Production method for an electroformed stencil with mark points

A production method and positioning point technology, which is applied in the direction of manufacturing tools, printing, printing plate preparation, etc., can solve the problems of insufficient board surface quality, steel mold opening accuracy and quality that cannot meet the requirements well, and achieve improved accuracy, Read the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

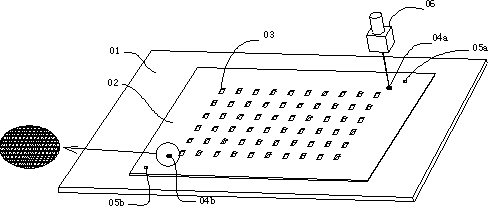

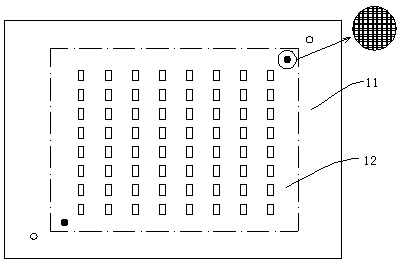

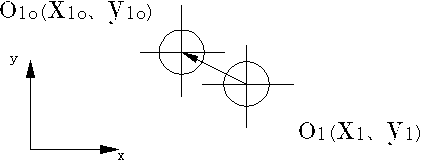

[0063] In order to better confront PCB, and to better transfer the accurate amount of materials to accurate positions, use the power casting process to make electric casting mesh. This process step includes:

[0064] (1) Core mold before processing: remove oil, pickle, and sand spraying core molds to remove the oil stain impurities on the surface, and polish the surface smoothly;

[0065] (2) Film: the film on the surface of the core;

[0066] (3) Exposure: expose the graphic opening area so that the unrepilling area can be removed through the development, leaving the exposure part as the protective film of the subsequent power casting steps;

[0067] (4) Single -sided development: The unprecedented part of the steps in the steps (3) leave the exposure part for the protective film of the subsequent power casting steps;

[0068] (5) Classes: The method of casting the power cast material is used to cast the electrical casting material to the unre exposed area;

[0069] (6) Fading me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com