Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Eliminate brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ocular lens material

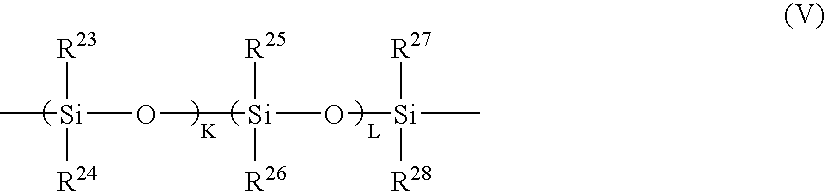

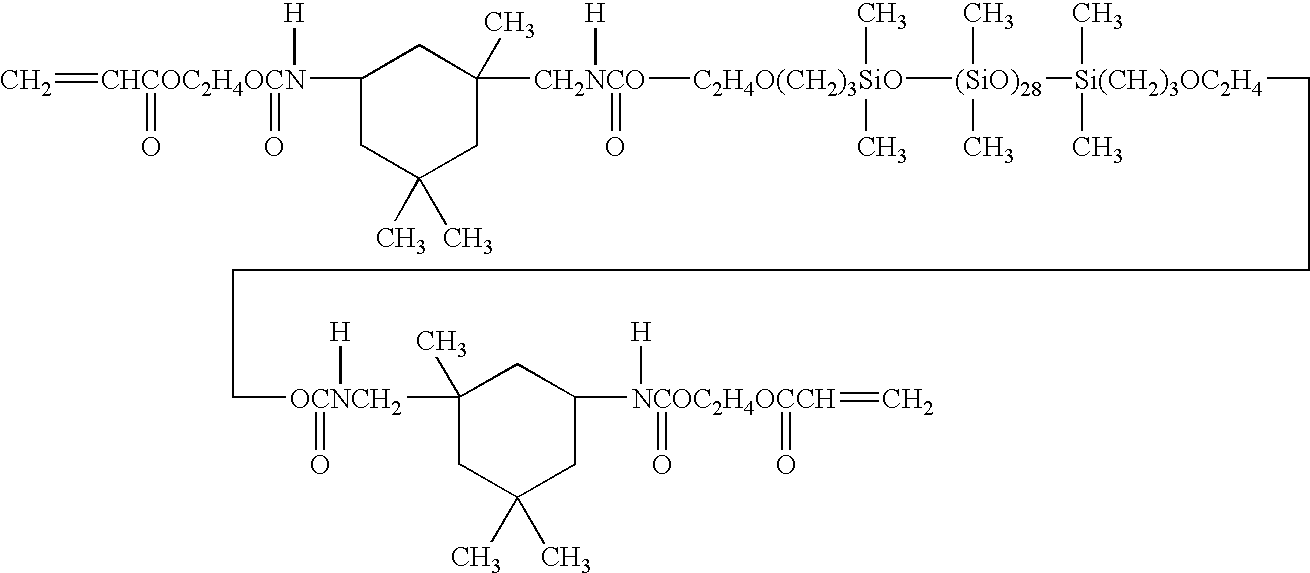

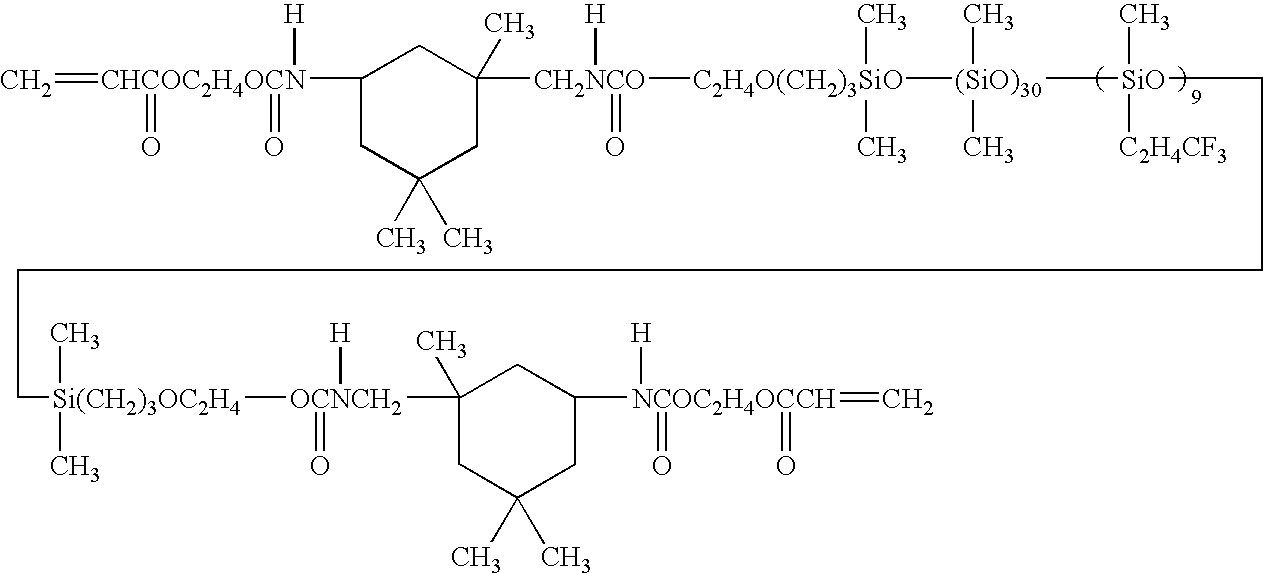

InactiveUS20040039077A1High oxygen permeabilityHigh mechanical strengthTissue regenerationProsthesisHydrophilic monomerPolymer science

An ocular lens material comprising a copolymer prepared by polymerization with heating of a monomer mixture and / or with irradiating a monomer mixture with ultraviolet ray by means of a molding method, the monomer mixture containing a polysiloxane macromonomer A, a Si-containing alkyl methacrylate B, a hydrophilic monomer C comprising NVP as C-1 and another hydrophilic monomer C-2, another monomer D and a crosslinkable monomer E comprising a crosslinkable monomer E-1 containing at least one group selected from acryloyl group, vinyl group and allyl group, and methacryloyl group, and a crosslinkable monomer E-2 containing at least two methacryloyl groups as main components, wherein (A+B) / C (weight ratio) is 30 / 70 to 70 / 30, A / B is 25 / 75 to 75 / 25, C-1 / C-2 is 50 / 50 to 100 / 0, the amount of D is 0 to 20% by weight in the monomer mixture, which has high oxygen permeability, high mechanical strength, excellent surface wettability and low surface frictional property.

