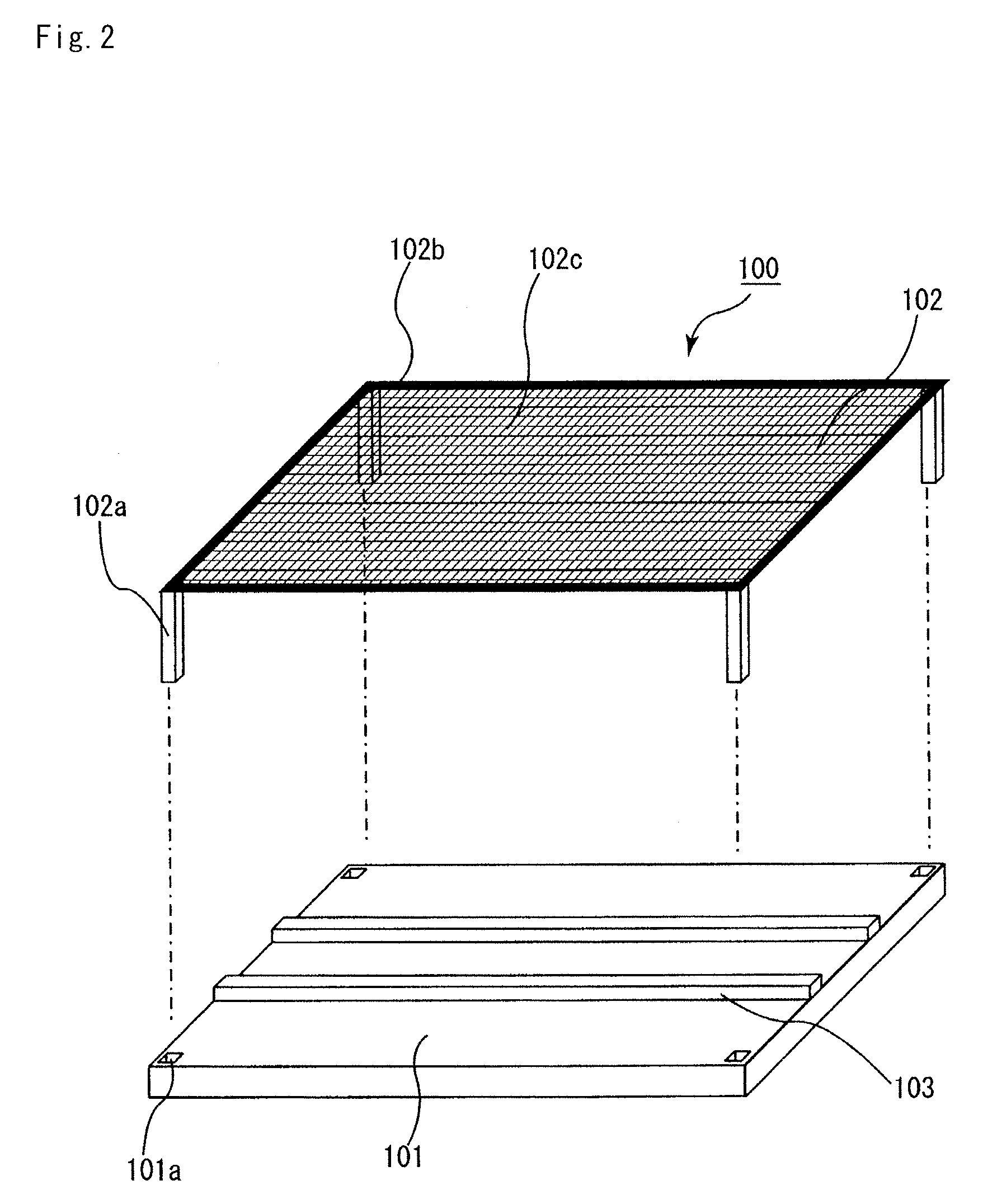

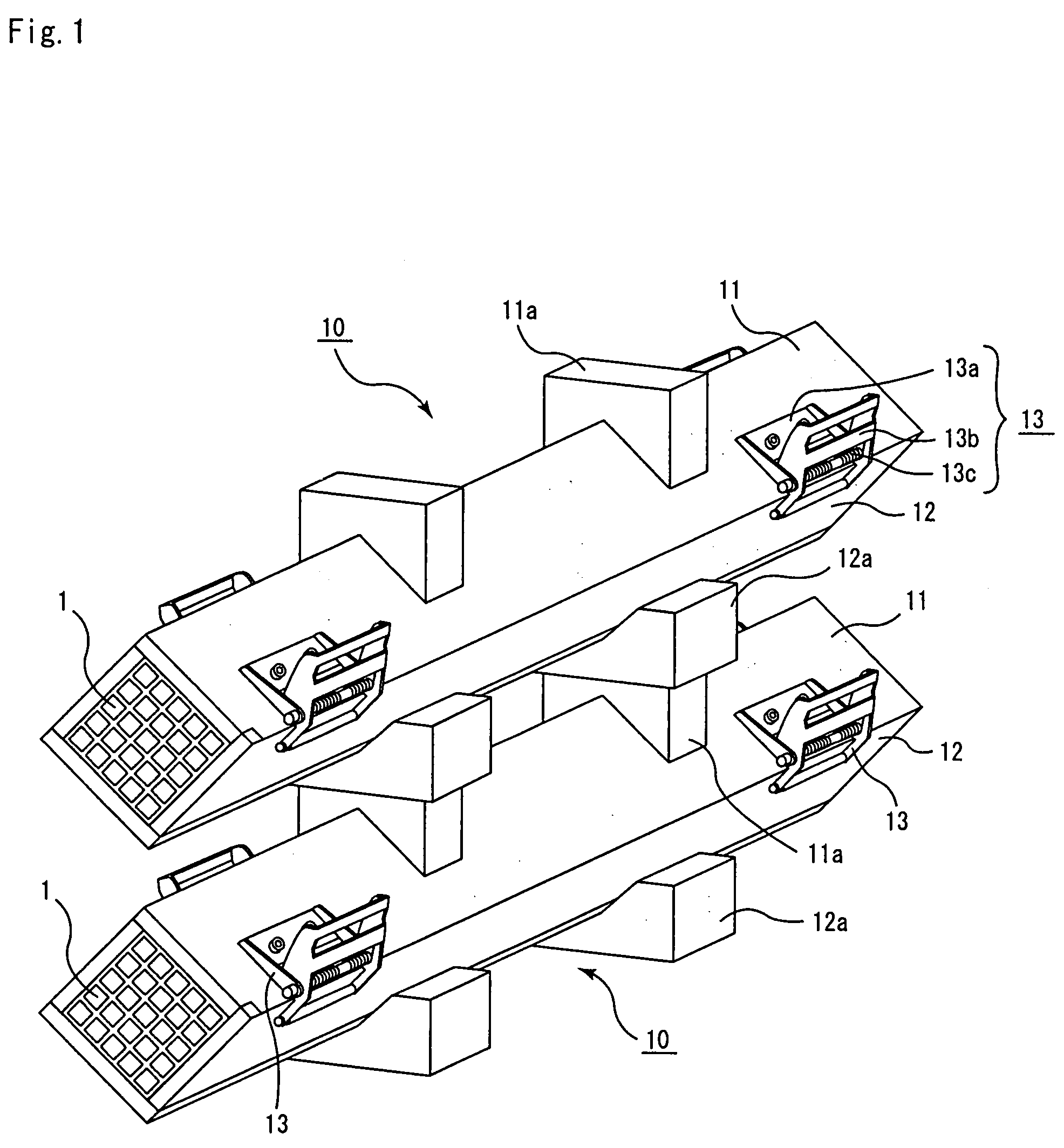

A drying jig circulating apparatus includes a drying jig assembling apparatus for assembling a drying jig on a movable table, a drying apparatus for drying a ceramic molded body held by the drying jig, and a drying jig disassembling apparatus for disassembling the drying jig on a movable table, and a drying jig circulating conveyor for transporting the drying jig from the disassembling apparatus to the assembling apparatus. The drying jig is configured by two or more separate jigs with a fixing member that integrates the separate jigs, or formed by one openable jig with a fixing member for maintaining a closed state. The drying jig assembling apparatus further includes a molded body mounting mechanism, a ceramic molded body holding mechanism, and a jig delivering mechanism. The drying jig disassembling apparatus further includes a jig receiving mechanism, a jig releasing mechanism, and a molded body taking-out mechanism.

Owner:IBIDEN CO LTD

Method for manufacturing a honeycomb structured body

A method for manufacturing a honeycomb structured body including molding ceramic raw material to form a pillar-shaped honeycomb molded body having a multiplicity of cells disposed in parallel with one another in the longitudinal direction with a cell wall therebetween, and filling in either one of the end portions of each of the cells with a plug material paste, and firing the honeycomb molded body to manufacture a honeycomb structured body comprising a honeycomb fired body, wherein after having filled in either one of the end portions of each of the cells of the honeycomb molded body with the plug material paste, a plug material paste drying process to dry the plug material paste is conducted by blowing hot air to an end face of the honeycomb molded body using a hot air drying apparatus.

Owner:IBIDEN CO LTD

Degreasing jig assembling apparatus, degreasing jig disassembling apparatus, degreasing jig circulating apparatus, method for degreasing ceramic molded body, and method for manufacturing honeycomb structured body

A degreasing jig assembling apparatus includes a robot arm and a table or a conveyor on which a degreasing jig including a bottom plate and a cover member is placed. A ceramic molded body is mounted on the degreasing jig upon degreasing the ceramic molded body. The ceramic molded body is mounted on the degreasing jig on the table or the conveyor. The degreasing jig assembling apparatus further includes a molding body mounting mechanism and a cover member. The molding body mounting mechanism mounts the ceramic molded body at a predetermined position on the bottom plate placed on the table or the conveyor by using the robot arm. The cover member attaching mechanism attaches the cover member to the bottom plate in a manner so as to cover the ceramic molded body mounted on the bottom plate.

Owner:IBIDEN CO LTD

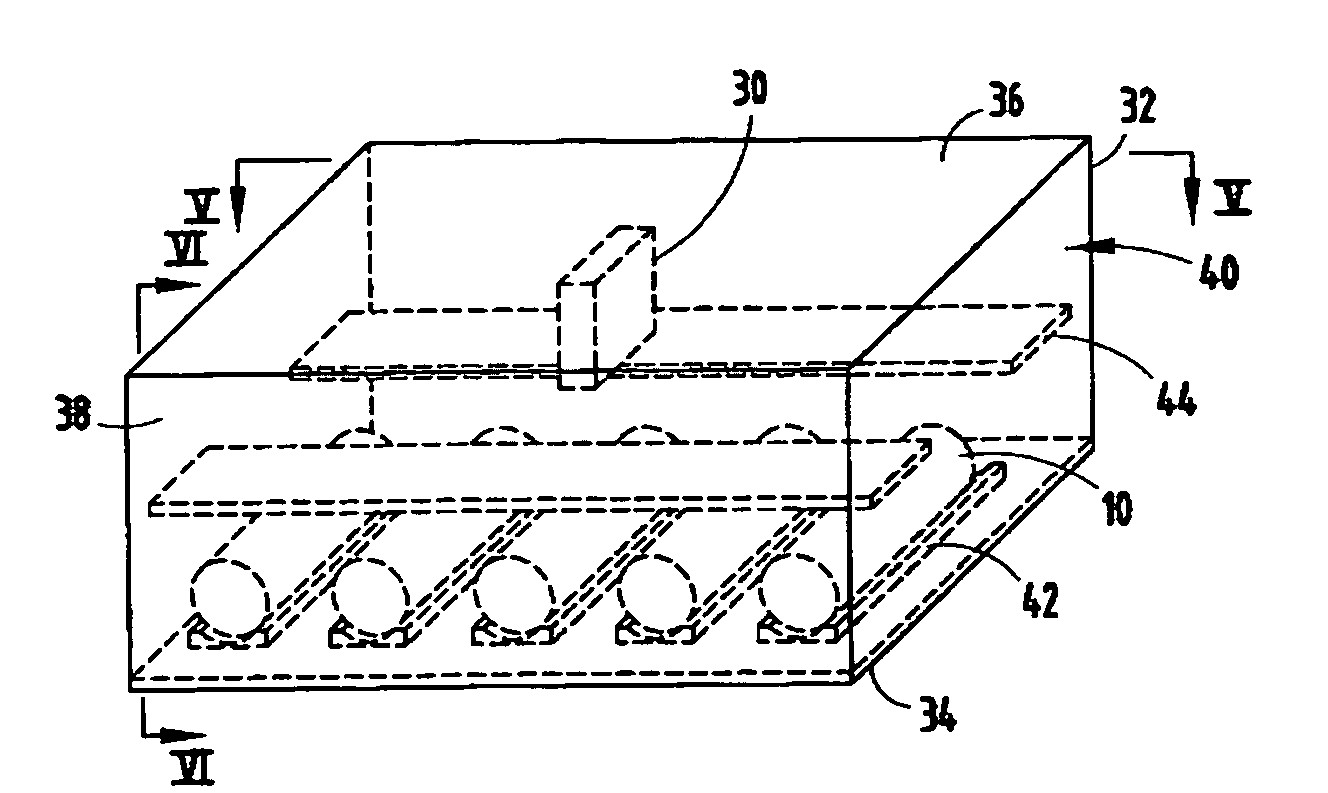

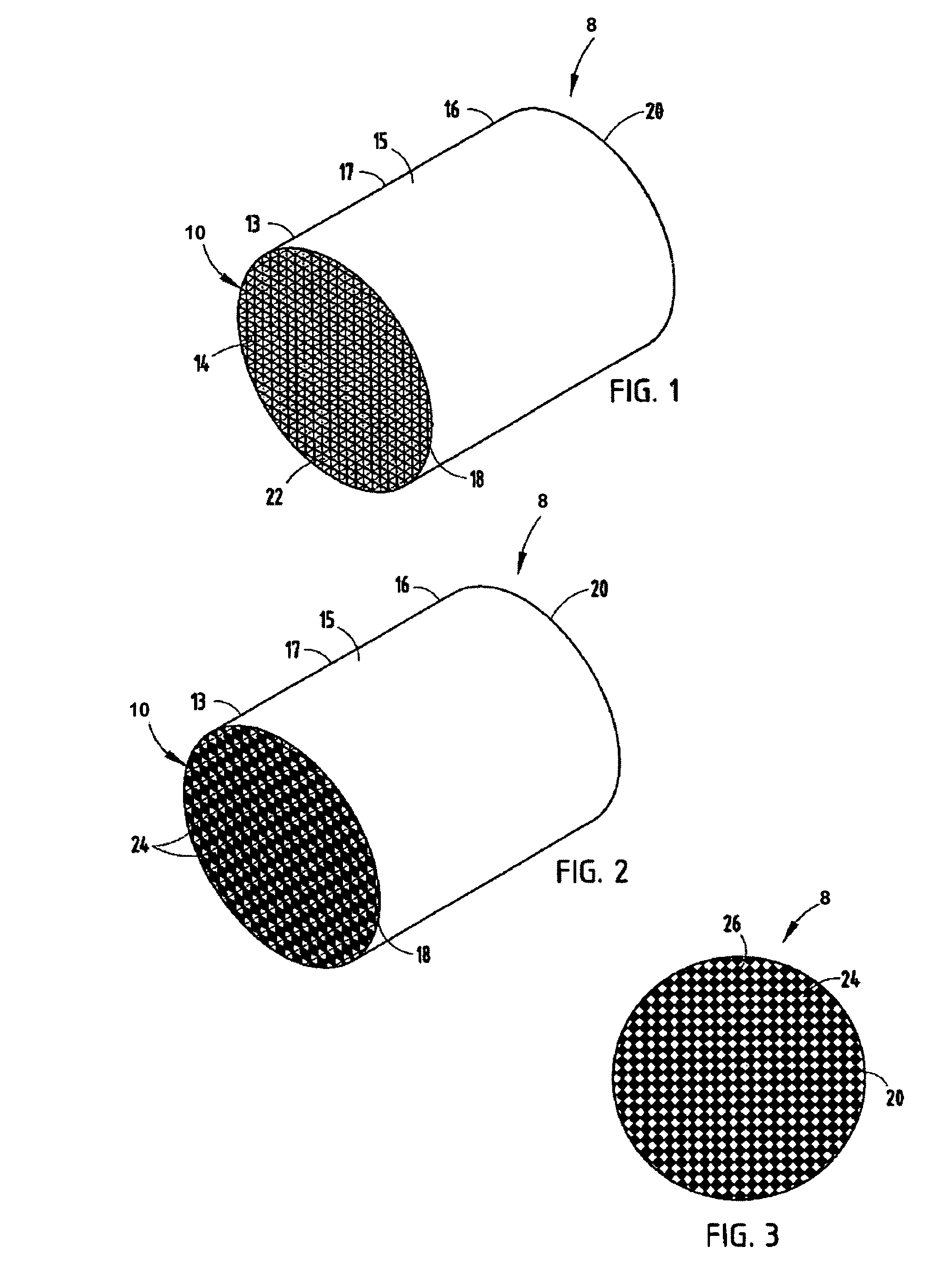

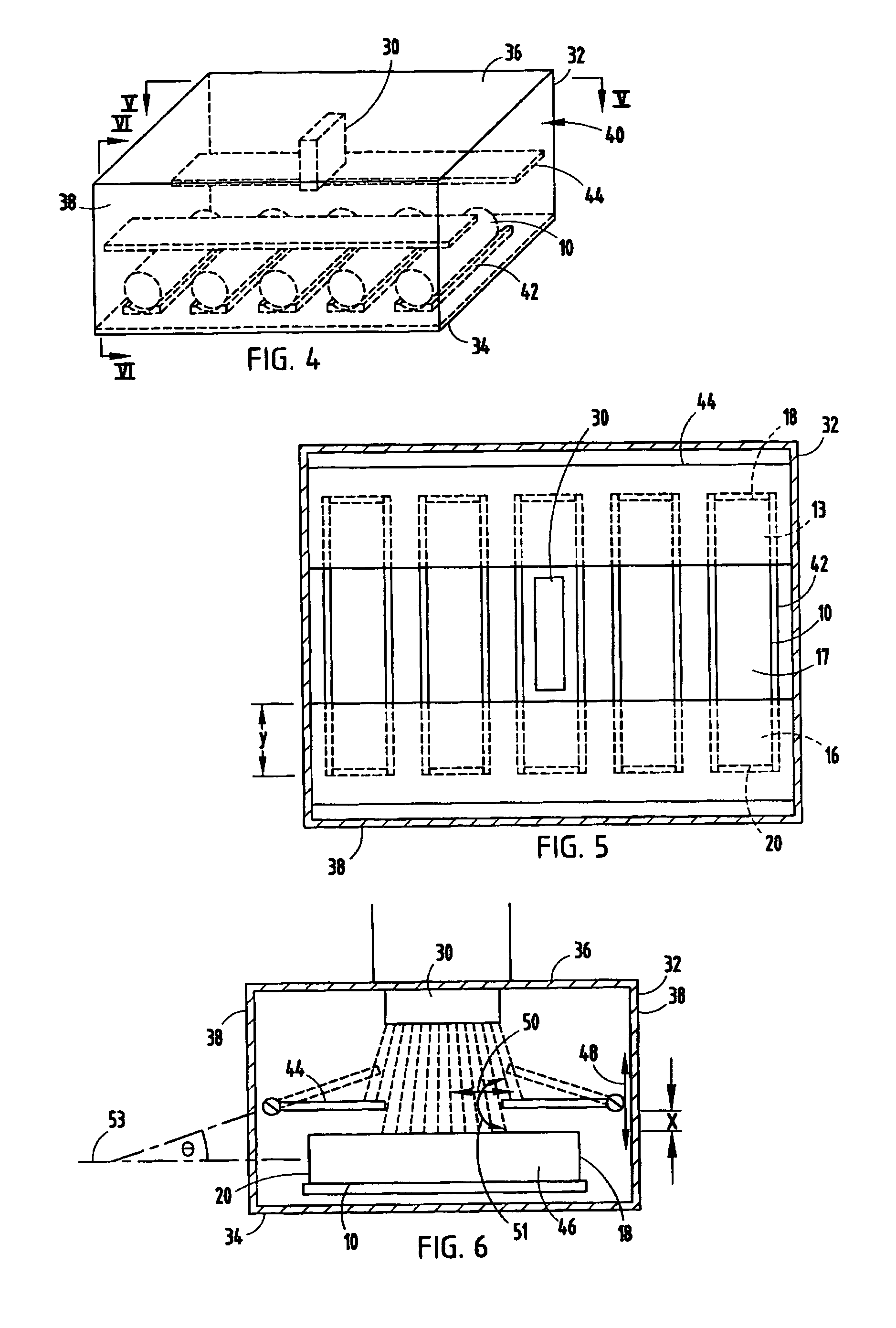

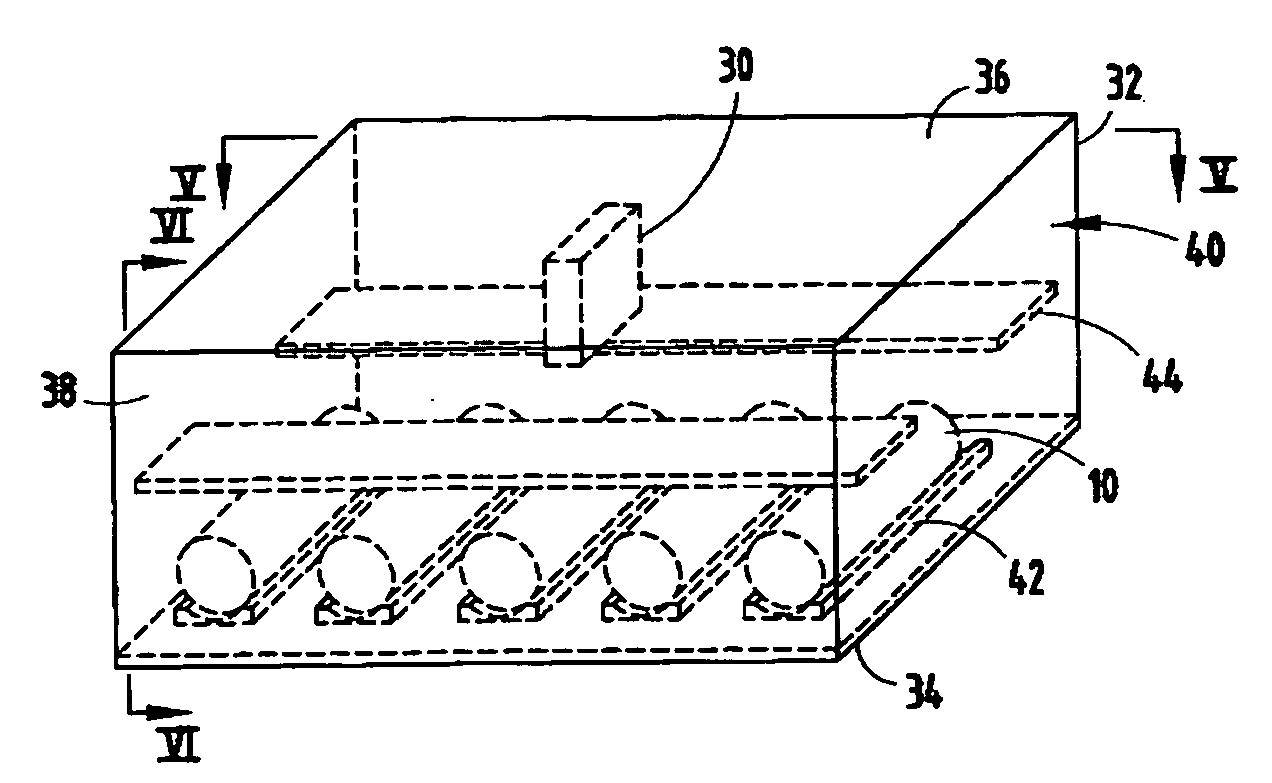

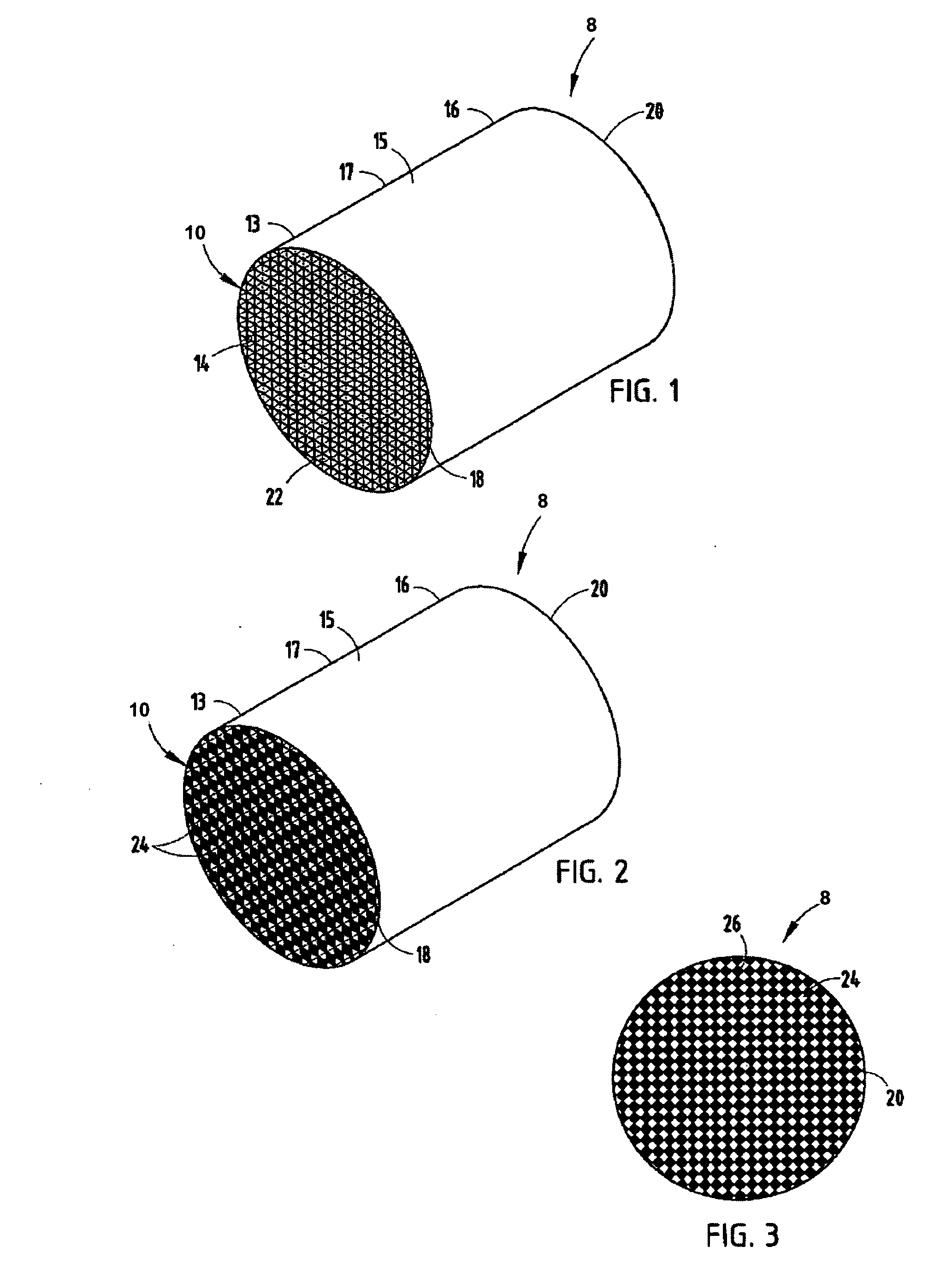

Microwave drying of ceramic structures

ActiveUS7596885B2Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

Owner:CORNING INC

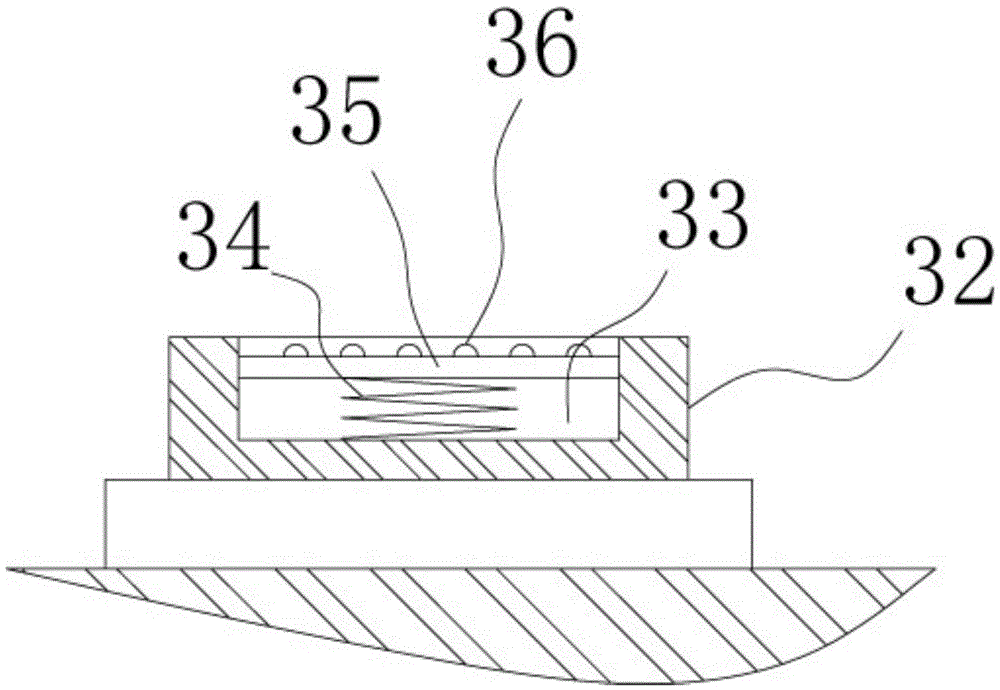

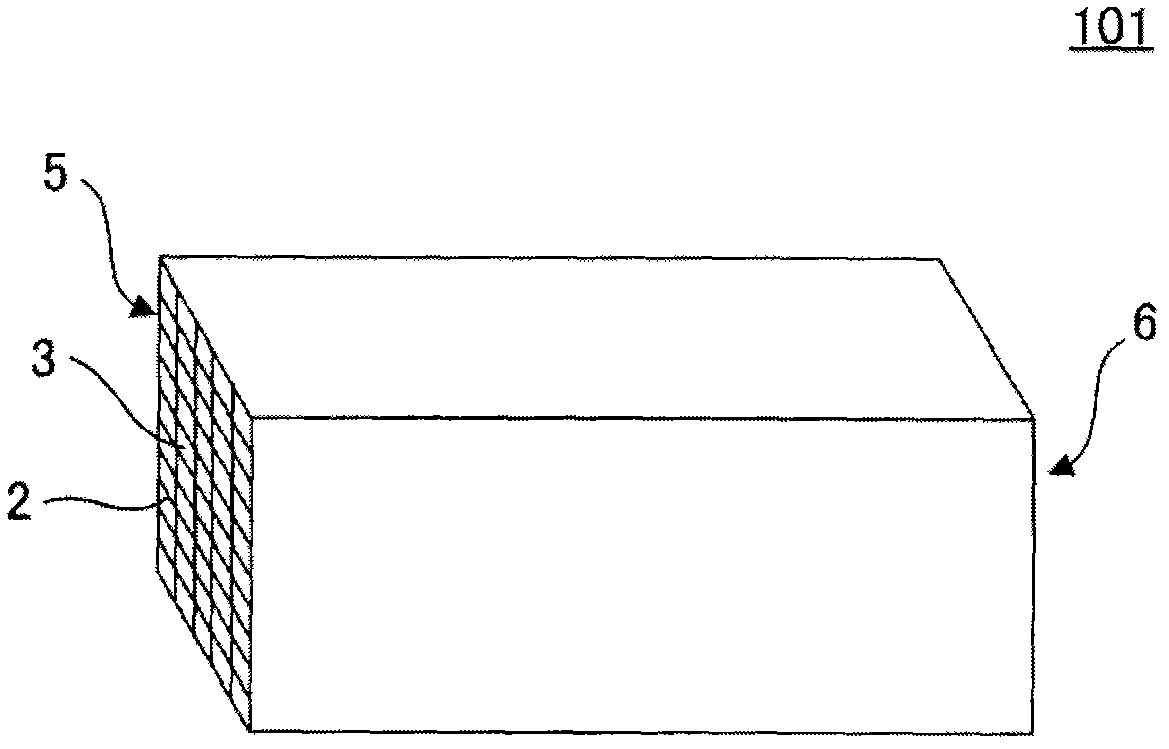

Drying jig, drying method of honeycomb molded body, and manufacturing method of honeycomb structured body

InactiveUS20090079111A1Avoid separationPrevent openingDielectric heatingConfectioneryEngineeringCell wall

A drying jig of the present invention is a drying jig for a pillar-shaped honeycomb molded body having a large number of cells longitudinally placed in parallel with one another with a cell wall therebetween, comprising: a fixing member for preventing separation or opening of the drying jig; and a piling member which enables the drying jig to be piled up in multi stage at the time of drying.

