Hydraulic forming press system and press method thereof

A technology of hydroforming and hydraulic pressure, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as small thickness and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

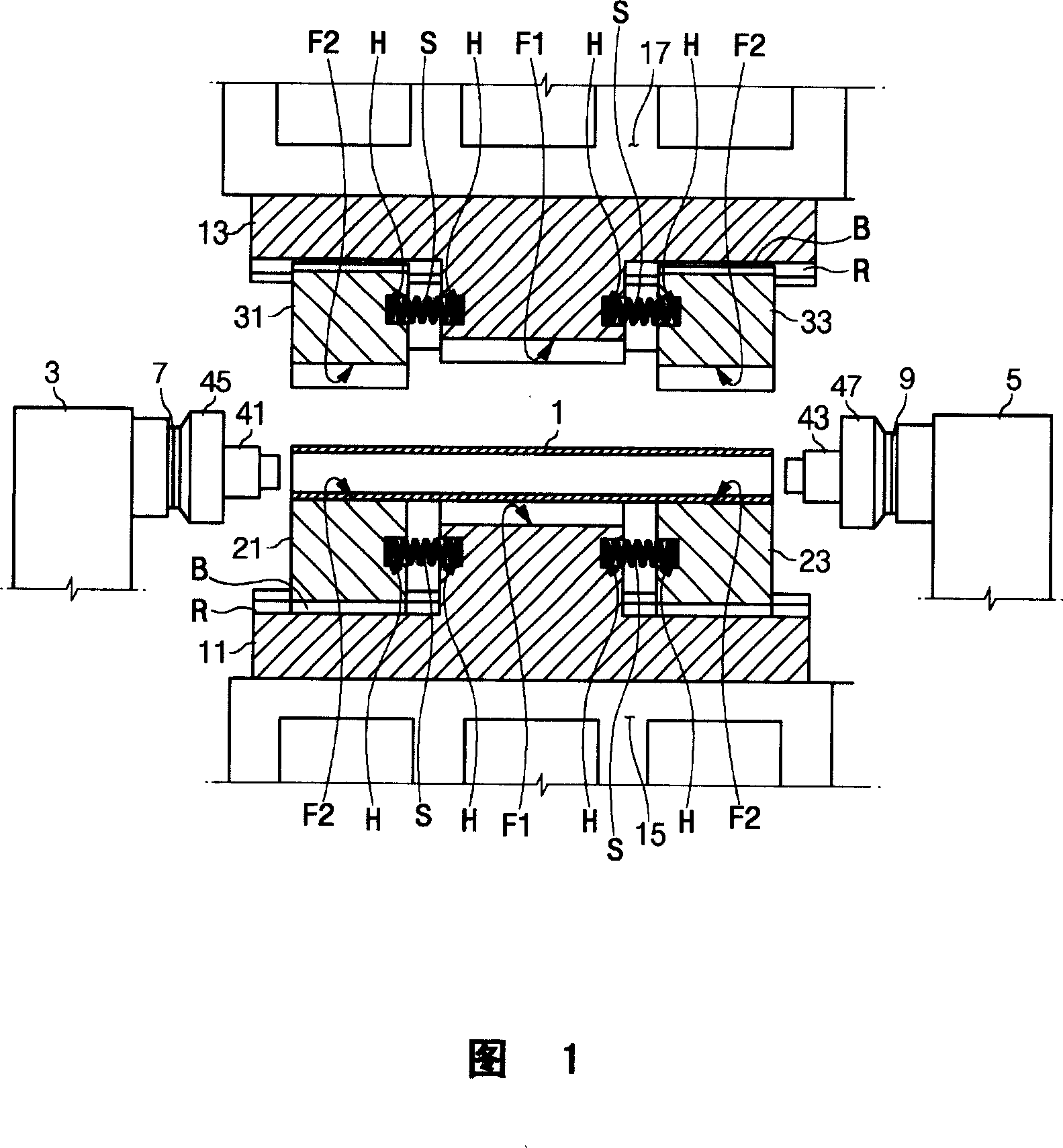

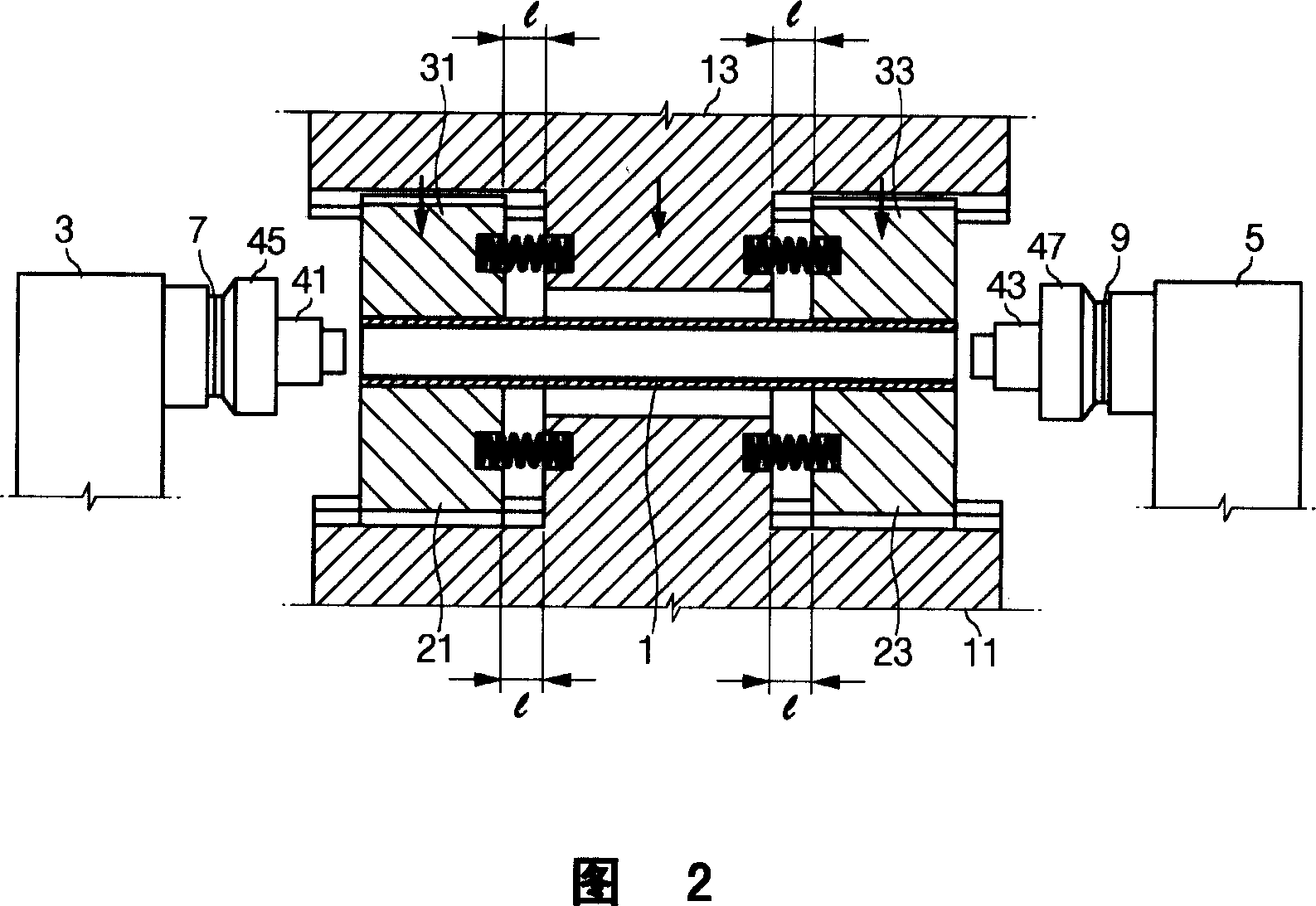

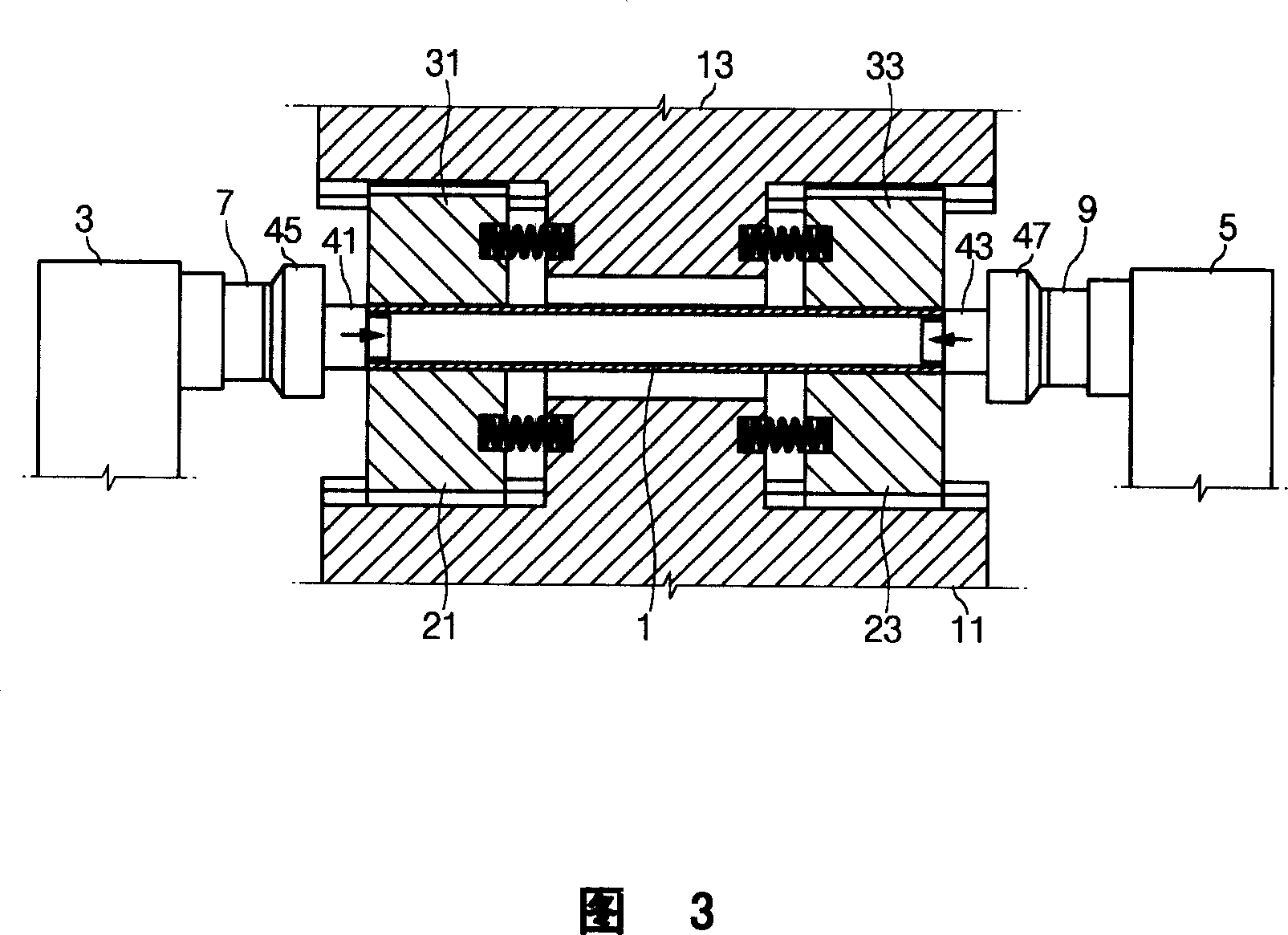

[0048] FIG. 1 is a cross-sectional view of a hydroforming pressing system according to an exemplary embodiment of the present invention. The hydroforming pressing system according to the exemplary embodiment of the present invention expands the pipe 1 by providing hydraulic pressure from both ends of the pipe. Hydraulic pressure is supplied by hydraulic pressure suppliers 3 and 5 placed at each end of the pipe 1 . As shown in FIG. 5, the tube 1 has a minimum curvature radius portion P2 at a maximum expansion portion P1.

[0049] A hydroforming pressing system according to an exemplary embodiment of the present invention includes a fixed lower mold 11, a fixed upper mold 13, movable lower molds 21 and 23 opposite to each other, movable upper molds 31 and 33 opposite to each other, an effective feeder 41 and 43 and movable blocks 45 and 47.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com