Owner:MENICON CO LTD

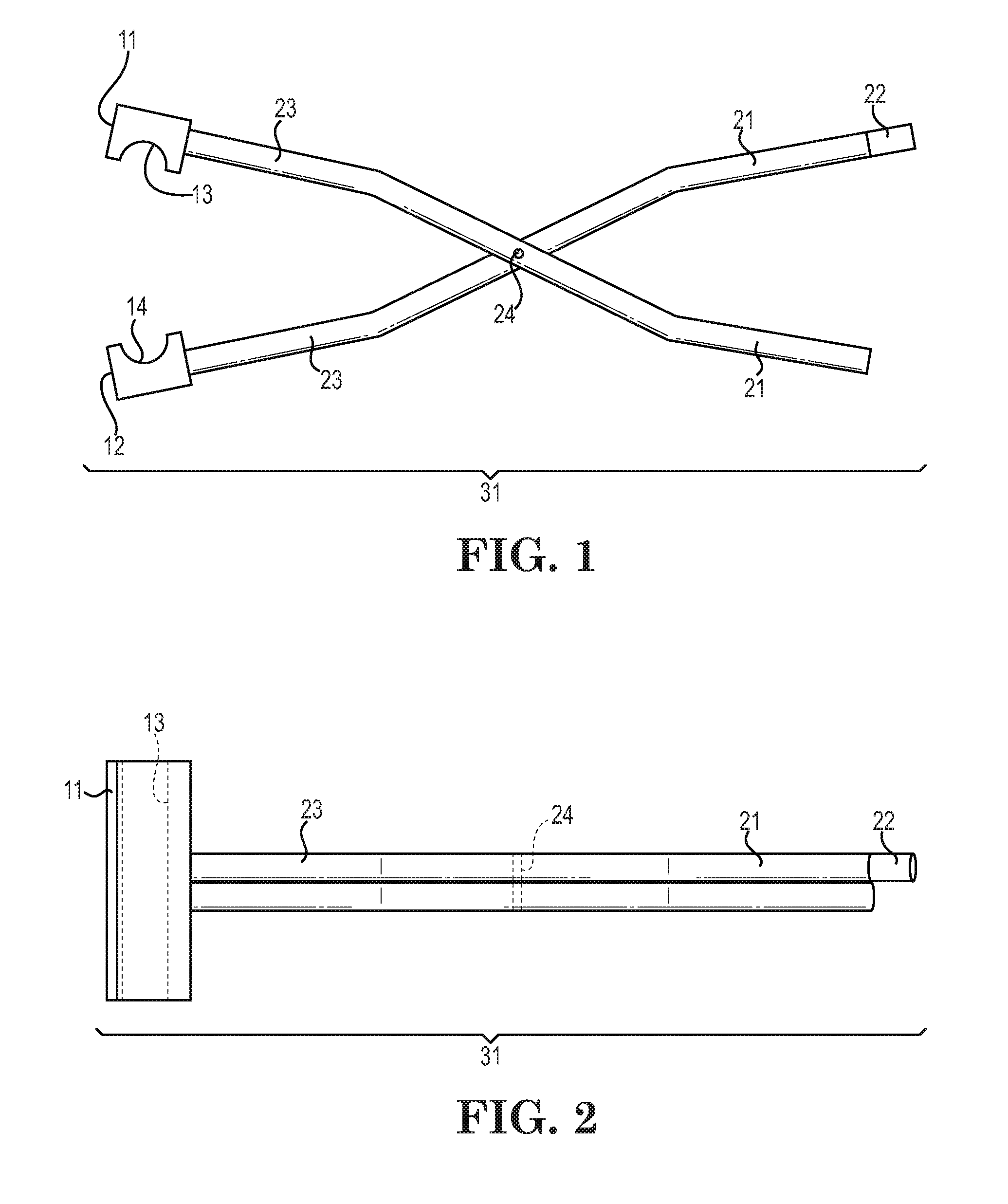

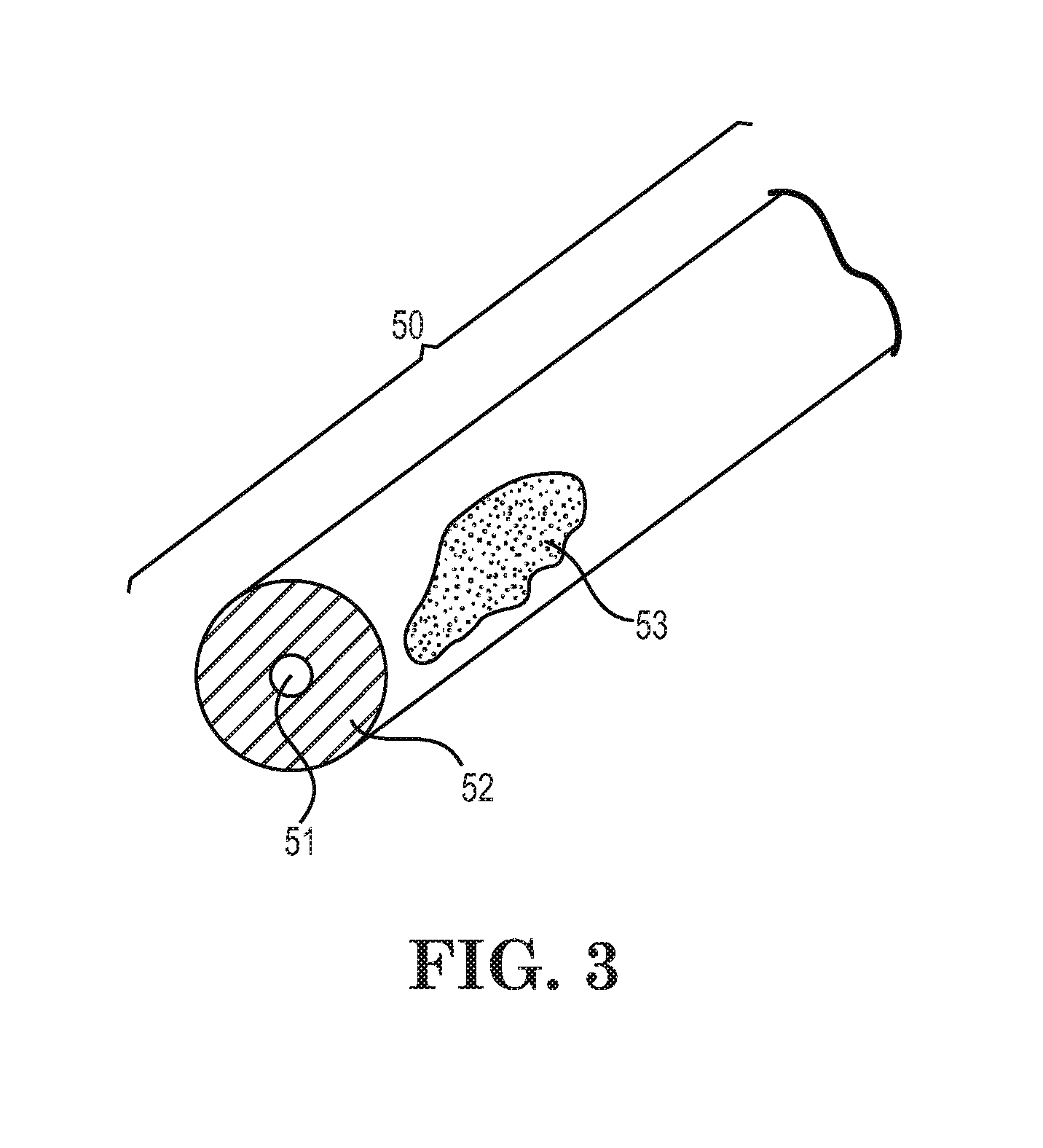

Composite material and method of making the composite material

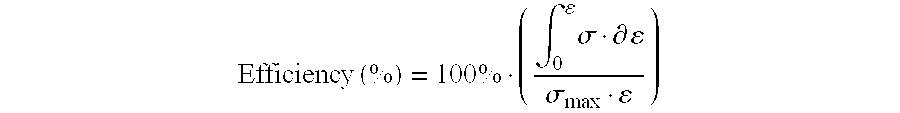

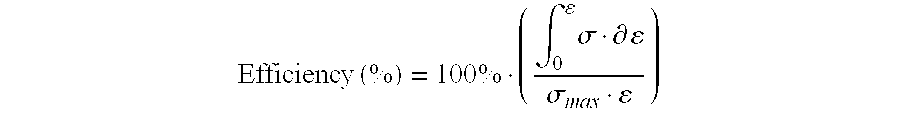

ActiveUS20080299379A1Improve compression efficiencyMore dissipationAntipyreticLayered productsCompressive strengthPolymer

An improved energy absorbing member comprising, an thermoplastic cellular polymer in contact with a structural element such as a metal guard rail or automotive door, wherein the cellular polymer has an average cell size of at least about 0.75 mm and at least one of CE / CT, CV / CT and CH / CT is about 0.25 to about 0.4 said one of CE / CT, CV / CT and CH / CT having a compressive efficiency of at least 70% at a 60% strain, CE, CV and CH being the compressive strength of the cellular polymer in each of three orthogonal directions E, V and H where one of these directions is the direction of maximum compressive strength in the foam and CT equals the sum of CE, CV and CH.

Owner:DOW GLOBAL TECH LLC

Heat-conducting electric-insulating epoxy resin potting adhesive and preparation method thereof

ActiveCN104178076AImprove brittlenessImprove and eliminate crackingNon-macromolecular adhesive additivesOther chemical processesChemistryHydroxyl-terminated polybutadiene