Owner:IBIDEN CO LTD

Microwave drying method

ActiveUS7017278B2Improve productivityEfficient dryingDrying solid materials with heatCeramic shaping apparatusMicrowaveShortest distance

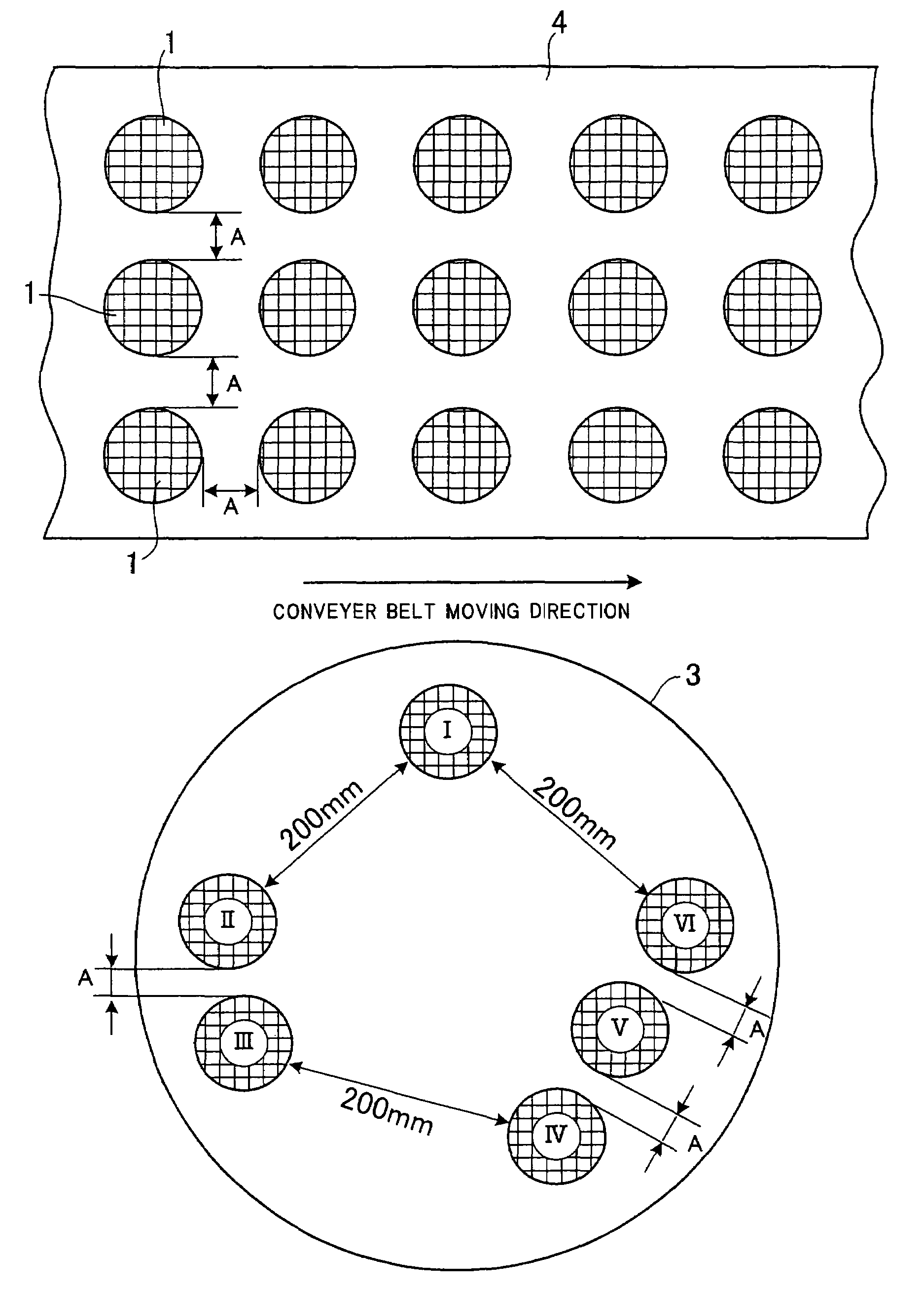

A method for drying a plurality of objects in a same space using a microwave, a method of uniformly drying all the objects to be dried while retaining the high productivity (mass productivity) as much as possible is provided. The method comprises laying a plurality of objects to be dried apart from each other by keeping, as a shortest distance between at least one pair of adjacent objects among them a distance equivalent to ¾ or more of the wavelength of the microwave to be used and irradiating them with the microwave.

