Spark identification tool-setting method and abrasive machining automatic system

An automation system and grinding technology, applied in metal processing equipment, parts of grinding machine tools, grinding/polishing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

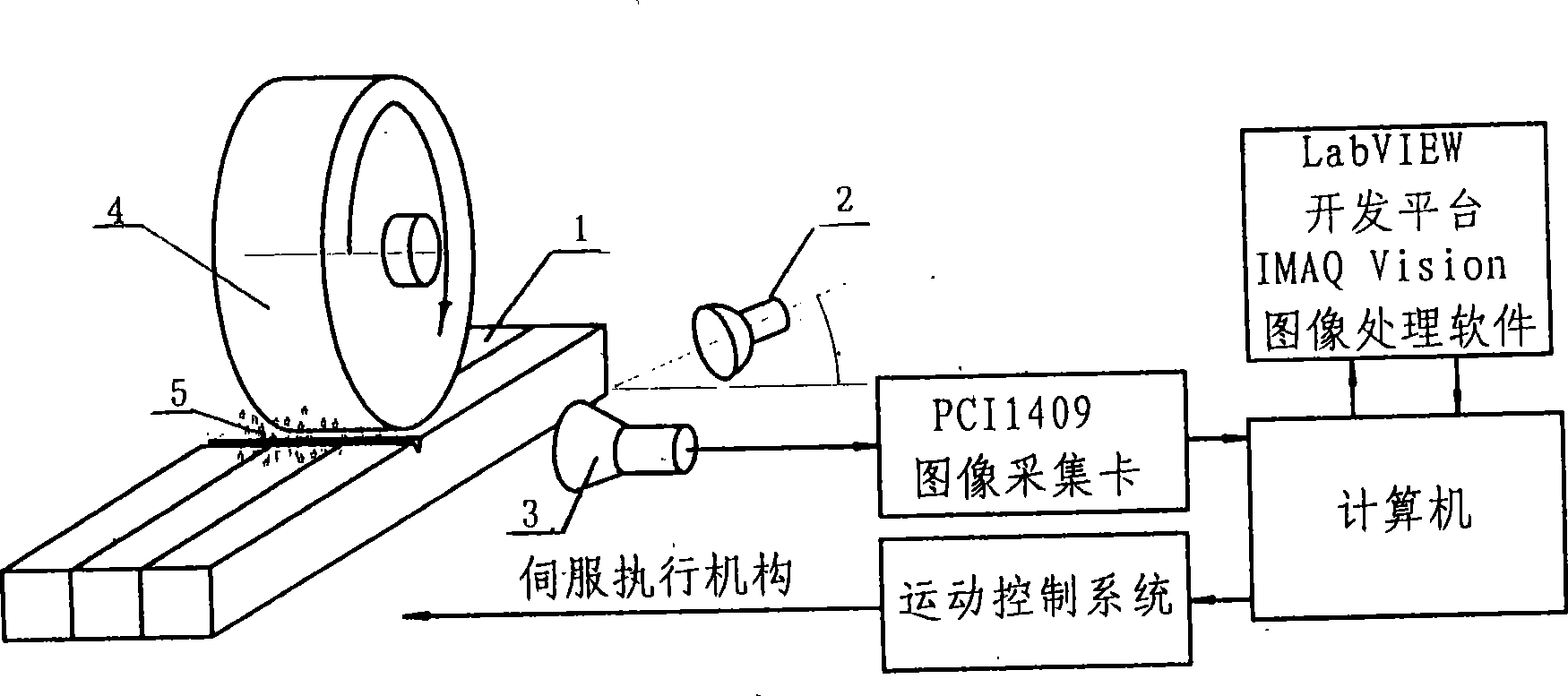

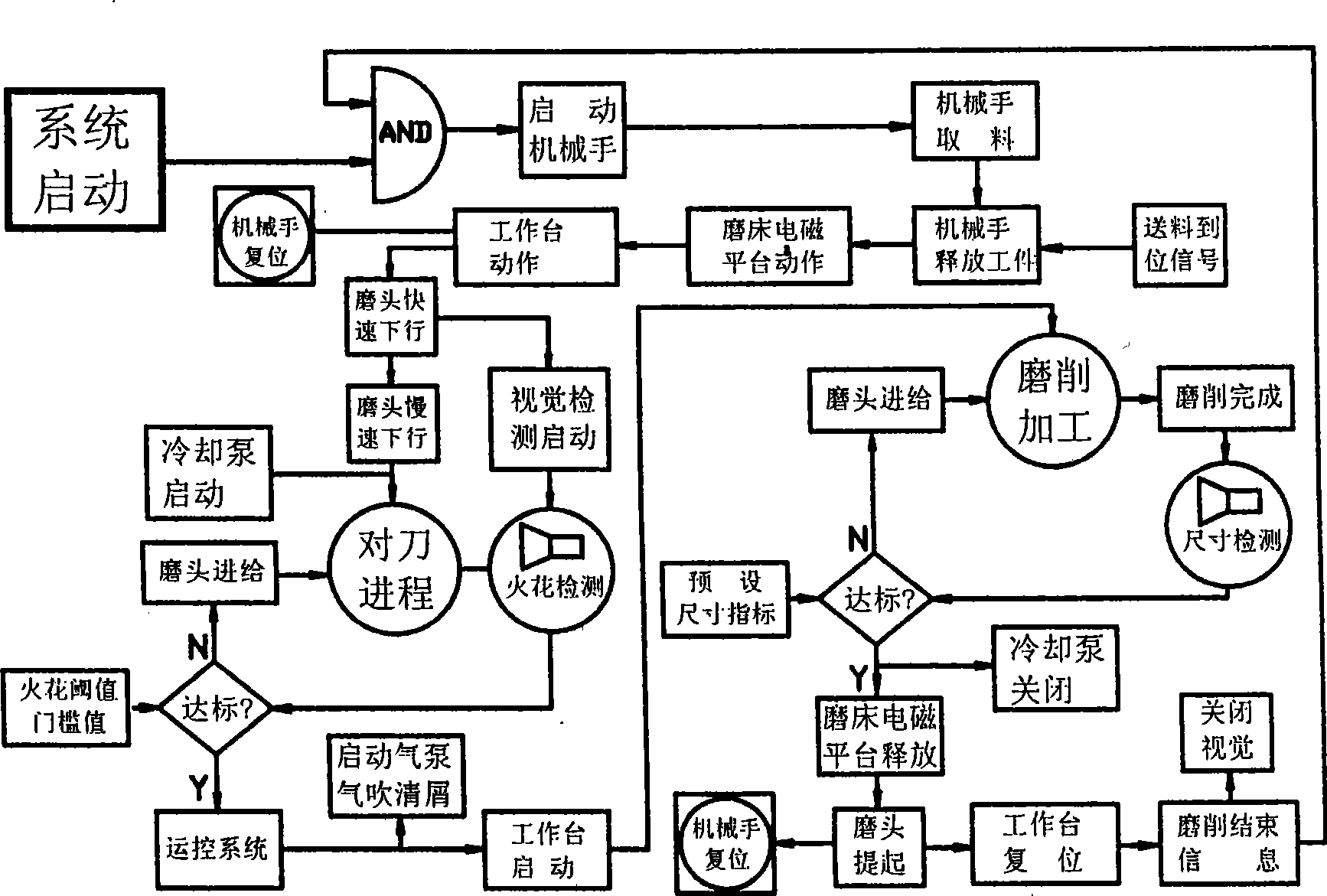

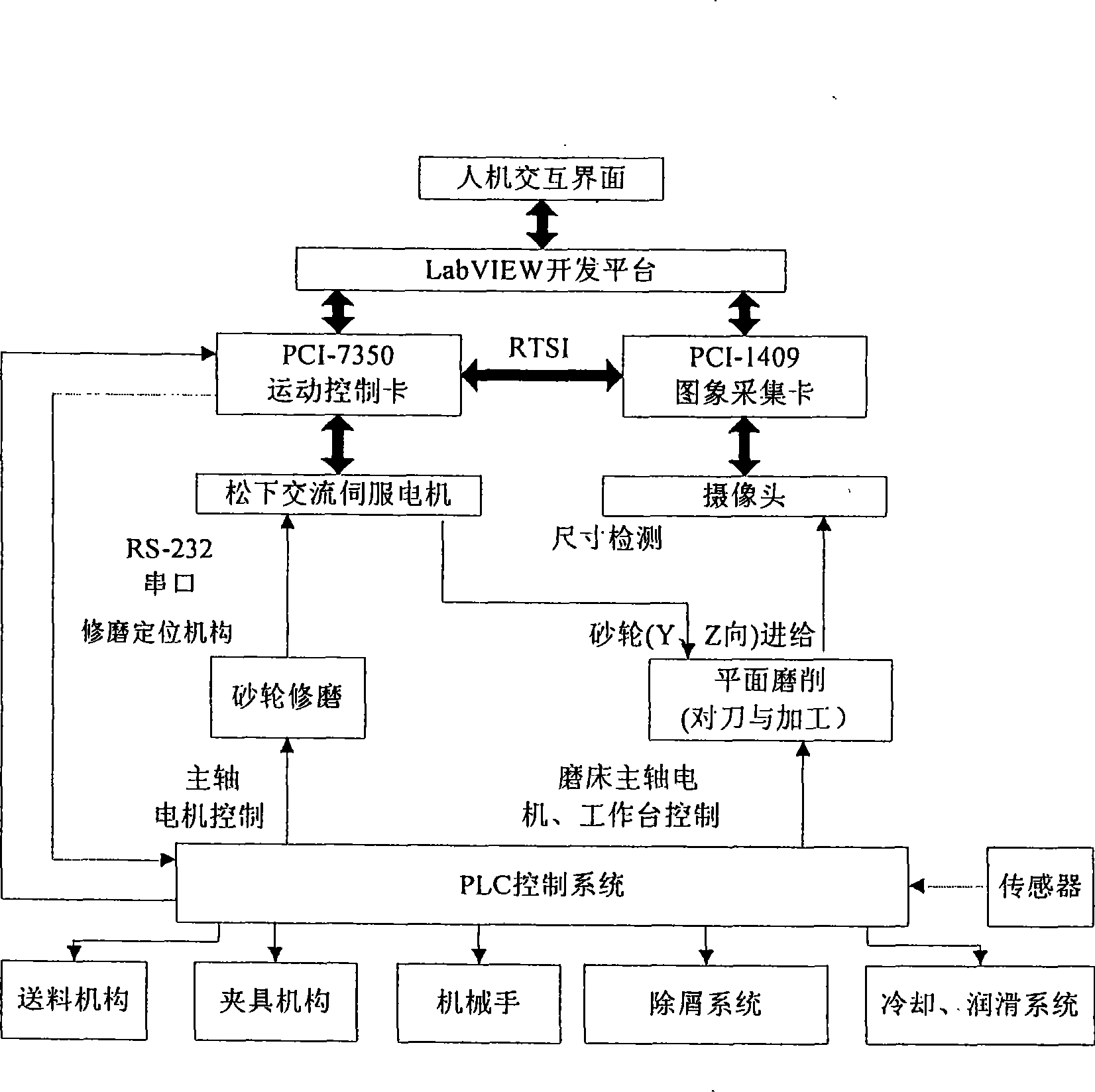

[0018] The overall structure of the visual tool setting and grinding control system is shown in Figure 1. During tool setting, the motion control system drives the grinding wheel to approach the grinding surface with an appropriate motion program, and the visual spark monitoring system starts at the right time. When the grinding wheel contacts the processing surface and generates tiny sparks, the sensitive visual system will immediately detect this information , send a command to the motion control system to stop feeding, and end the tool setting process. Since the information for judging the tool setting situation is the friction spark, the whole tool setting process has nothing to do with the actual size of the grinding wheel and the feeding stroke, thus completely avoiding the problem of grinding wheel wear compensation. At the end of the tool setting, the base point (zero point) of the grinding motion control is determined, and the motion control system immediately enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com