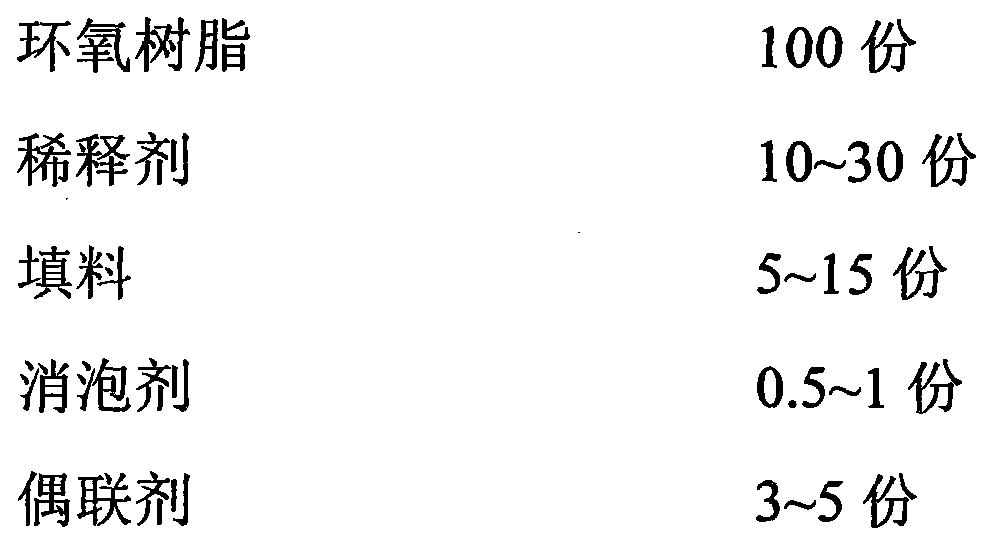

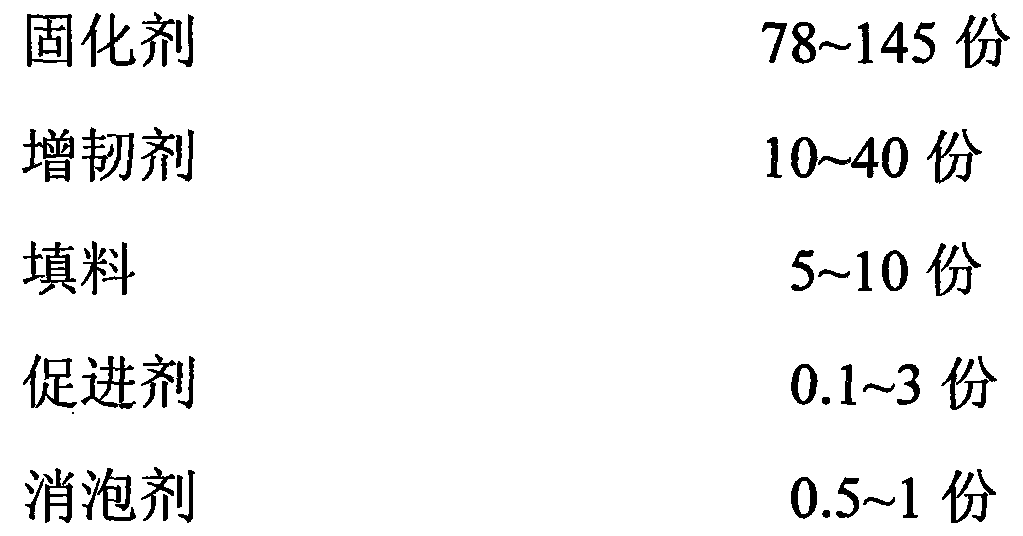

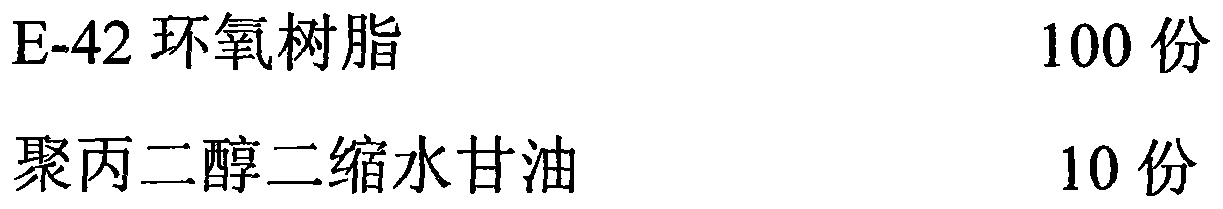

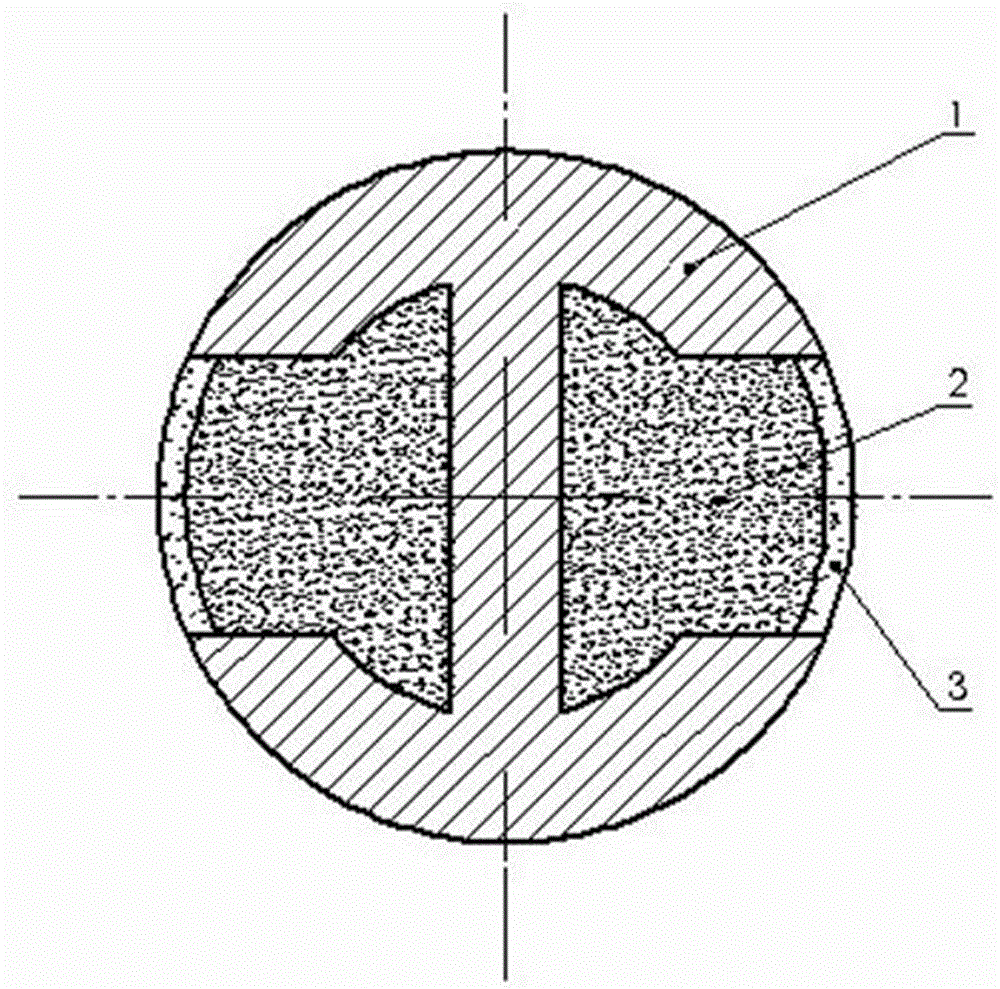

The invention discloses a heat-conducting electric-insulating epoxy resin potting adhesive which is composed of an epoxy resin, a curing agent, a toughener, a diluter, a filler, an accelerator and a defoaming agent. The component A is composed the following components in parts by weight: 100 parts of epoxy resin, 10-30 parts of diluter, 5-15 parts of filler, 0.5-1 part of defoaming agent and 3-5 parts of coupling agent. The component B is composed the following components in parts by weight: 78-145 parts of curing agent, 10-40 parts of toughener, 5-10 parts of filler, 0.1-3 parts of accelerator and 0.5-1 part of defoaming agent. The A / B weight ratio is 1:1. The toughener is epoxy hydroxyl-terminated polybutadiene acrylonitrile. The filler is composite powder composed of nano magnesium silicon nitride, nano silicon carbide, nano aluminum nitride, nano boron nitride, high-sphericity nano aluminum oxide and nano silicon nitride with different particle sizes, and the average particle size is 40-60nm. The potting adhesive has the advantages of favorable thermal conductivity and favorable electric insulating property.