Owner:NGK INSULATORS LTD

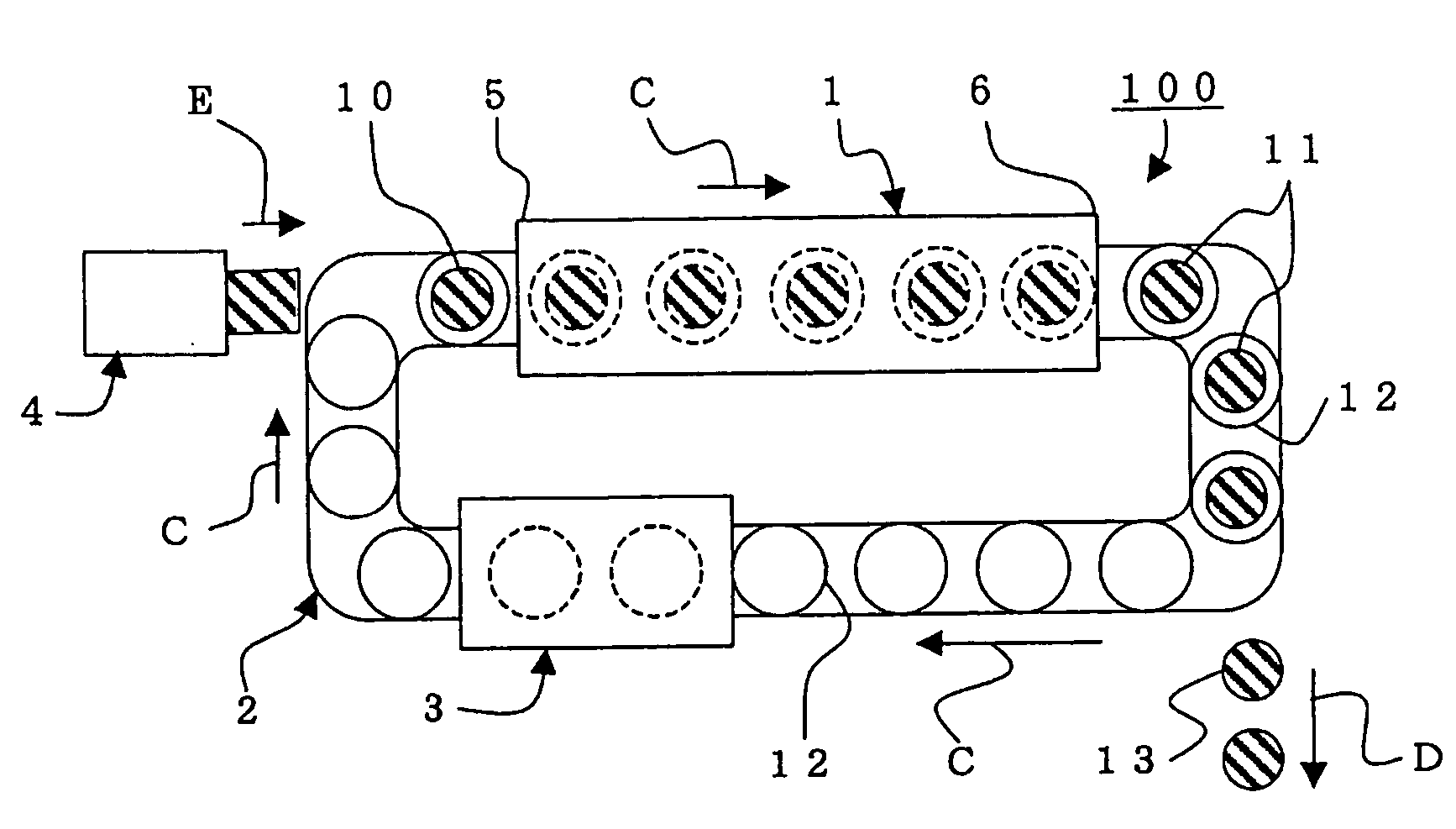

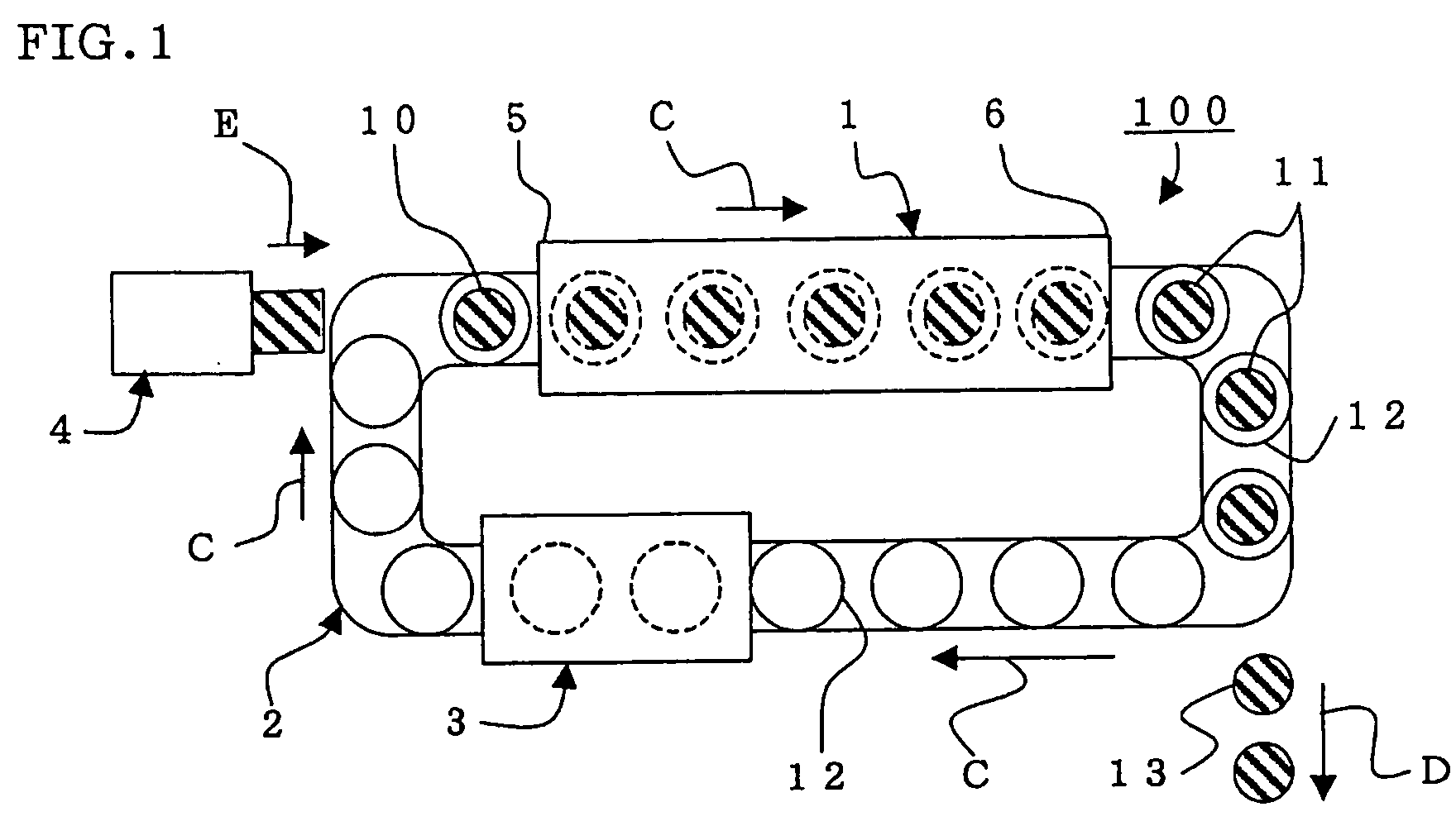

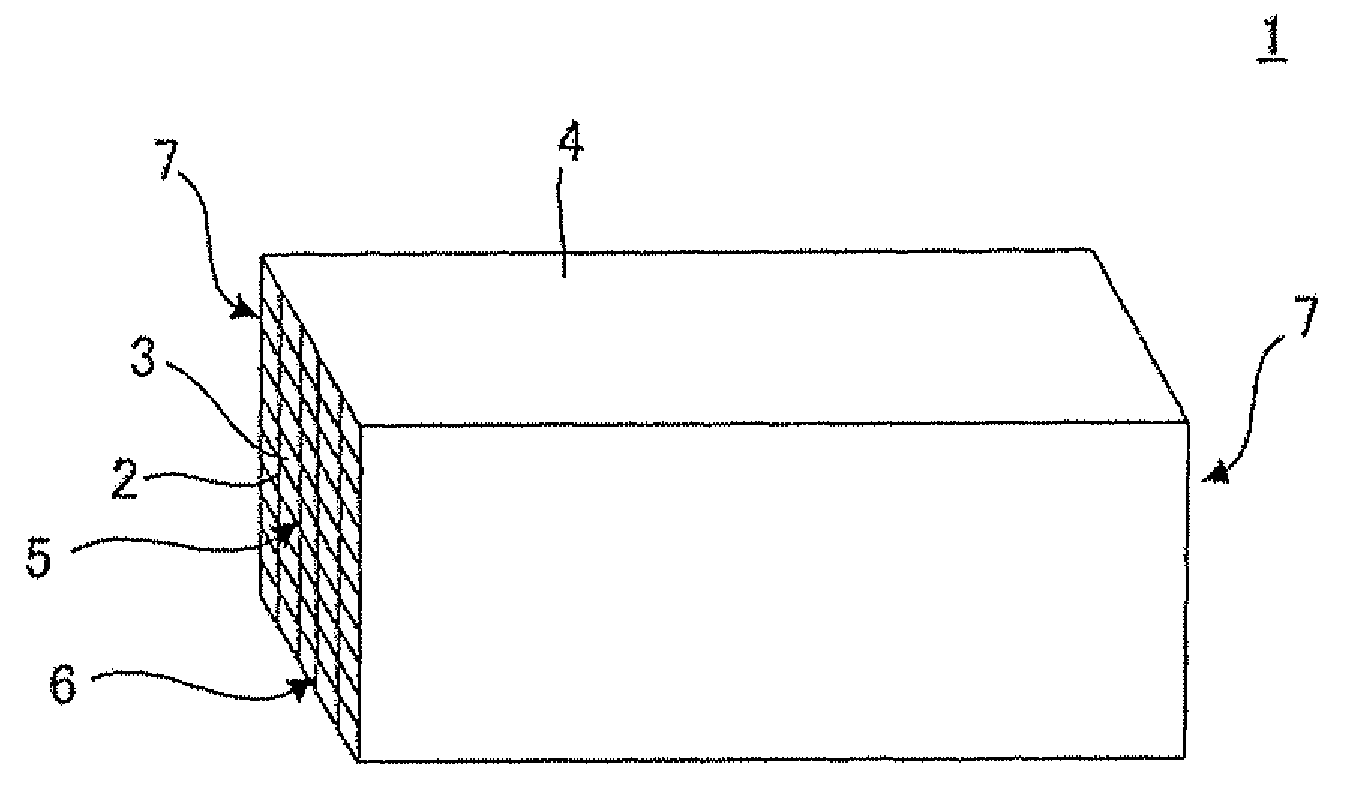

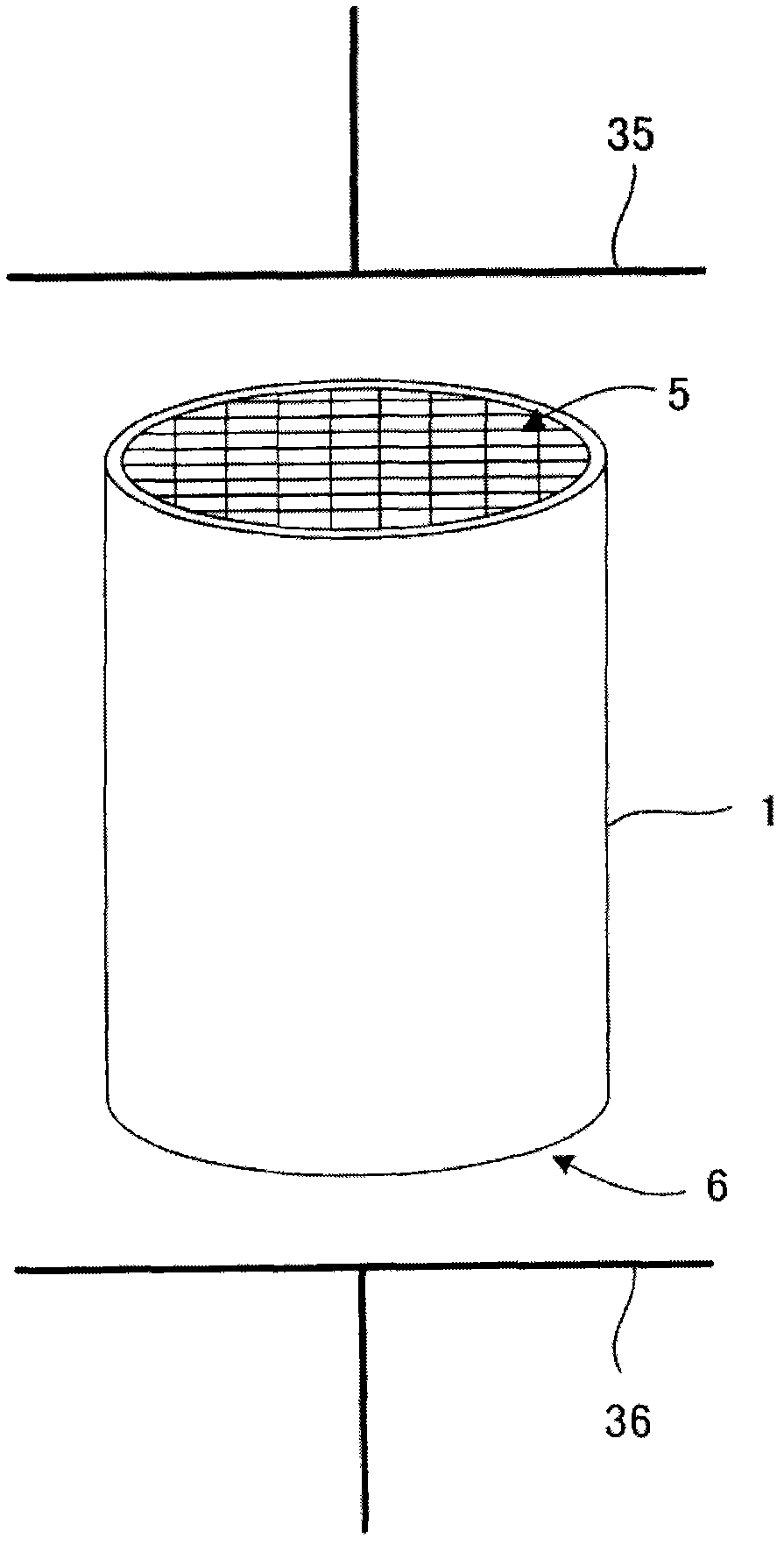

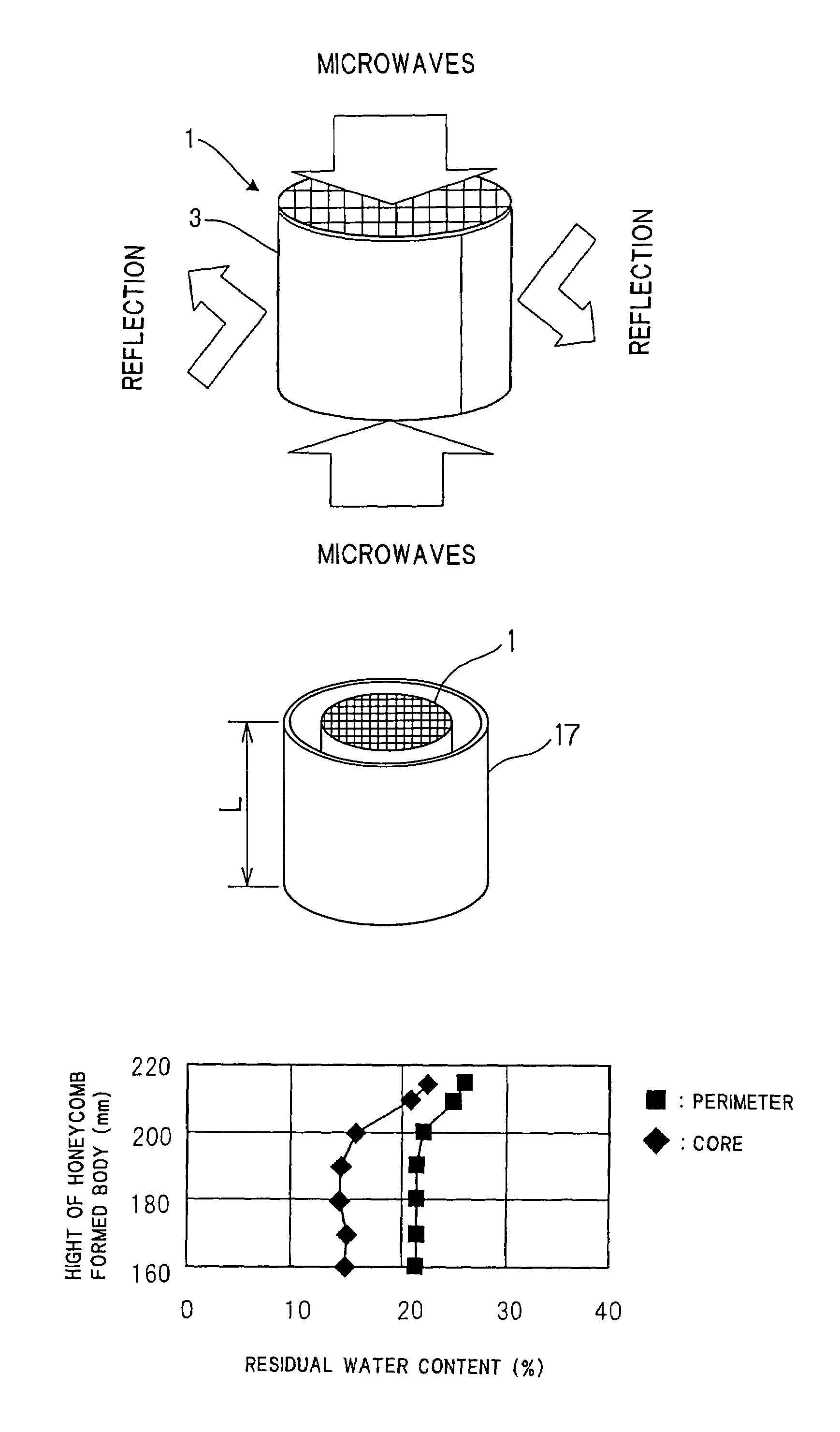

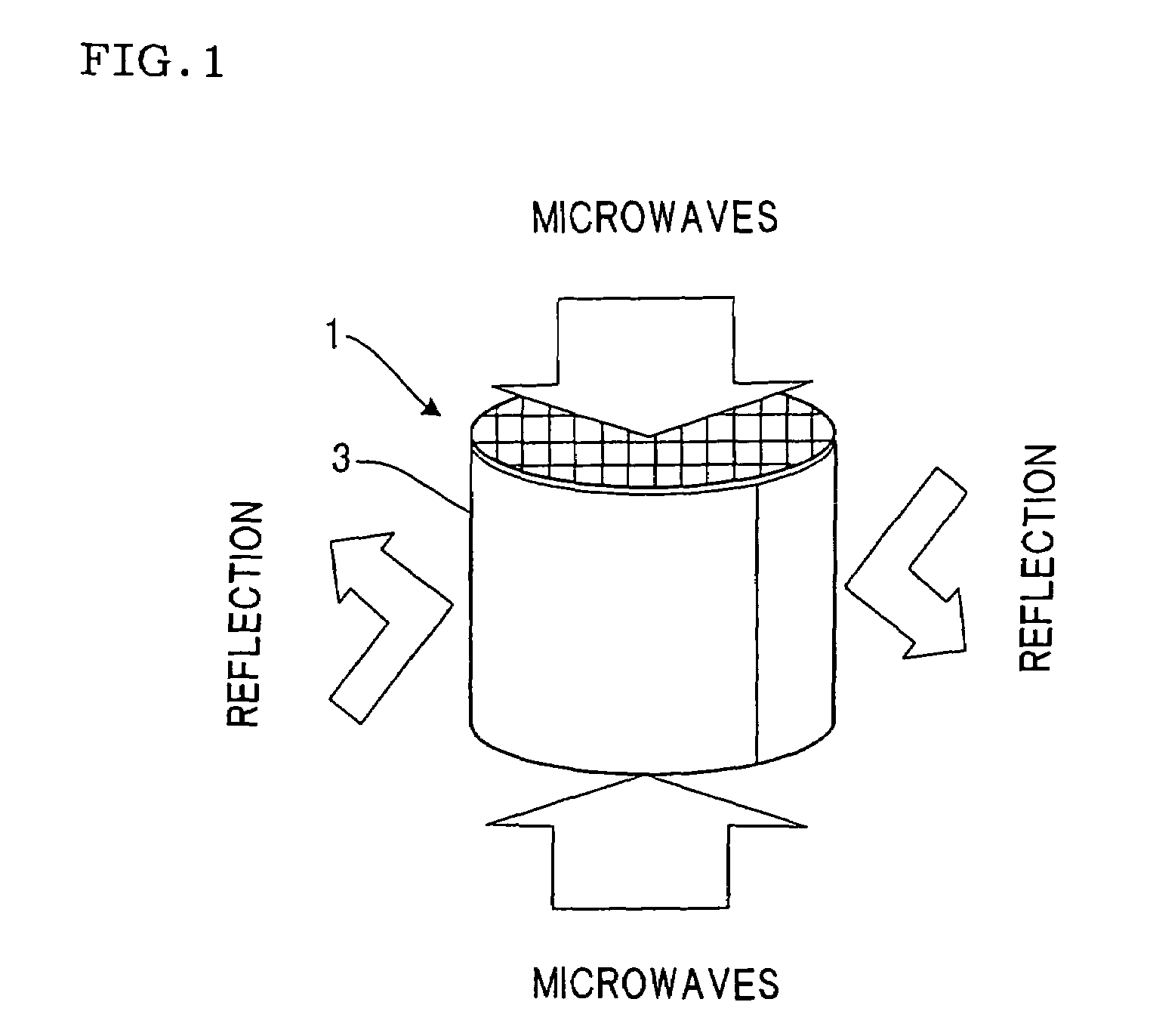

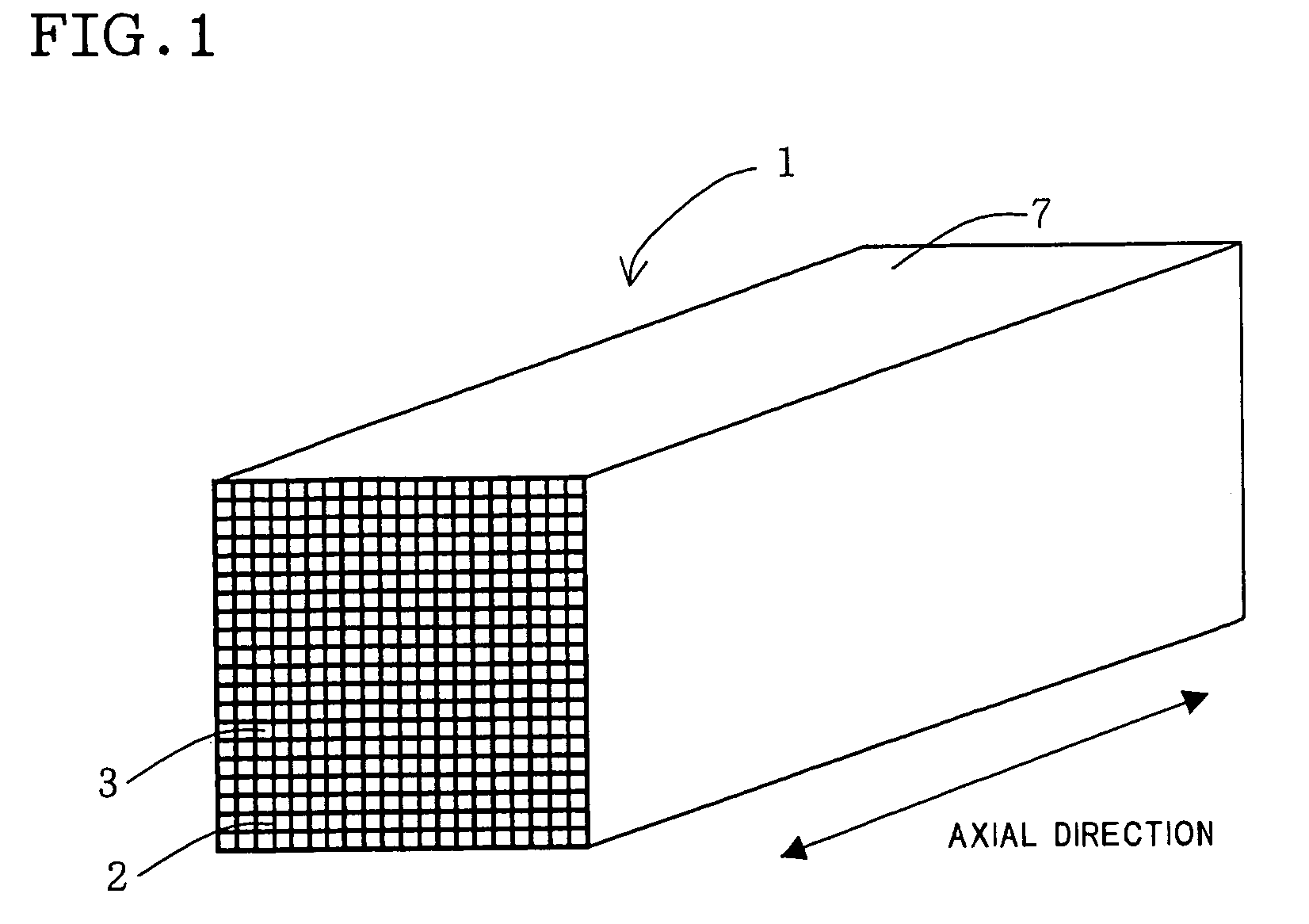

Microwave drying method of honeycomb formed bodies

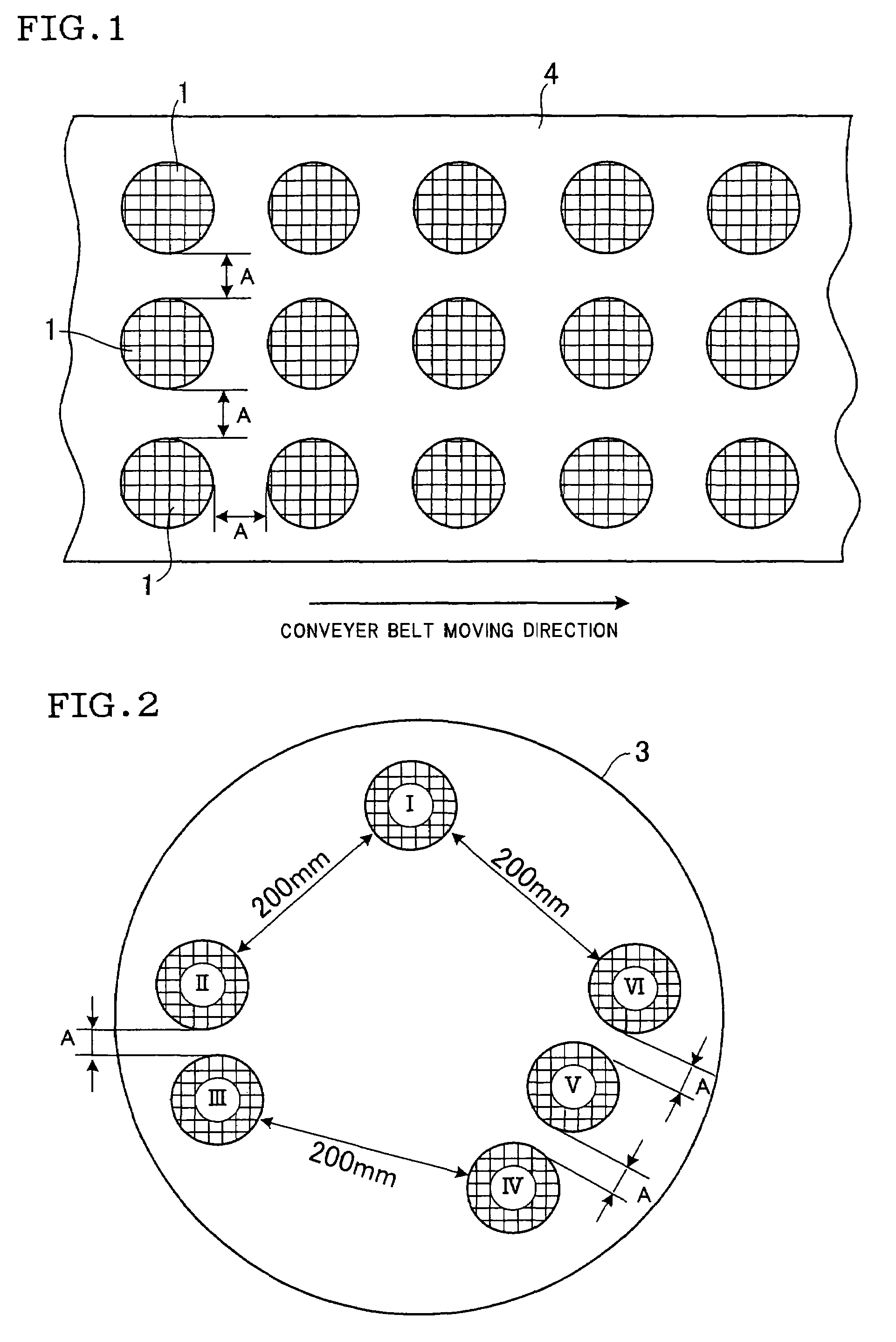

ActiveUS20060042116A1Lot differenceReduce the differenceDrying solid materials with heatCeramic shaping apparatusHoneycombCell axis

A method for drying a honeycomb formed body using microwaves is provided. The method can reduce the difference in the drying speed inside the honeycomb formed bodies during the drying process and can dry the honeycomb formed bodies without cell deformation. The method comprises placing the honeycomb formed body in a drying furnace with the cell axis in the vertical direction and irradiating the honeycomb with microwaves at a frequency of 300-30,000 MHz. The difference of the water content in the vertical direction of the honeycomb formed body 1 is maintained at 0.3% per mm or less during microwave irradiation.

Owner:NGK INSULATORS LTD

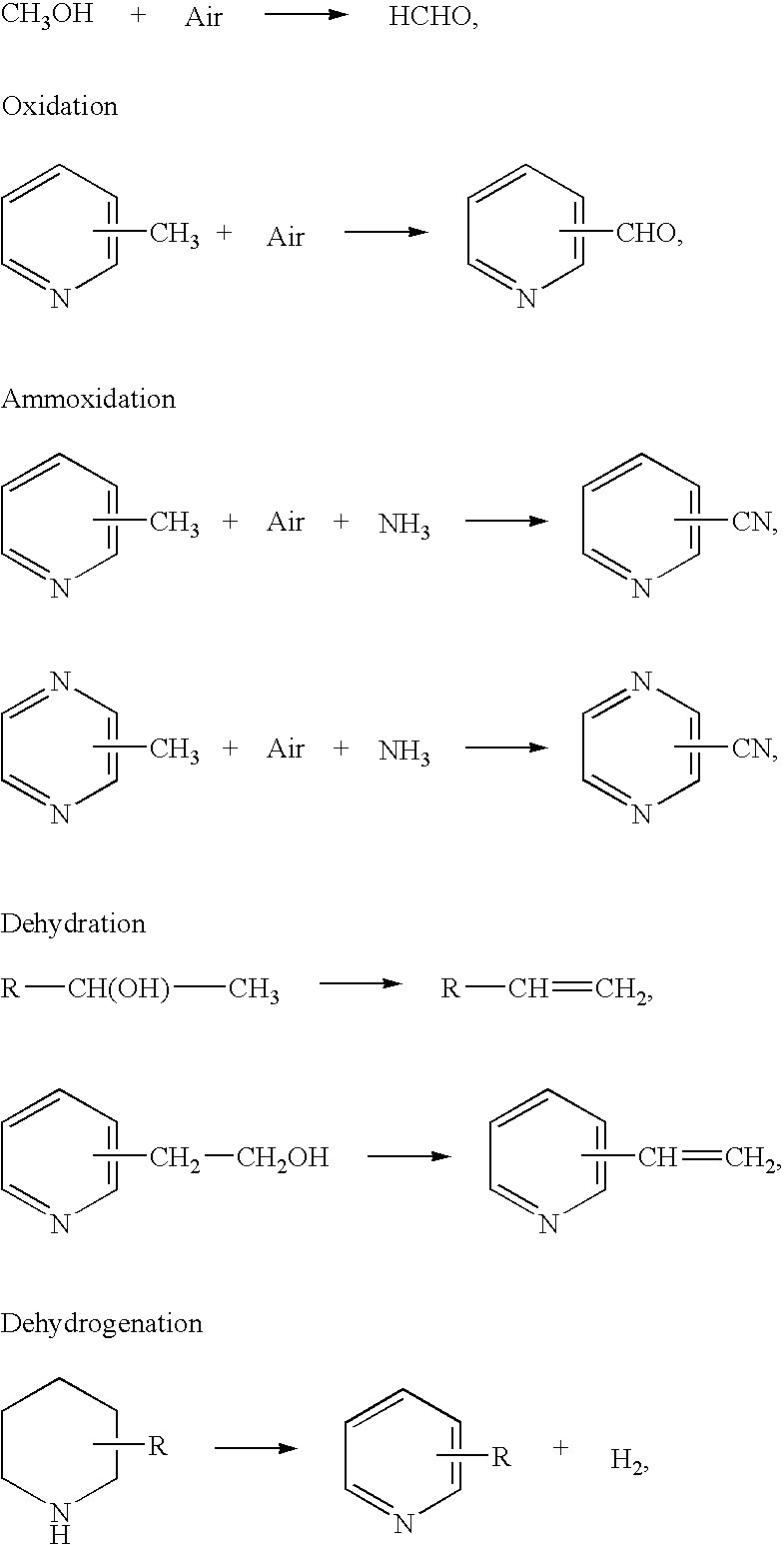

Carbon black monolith, carbon black monolith catalyst, methods for making same, and uses thereof

InactiveUS20080132408A1Easy to integrateShort timeLayered productsDrying solid materials without heatPtru catalystChemical reaction

A carbon black monolith comprising a matrix comprising ceramic material and carbon black dispersed throughout the matrix and a method for making a carbon black monolith comprising extruding an extrudable mixture including a carbon black, a ceramic forming material, water, an extrusion aid, and a flux material. A carbon black monolith catalyst comprising a finished self-supporting carbon black monolith having at least one passage therethrough, and comprising a supporting matrix and carbon black dispersed throughout the supporting matrix and at least one catalyst precursor on the finished self-supporting carbon black monolith. A method for making and a method for use of such a carbon black monolith catalyst in catalytic chemical reactions are also disclosed.

Owner:APPL TECH LLP

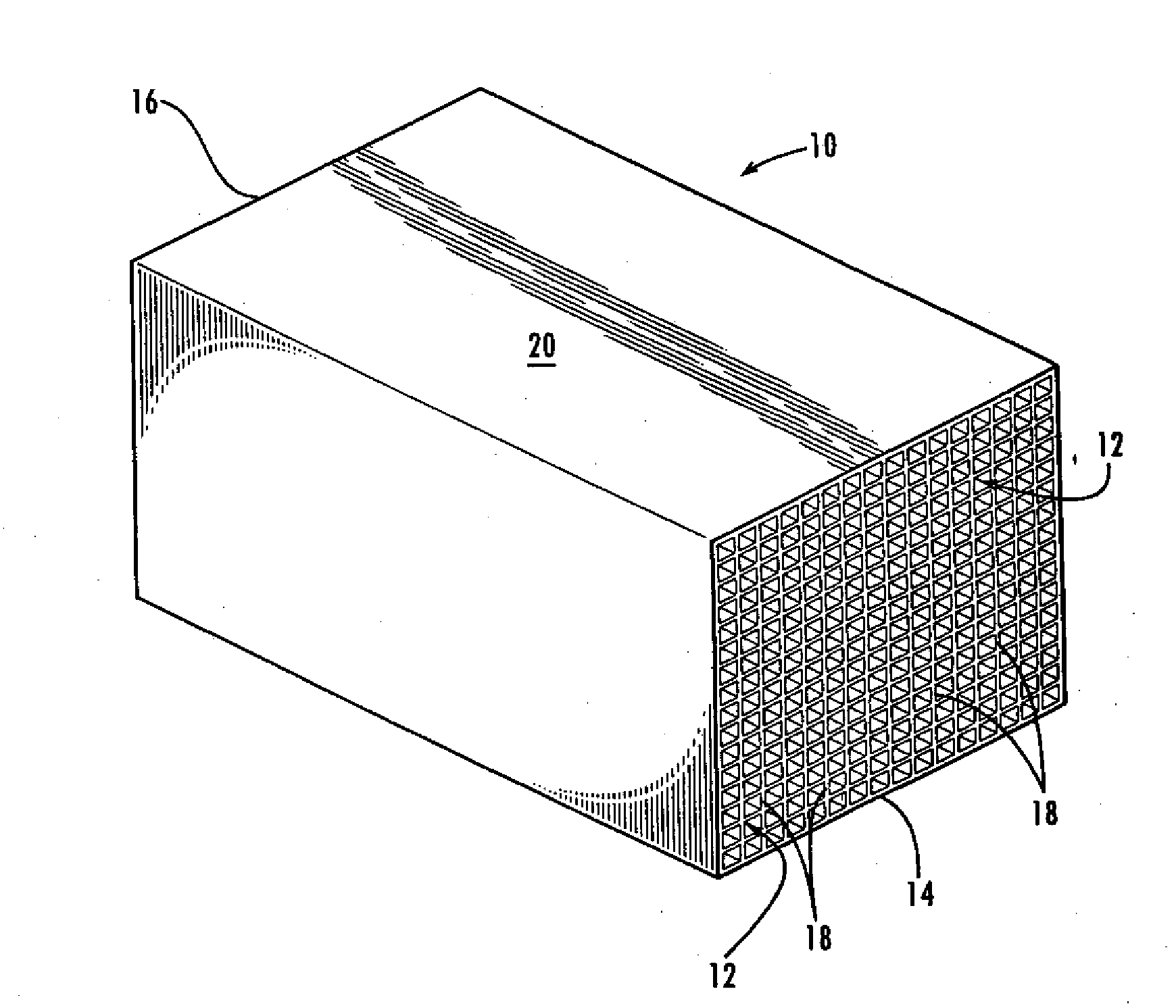

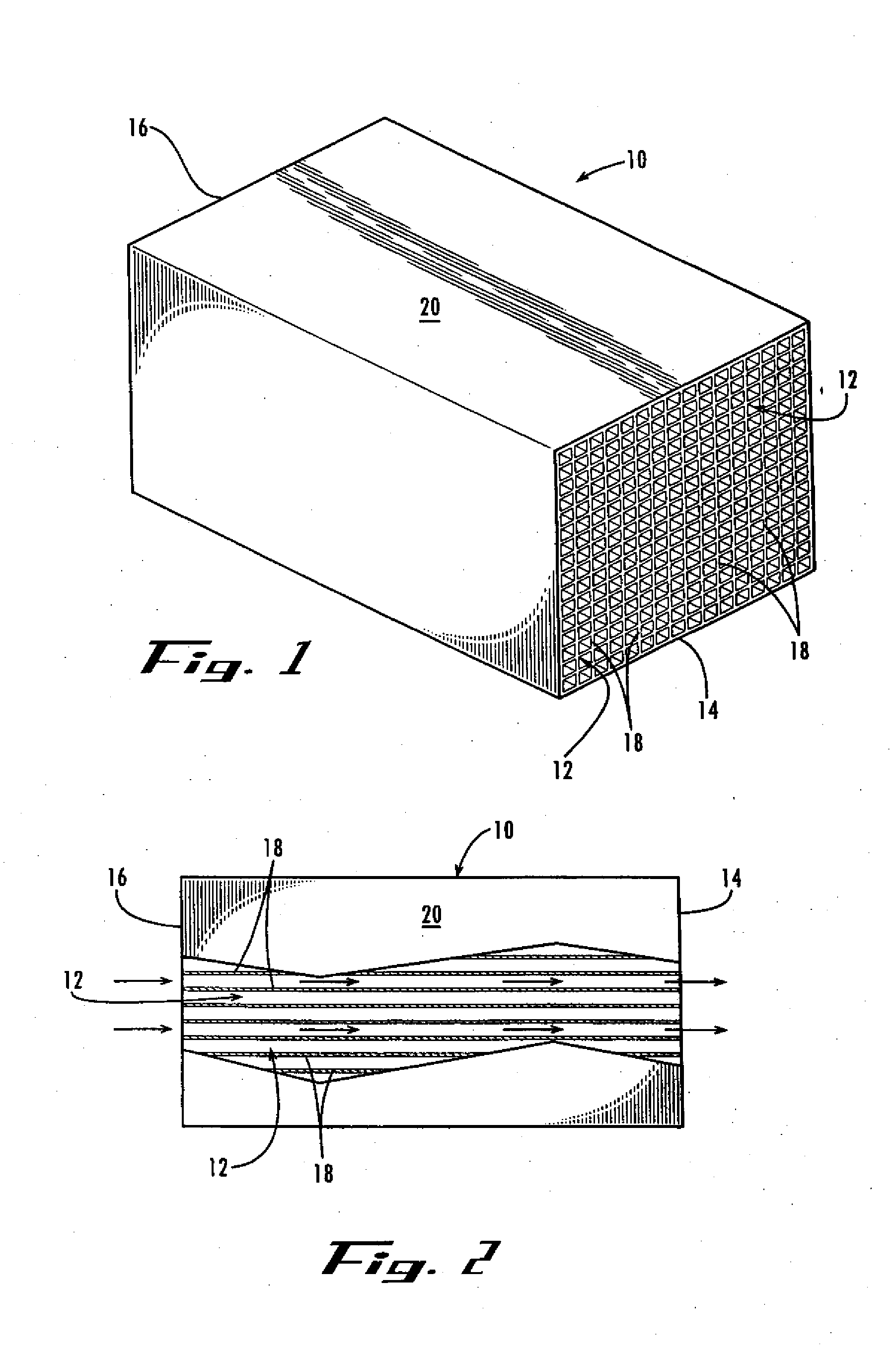

Microwave drying of ceramic structures

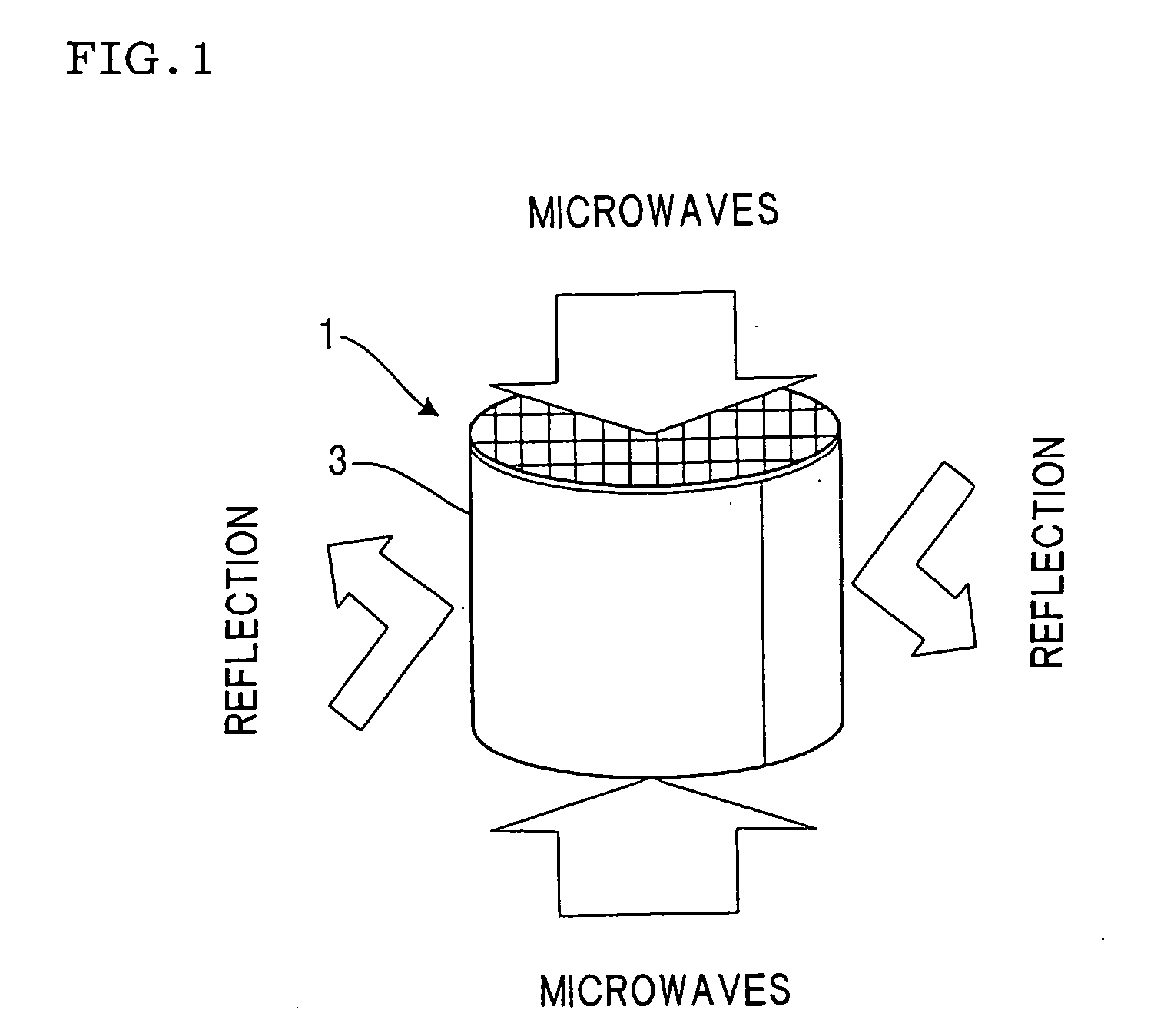

ActiveUS20080023886A1Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

A method for drying a ceramic article comprises providing microwave radiation from a microwave generating source, providing a ceramic honeycomb structure having a middle portion and at least one end, and exposing the ceramic honeycomb structure to the microwave radiation while shielding the at least one end from directly receiving the microwave radiation, such that the radiation absorbed by the middle portion is equal to or greater than the radiation absorbed by the at least one end, and the proper drying of the entire honeycomb structure without heat-induced structural degradation is thus ensured.

Owner:CORNING INC

Method and apparatus for drying honeycomb formed body

ActiveUS20070006480A1Avoid deformationReduce the differenceDielectric heatingDrying solid materials with heatHoneycombMaterials science

An undried honeycomb formed body 41 is subjected to high-frequency heating in an atmosphere where humidity and temperature are maintained at 30 to 65% and 75 to 130° C., respectively, such that 50 to 99 mass % of water contained in the undried honeycomb formed body 41 is evaporated at the end of high-frequency heating, whereby the amount of water vaporized from the outer part of the undried honeycomb formed body 41 is increased, thereby reducing a difference between amount of water vaporized from the inner part of the undried honeycomb formed body 41 and that of water vaporized from the outer part thereof as well as reducing a difference between drying degree of the inner part of the undried honeycomb formed body 41 and that of the outer part thereof, thereby producing a dried honeycomb formed body 42 in which deformation of the partition walls is suppressed. The invention provides a honeycomb formed body drying method which prevents deformation of partition walls of the honeycomb formed body during drying thereof.

