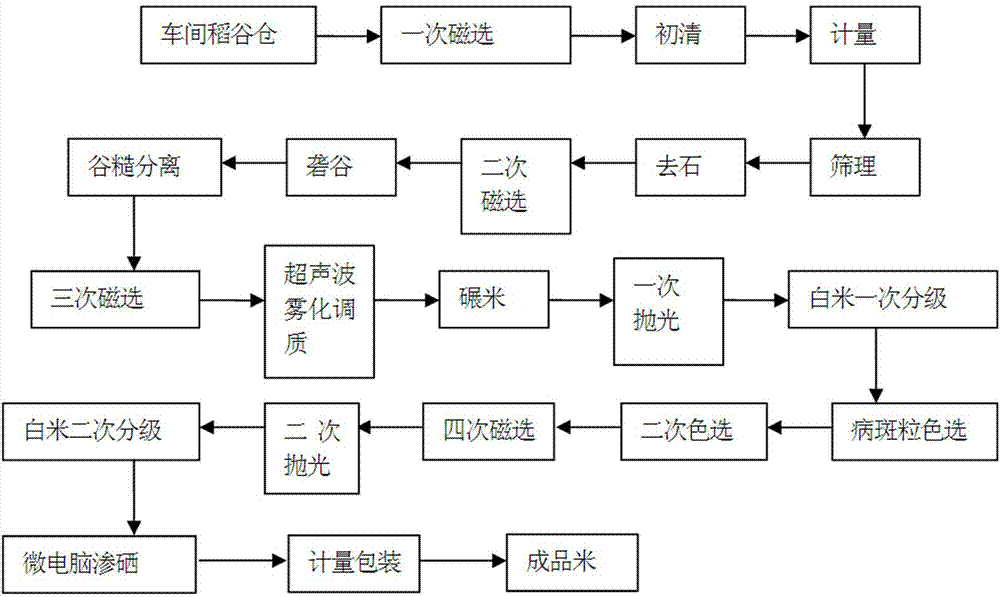

High-quality rice fine processing process

A rice and craft technology, applied in grain processing, grain milling, application, etc., can solve the problems of low processing whole rice rate, unutilized, short shelf life, etc., to reduce free fatty acid content, improve color sorting efficiency and purity , The effect of reducing the value of free fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Such as figure 1 As shown, the rice finishing process of the present invention is to store the harvested rice raw materials in the rice barn of the processing workshop in time, and first use a magnetic separation device to perform a magnetic separation to remove metal foreign matter mixed in the harvesting process, and then perform initial cleaning to remove the rice. The sundries and dust in the grain are sieved by a sieving machine after being weighed, and the sand and gravel mixed in the grains with a relatively heavy specific gravity are sieved out, and then destoned, that is, the sifted sand and gravel are removed, and then After the second magnetic separation, the metal foreign matter still mixed in the grain is removed, and then the rice huller is used to hustle the rice, and the chaff is removed from the rice to make brown rice. , to further remove the metal foreign matter contained in the rice grains, and then use an ultrasonic atomization device to humidify an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com