Owner:LIMING RES INST OF CHEM IND

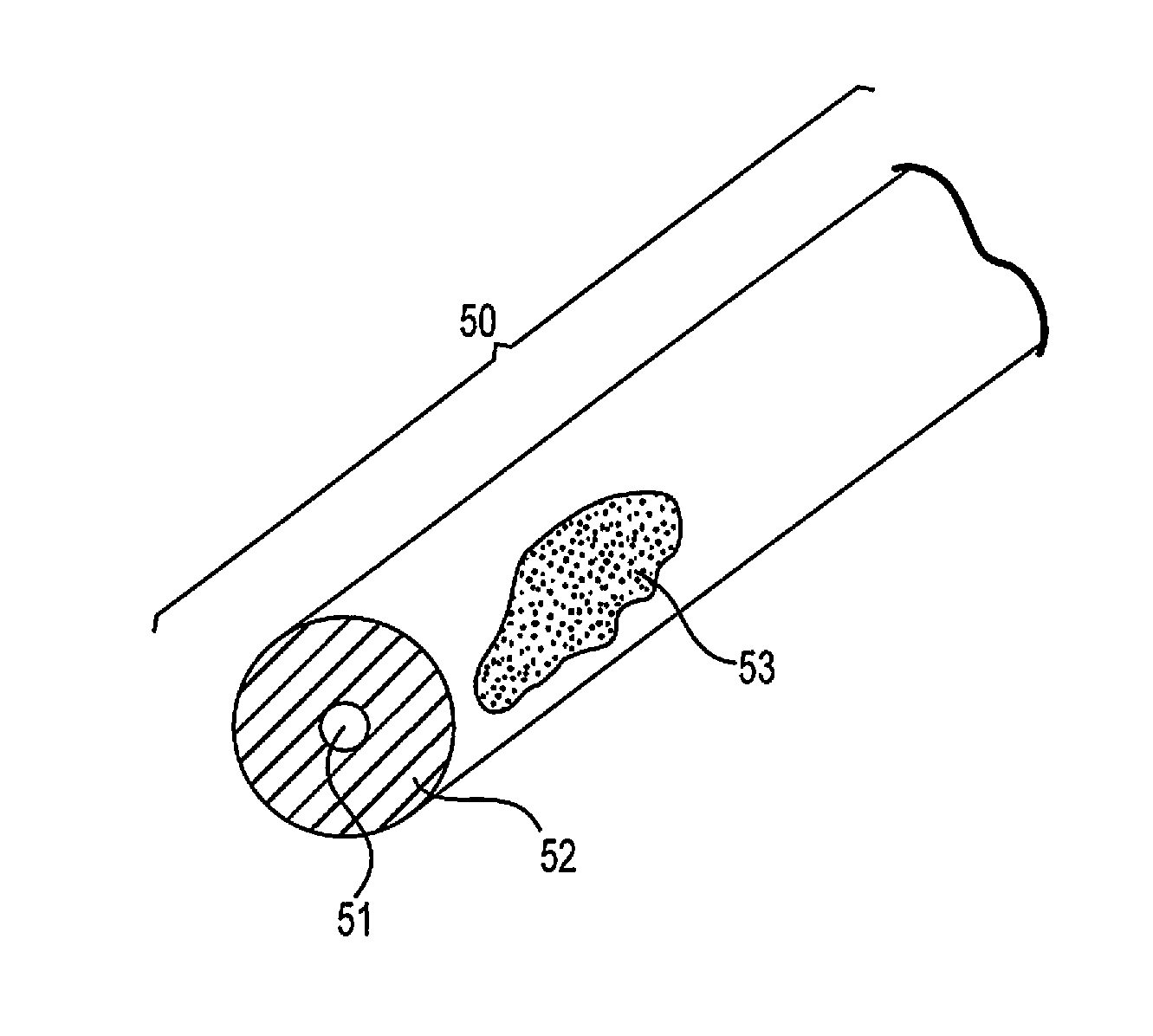

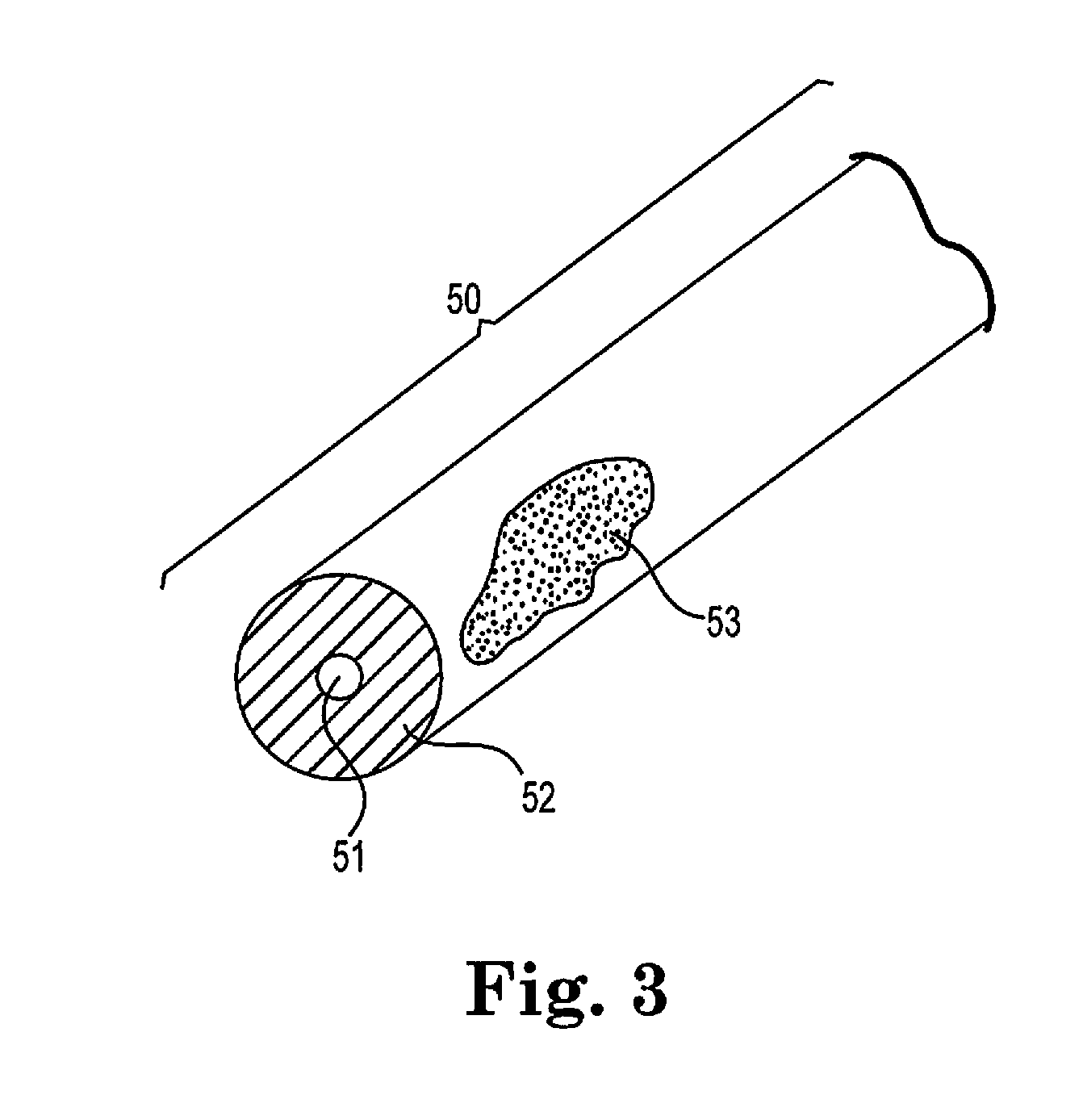

Continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide and preparation method of continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide

InactiveCN105834609AImprove toughnessImprove plasticityWelding/cutting media/materialsWelding/soldering/cutting articlesTrioxideFiller metal

The invention discloses a continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide and a preparation method of the continuous brazing composite aluminum-based brazing wire applying the nanometer aluminum trioxide. The continuous brazing composite aluminum-based brazing wire applying the nanometer aluminum trioxide is composed of an aluminum-based brazing filler metal core material with a groove formed in the outer surface, a no-corrosive flux used for aluminum and applied in the peripheral groove of the core material in a wrapping manner, and a coating layer sprayed on the surface of the composite brazing flux. The obtained product is excellent in material performance, easy to machine and form, good in brazing process performance, capable of fully adapting to efficient and continuous brazing and excellent in brazing connector performance.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

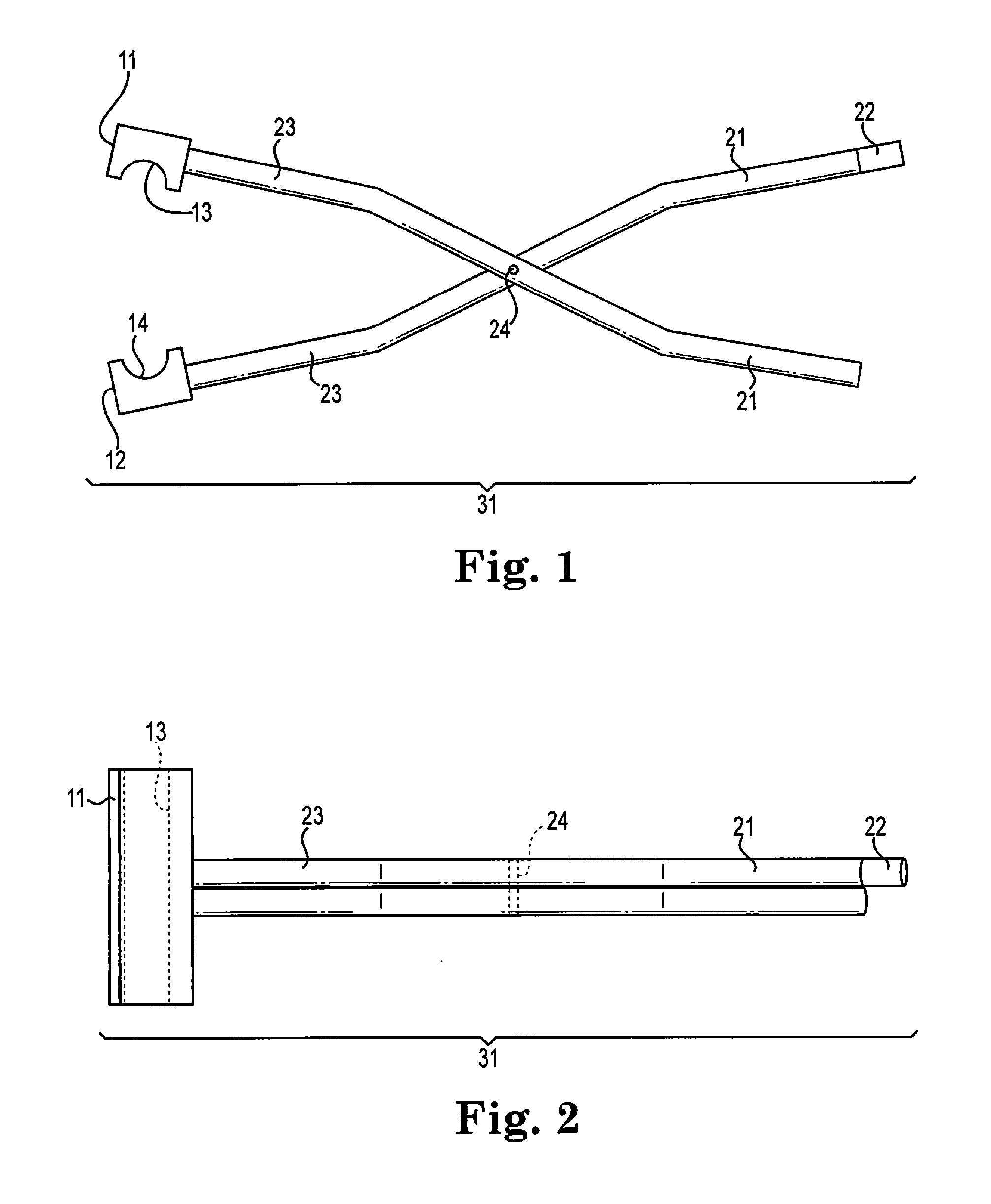

Low-Melt Poly(Amic Acids) and Polyimides and their Uses

ActiveUS20110212334A1Eliminate brittlenessRepair damageApparatus for heat treatmentApparatus for repairing insulation/armouring cablesElectricityElectric wire

Owner:NASA

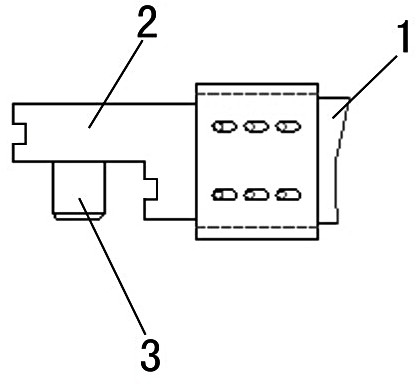

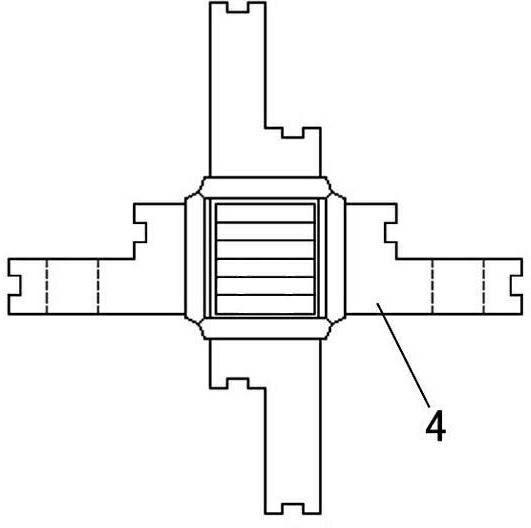

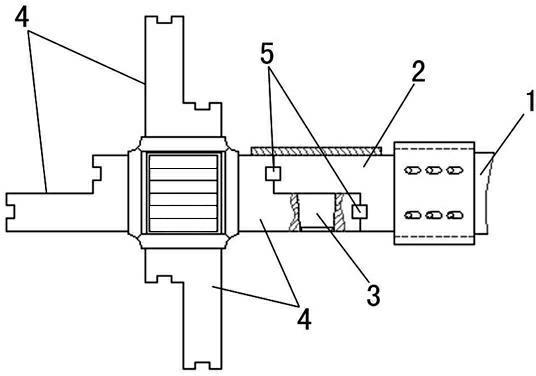

Steel structure building beam or pillar node interface

InactiveCN102561527AImprove bearing capacityHigh longitudinal tensile strengthBuilding constructionsBreaking strengthButt joint