Owner:NGK INSULATORS LTD

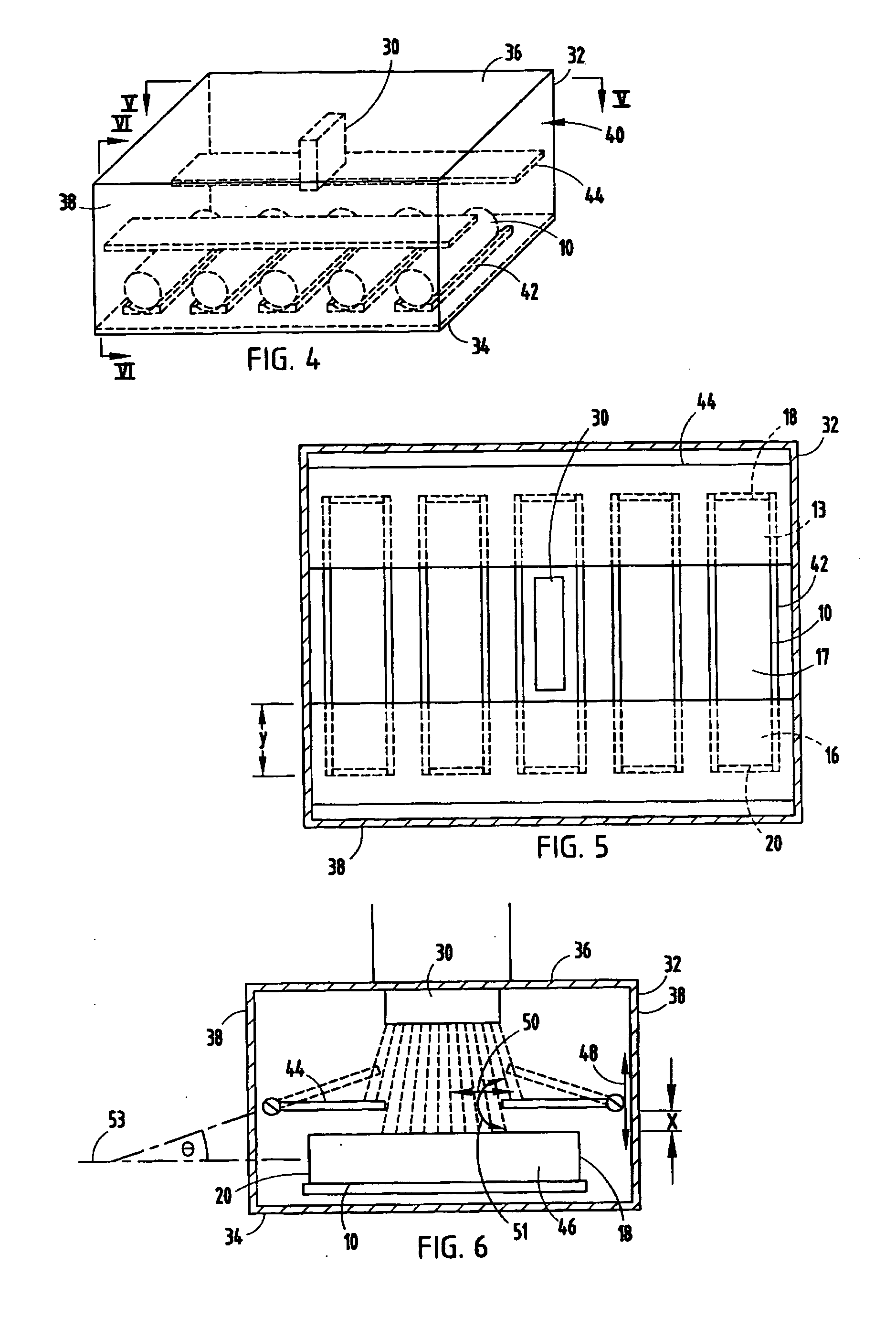

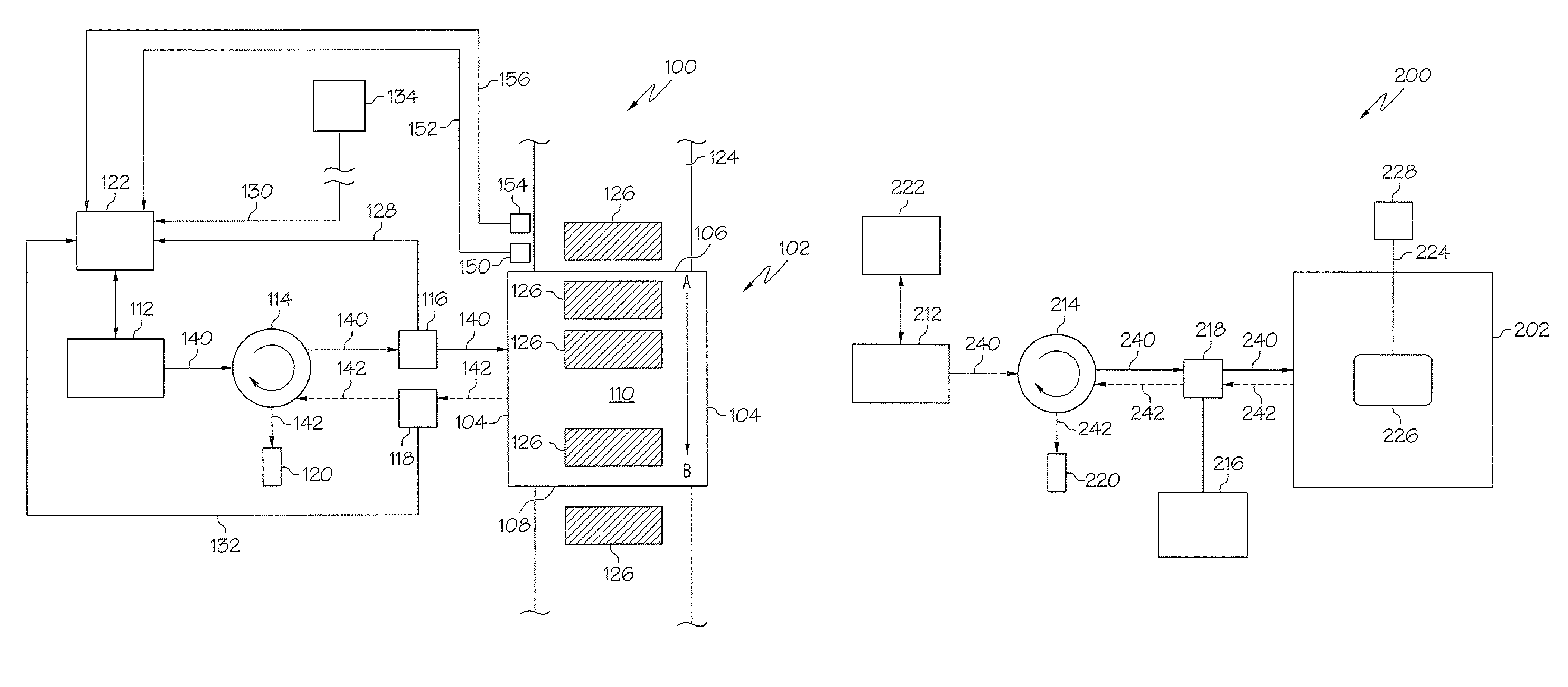

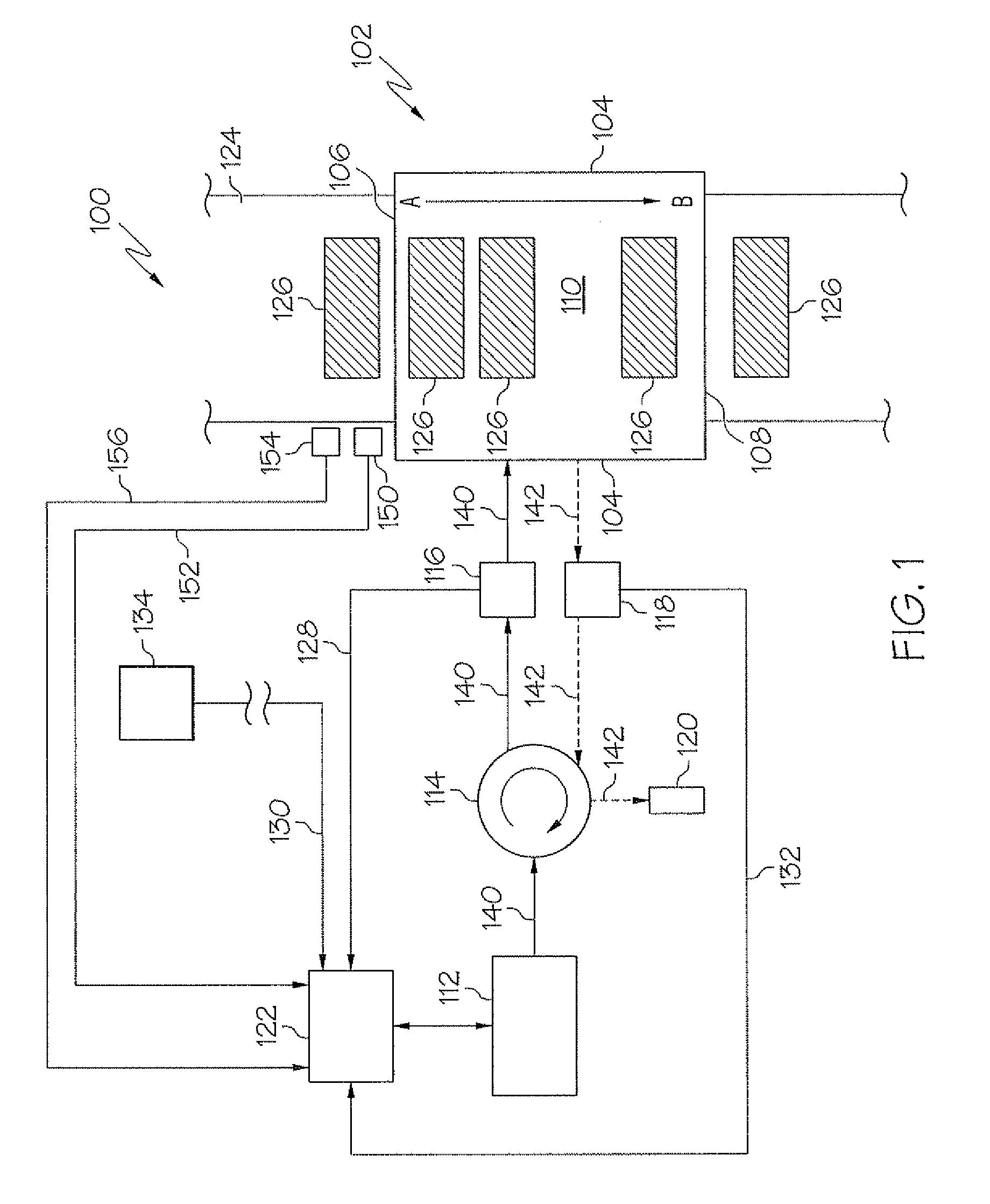

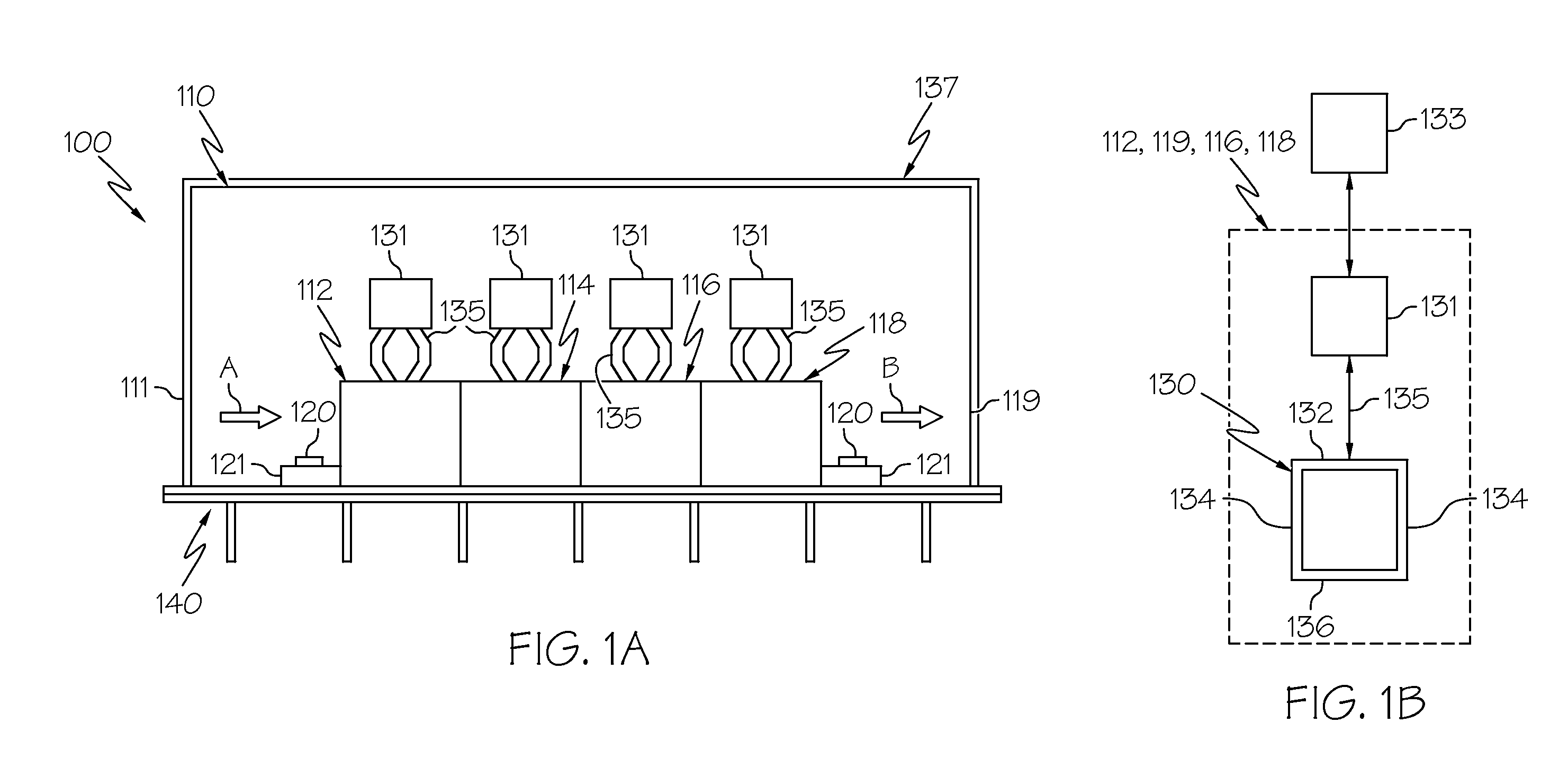

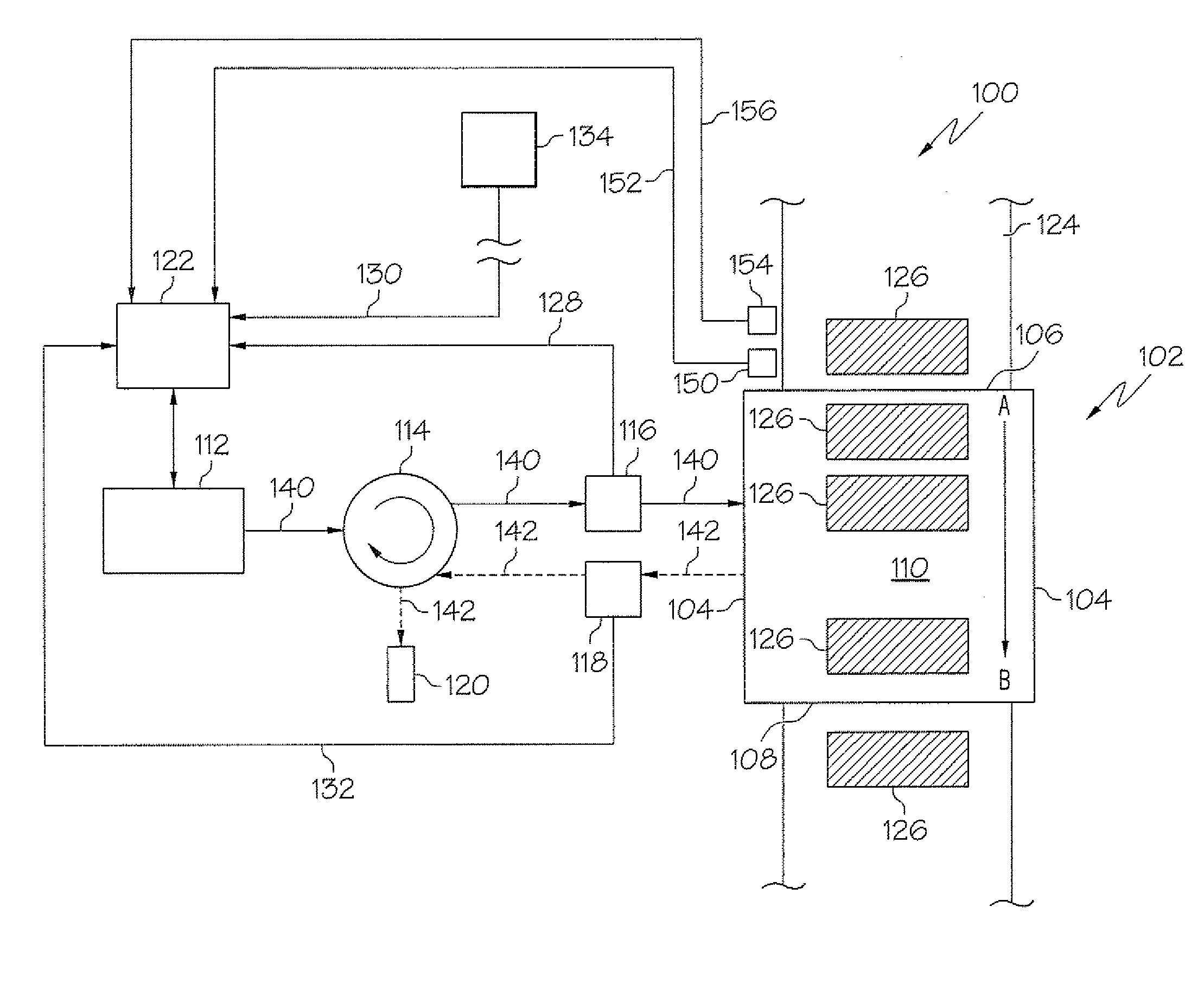

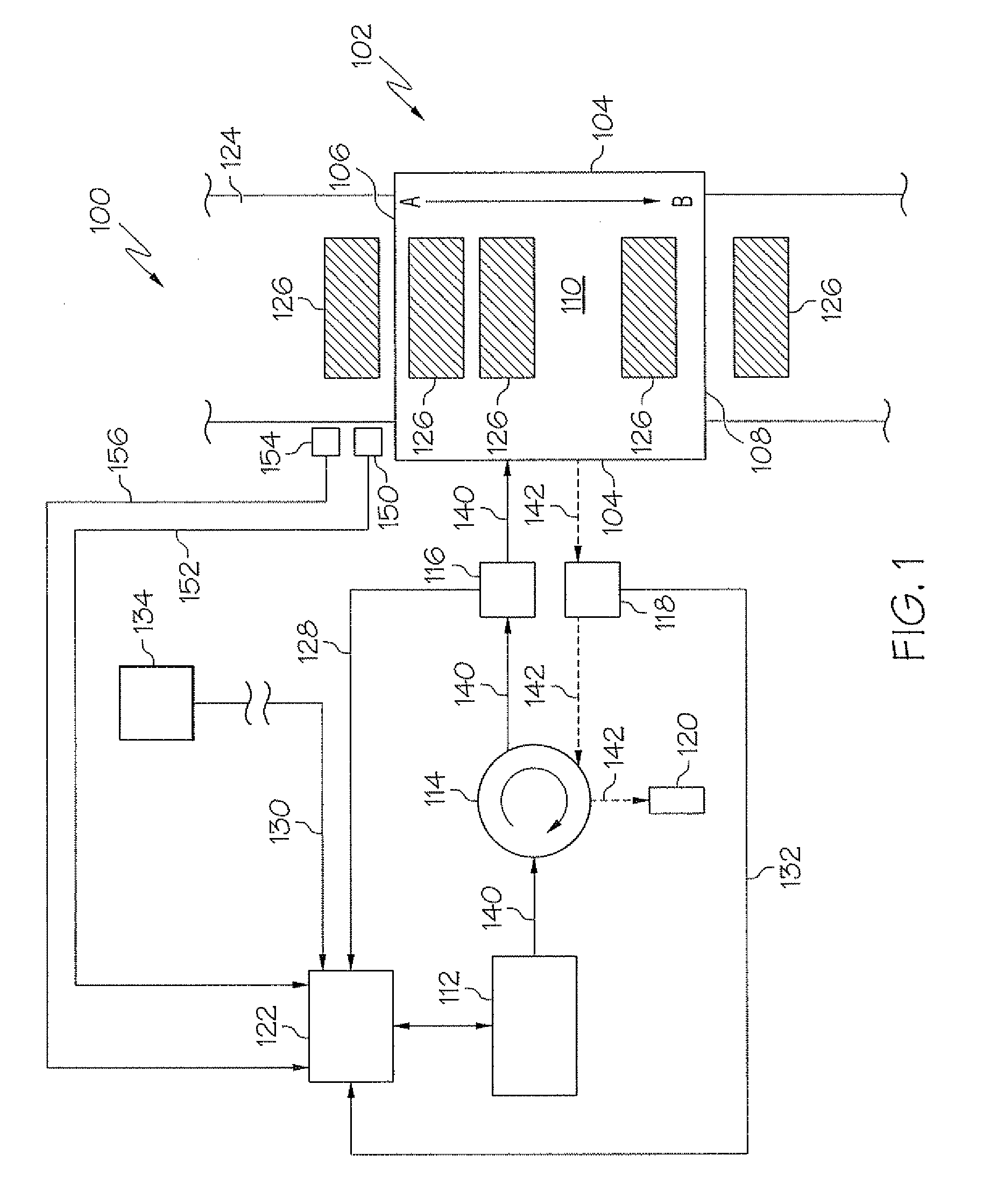

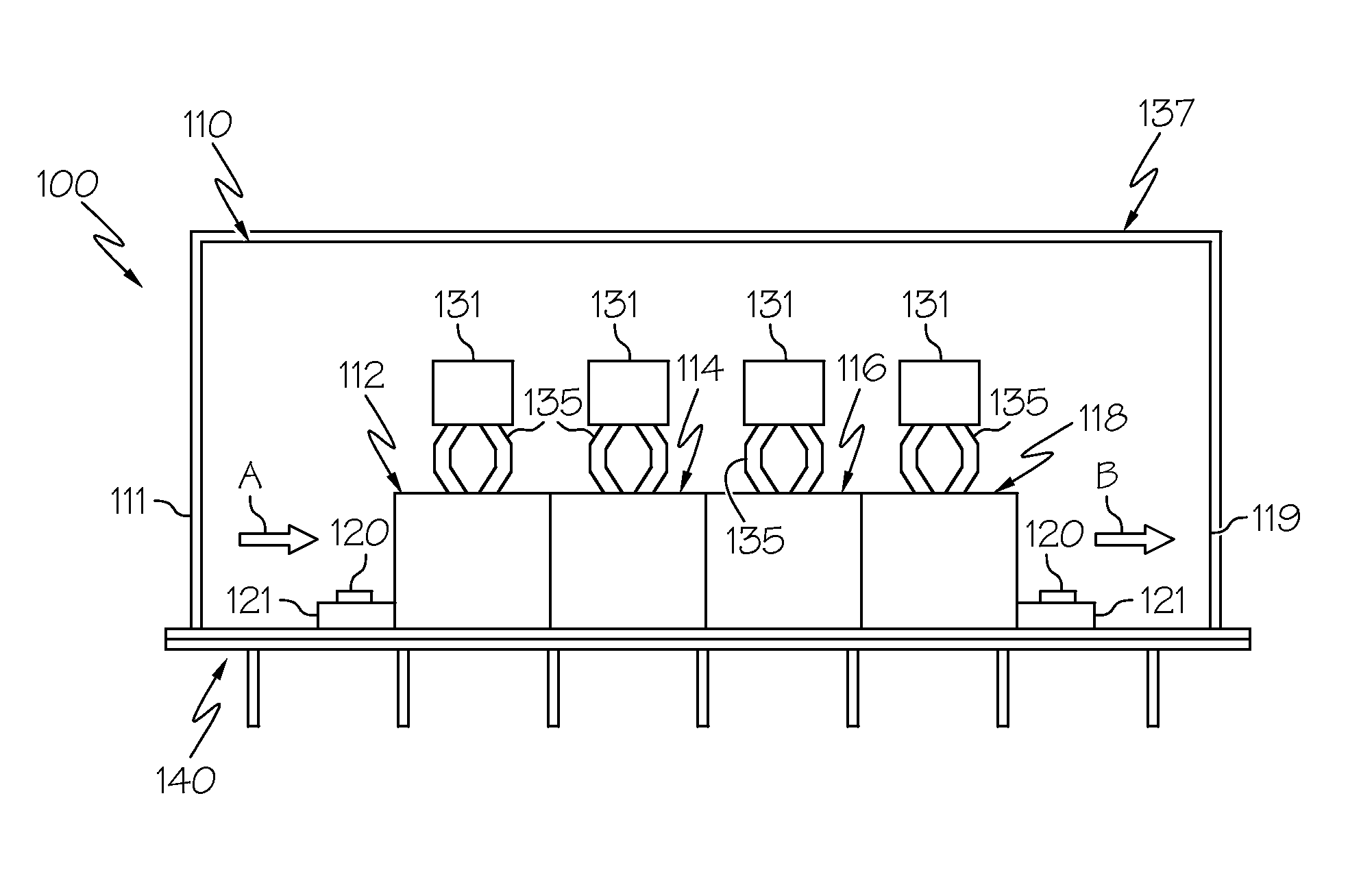

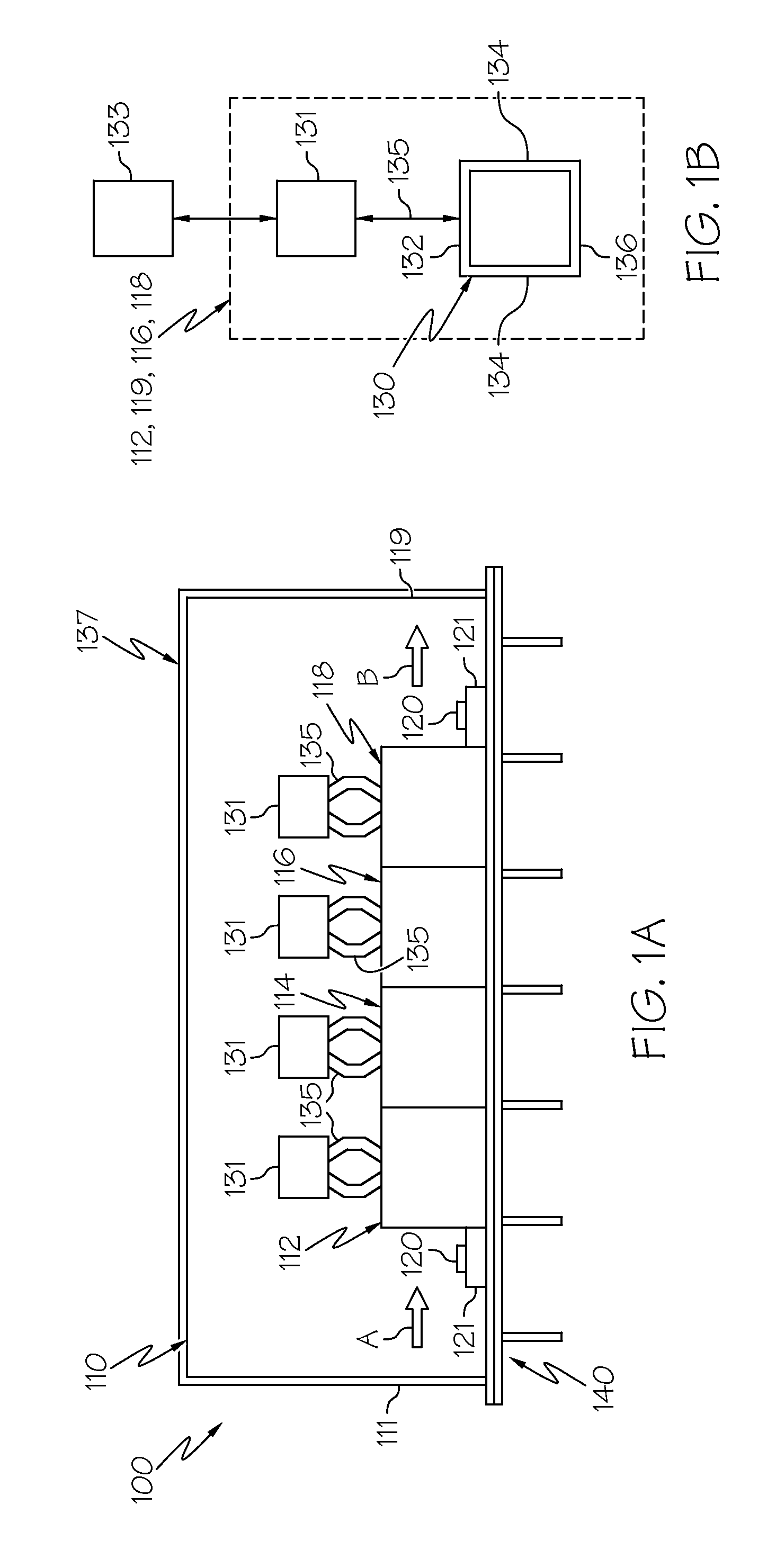

Methods and apparatus for drying ceramic green bodies with microwaves

Methods and apparatus for drying ceramic green bodies include providing one or more ceramic green bodies in a microwave heating chamber operatively connected to a microwave source and a PLC. The total mass of the ceramic green bodies present in the microwave heating chamber is determined. Microwave energy is generated with the microwave source and transmitted from the microwave source to the microwave heating chamber. A transmitted power of the microwave energy transmitted from the microwave source to the microwave heating chamber is measured with power sensors. The reflected power of reflected microwave energy reflected back from the microwave heating chamber is also measured. The power of the microwave energy transmitted from the microwave source to the microwave heating chamber is adjusted based on the total mass of ceramic green bodies present in the microwave heating chamber, the measured transmitted power and the measured reflected power.

