Measurement device for friction force and wearing process of lubrication film on the condition of different slide-roll ratios

A technology for measuring devices and lubricating films, applied in measuring devices, force/torque/work measuring instruments, testing wear resistance, etc. Simultaneous measurement of friction, film thickness and wear, etc., to achieve controllable exposure time, no acquisition loss, and low distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

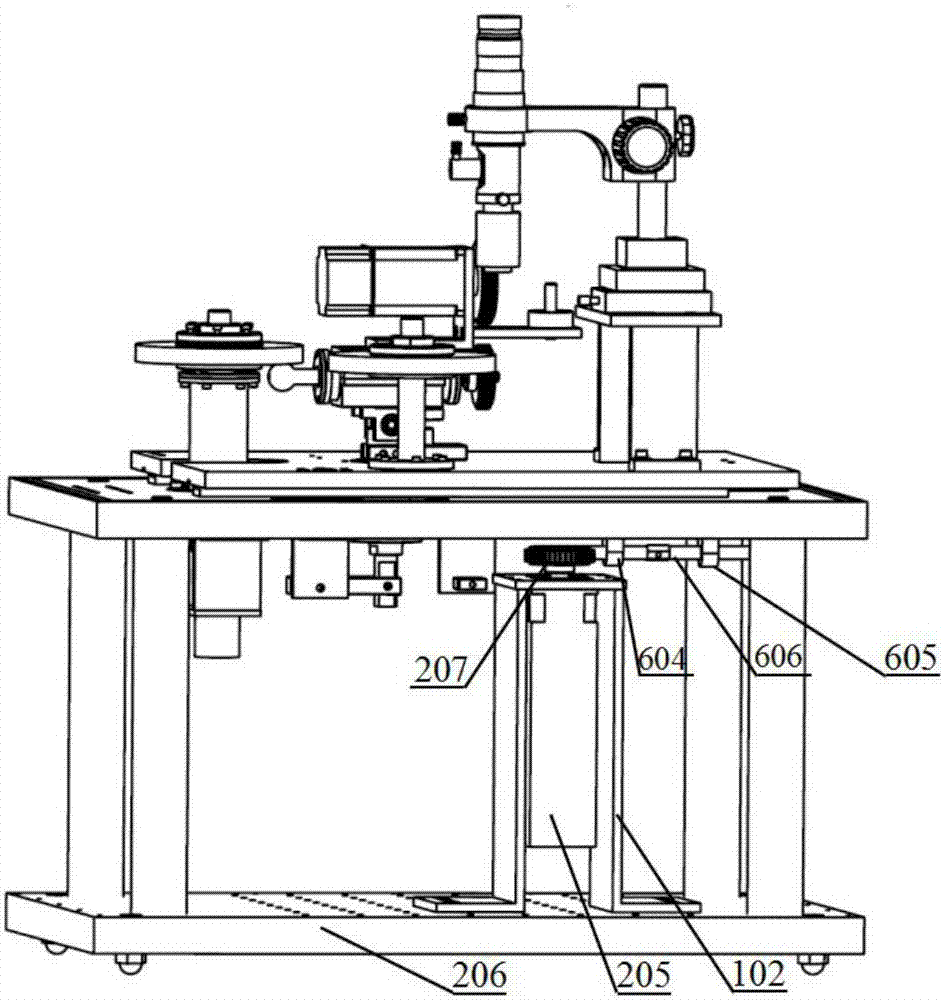

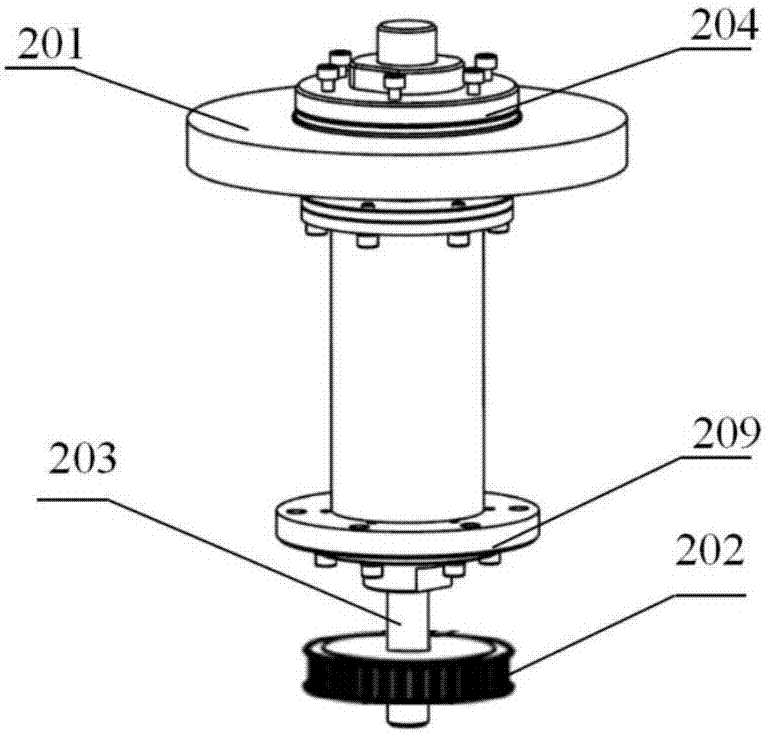

[0044] The main structure of the measuring device for measuring the friction force and wear process of the lubricating film under different slip-to-roll ratios in this embodiment includes: a support platform 1, a disc drive device 2, a ball-drive loading revolving device 3, a revolving device 4, and abrasion measurement Device 5, translation device 6, speed measuring device 7 and sensor fixing device 8.

[0045] The main structure of the supporting platform 1 includes an upper platform 101, a lower platform 102, a supporting column 103, a supporting leg 104, and a through hole 105. The upper platform 101 and the lower platform 102 are both square-structured metal structures, and the upper platform 101 and The length and width of the lower platform 102 are equal. The upper platform 101 and the lower platform 102 are connected by cylindrical metal support columns 103 at the four corners. The lower side of the lower platform 1 is fixed with support feet 104 for supporting the base. ...

Embodiment 2

[0056] In this embodiment, when measuring the friction and wear of the lubricating oil film with high-stress contact and variable slip ratio, the specific operation steps are as follows:

[0057] (1) Loading of the steel ball: adjust the upper spring support 311 and the cylindrical spring 409 to zero the contact load of the steel ball 301 and the round steel plate 201, and then place the weight 312 on the loading plate 308 to the load required for the experiment;

[0058] (2) Start-up of the equipment: start the fixed disk drive motor 206 and the servo motor 305 to drive the round steel plate 201 and the steel ball 301 to rotate respectively;

[0059] (4) Obtaining, measuring and storing frictional force: under the action of the friction force of the contact pair, the steel ball 301 will have a tendency to rotate, which will drive the ball drive loading device 3 to rotate, and the ball drive loading device 3 will further pass the rotation trend back The rotating shaft 405 is transfer...

Embodiment 3

[0069] In this example, the friction coefficient of the lubricating film and the wear process measurement device under different sliding-roll ratios described in Example 1 is used to measure the friction coefficient under the sliding-roll ratio in the range of 0-2. The test conditions are as follows, using PAO6 lubricant Measured under the working condition of 32N load and 128mm / s entrainment speed, the test results are as follows Picture 10 As shown, the friction coefficient increases significantly with the increase of the slip-to-roll ratio. When the slip-to-roll ratio reaches 0.2, the wear measuring device 5 is used to observe the shape of the steel ball. The test results are as follows Picture 11 with Picture 12 As shown, Picture 11 with Picture 12 These are the optical interference images before and after the oil film friction force measurement experiment. The surface morphology and waviness of the steel ball can be clearly seen before wear. After the wear, it can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com