The invention relates to a steel structure building beam or a steel structure pillar node interface, which is used for connecting convergent nodes of a steel structure building beam or a steel structure pillar and overcoming the shortages of toilsome assembly, bad accuracy, low connection strength, and the like in the existing connection mode. The steel structure building beam or pillar node interface is composed of joints of the end part of the beam or the pillar and joint seats converged on the node, wherein the joints lack a half at the end part in the horizontal direction to form a ladder shape. The shape and the size of the joint seats are the same with that of the joints. A connection insertion tenon is arranged on a mutual faying surface formed when the joint is butt jointed with the joint seat, the connection insertion tenon is vertical to the faying surface and a fastening structure for preventing the joint and the joint seat from horizontally separating is arranged at the faying position of the joint and the joint seat. According to invention, the steel structure building beam or pillar node interface has the beneficial effects that the faying mode bearing of the interface has large bearing capacity; the steel structure building beam-pillar node interface has high longitudinal tensile strength, is provided with the fastening member for preventing the joint and the joint seat from horizontally separating so that the connection of the node of the beam and the pillar has multi-directional higher anti-breaking strength, has a simple structure, and is convenient to manufacture and install; and with the adoption of the steel structure building beam or pillar node interface, the conditions are created for modularization, standardization and serialization of steel structure housing construction.

Owner:罗大威

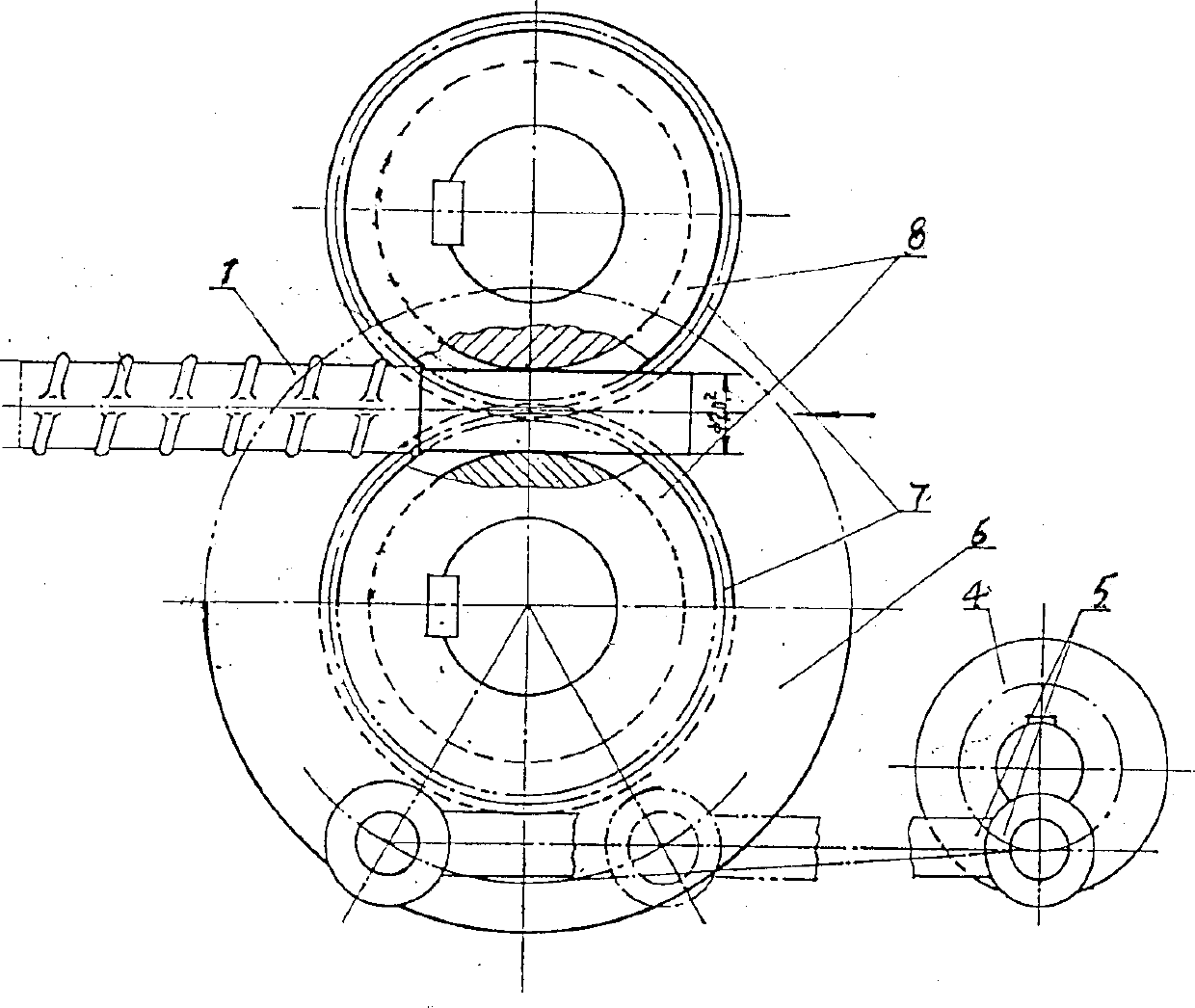

Projection welding method of double pulse high capacity capacitance for energy storage

InactiveCN1736649AImprove toughnessEliminate brittlenessStorage discharge weldingCapacitanceTransformer

Disclosed is a method for double-pulse high capacity condenser energy storage projection welding in the field of welding technique, which contains: overlapping and locating the two low-alloy steel workpieces on the static lower-electrode, the upper-electrode down to compact the joint of workpieces, charging the condenser bank to Uc1, after first-time discharging to welding transformer by the closure of the commutator and the trigger of thyristors which are controlled by a program, breaking the commutator; cooling, and charging the condenser bank to Uc2, and generating the second-time discharging to welding transformer by the closure of the commutator and the trigger of thyristors; breaking the commutator after the energisation, releasing the upper-electrode after constant pressure-maintaining, and the welding process being completed. The invention realizes welding and tempering double-pulse welding in the energy storage resistance projection welding, especially applies to the point welding (projection welding) of thick low-alloy steel, and it has a key action to the joint strength, the joint tenacity and the surface quality. And, compared with other resistance welding power, it decreased the capacity requirement to the power of live wire entanglement.

Owner:SHANGHAI JIAO TONG UNIV

Polyamide-imide fiber wet one-step spinning process

ActiveCN103757721ASolve the problem of fast formingEliminate brittlenessArtificial filament heat treatmentWet spinning methodsFiberYarn

The invention provides a polyamide-imide fiber wet one-step spinning process. The process is characterized by including the steps: defoaming polyamide-imide spinning dope in a storage tank by standing, metering usage of the dope by a metering pump, spinning with a spinning unit, and subjecting obtained yarns to batching with first coagulating bath, second coagulating bath, plastic drafting bath and water and then dried to obtain primary fiber of polyamide-imide. The first coagulating bath is composed of 60-80wt% of aprotic polar solvent, 5-20wt% of CaCl2, and the balance of water; the second coagulating bath is composed of 50-80wt% of aprotic polar solvent, 5-20wt% of CaCl2, and the balance of water; the concentration of the aprotic polar solvent in the second coagulating bath is lower than that of the aprotic polar solvent in the first coagulating bath. Filament fiber obtained by the process has high mechanical properties. The polyamide-imide fiber wet one-step spinning process has the advantages that equipment is simple, control is simple and cost is low.

Owner:JIANGSU JUXIAN SYNTHETIC MATERIAL

Regenerated sponge rubber and preparation method thereof

InactiveCN104311771ABreak the shortcomings of poor adhesion and strong odorImprove adhesionPolyureas/polyurethane adhesivesPolyolPolymer science

The invention belongs to the chemical field and in particular relates to regenerated sponge rubber and a preparation method thereof. The regenerated sponge rubber is prepared from the following raw materials in parts by weight: 45-85 parts of polyether polyol, 1.5-4.0 parts of a catalyst, 20-25 parts of a diluent and 10-15 parts of polyisocyanate, wherein NCO percent of a synthetic product is 5.0-7.0 percent. The preparation method comprises the following steps: raising temperature of the polyether polyol until 100-110 DEG C, carrying out vacuum dewatering for 2-2.5h, cooling to 50-60 DEG C, adding the polyisocyanate, raising temperature until 80-85 DEG C, reacting for 2-3h, cooling below 50 DEG C, adding the diluent and the catalyst, and stirring for 20-30min to obtain the synthetic product. The regenerated sponge rubber has the advantages of high bonding degree, good toughness, large tear strength, no peculiar smell, environmental protection, no three wastes discharge in production of the product and the like.