Owner:CORNING INC

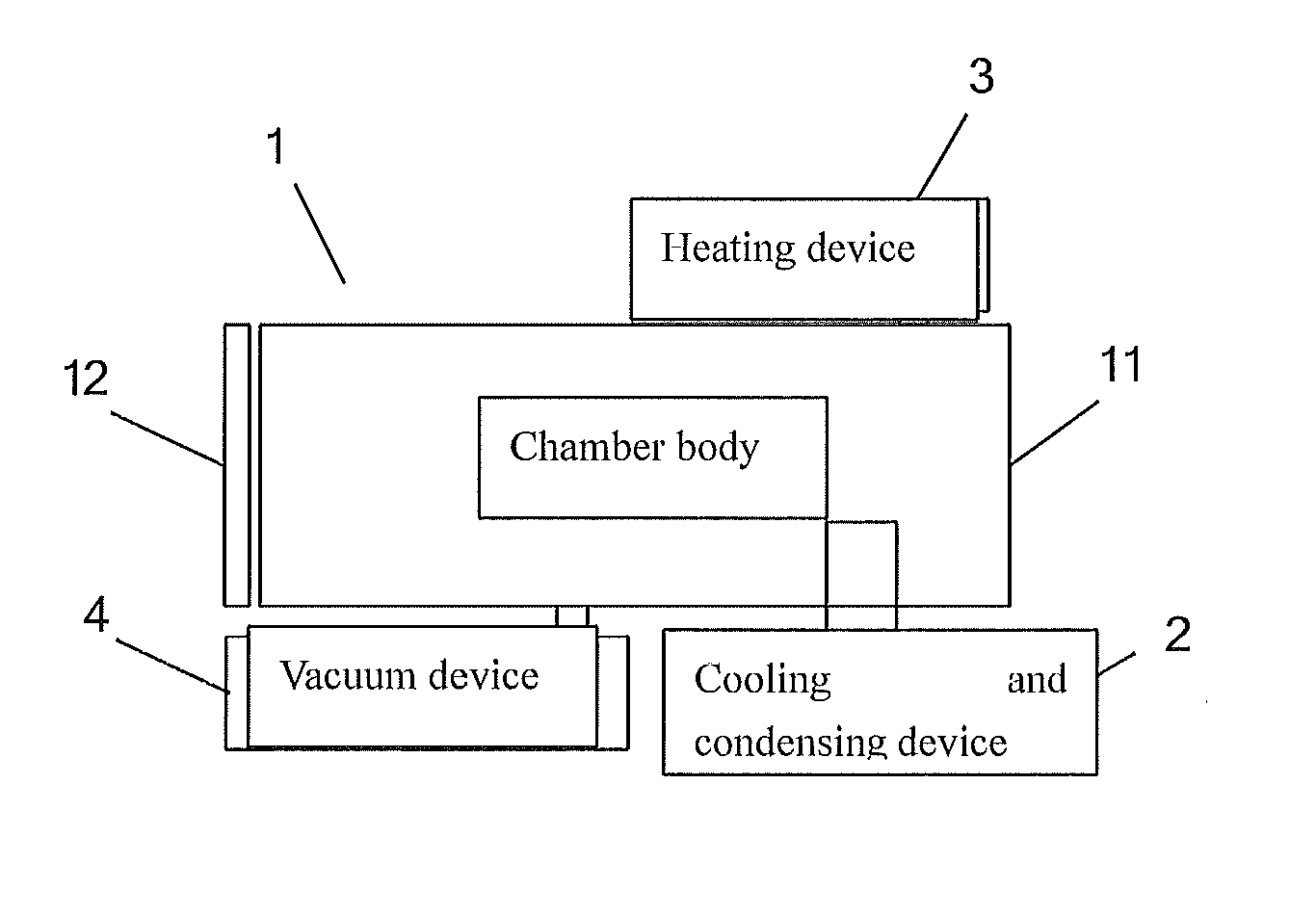

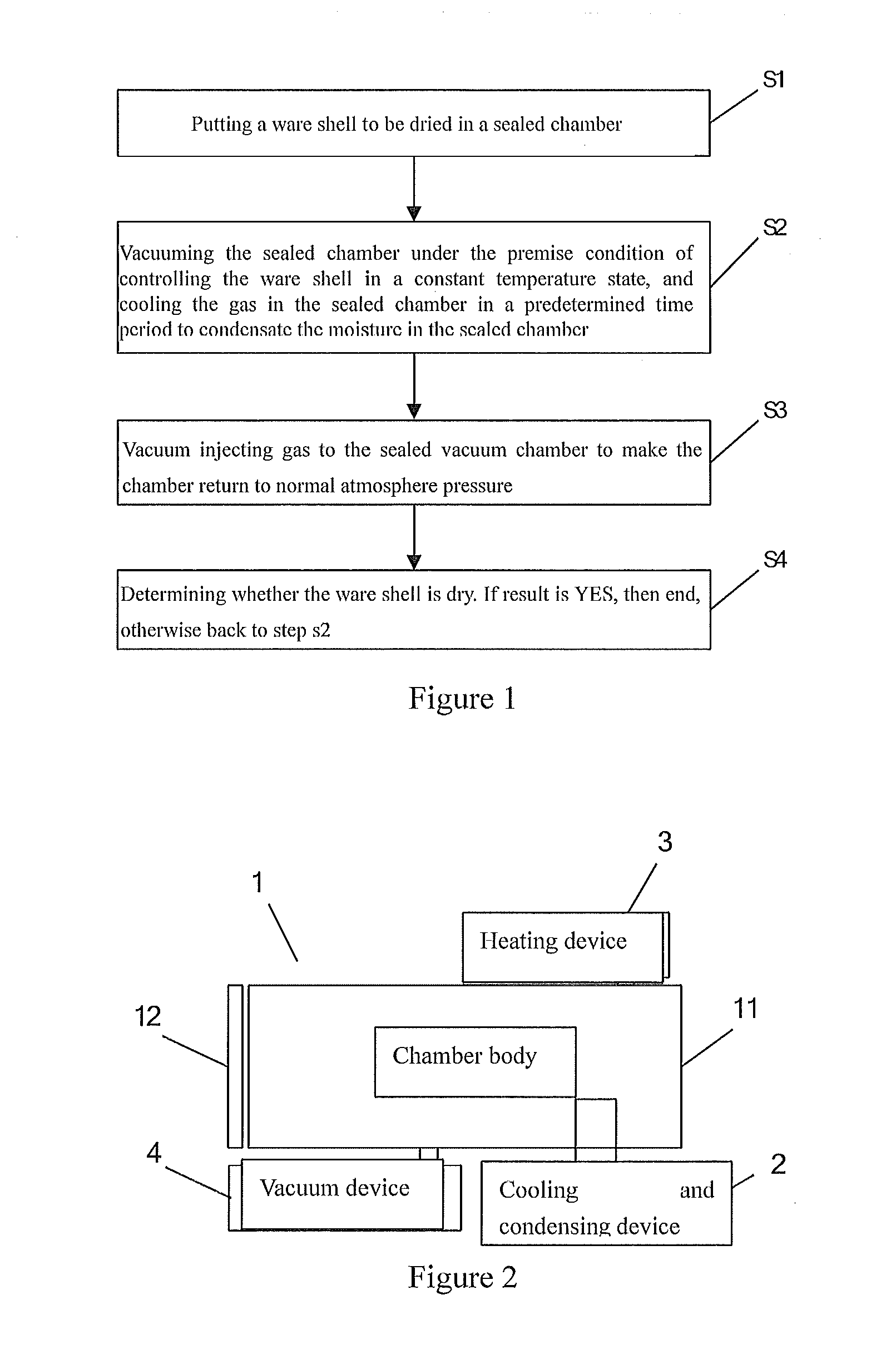

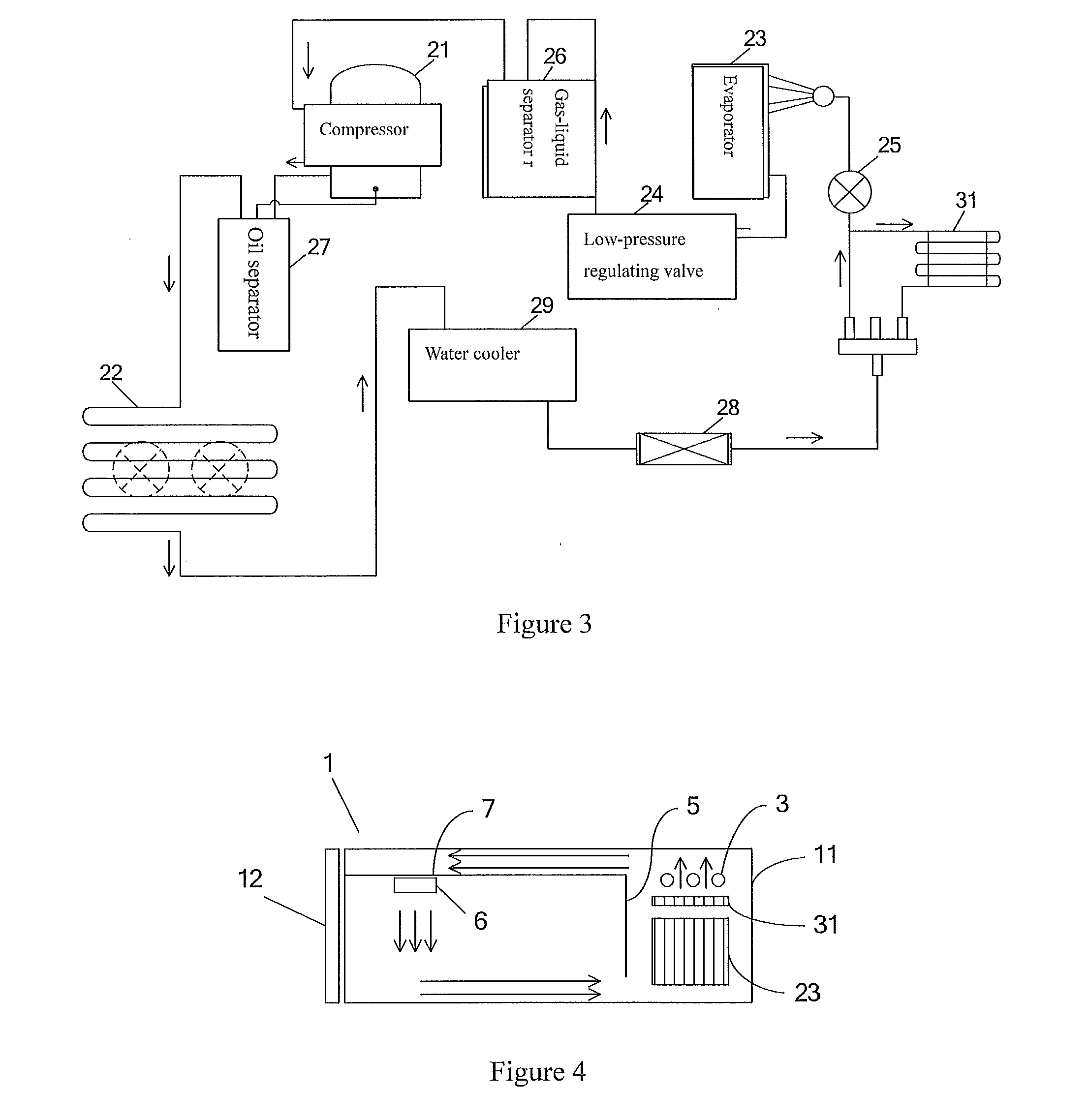

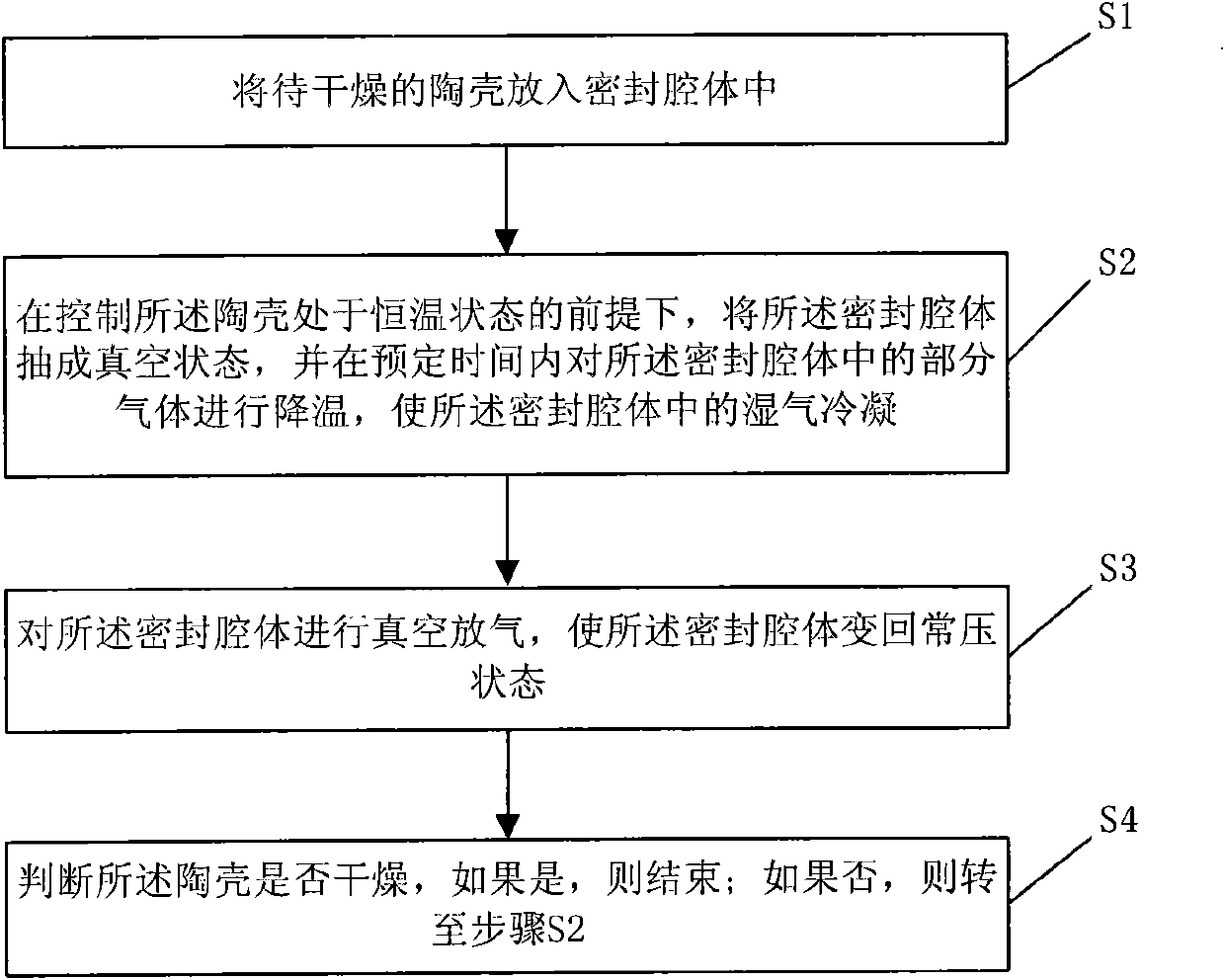

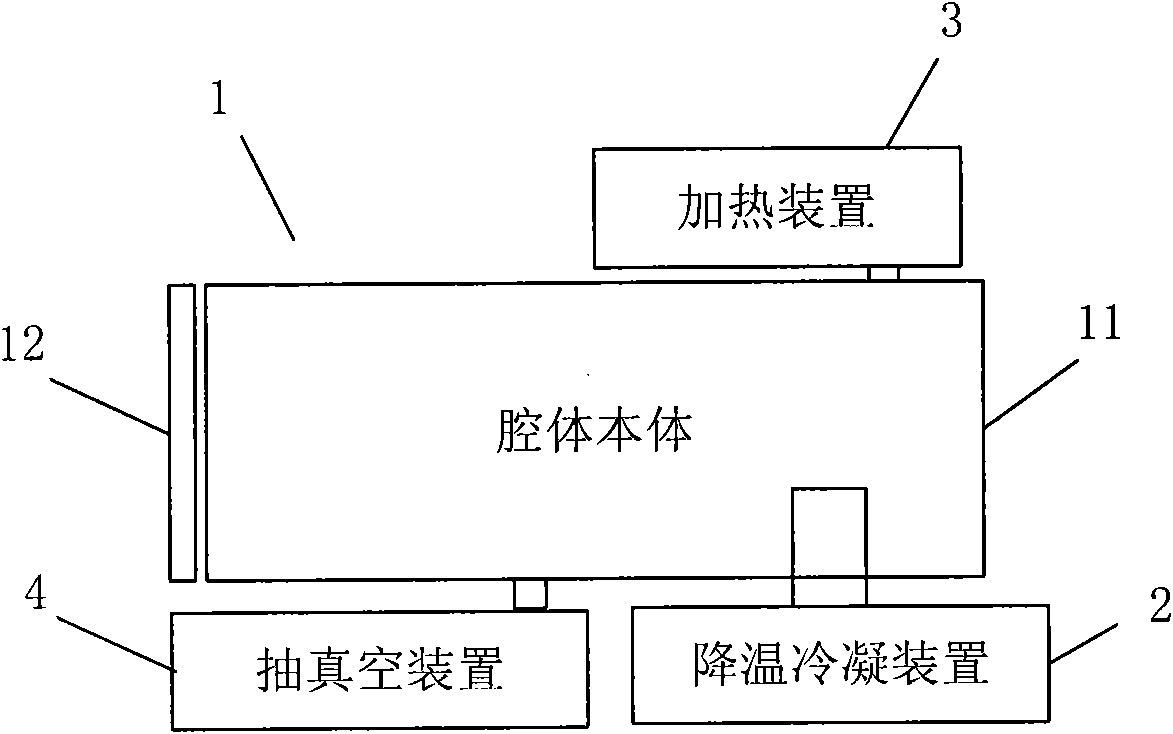

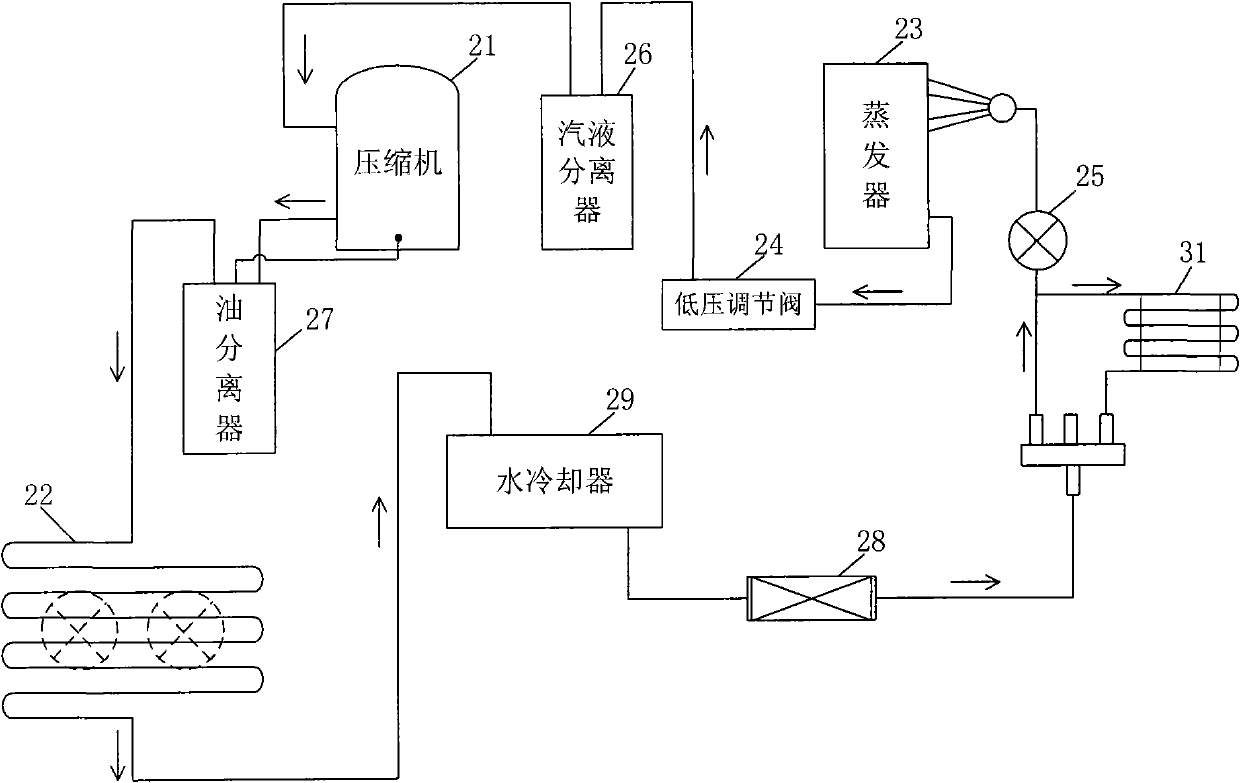

Method and device for rapidly drying ware shell and ware shell

InactiveUS20120171462A1Ensure qualityFast dryingLayered productsDrying solid materials without heatProcess engineeringVacuum chamber

A method and a device for rapidly drying ware shell, and a ware shell, are provided, in the field of precision casting technology. Conventionally, the ware shell drying process fails to ensure high quality of a ware shell and rapid drying simultaneously when the ware shell has a complex structure. The method includes the following steps: a. putting a ware shell to be dried in a sealed chamber; b. vacuuming the sealed chamber under the premise condition of controlling the ware shell in a constant temperature state, and cooling the gas in the sealed chamber in a predetermined time period to condense the moisture in the sealed chamber; c. vacuum injecting gas to the sealed vacuum chamber to make the chamber return to normal atmosphere pressure; d. determining whether the ware shell is dry. If result is YES, then end, otherwise back to step b.

