High-silicon stainless

a technology of stainless steel and high-silicon, which is applied in the field of high-silicon stainless steel, can solve the problems of insufficient corrosion resistance, difficult subsequent finishing work, and few materials can meet all of these requirements, and achieve the effects of high si content, corrosion resistance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

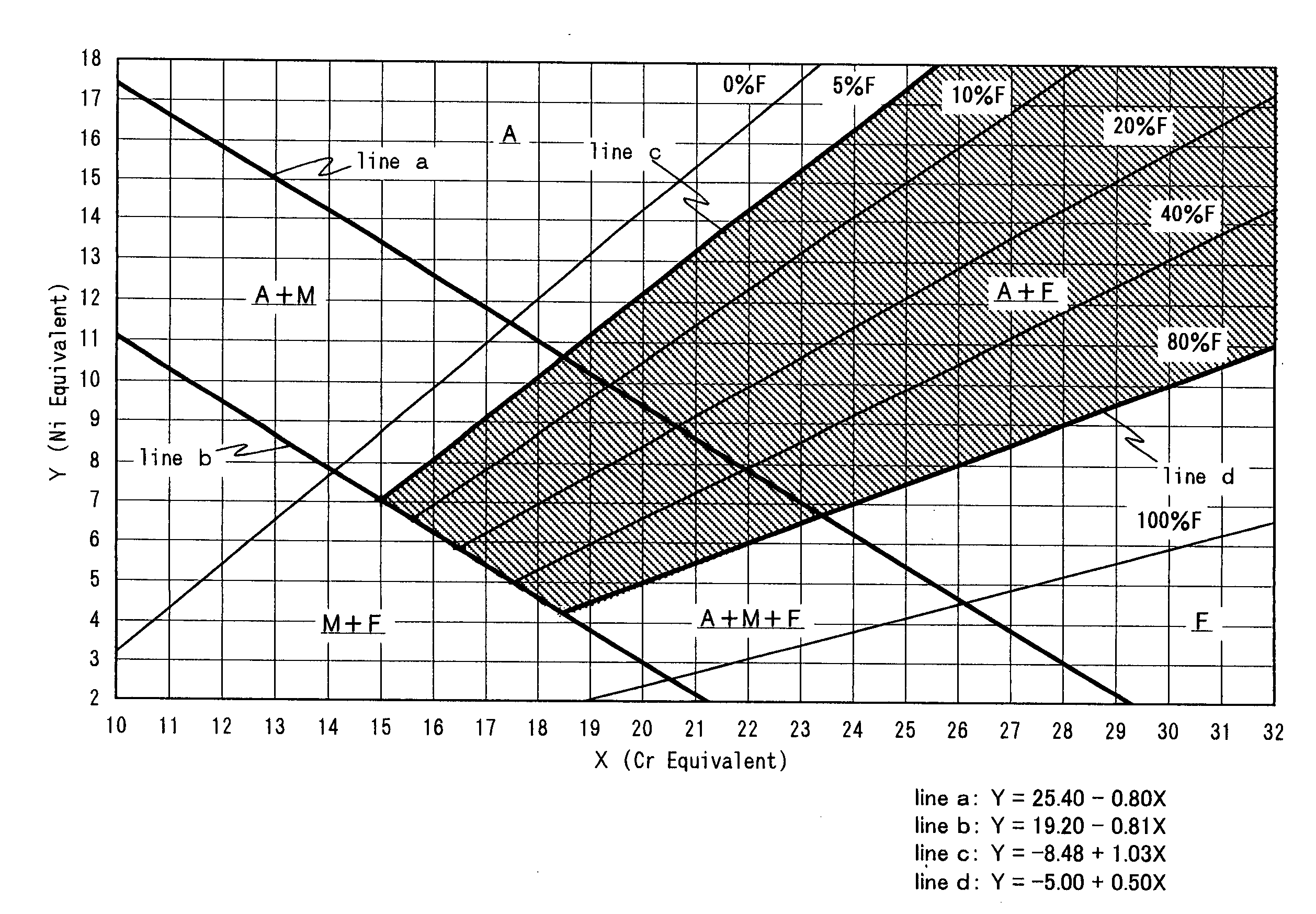

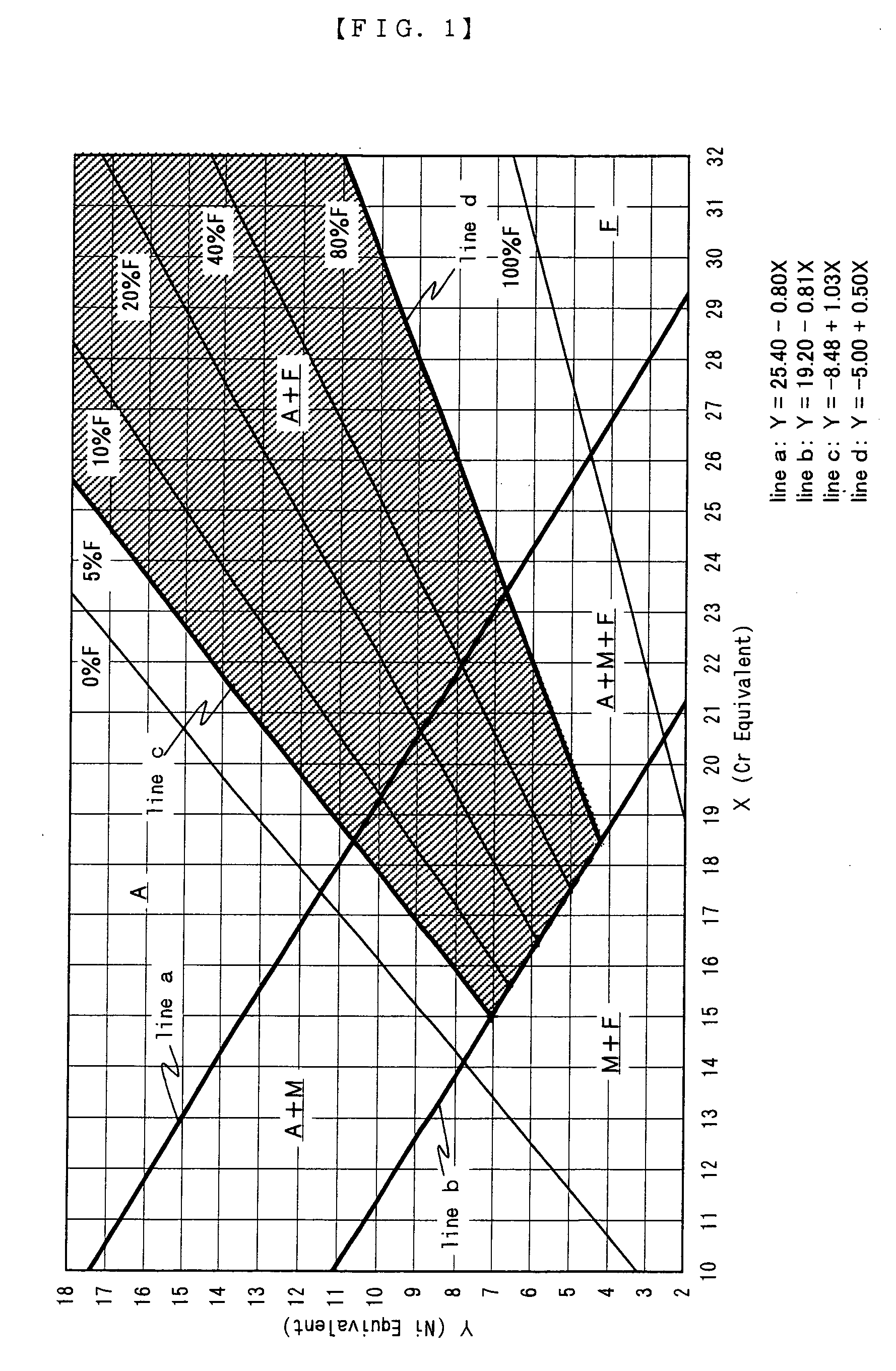

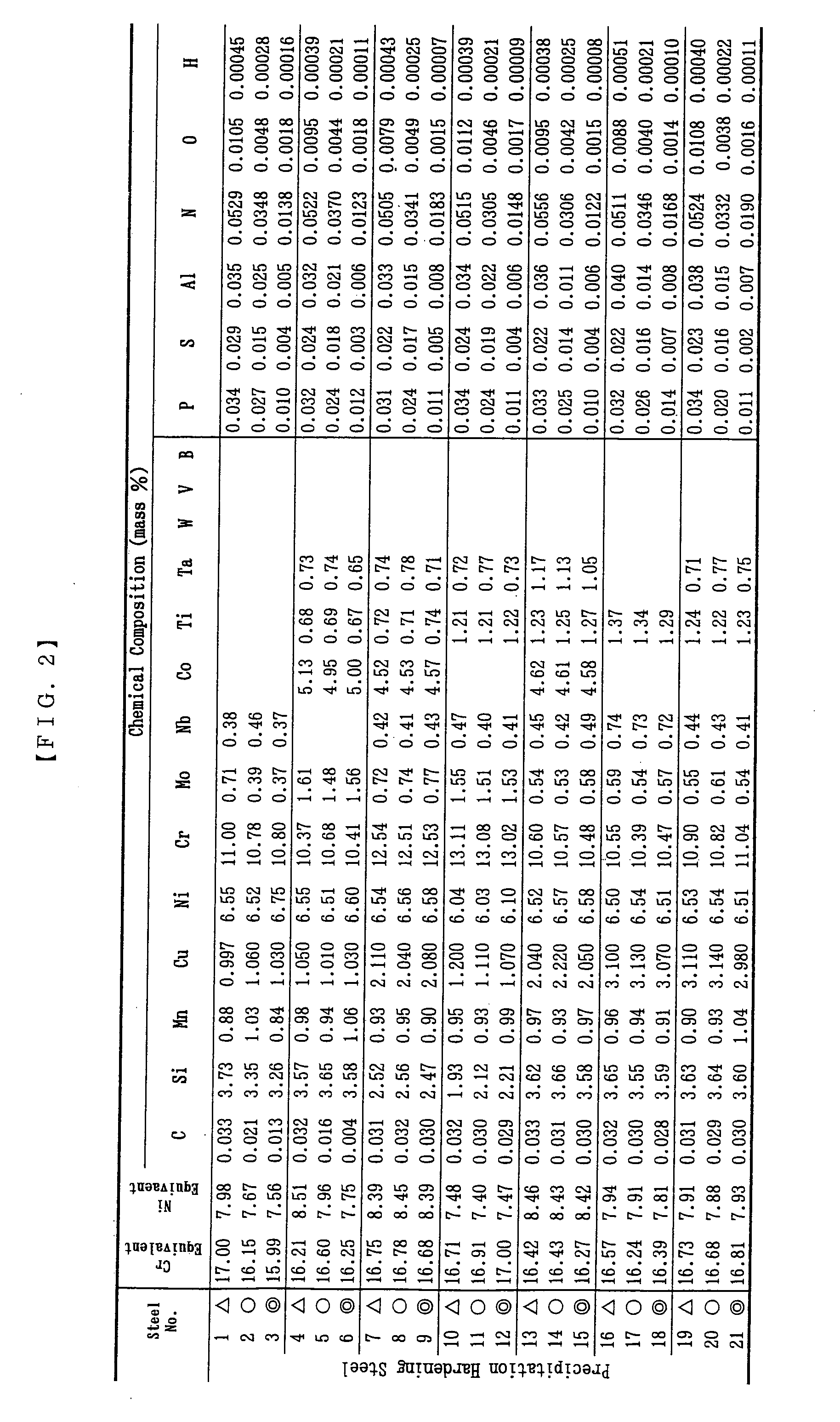

[0139] 1. Materials Used

[0140] Thirty-six steels specified in FIG. 2 and FIG. 3 were used as test materials. These steels could be divided into groups of three (e.g. steels Nos. 1 to 3, steels Nos. 4 to 6, . . . ) and the three in each group were of the same steel group. In the three steels, one marked with .DELTA. is a comparative steel having relatively high impurity levels, one marked with .largecircle. is a steel according to the invention having a high cleanliness index with suppressed impurity levels, and one marked with .circleincircle. is a steel according to the invention having an ultrahigh cleanliness index with still further decreased impurity levels. Steels Nos. 34, 35 and 36 are the conventional steels (commercial ones), corresponding to JIS SUS 304, SUS 630 and SUS 420 J2, respectively.

[0141] Each of the above test materials was hot-forged into a round bar with a diameter of 20 mm and this round bar was subjected to solution heat treatment 1 under the conditions shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com