Method for improving cleanliness of low-carbon molten aluminum-killed steel

A low-carbon aluminum-killed steel, cleanliness technology, applied in the field of killed steel, can solve the problems of poor castability and nozzle blockage in continuous casting, achieve good castability of molten steel, low production cost, and promote the effect of floating inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

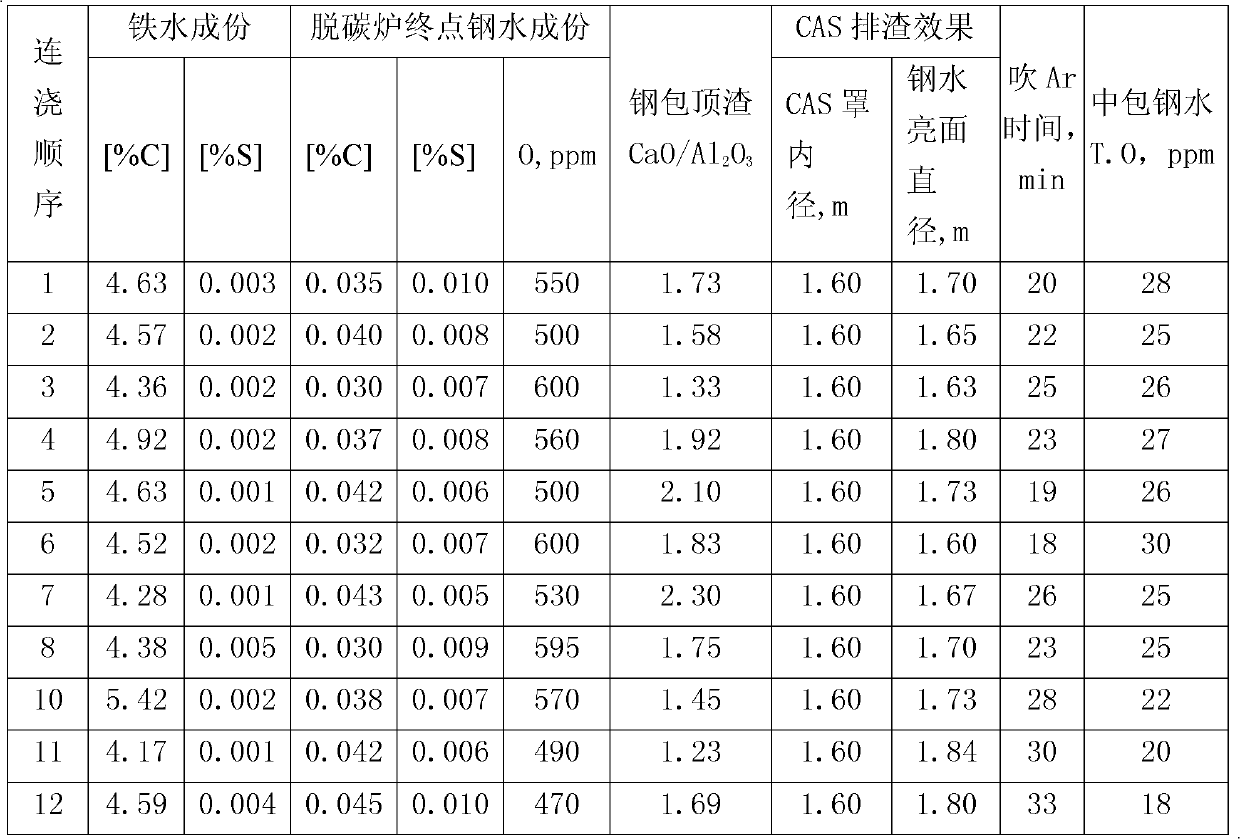

[0026] According to a method for improving the cleanliness of low-carbon aluminum-killed steel molten steel provided by the present invention, the sulfur content in molten iron is reduced to less than 50 ppm by using KR molten iron desulfurization, and the composition of molten iron after desulfurization is shown in Table 1. Low-carbon aluminum-killed steel is smelted in the two-step steelmaking process of "less slag decarburization steelmaking". Al iron is deoxidized, and lime is added to the steel ladle during the tapping process to modify the top slag of the ladle. The bottom blowing at the concentric position of the CAS cover is used for slag discharge. When the diameter of the discharged slag hole exceeds the inner diameter of the CAS cover, the cover is lowered, and then the flow rate of the bottom blowing is reduced, and the CAS bottom blowing Ar and alloy, temperature adjustment, CAS cover inner diameter, slag discharge The diameter of the bright surface of the molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com