Owner:TSAI YUCHI

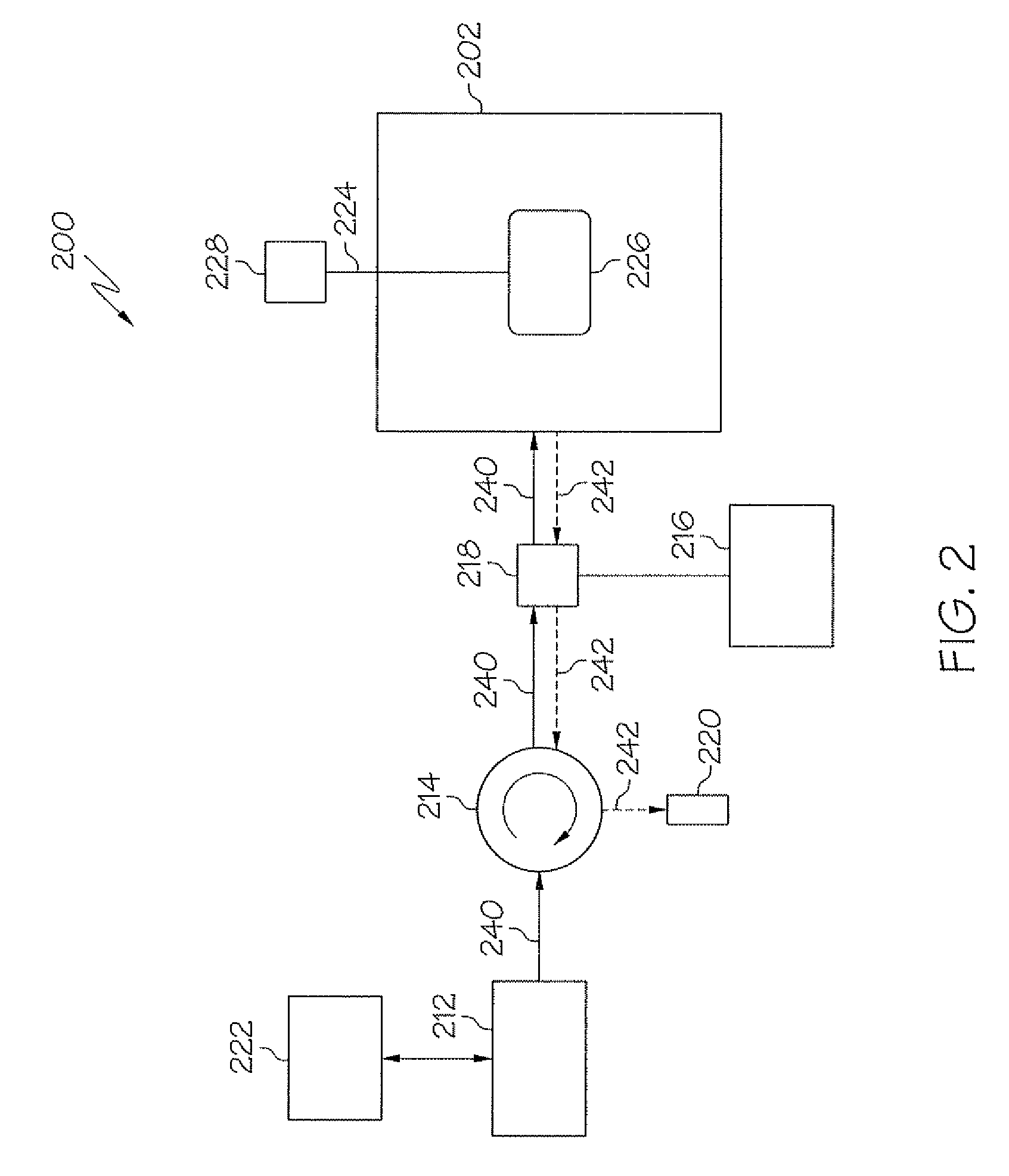

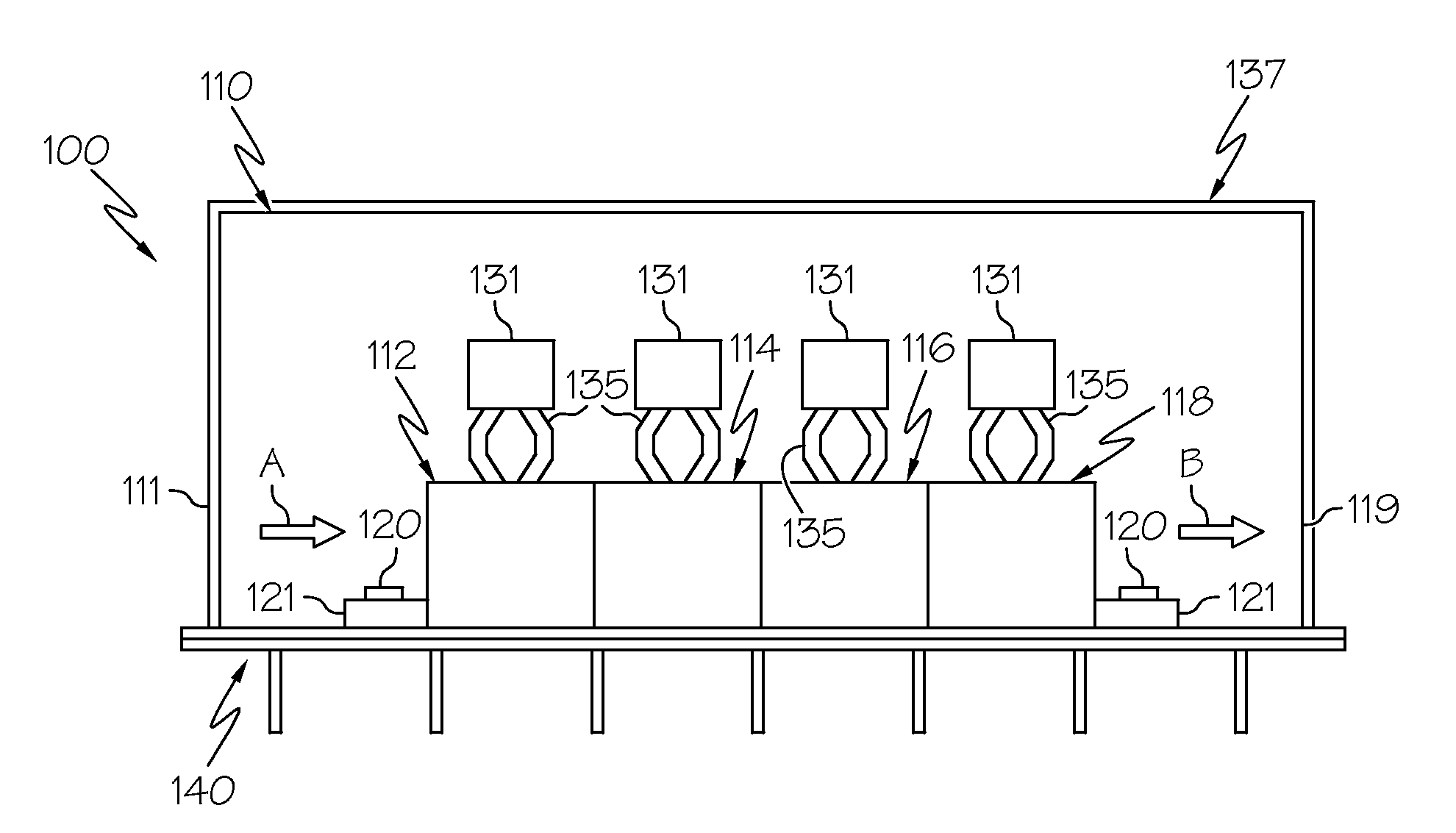

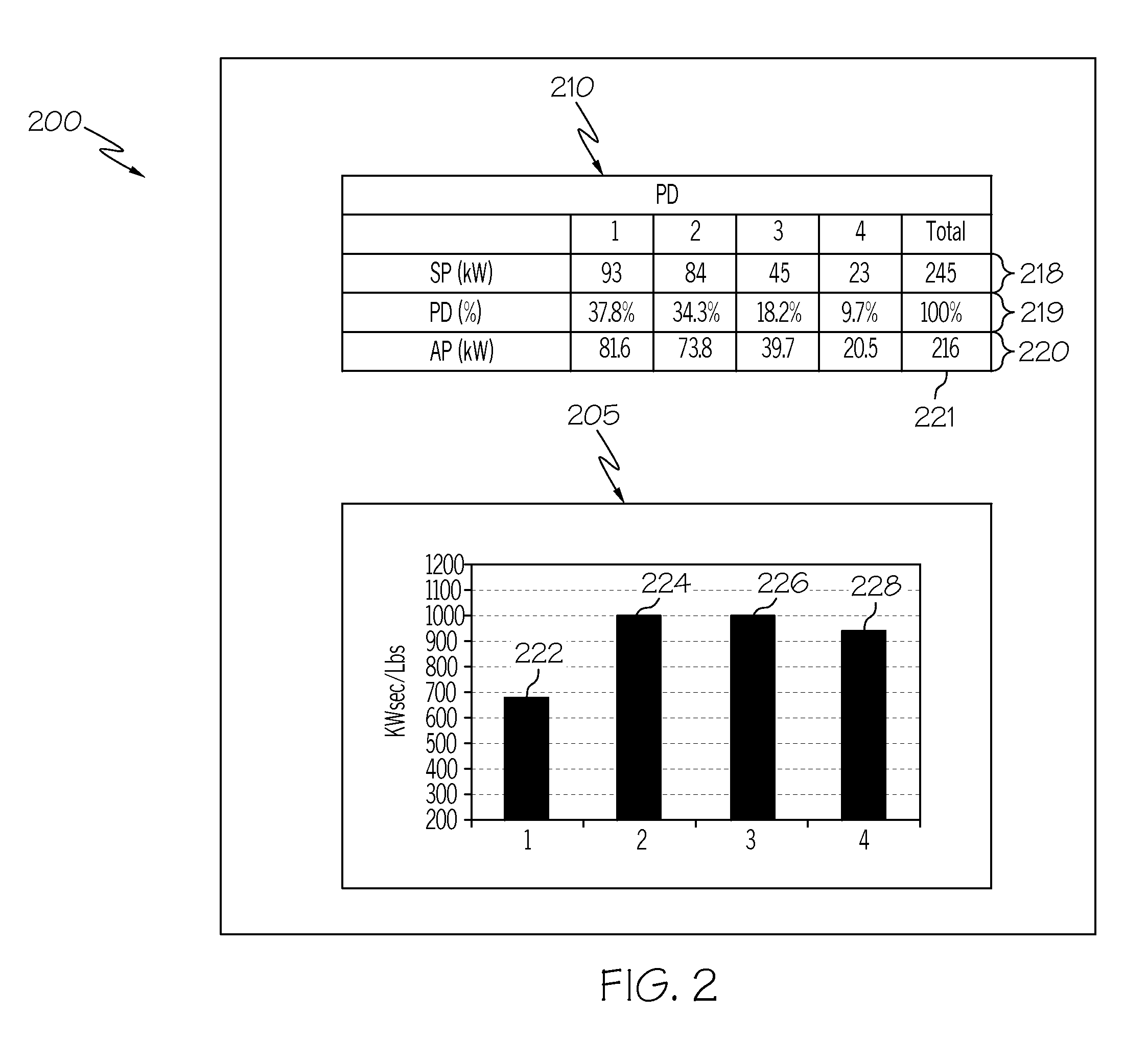

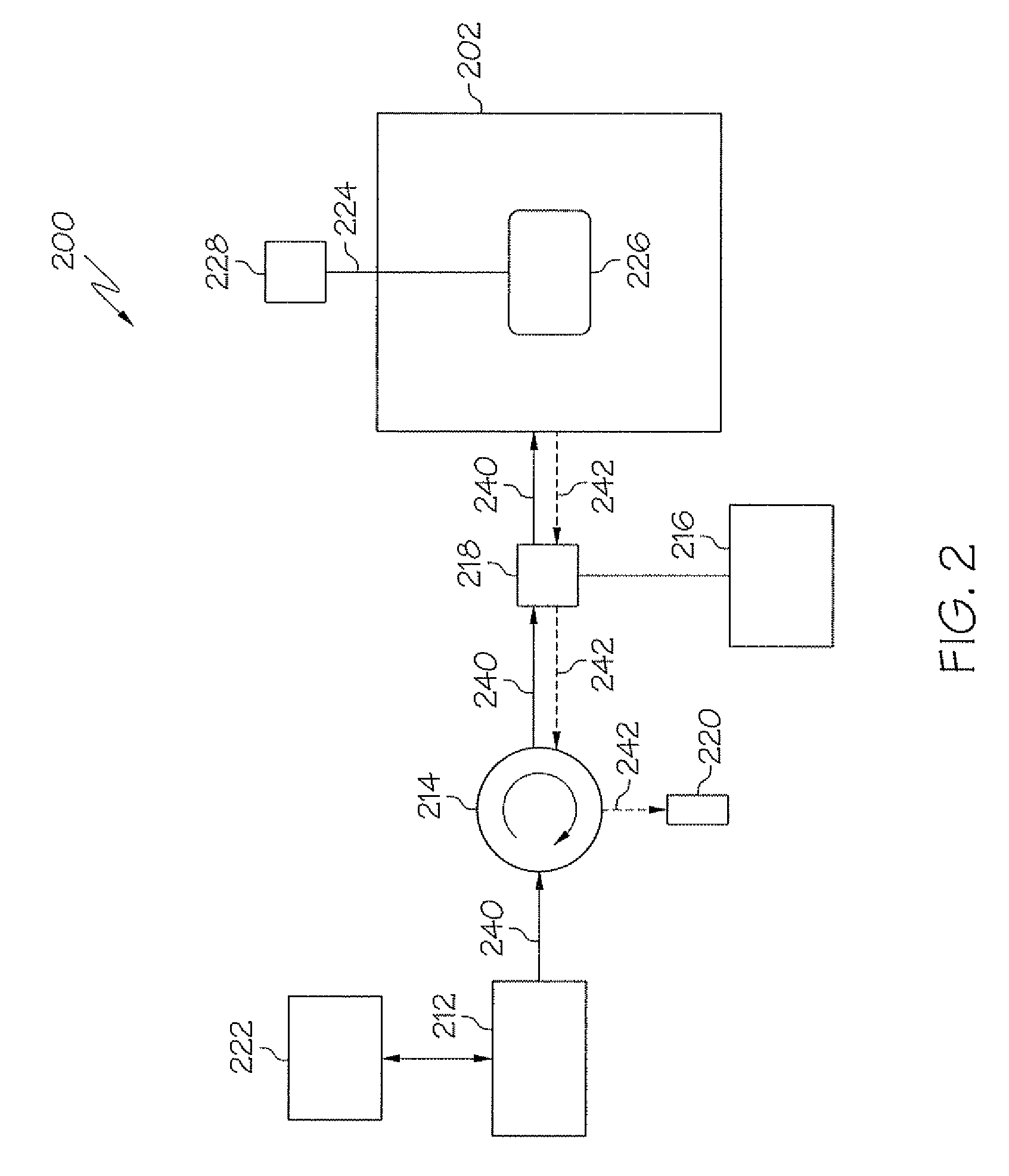

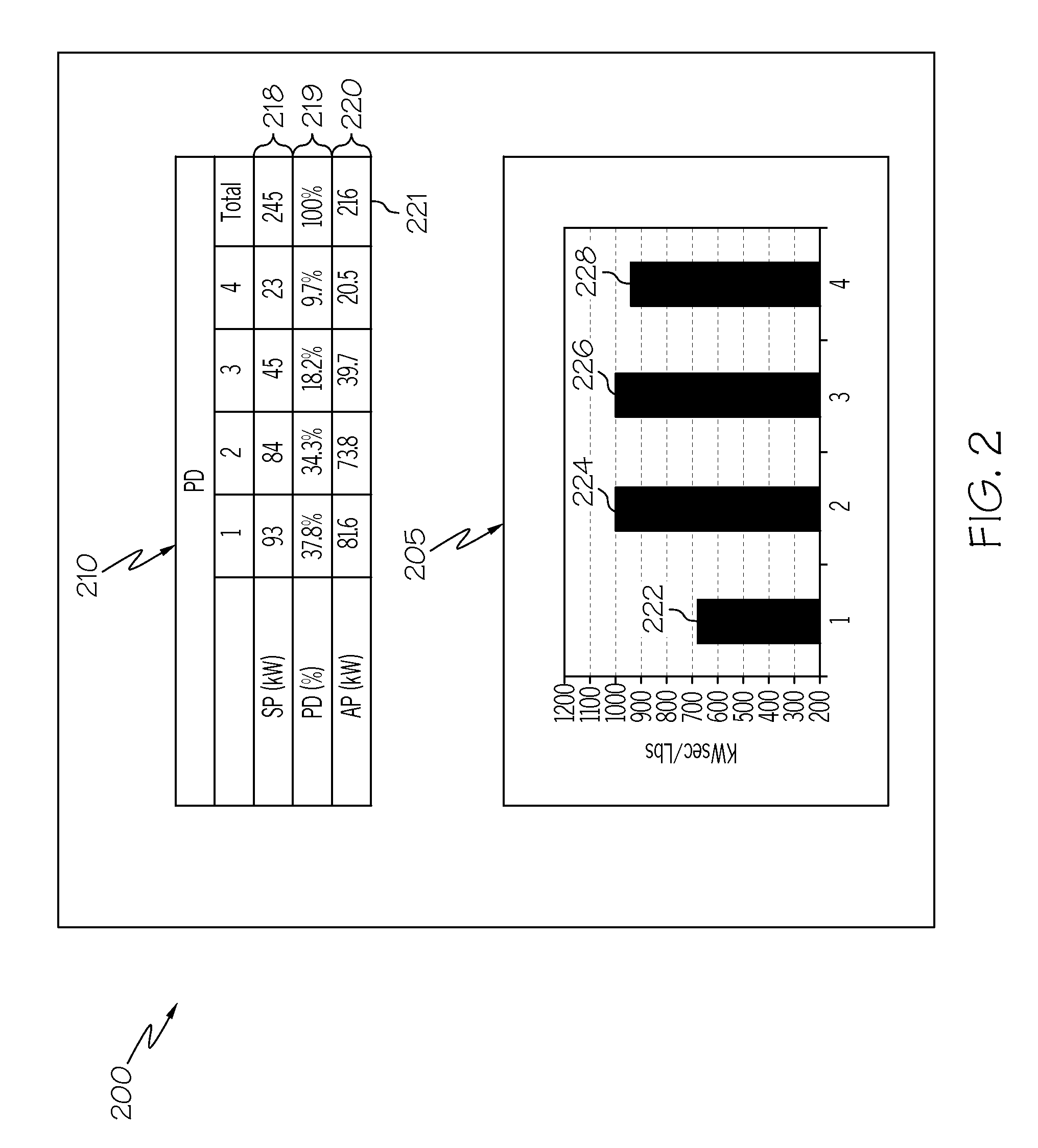

Methods For Drying Ceramic Materials

InactiveUS20110120991A1Drying solid materials with heatCeramic shaping apparatusMaterials scienceMicrowave applicator

Methods for drying ceramic materials are provided. In one embodiment, a first power set-point of a first microwave applicator of a drying apparatus is determined Power set-points for at least two additional microwave applicators in the drying apparatus are determined such that a power distribution among the microwave applicators provides an energy per unit of water profile for the additional microwave applicators that is substantially uniform. The microwave applicators may be operated at the determined power set-points as the ceramic material is passed through the drying apparatus.

Owner:CORNING INC

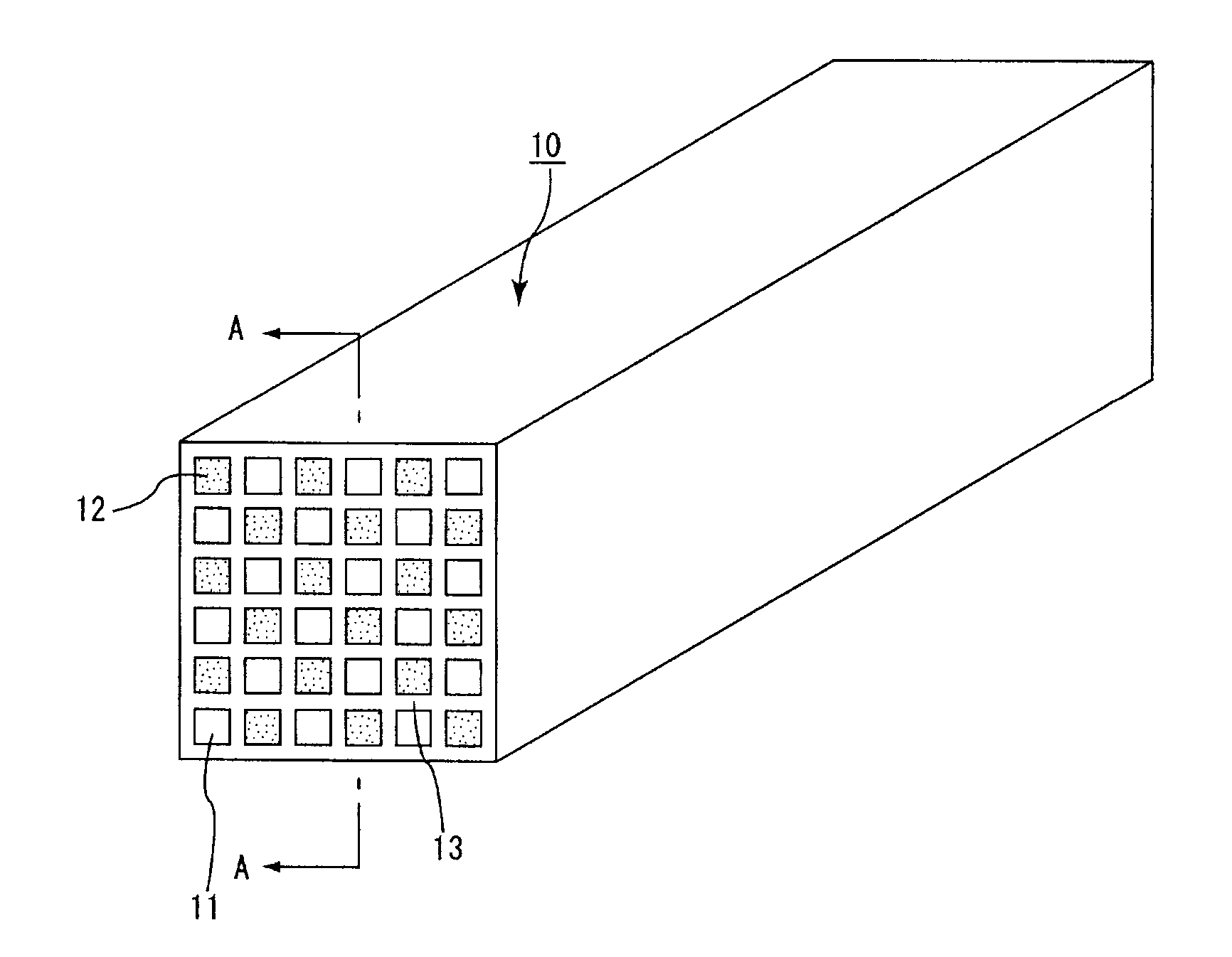

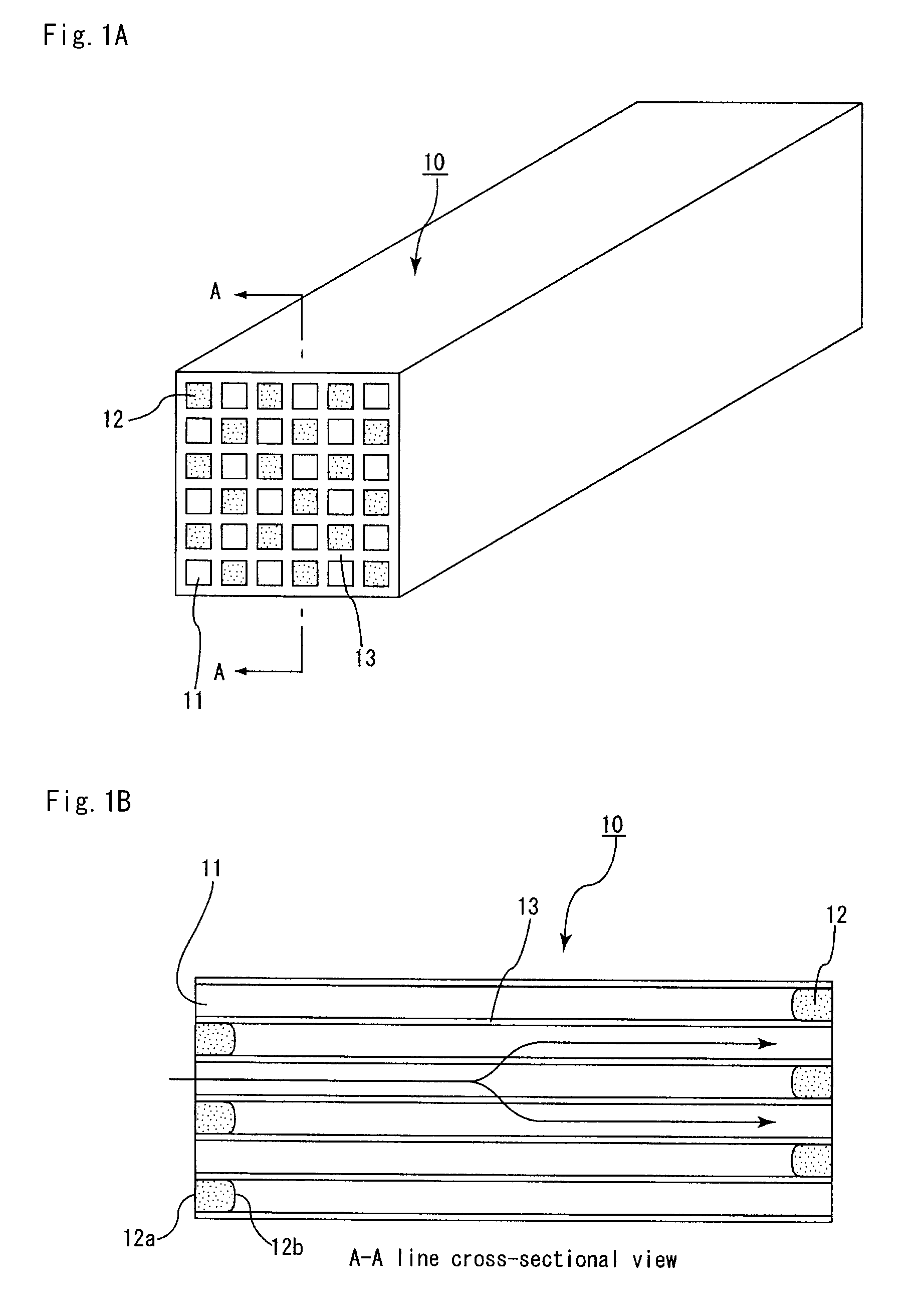

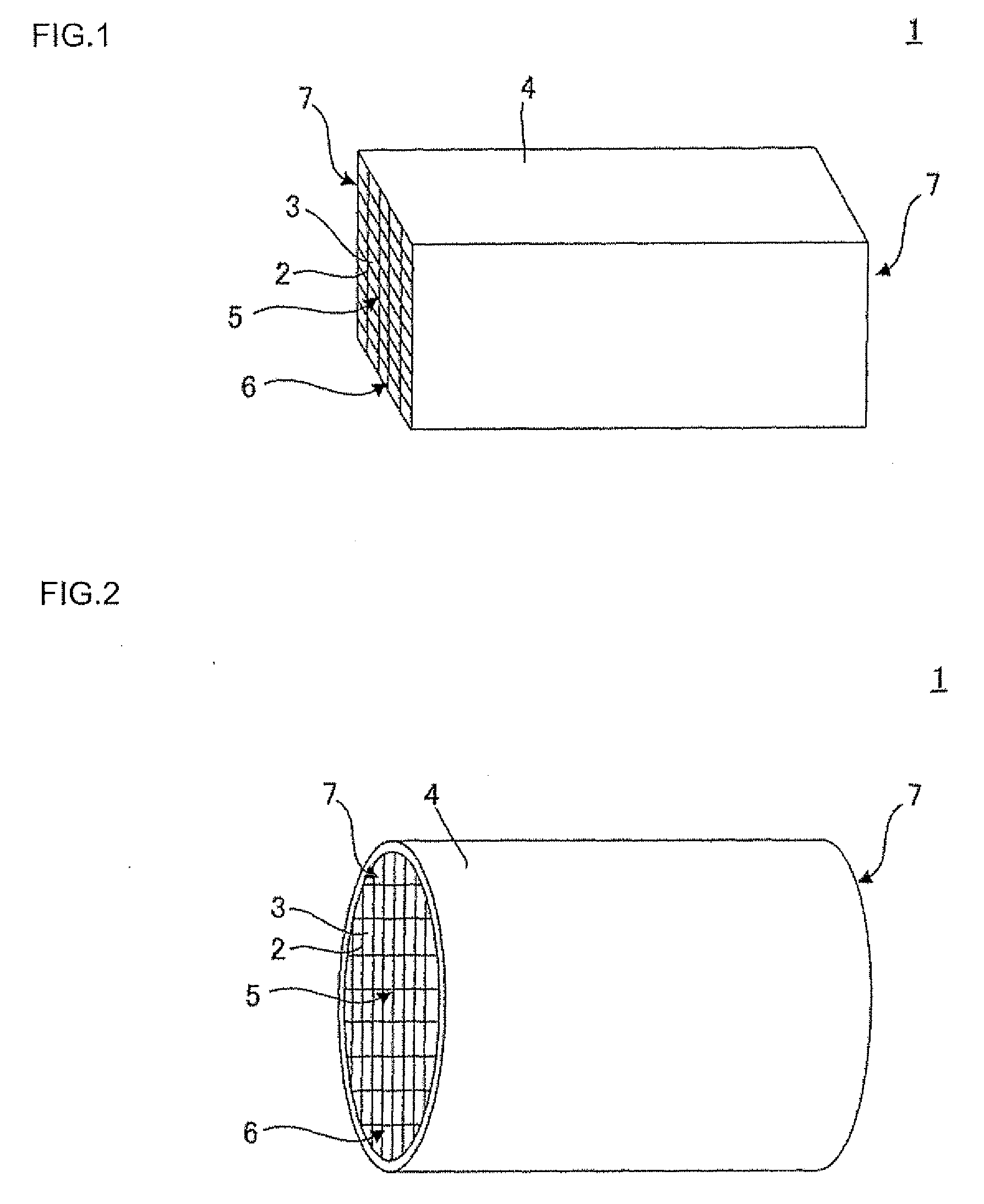

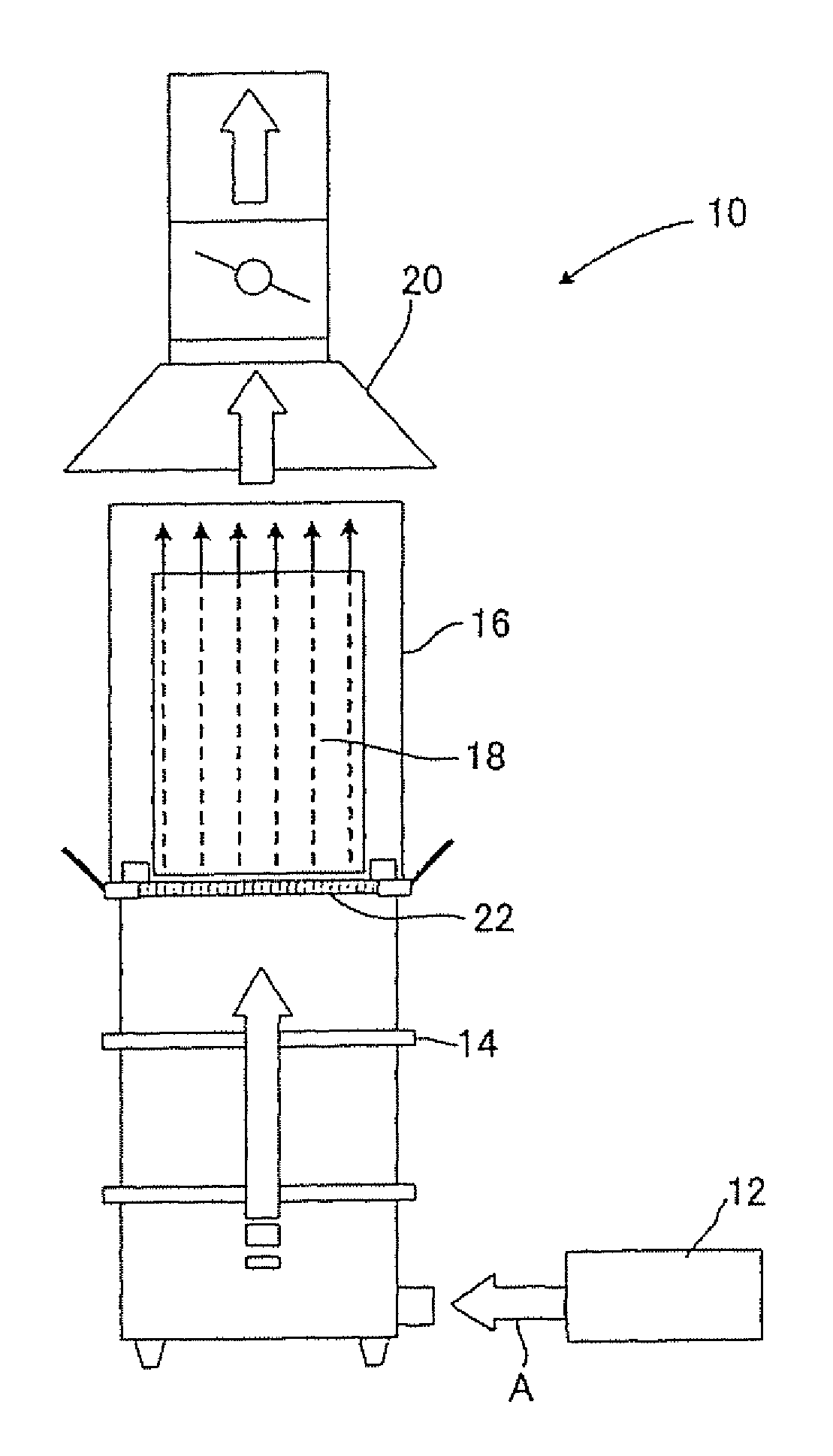

Method for drying honeycomb formed structure

ActiveUS20060283039A1Avoid deformationPartly driedDielectric heatingDrying using combination processesHoneycombHoneycomb like

The invention provides a honeycomb formed structure drying method including causing undried honeycomb formed structures 10 placed on stands 12 to pass through a drying apparatus 1, thereby drying the undried honeycomb formed structures through high-frequency heating, to thereby form dried honeycomb formed structures 11; removing the dried honeycomb formed structures 11 from the stands 12; cooling the stands 12 which have been heated dried in the drying apparatus 1 are cooled to a temperature lower than the gelation temperature of the undried honeycomb formed structures 10; placing newly formed undried honeycomb formed structures 10 on the cooled stands 12; drying the undried honeycomb formed structures by passing through the drying apparatus 1; and repeating these operations. The honeycomb formed structure drying method prevents deformation such as warpage of partition walls of honeycomb formed structures during drying thereof.

Owner:NGK INSULATORS LTD

Methods and Apparatus for Drying Ceramic Green Bodies with Microwaves

ActiveUS20100107435A1Dielectric heatingDrying using combination processesPower sensorMicrowave method

Methods and apparatus for drying ceramic green bodies include providing one or more ceramic green bodies in a microwave heating chamber operatively connected to a microwave source and a PLC. The total mass of the ceramic green bodies present in the microwave heating chamber is determined. Microwave energy is generated with the microwave source and transmitted from the microwave source to the microwave heating chamber. A transmitted power of the microwave energy transmitted from the microwave source to the microwave heating chamber is measured with power sensors. The reflected power of reflected microwave energy reflected back from the microwave heating chamber is also measured. The power of the microwave energy transmitted from the microwave source to the microwave heating chamber is adjusted based on the total mass of ceramic green bodies present in the microwave heating chamber, the measured transmitted power and the measured reflected power.

