Shield / TBM hob wear measuring device and measuring method thereof

A technology of measuring device and hob, applied in the direction of measuring device, instrument, etc., can solve the problems of inability to effectively grasp comprehensive information of wear section, high cost of hob online measurement technology, and large force on the tool, so as to achieve strong practicability and improve The effect of construction efficiency and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

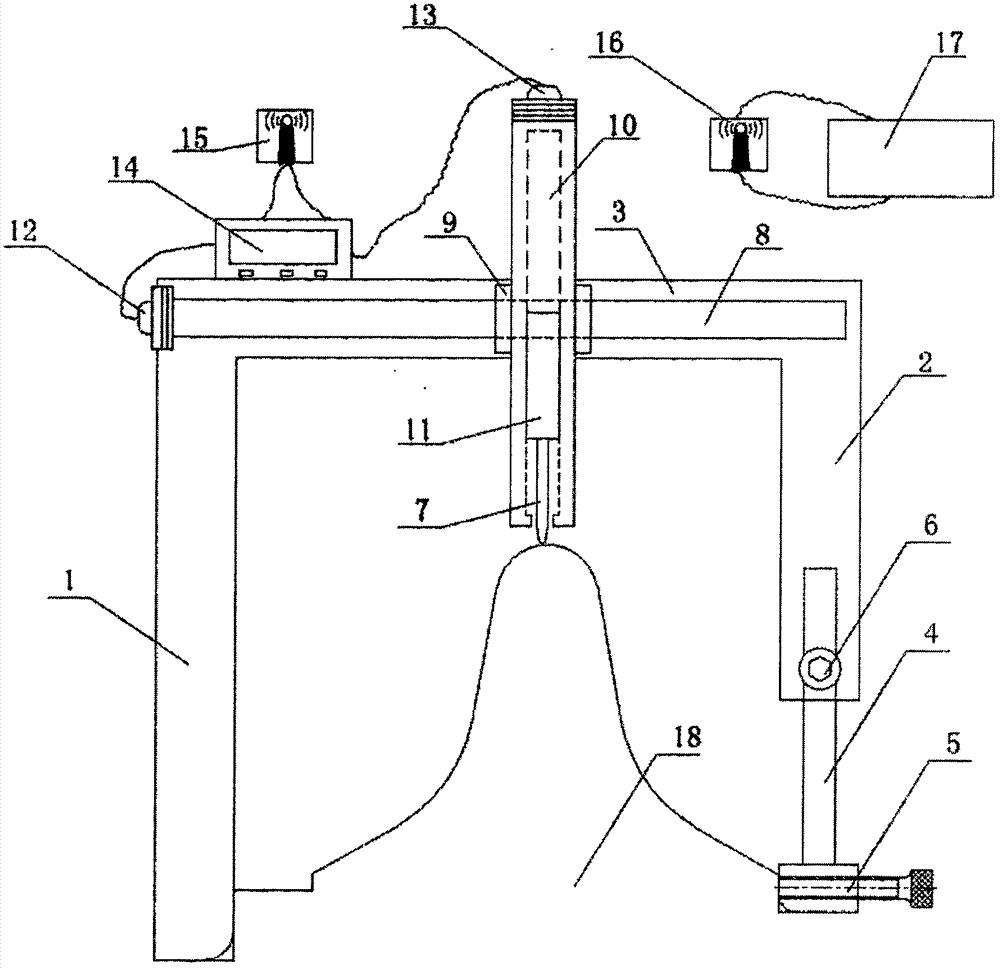

[0031] Embodiment 1: A kind of shield / TBM hob wear measurement device, see figure 1 , including frame body, fastening components and mobile measurement components. The frame body includes a beam 3, a fixed pole 1 and an adjustable pole 2 which are arranged at both ends of the beam 3 and vertically connected with the beam 3, and the distance between the fixed pole 1 and the adjustable pole 2 is greater than that of the shield machine to be tested. / Width of the step face of the TBM hob. In the vertical direction of the adjustable pole 2, a track is provided, and the fastening assembly includes a movable leg 4 and a fastening bolt 5 arranged at the lower end of the movable leg 4, and the upper end of the movable leg 4 is slidably installed in the track. The track is also provided with limit bolts 6 for adjusting and fixing the position of the movable legs.

[0032] The mobile measurement assembly includes a measuring head 7, a horizontal guide rail 8 arranged on the beam 3, a ...

Embodiment 2

[0035] Embodiment 2: a kind of shield machine / TBM hob wear measurement method, uses the measuring device in embodiment 1 to measure, comprises the following steps:

[0036] (1) Reference data for measuring unworn hobs of the same type:

[0037] a. Install the measuring device; first fit the lower end of the fixed support rod 1 to the step surface of the hob, then adjust the height of the movable outrigger 4 to a suitable position, and use the limit bolt 6 to connect the movable outrigger 4 to the adjustable The poles 2 are fixed together, and then the fastening bolts 5 are tightened so that the hob 18 is clamped between the fixed pole 1 and the movable leg 4;

[0038] b. Measurement reference data: adjust the position of the horizontal slider in the horizontal guide rail and the position of the vertical slider in the vertical guide rail respectively, so that the measuring head moves on the contour surface of the hob, and obtain the contour surface of the hob through the displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com