500MPa-grade cold rolling dual-phase steel and production method thereof

A production method and technology for dual-phase steel, applied in the field of metallurgical sheet production, can solve the problems of decreased austenite stability, increased production control difficulty, decreased smelting pourability, etc. good effect of stability and production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

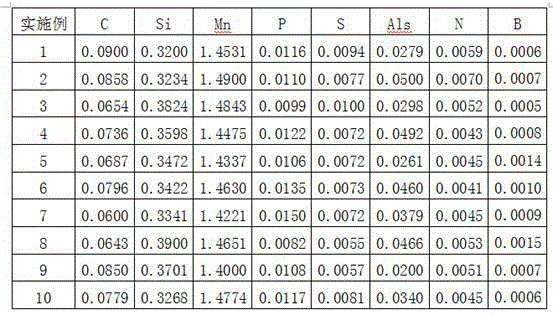

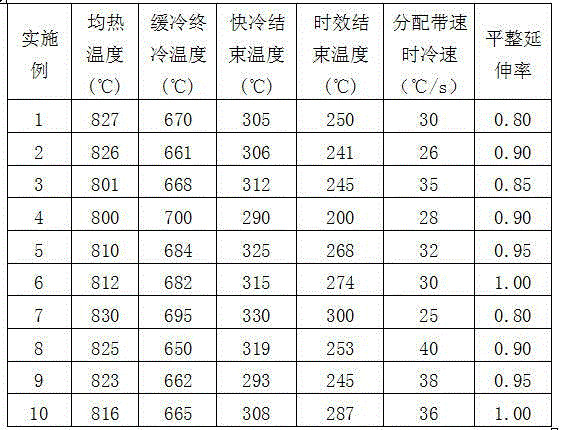

[0012] Embodiments 1-10: The final chemical composition of the 500 MPa grade cold-rolled dual-phase steel and the process conditions of the production method are as follows.

[0013] (1) This cold-rolled dual-phase steel is prepared by converter smelting, LF refining, continuous casting, hot rolling and cold rolling and continuous annealing processes. The chemical composition of the castings after the continuous casting process is shown in Table 1.

[0014] Table 1: Casting Chemical Composition (wt%)

[0015]

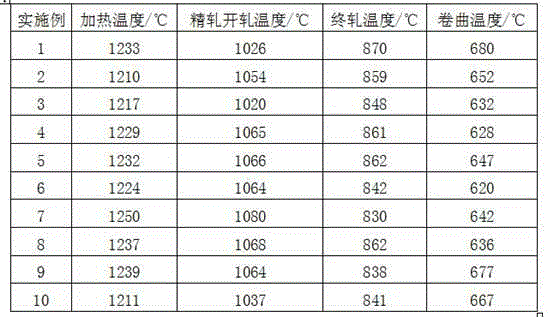

[0016] (2) Hot rolling process:

[0017] The hot rolling process requires low-temperature heating, high-temperature final rolling, and high-temperature coiling, which is beneficial to prevent AlN particles from remelting, obtain coarse AlN particles, and enhance the precipitation strengthening effect of AlN. During the hot rolling process, the coiling temperature matches the finished product specifications; the rough rolling insulation cover is normally put into use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com