Owner:ZIBO DEXIN LIANBANG CHEM IND

Preserved donkey-hide gelatin hawthorns and production method thereof

The invention belongs to the technical field of food processing, and particularly relates to preserved donkey-hide gelatin hawthorns and a production method thereof .The preserved donkey-hide gelatin hawthorns are made from, by weight, 40-70 parts of hawthorns, 1-3 parts of donkey-hide gelatin, 250-350 parts of white granulated sugar and 65-94.5 parts of fructose .The production method includes the steps of material selecting, soaking, sugar liquor precooking, sugar liquor soaking, cooking and sugaring, baking, shaping and packaging .By preparing sugar liquor into a solution with mass concentration changing in a gradient mode and cooking the solution in twice, the preserved donkey-hide gelatin hawthorns prepared according to the optimal ratio of white granulated sugar to fructose are excellent in taste and good in property, are light red and semitransparent, have functions of softening blood vessels, reducing pressure and lipid, activating blood circulation to remove stasis, tonifying the spleen and removing food retention, and nourishing blood and keeping beauty, and are healthy food suitable for people of all ages and convenient to eat.

Owner:SHANDONG HONGJITANG PHARMA GRP JINAN E JIAO PROD CO LTD

Heat treatment and grinding method in kitchen knife manufacturing process

InactiveCN104141038AHigh hardnessImprove toughnessFurnace typesOther manufacturing equipments/toolsHardnessSpecific time

The invention relates to a heat treatment and grinding method in a kitchen knife manufacturing process, and the heat treatment and grinding method includes a heat treatment process and a grinding process. According to the method, an ordinary steel plate and V steel are compounded by argon arc welding to form a knife blank, and by quenching in specific time and at specific temperature and tempering in specific time and at specific temperature, the hardness and toughness of the knife blank are improved, internal stress, deformability and brittleness of the knife blank are eliminated, edge grinding of the knife blank is fully completed by hand, the edge grinding is very fine, although the processing time is slightly increased, service life and exquisite degree of a prepared kitchen knife are much higher than that of a traditional full steel kitchen knife, the sale profit is higher, and the economic income of manufacturers is improved.

Owner:TIANJIN MINGRUN KNIFE & SCISSOR CO LTD

Later-support vacuum glass manufacturing method

ActiveCN104591527APlay a supporting roleReduce cumbersomeGlass reforming apparatusGlass productionSolderingIrradiation

The invention discloses a later-support vacuum glass manufacturing method which comprises the following steps: cooling after high-temperature exhaustion; laying a soldering flux at a preset sealing area when the temperature is cooled to 150 DEG C; directly superposing two glass plates in parallel without set supports; raising the temperature to 200 DEG C, welding the soldering flux and sealing the edge; cooling to 150 DEG C and selecting points from one or two surfaces to carry out laser fixed-point irradiation after close welding to ensure that bulges are formed between the two glass plates at the irradiation points; and forming support between the two glass plates by bulges formed by one or more points. The later-support vacuum glass manufacturing method has the advantages of abandoning the complicated manner of previously laying a support, greatly improving the vacuum degree, simplifying the manufacturing process and improving the wind-resistant performance of the vacuum glass.

Owner:王磊

Passion fruit and pine needle tea drink

InactiveCN104223251AReduce degradationPlay a role in metabolismTea substituesNatural extract food ingredientsPassion fruitFruit drinks

The invention discloses a passion fruit and pine needle tea drink which specifically comprises passion fruit juice and pine needle juice. A preparation method of the passion fruit and pine needle tea drink comprises the following steps: firstly, preparing passion fruit pulp into passion fruit juice, and meanwhile, acquiring pine needle leaves as raw materials and boiling in water to prepare pine needle juice; then, uniformly mixing the passion fruit juice with the pine needle juice in proportion to obtain the passion fruit and pine needle tea drink. According to the passion fruit and pine needle tea drink, a formula and a preparation process are simple; the prepared tea drink is good in palatability; the effects of the two raw materials in the formula supplement each other, so that the prepared tea drink can build bodies, improve the immunity, delay ageing, maintain beauty and keep young, and is first-class health tea; in addition, the prepared passion fruit and pine needle tea drink is low in cost, good in health effect and suitable for most people, and has very good market prospects.

Owner:黄秀英

Manufacturing method of composite shear blade

PendingCN112605621AMeet the needs of hardnessLow costFurnace typesHeat treatment furnacesCarbon steelMachining

The invention discloses a manufacturing method of a composite shear blade, and belongs to the technical field of shear blade manufacturing and processing. The manufacturing method comprises the following specific steps: step 1, manufacturing a blank, step 2, forging and compounding two materials, step 3, spheroidizing and rough machining, step 4, heat treatment, and step 5, detection. The shear blade can be used for shearing high-precision and high-strength steel plates, is made of composite materials, adopts about half of carbon steel materials, reduces the content of precious metal, saves the cost and is environmentally friendly, meanwhile, the brittleness of the shear blade is reduced, so that the cracking phenomenon is reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

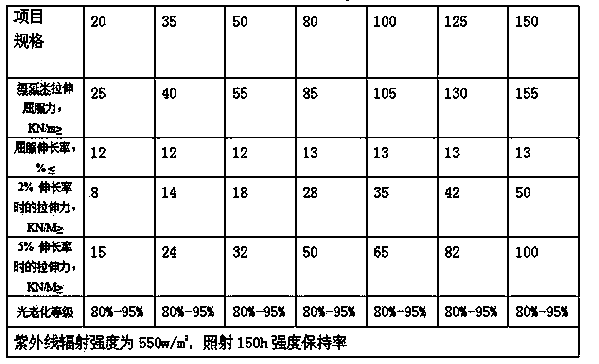

Styrene elastomer geogrid and preparation method thereof

The invention relates to a styrene elastomer geogrid prepared by processing the following raw materials in parts by weight: 70-80 parts of PP resin, 20-30 parts of styrene elastomers, 0.2-0.4 part of barium stearate, 0.2-0.4 part of antioxidant 300, 0.1-0.2 part of antioxidant 1076, 0.1-0.3 part of ultraviolet absorbent UV-9 and 25-35 parts of modified filler. The preparation method of the styrene elastomer geogrid comprises the steps of mixing all the materials in the formula, and extruding to obtain a melt; forming a plate from the melt by using a three-roll calendar; punching the plate by using a punching machine; and stretching after heating the pore plate to obtain the geogrid. The modified geogrid prepared by processing the raw materials is high in stretching strength, corrosion-resistant, good in mechanical properties and low in production and processing costs.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