Owner:CORNING INC

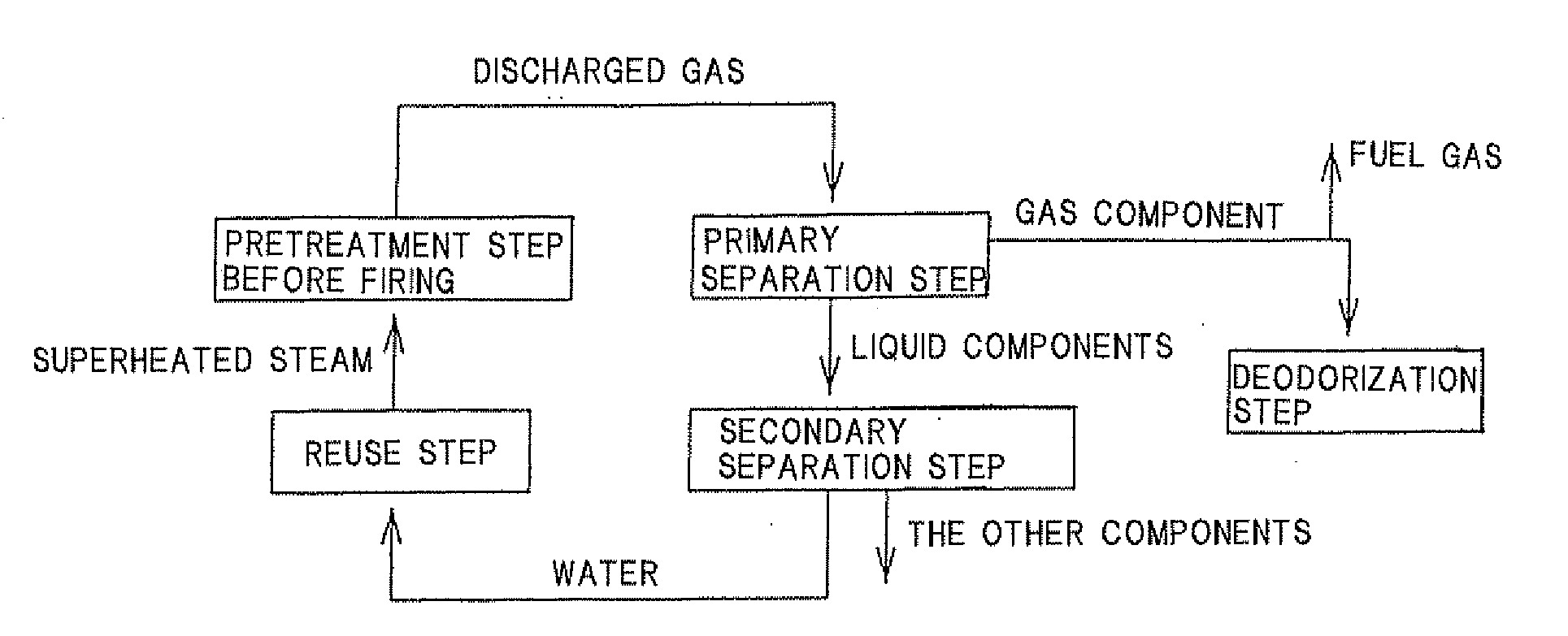

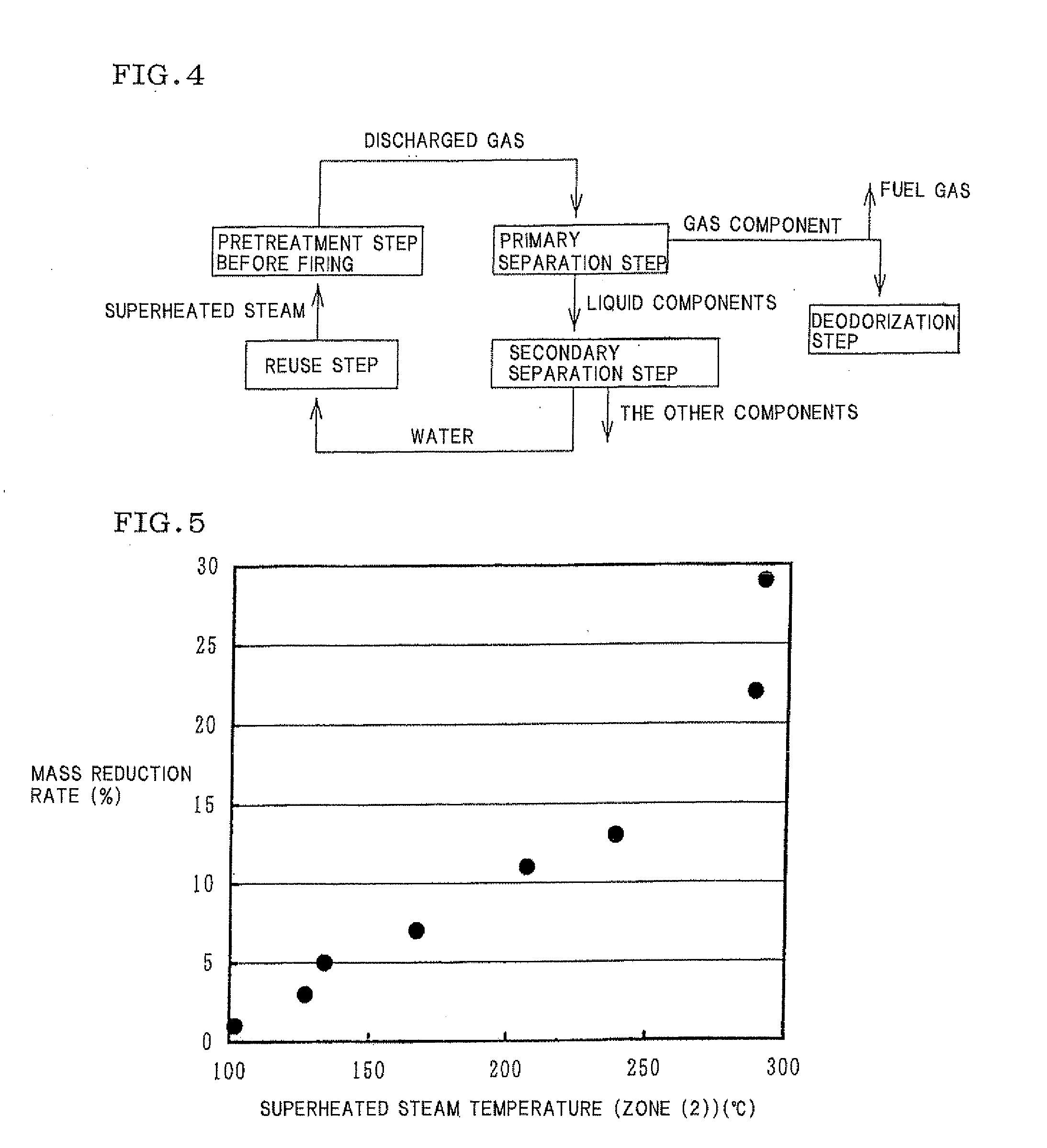

Method for pretreating honeycomb formed article before firing and system for pretreating honeycomb formed article before firing

InactiveUS20090200712A1Suppress generationDrying solid materials with heatDrying gas arrangementsHoneycombPre treatment

A method for pretreating an unfired honeycomb formed article of a raw material composition containing a ceramic raw material, water, and a binder and having a plurality of cells separated by partition walls and functioning as fluid passages before firing. The method has a first step of passing superheated steam having a temperature of 100 to 150° C. through the cells to raise temperature of the honeycomb formed article and then maintaining the temperature of the superheated steam at the temperature of the superheated steam passed through the cells or more and 200° C. or less. The method can provide a pretreatment to a honeycomb formed article in a shorter time with inhibiting generation of a defect such as a deformation or a damage.

Owner:NGK INSULATORS LTD

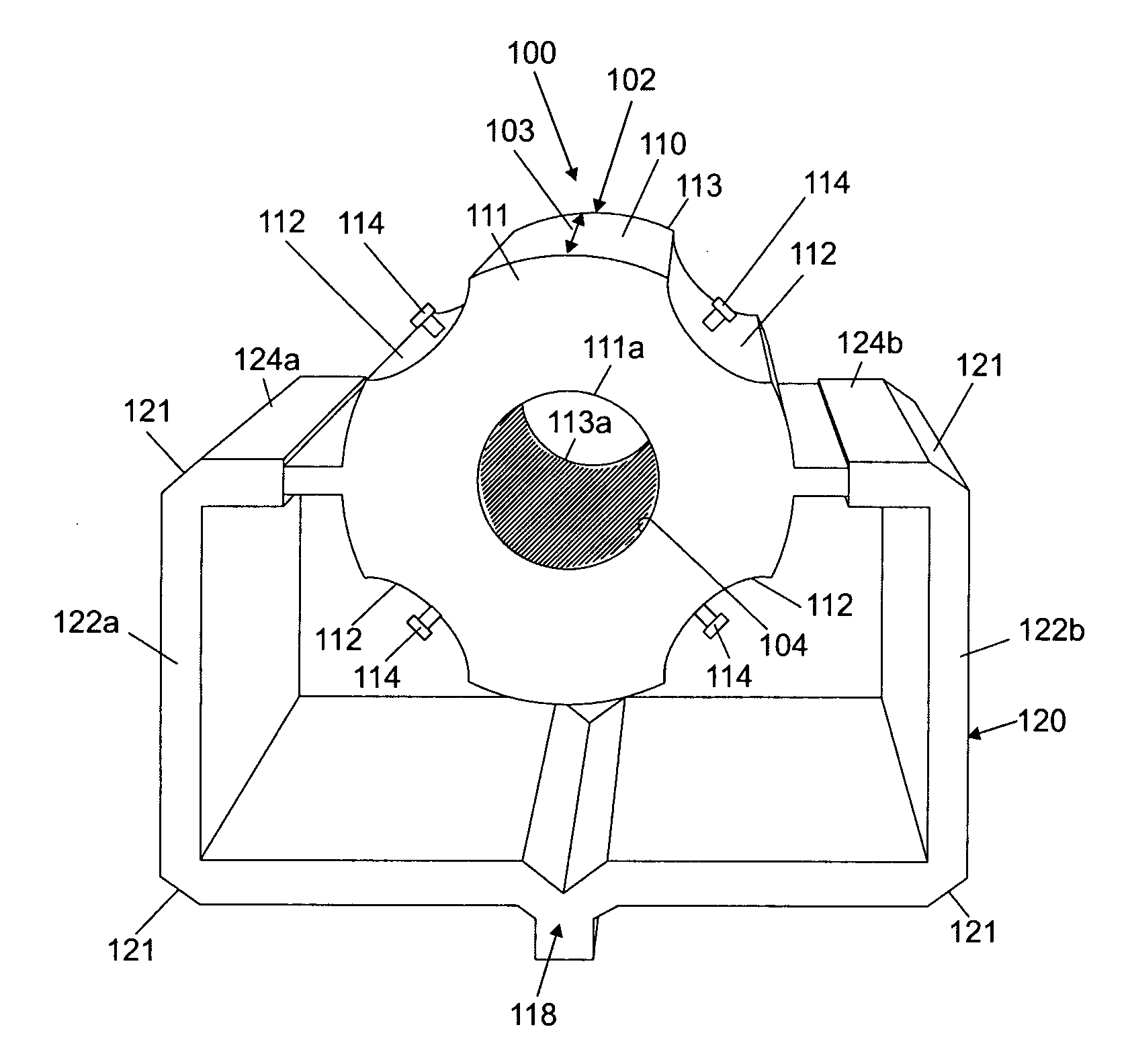

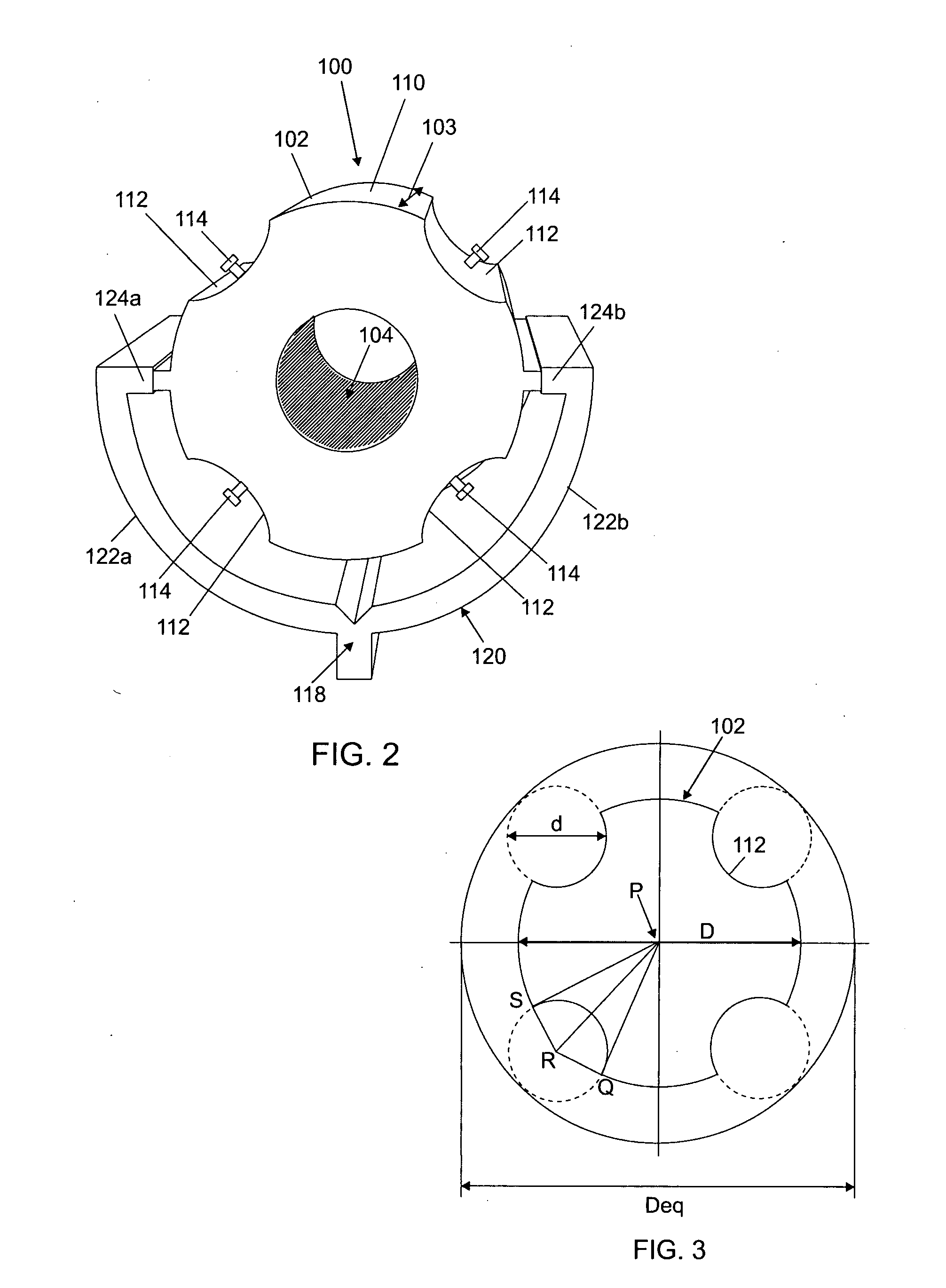

Microwave applicator, system, and method for providing generally circular heating

ActiveUS20090166355A1StiffenDecrease in moisture levelDrying solid materials with heatCeramic shaping apparatusEngineeringWaveguide

A microwave applicator assembly includes a microwave applicator that excites TE modes and provides a generally circular heating pattern in a lossy dielectric material. The microwave applicator has a processing chamber bounded by a circumferential wall in which a plurality of indents are formed. The microwave applicator assembly may further include a feed waveguide coupled to the microwave applicator for inputting microwaves into the processing chamber. The microwave applicator assembly may further include one or more choking sections in communication with the processing chamber to enhance heating efficiency and reduce microwave leakage.

Owner:CORNING INC

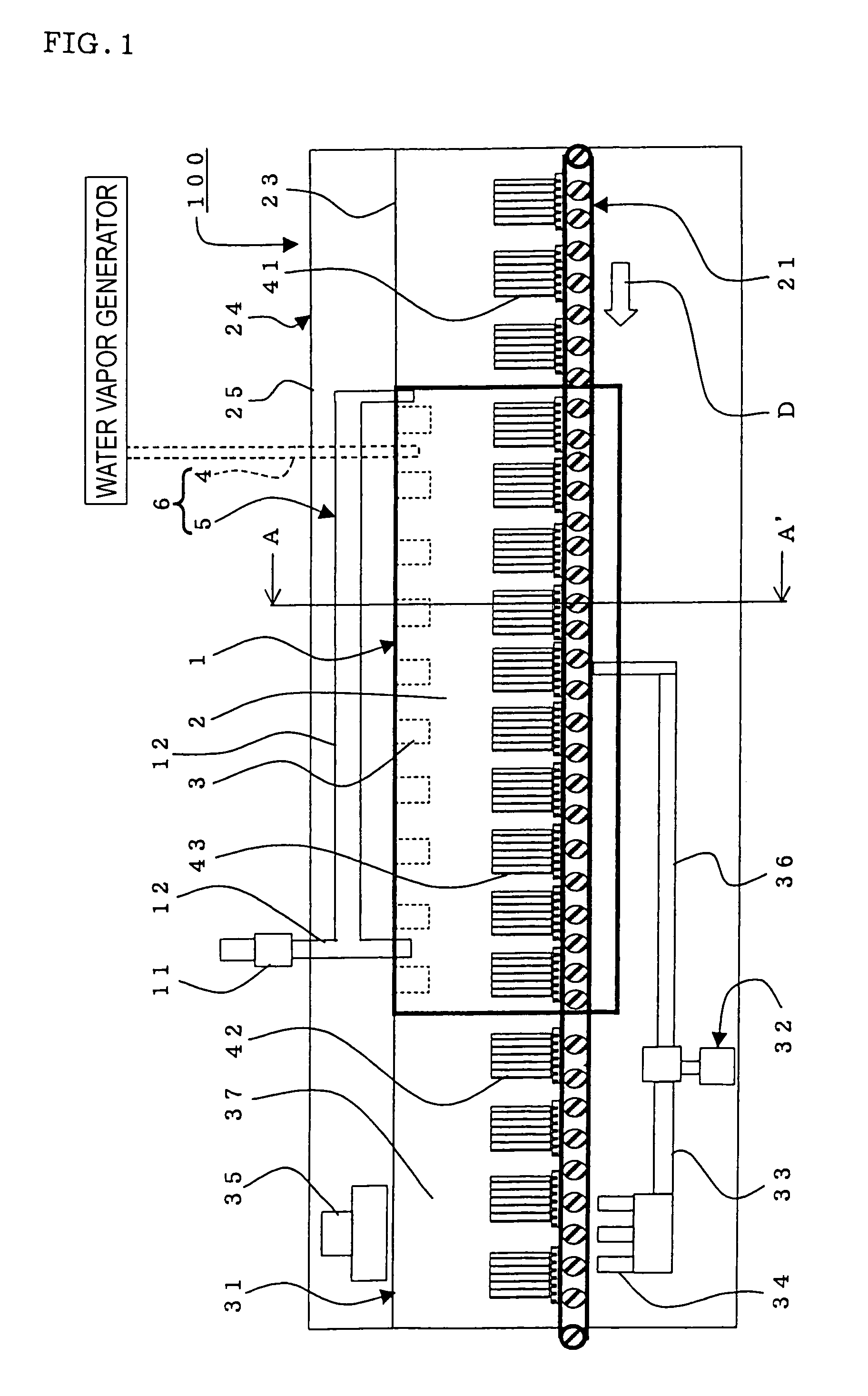

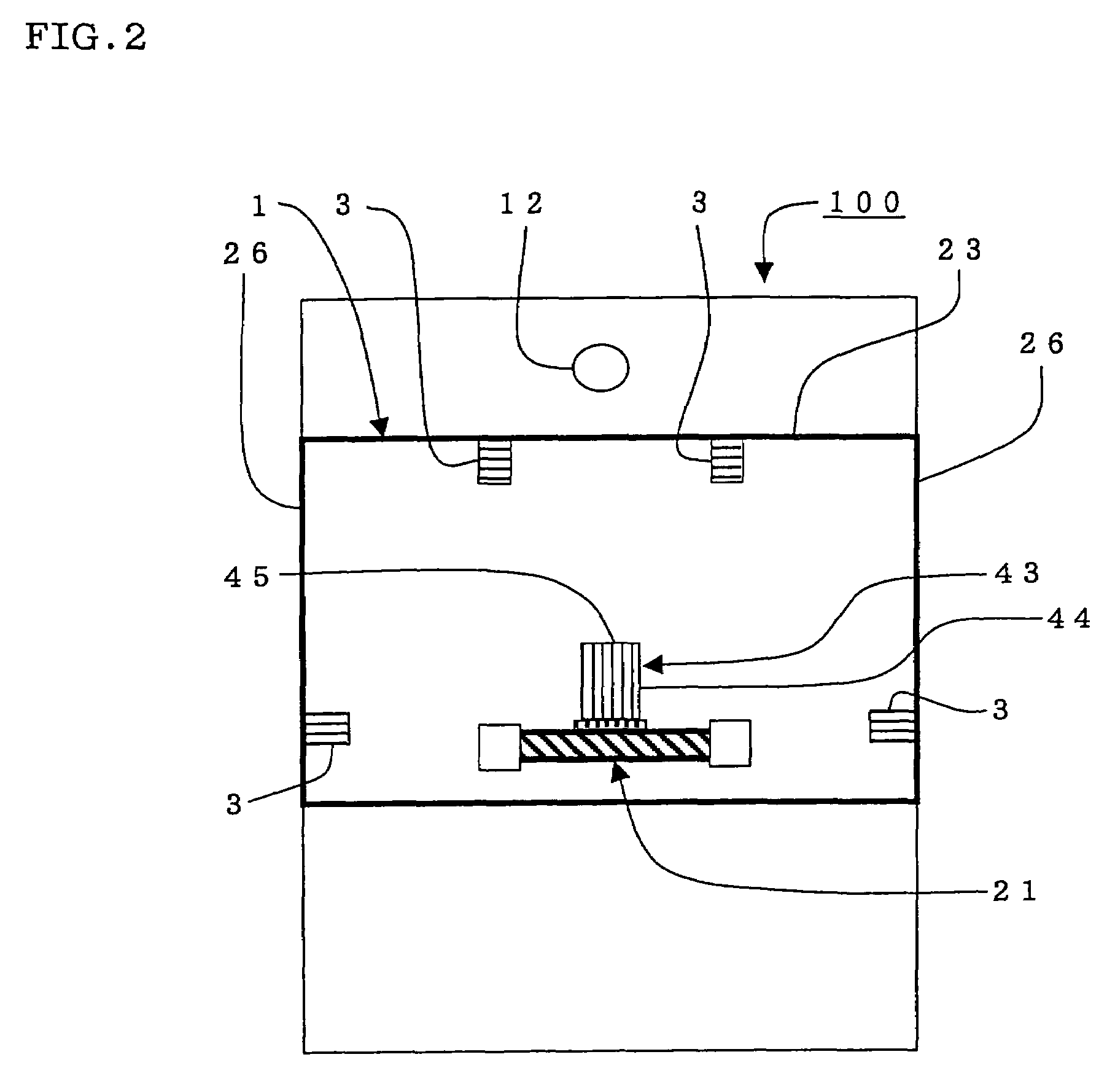

Method for drying honeycomb formed article

ActiveUS20100078859A1Avoid it happening againInhibition of defect generationDrying solid materials with heatDrying gas arrangementsMicrowaveHoneycomb

There is provided a method for drying a honeycomb formed article 1. The method has the first step, where an unfired honeycomb formed article 1 having a plurality of cells separated by partition walls made from raw material composition containing a ceramic raw material, water, and a binder is heated and dried by microwave drying or dielectric drying, and a second step, where the honeycomb formed article 1 is dried by hot air drying, where hot air whose humidity was adjusted to have a wet-bulb temperature of 50 to 100° C. using a hot air drying apparatus 11 after the first step is passed through the cells. The method can dry a honeycomb formed article in a shorter period of time with inhibiting generation of a defect such as a deformation or breakage.

Owner:NGK INSULATORS LTD

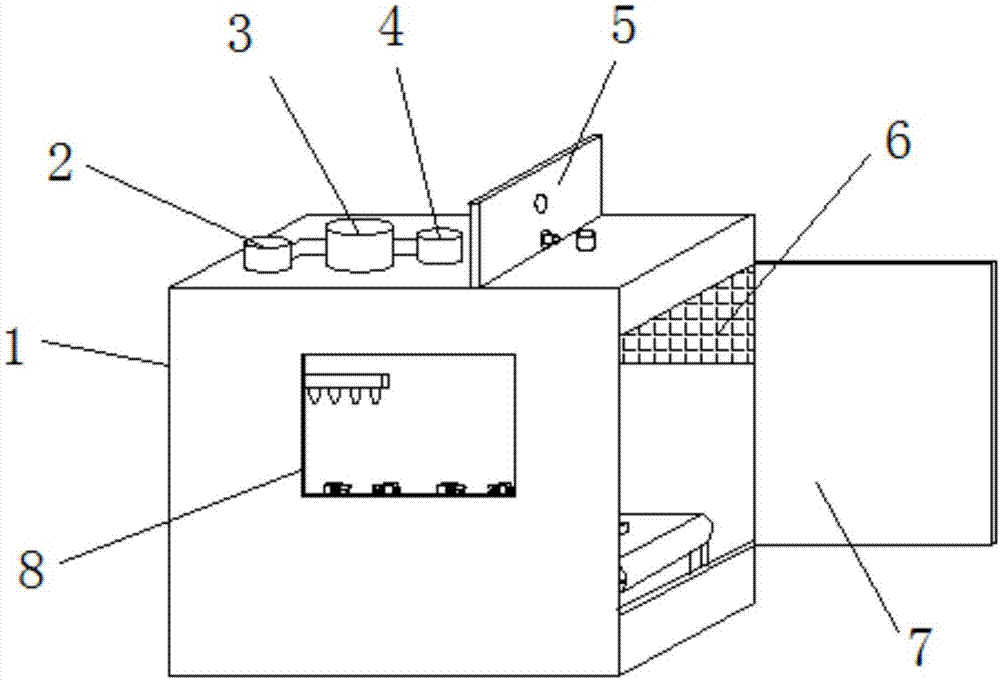

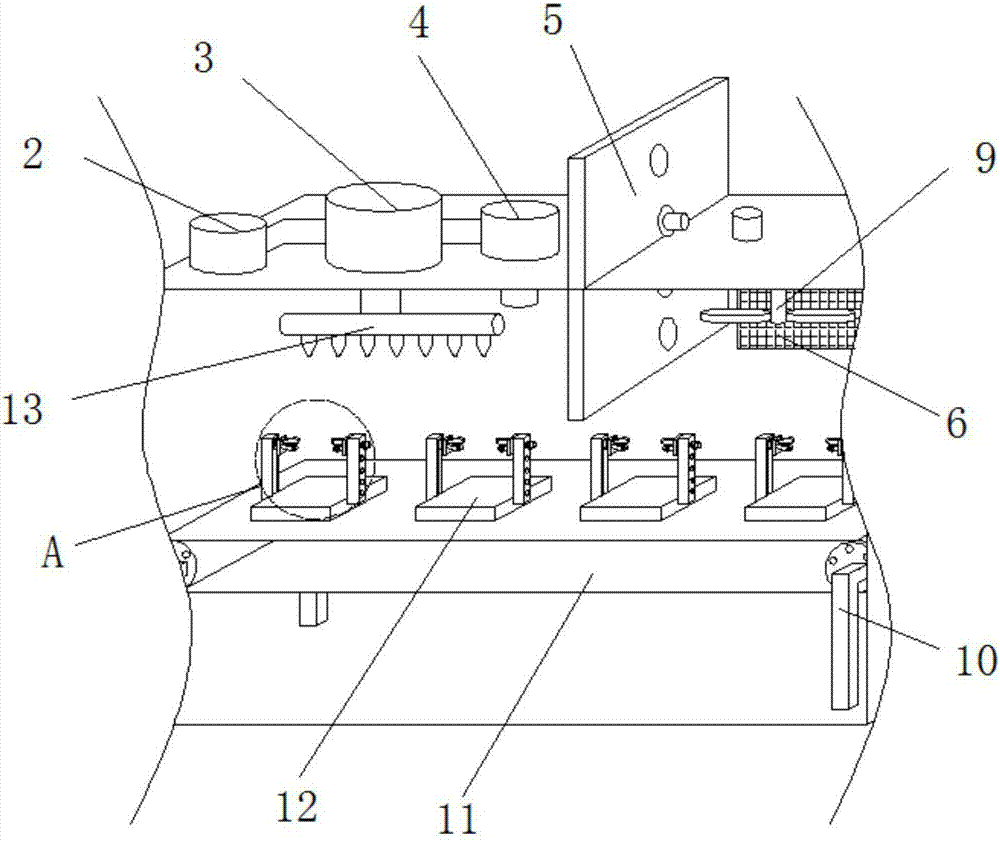

Self-rotary ceramic product processing oven

ActiveCN105651018ARapid coolingDry evenlyDrying gas arrangementsDrying solid materialsEngineeringProduct processing

The invention discloses a self-rotary ceramic product processing oven which comprises an oven body. A plurality of supporting legs are fixed to the bottom face of the oven body. A push cylinder is fixed to the bottom face of a bottom plate of the oven body. A push rod of the push cylinder vertically and upwards stretches into the oven body, a placement plate is fixed to the end of the push rod of the push cylinder and is placed in the oven body, a rotary motor is fixed to the top face of the oven body, an output shaft of the rotary motor is hinged to a top plate of the oven body, the output shaft of the rotary motor vertically penetrates through an upper top plate and is fixedly provided with an upper clamping block, a lower clamping block is fixed to the middle of the top face of the placement plate, and the upper clamping block and the lower clamping block correspond to each other in the vertical direction. A ceramic product placed in the oven can be clamped between the upper clamping block and the lower clamping block, automatically rotate and be evenly dried. Besides, the oven body can be cooled quickly, an oven door and the oven body are separated, installation and detachment are convenient, and accordingly independent cleaning is facilitated.

