Method for comprehensive treatment of oilfield waste

A technology for comprehensive treatment of oilfield waste, applied in the field of comprehensive treatment of drilling waste, can solve problems such as solidification treatment that does not meet environmental protection requirements, achieve the effects of reducing treatment costs, large treatment capacity, and solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

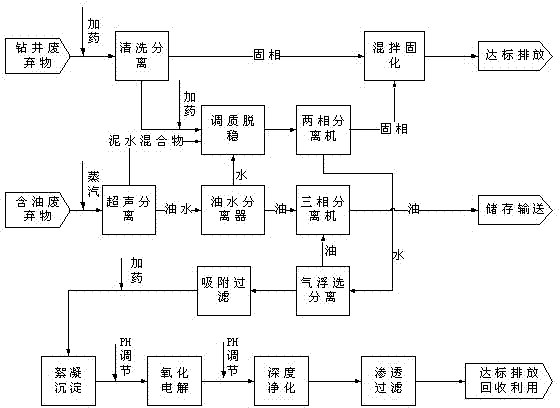

[0024] Example 1, see Figure 1, after recovering the drilling waste from the oilfield waste, it first enters the cleaning and separation system, and after mixing with water in the cleaning and separation system at a volume ratio of 1:3, a separating agent with a volume of 20% of the mixture is added, After circulating and stirring in the tank, the solid phase screened by the vibrating screen is transported to the mixing and curing system by the screw conveyor at the lower part of the vibrating screen, and the solid phase is mixed with bitter soil in a weight ratio of 2:1:1 Powder, lime and ferrous sulfate are mixed, and the solid phase material with a certain strength is output by the lower belt conveyor, which can be used as building material raw materials. The solid phase solidified after mixing and mixing has been tested to meet the national emission standards; screening by vibrating sieve After the liquid phase enters the lower buffer tank, it is pumped to the conditioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com