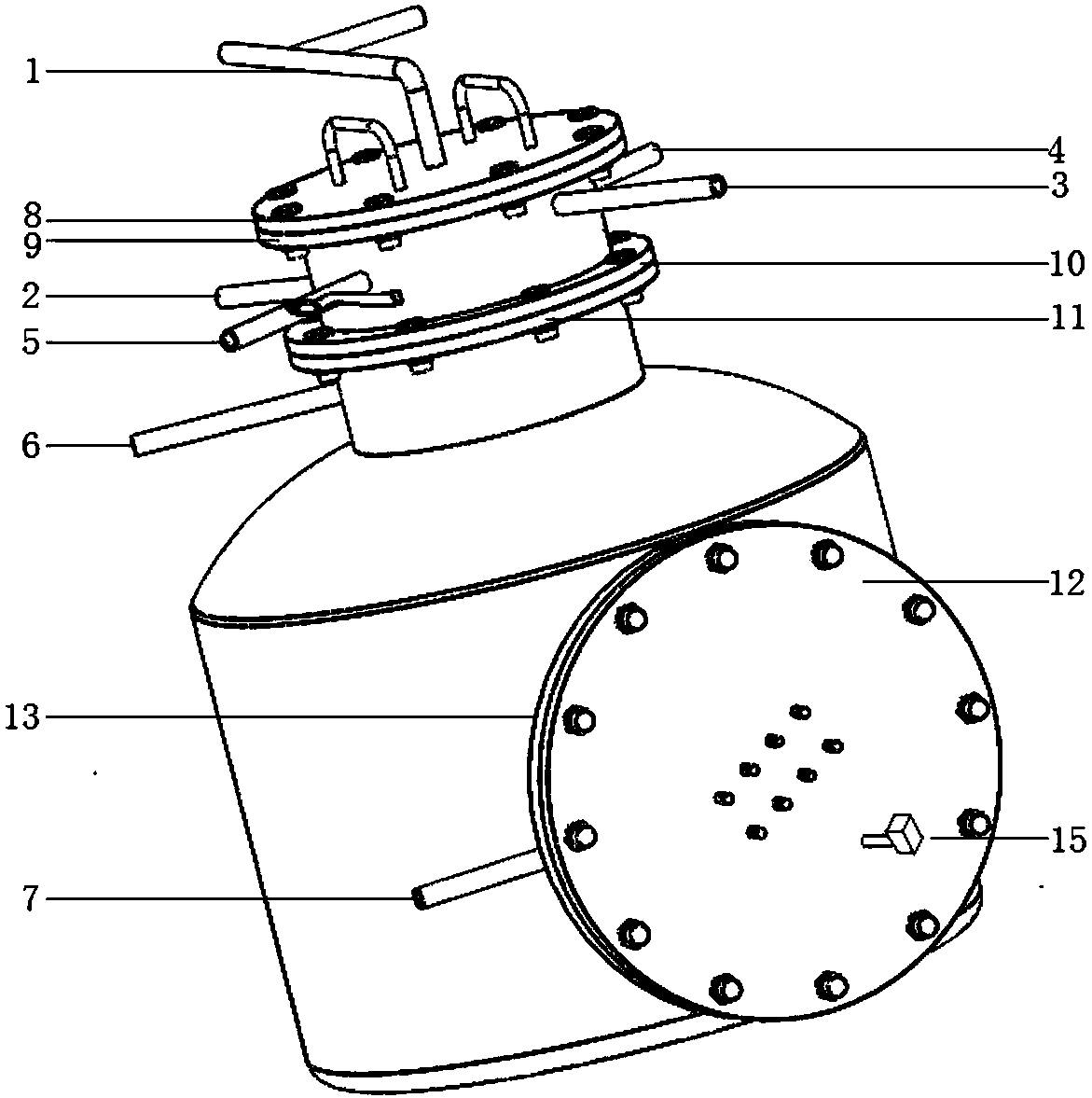

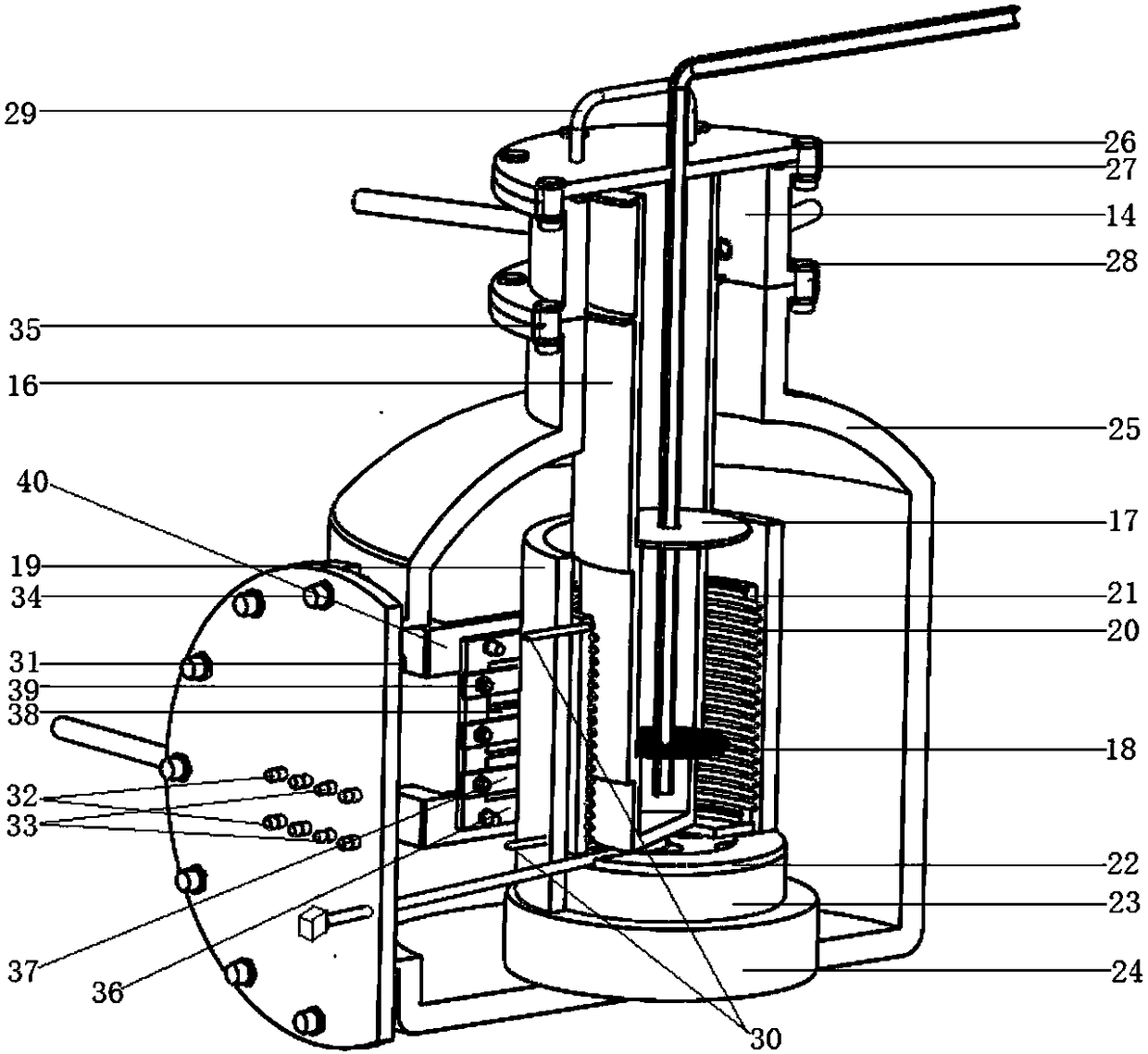

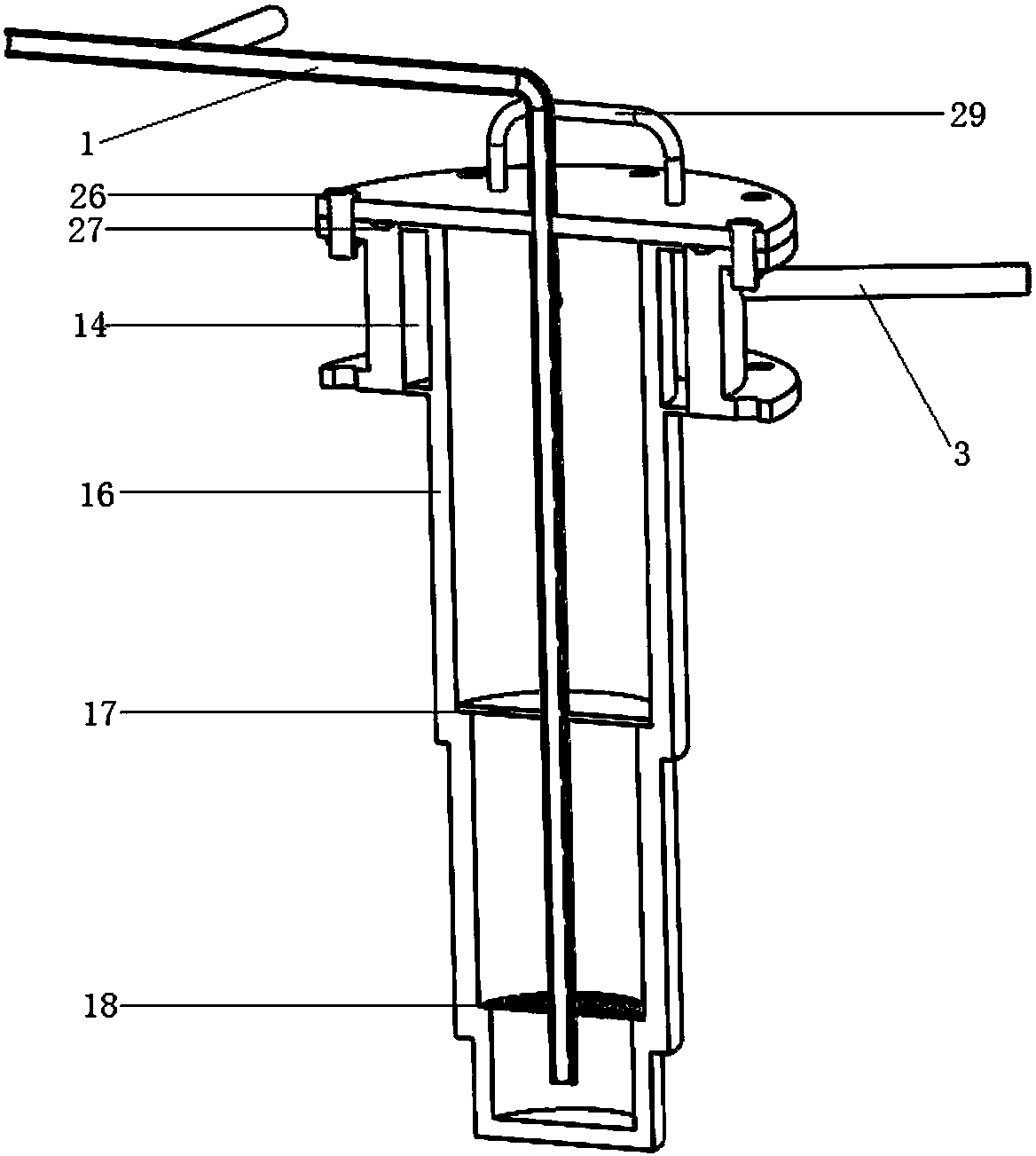

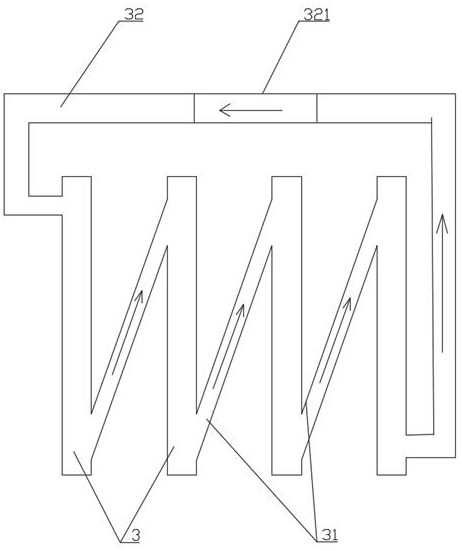

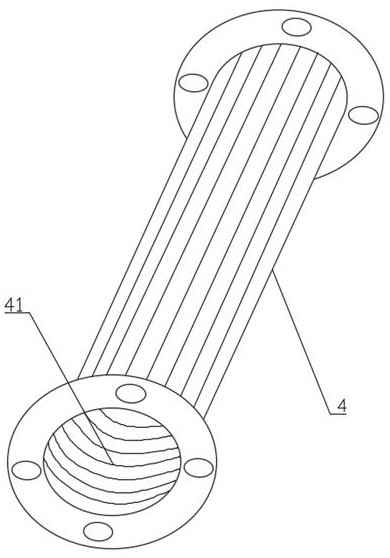

Nitriding furnace with magnetic field auxiliary mechanism

ActiveCN108193165AIncrease nitriding speedNitriding time is shortSolid state diffusion coatingFastenerEngineering