Owner:HAIMEN ZHUOWEI TEXTILE CO LTD

Drying device used for ceramic ware production

InactiveCN107228553AImprove dry strengthImprove drying effectDrying gas arrangementsDrying machines with progressive movementsEngineeringUltimate tensile strength

The invention discloses a drying device for the production of pottery, which comprises a casing, a cavity is arranged inside the casing, four supporting legs are arranged at the bottom of the cavity, and the upper ends of the supporting legs are A conveying device is provided, the upper end of the conveying device is equidistantly provided with several placing plates, both sides of the placing plate are provided with supporting columns, and the opposite side of the two supporting columns is provided with chute, and the sliding A slider is installed in the groove, and the side of the slider away from the chute is provided with an electric telescopic rod. The end of the electric telescopic rod is provided with a support plate, and the support plates are provided with two mutually hinged grippers. , and pin holes are provided on the grippers, and several threaded through holes are arranged at equal intervals along the vertical direction on the support column, and locking devices are installed in the threaded through holes. The present invention carries out secondary drying treatment on pottery, has high drying intensity and good drying effect, and performs secondary utilization of resources, is environmentally friendly and energy-saving, and is suitable for popularization.

Owner:CHONGQING YAYU CERAMICS CO LTD

Method of drying a honeycomb formed body

ActiveCN102235803AReduced deterioration of cross-sectional shapeReduce diameter differenceDrying solid materials with heatCeramic shaping apparatusMetallurgyHoneycomb structure

The present invention relates to a method of drying honeycomb formed bodies. More specifically, the present invention relates to a method of drying honeycomb formed bodies with which they cannot easily be affected by an atmosphere in a dry space and can be dried without occurrence of deformation and cracks of outer peripheries thereof even when partition walls thereof are thin. The method of drying a ceramic formed body comprising the step of performing dielectric drying on an unfired honeycomb formed body formed with a ceramic material as a main raw material under a condition that a power density is 5 to 20 [kW / kg (water)].

Owner:NGK INSULATORS LTD

Method of drying honeycomb article, and drying apparatus therefor

ActiveUS20090320315A1Avoid defectsNo longer dryDrying using combination processesDrying solid materials with heatHoneycombEngineering

The drying method performs drying the honeycomb formed article by such an arrangement that superheated steam or mixed gas of steam and hot air, temperature and humidity of which is regulated so that wet-bulb temperature thereof becomes 70° C. or higher, is made to pass through the cells of the honeycomb formed article. The drying apparatus includes a steam supply unit that supplies the superheated steam, a buffer chamber that aligns the superheated steam supplied from the steam supply unit, an upper chamber disposed above the buffer chamber to locate the honeycomb formed article, and a hood unit that recovers the superheated steam which has passed through the honeycomb formed article.

Owner:NGK INSULATORS LTD

Method of honeycomb molding pretreatment for burning and system for honeycomb molding pretreatment for burning

InactiveCN101563304AShorten the timeDrying solid materials with heatDrying gas arrangementsWater vaporHoneycomb

A method in which an unburned honeycomb molding which has been formed from a raw-material composition comprising a raw ceramic material, water, and a binder and has cells serving as fluid channels and separated by partitions is subjected to a pretreatment for burning. The method includes a first step in which 100-150 DEG C overheated water vapor is passed through the cells to heighten the temperature of the honeycomb molding and then the overheated water vapor being passed is kept at a temperature which is not lower than the temperature of the overheated water vapor having been passed through the cells and is not higher than 200 DEG C. By the method of honeycomb molding pretreatment for burning, the honeycomb molding can be pretreated prior to burning in a shorter time while inhibiting the occurrence of troubles such as deformation and breakage.

Owner:NGK INSULATORS LTD

Ceramic shell rapid drying method and device as well as ceramic shell

ActiveCN102019361AReduce humidityDry fastDrying solid materials without heatFoundry mouldsMoistureCeramic

Owner:蔡欲期

Microwave drying method of honeycomb formed bodies

ActiveUS7197839B2Lot differenceReduce the differenceDrying solid materials with heatCeramic shaping apparatusHoneycombCell axis

A method for drying a honeycomb formed body using microwaves is provided. The method can reduce the difference in the drying speed inside the honeycomb formed bodies during the drying process and can dry the honeycomb formed bodies without cell deformation. The method comprises placing the honeycomb formed body in a drying furnace with the cell axis in the vertical direction and irradiating the honeycomb with microwaves at a frequency of 300–30,000 MHz. The difference of the water content in the vertical direction of the honeycomb formed body 1 is maintained at 0.3% per mm or less during microwave irradiation.

Owner:NGK INSULATORS LTD

Method and apparatus for drying honeycomb formed body

ActiveUS7721461B2Avoid deformationReduce the differenceDielectric heatingDrying solid materials with heatHoneycombMaterials science

An undried honeycomb formed body 41 is subjected to high-frequency heating in an atmosphere where humidity and temperature are maintained at 30 to 65% and 75 to 130° C., respectively, such that 50 to 99 mass % of water contained in the undried honeycomb formed body 41 is evaporated at the end of high-frequency heating, whereby the amount of water vaporized from the outer part of the undried honeycomb formed body 41 is increased, thereby reducing a difference between amount of water vaporized from the inner part of the undried honeycomb formed body 41 and that of water vaporized from the outer part thereof as well as reducing a difference between drying degree of the inner part of the undried honeycomb formed body 41 and that of the outer part thereof, thereby producing a dried honeycomb formed body 42 in which deformation of the partition walls is suppressed. The invention provides a honeycomb formed body drying method which prevents deformation of partition walls of the honeycomb formed body during drying thereof.

Owner:NGK INSULATORS LTD

Method for drying honeycomb formed structure

ActiveUS7320183B2Avoid deformationPartly driedDielectric heatingDrying using combination processesHoneycombHoneycomb like

Owner:NGK INSULATORS LTD

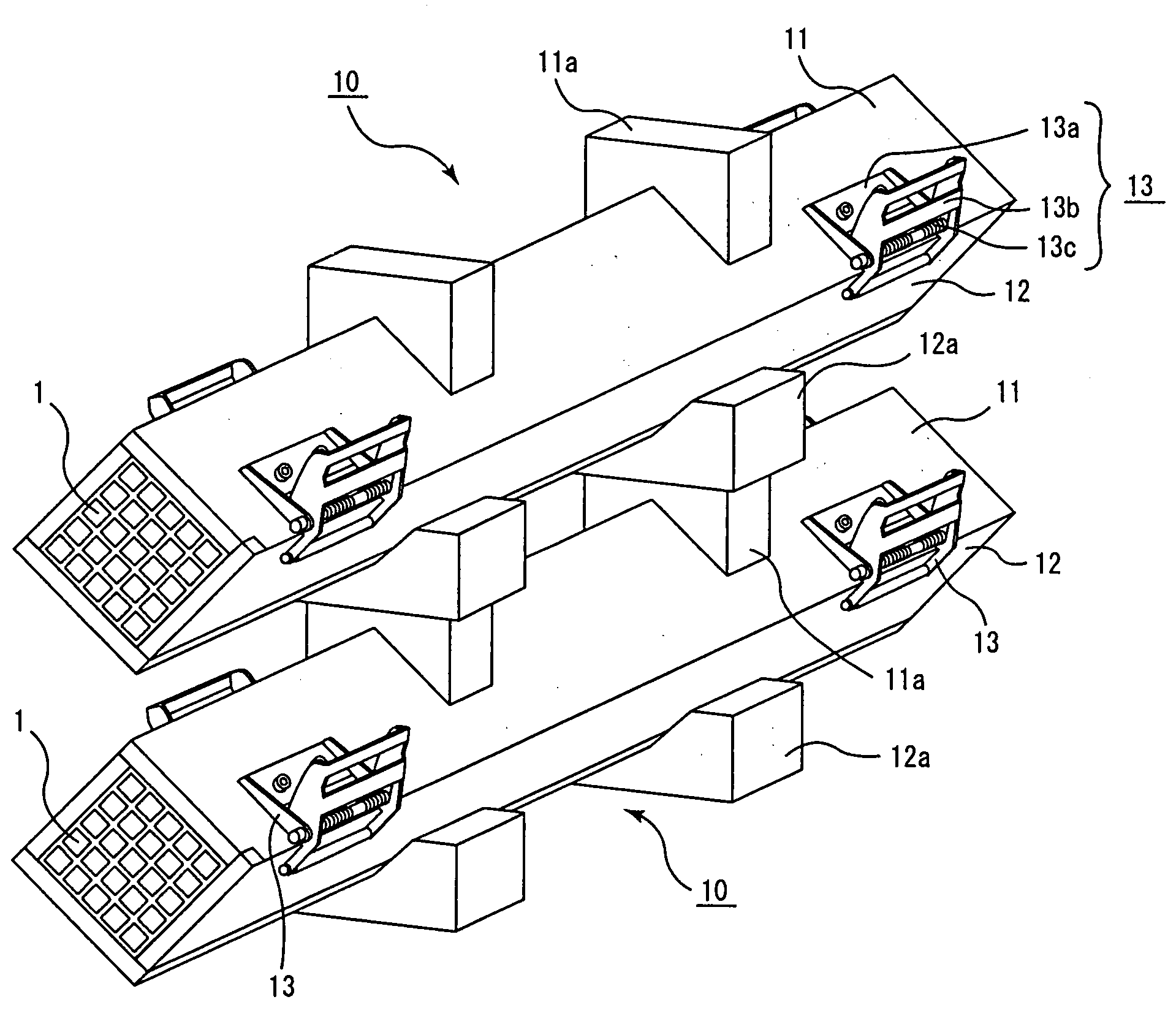

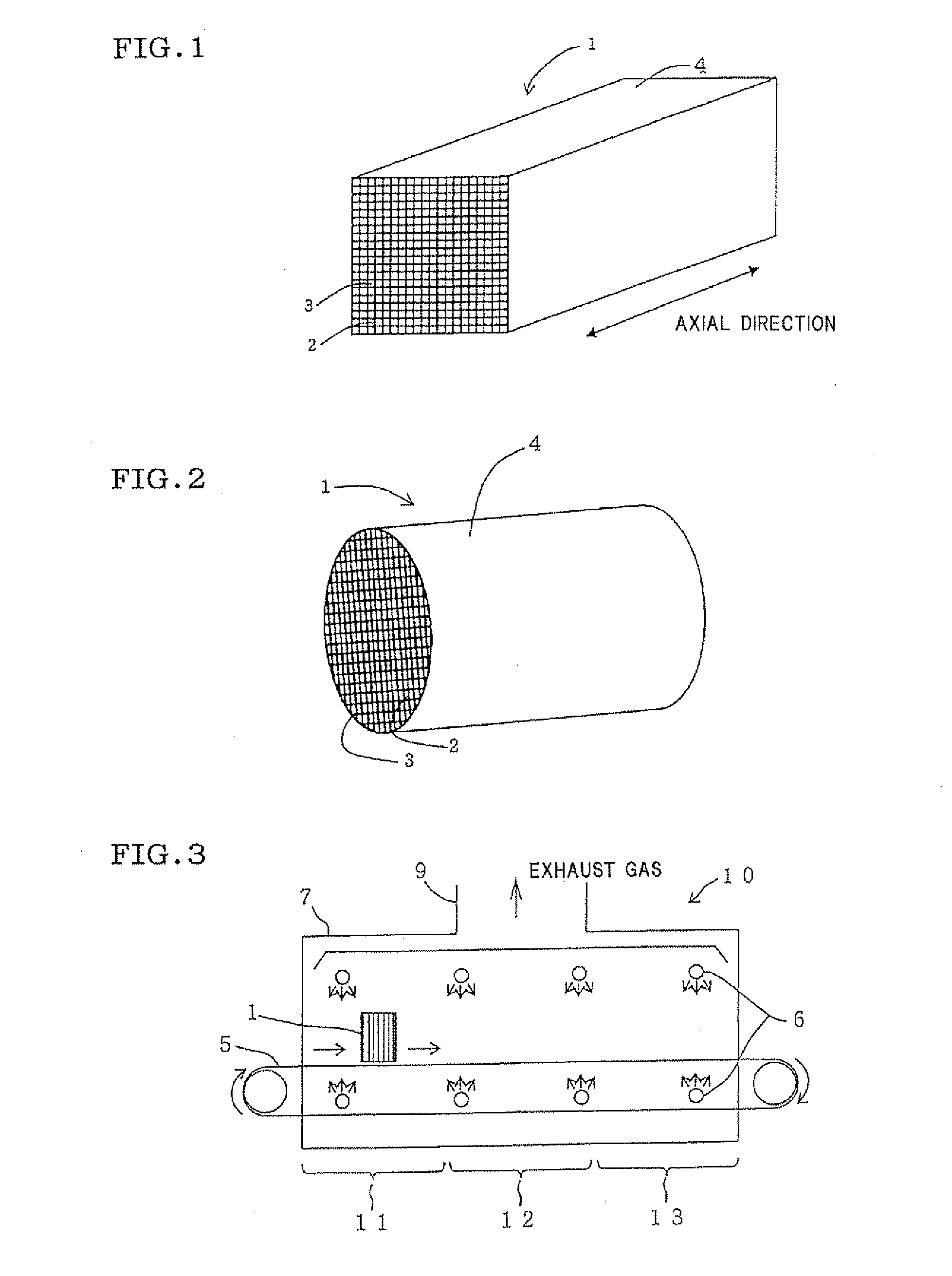

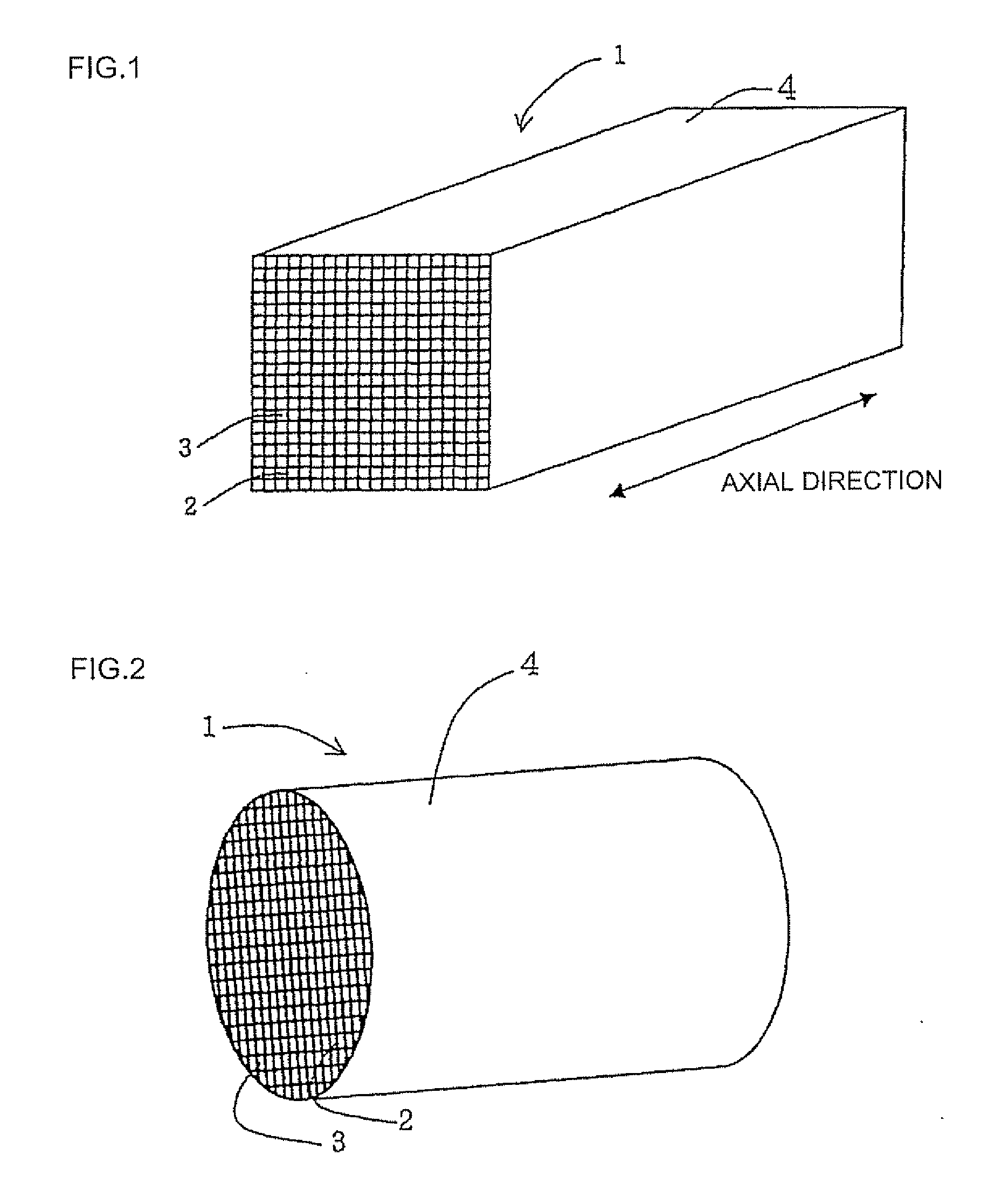

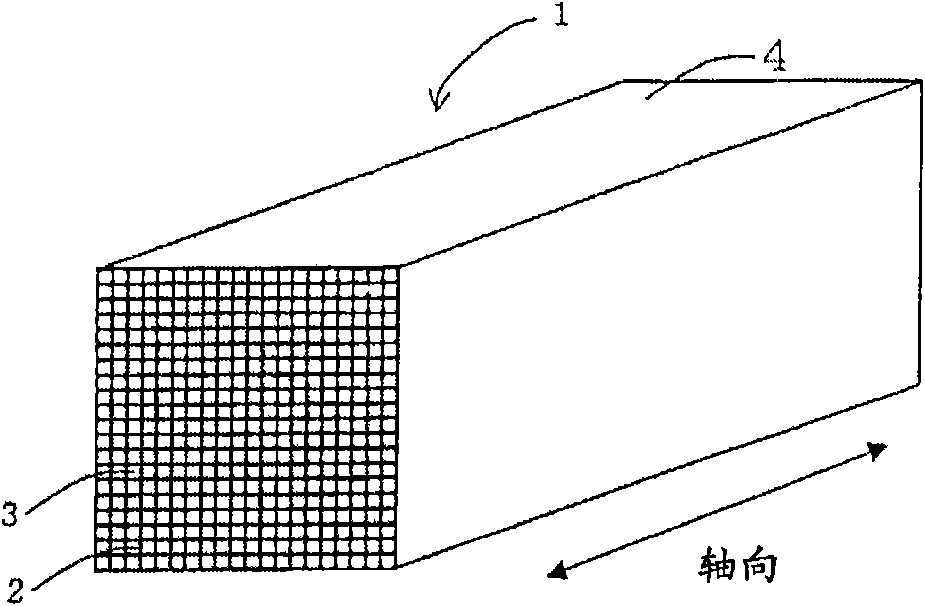

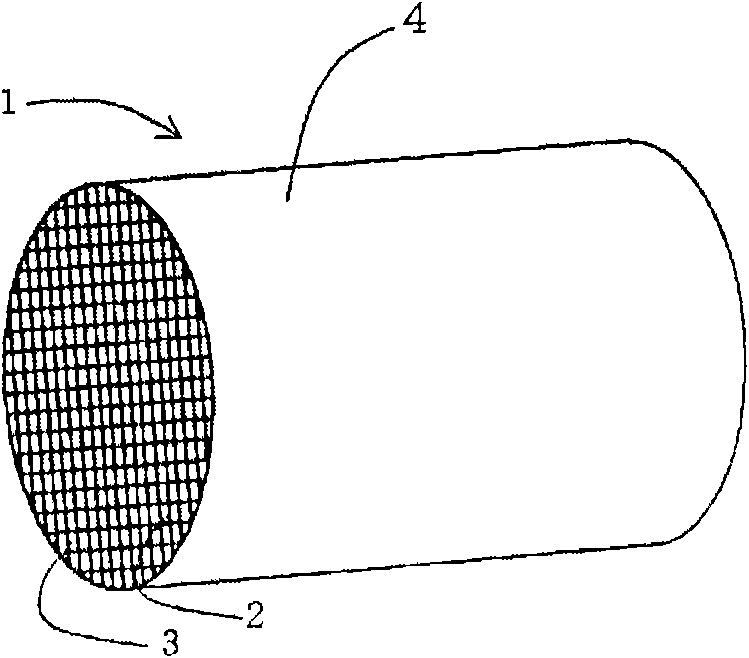

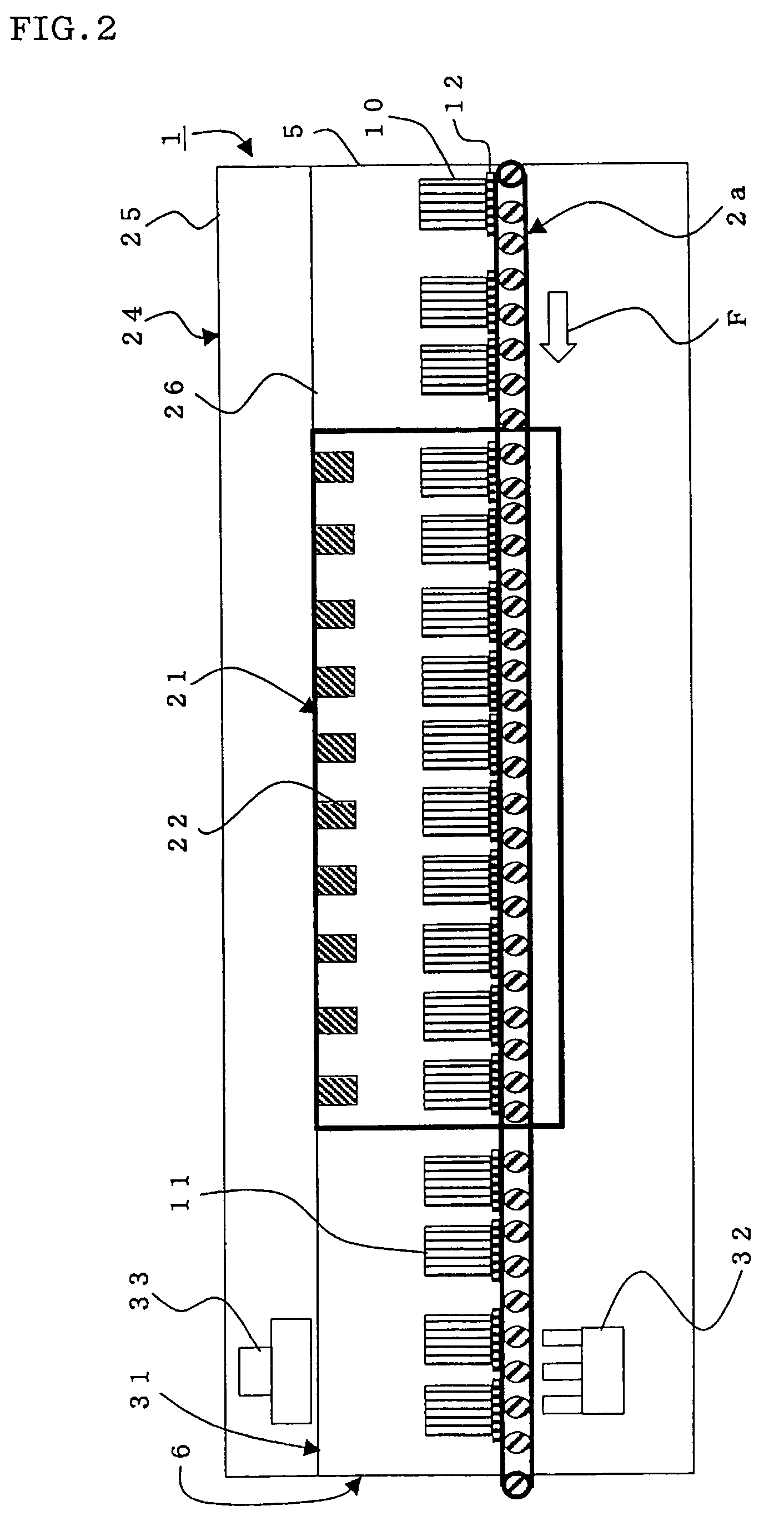

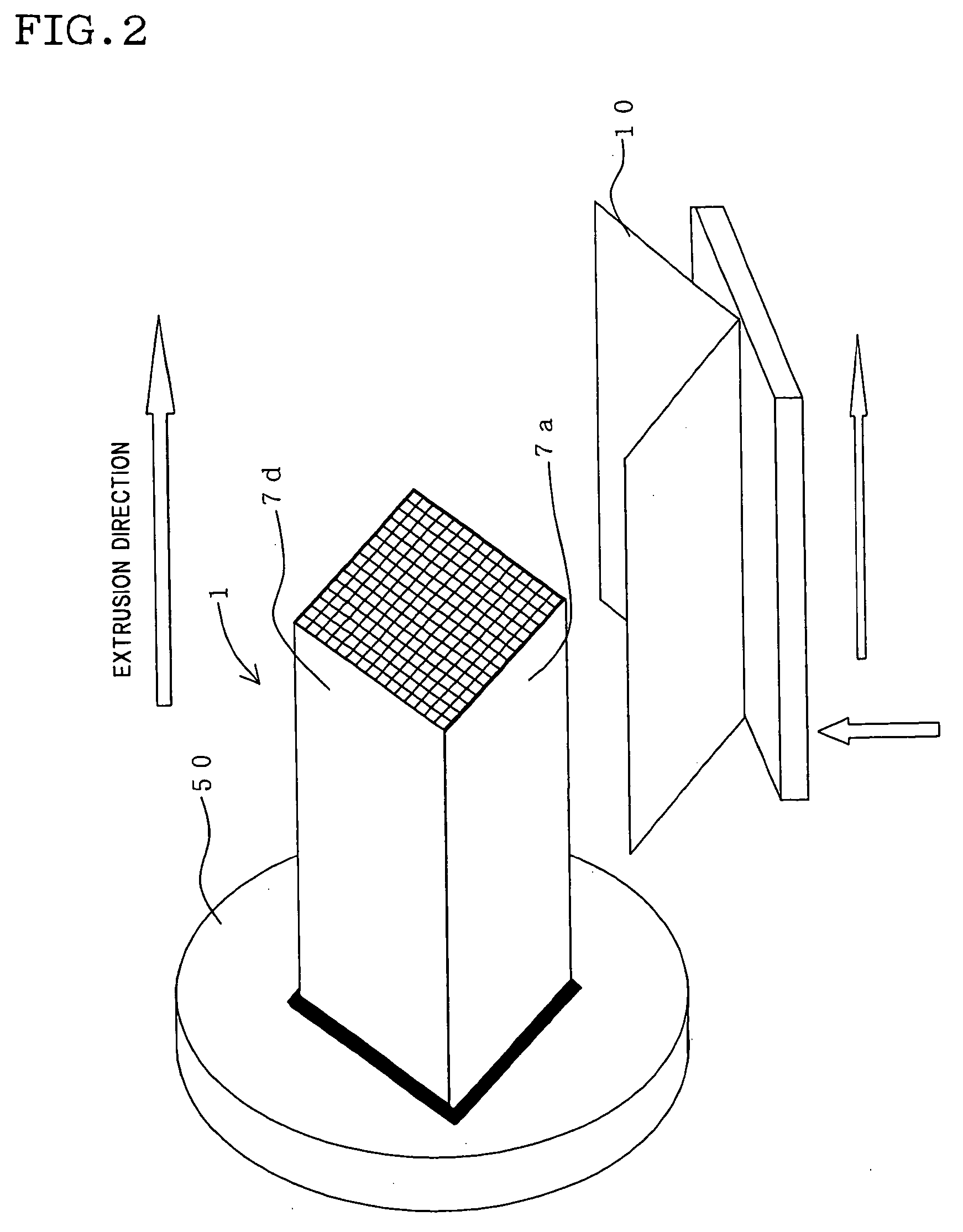

Method for manufacturing honeycomb structure

ActiveUS20050167880A1Reduce distortionReduce cross sectional deformationPhysical/chemical process catalystsDrying solid materials with heatEngineeringMechanical engineering

The present invention provides a method for manufacturing a honeycomb structure, the method including steps of: forming, by extrusion, a formed body 1 having an outer wall, partition walls provided inside the outer wall, and cells each surrounded by the partition walls as well as extending to an axial direction of the body; and drying the formed body 1. The method for manufacturing the honeycomb structure is characterized in that the forming step includes receiving the formed body on a cradle 10 which receives the formed body so that an angle of a face 7a of the outer wall on the cradle 10 relative to the horizontal plane is 15 to 35 degrees, a cradle which has a V-shaped cross section with a cut at an apex of the V shape and which receives the formed body so that the angle relative to the horizontal plane is 15 to 45 degrees, or a cradle which receives one face of the formed body and characterized in that the drying step includes drying the formed body 1 in a state of being received on the cradle 10 having the predetermined angle. The method for manufacturing the honeycomb structure reduces distortion and deformation of the honeycomb structure.

Owner:NGK INSULATORS LTD

Methods for drying ceramic materials

InactiveUS8481900B2Drying solid materials with heatCeramic shaping apparatusMaterials scienceMicrowave applicator

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com