The invention relates to a nitriding furnace with a magnetic field auxiliary mechanism. The nitriding furnace with the magnetic field auxiliary mechanism is mainly characterized in that connecting pieces are arranged on two opposite sides in a furnace shell and are each provided with a flat plate-shaped magnet frame; the two flat plate-shaped magnet frames are parallel to a center line of a side through hole of the furnace shell; an upper horizontal strip-shaped baffle plate, a middle horizontal strip-shaped baffle plate and a lower horizontal strip-shaped baffle plate are arranged on each magnet frame and are connected with the magnet frames through fastening pieces; two electromagnets arranged in parallel to form a group and provided with iron blocks in coils are clamped between each baffle plate and the corresponding magnet frame; two guide wires of each group of electromagnet coils are connected with a binding post arranged on a side furnace cover; and the upper groups of electromagnets, the middle groups of electromagnets and the lower groups of electromagnets on two sides of the furnace shell are symmetrically arranged. According to the nitriding furnace with the magnetic field auxiliary mechanism provided by the invention, the workpiece nitriding speed can be accelerated, the nitriding time is short, a nitriding cycle is greatly reduced, the process cost is reduced, theworkpiece deformation is reduced, the quality of a nitriding layer is improved, the nitrogen-containing concentration of the nitriding layer of a workpiece is increased, the fragility of the nitridinglayer is eliminated, and a mechanical property of a surface layer is improved; and the nitriding furnace with the magnetic field auxiliary mechanism is advanced and reasonable in structure, convenient to operate, reliable to operate, and durable in use.

Owner:YANSHAN UNIV

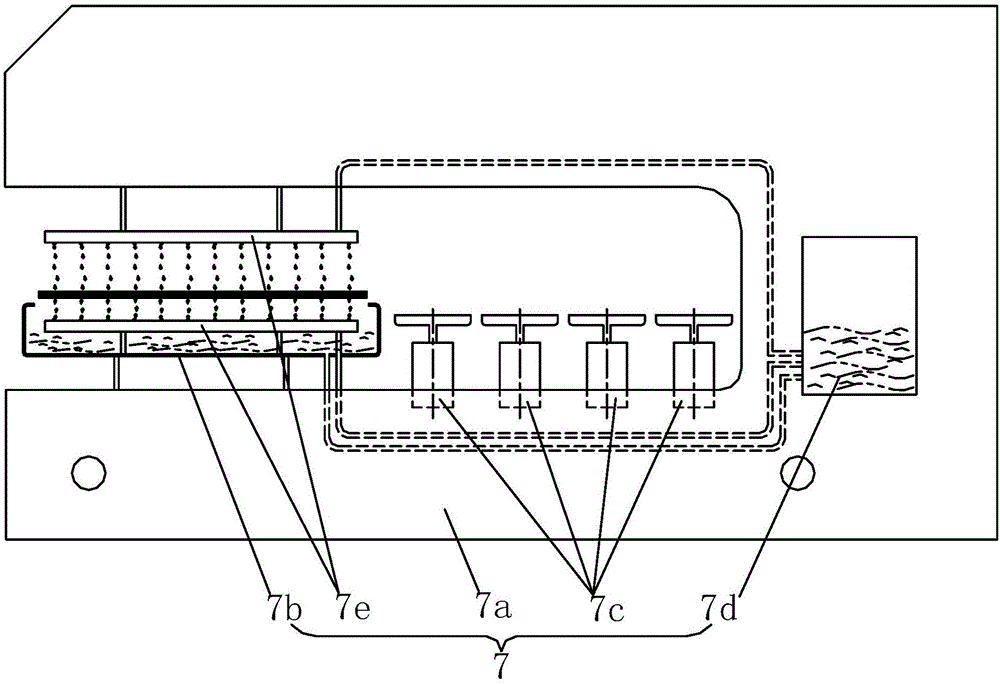

Resistance welding technology with online continuous weld heat treatment

InactiveCN106346122AReduce welding stressReduce welding strain rateWelding/soldering/cutting articlesMetal working apparatusHeat treatedStrip steel

The invention discloses a resistance welding technology with online continuous weld heat treatment. The method comprises the following steps: (1) The online strip steel is sheared and seamed in the shearing station of the welding process. (2) After shearing and seaming, the welding area of the online strip steel is online continuously preheated by the preheating device in the preheating station of the welding process. (3) After preheating, the online strip steel is welded in the welding station of the welding process. (4) After welding, the welding area of online strip steel is online continuously welded and normalized by the normalizing mechanism in the normalizing station of the welding process. (5) After normalizing, the welding area of the online strip steel is online continuously welded and rolled by the rolling device in the rolling station of the welding process. (6) After rolling, the welding area of the online strip steel is online continuously welded and tempered by the tempering mechanism in the tempering station of the welding process or online continuously welded and taken brittle processing by the brittle processing device in the brittle processing station of the brittle processing process. The resistance welding technology with online continuous weld heat treatment is suitable for welding.

Owner:WUHAN KAIQI SPECIAL WELDING EQUIP

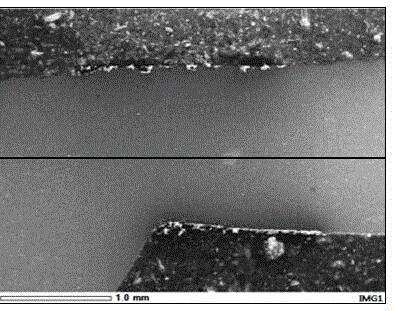

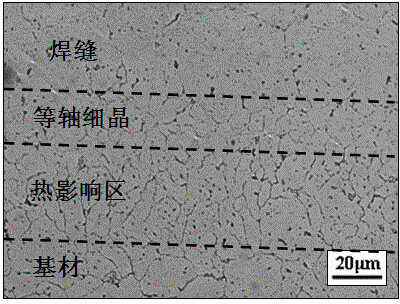

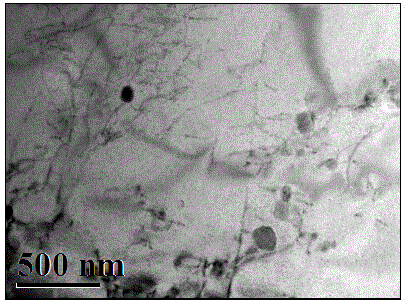

Thermal-cold cycling treatment method for high-speed train body structure material

InactiveCN104862626AIntensive control of static tensile propertiesLow temperature toughness strengthening controlFlow stressRoom temperature

The invention discloses a thermal-cold cycling treatment method for a high-speed train body structure material. An aluminum alloy fusion arc welding joint workpiece of a high-speed train body structure is put into a crucible type resistance furnace for uniformly annealing by 2-5 hours at a temperature of 410-430 DEG C; the workpiece is taken out to put in air for cooling to the room temperature; the workpiece is put into a deep cooling cabinet; firstly, the workpiece is cooled to a temperature of -40 to -60 DEG C, and the temperature is kept by 30-50 minutes; then, the workpiece is continuously cooled to a temperature range of -160 to -180 DEG C with a cooling speed of 15 DEG C / min, and the temperature is kept by 6-8 hours; and finally, the workpiece is heated up to a temperature of -40 to -60 DEG C, and the temperature is kept by 30-50 minutes. The thermal-cold cycling treatment method combines the low-temperature deep cooling treatment with the high-temperature annealing process to realize the intensified control of the static tensile property and the low-temperature plasticity and toughness of materials, so that the structure morphology is improved, the influence of the flow stress is eliminated, and the tensile strength, the ductility and the impact toughness of the materials are improved.

Owner:JIANGSU UNIV OF SCI & TECH

Low-melt poly(amic acids) and polyimides and their uses

ActiveUS9365756B1Low costEliminate brittlenessApparatus for heat treatmentSynthetic resin layered productsCross-linkAdhesive

Provided are low-melt polyimides and poly(amic acids) (PAAs) for use as adhesives, and methods of using the materials for attaching two substrates. The methods typically form an adhesive bond that is hermetically sealed to both substrates. Additionally, the method typically forms a cross-linked bonding material that is flexible.

Owner:NASA

Rhenium-tungsten multi-element transmitting filament and applications thereof

InactiveCN101640155AStable and long service lifeImprove toleranceTransit-tube cathodesCold cathode manufactureRheniumMicrowave oven

The invention discloses a rhenium-tungsten multi-element transmitting filament and applications thereof. The filament mainly consists of rhenium and tungsten. The filament has the advantages of stableworking performance, long service life, environmental protection, and brittleness and radiation elimination. The invention is mainly used for manufacturing transmitting filaments in transmitting tubes and magnetrons in microwave ovens, convection ovens and high-power microwave ovens.

Owner:朱惠冲

Composite material and method of making the composite material

ActiveUS7931963B2More dissipationMinimizing and essentially eliminating friabilityAntipyreticLayered productsCompressive strengthPolymer

An improved energy absorbing member comprising, an thermoplastic cellular polymer in contact with a structural element such as a metal guard rail or automotive door, wherein the cellular polymer has an average cell size of at least about 0.75 mm and at least one of CE / CT, CV / CT and CH / CT is about 0.25 to about 0.4 said one of CE / CT, CV / CT and CH / CT having a compressive efficiency of at least 70% at a 60% strain, CE, CV and CH being the compressive strength of the cellular polymer in each of three orthogonal directions E, V and H where one of these directions is the direction of maximum compressive strength in the foam and CT equals the sum of CE, CV and CH.

Owner:DOW GLOBAL TECH LLC

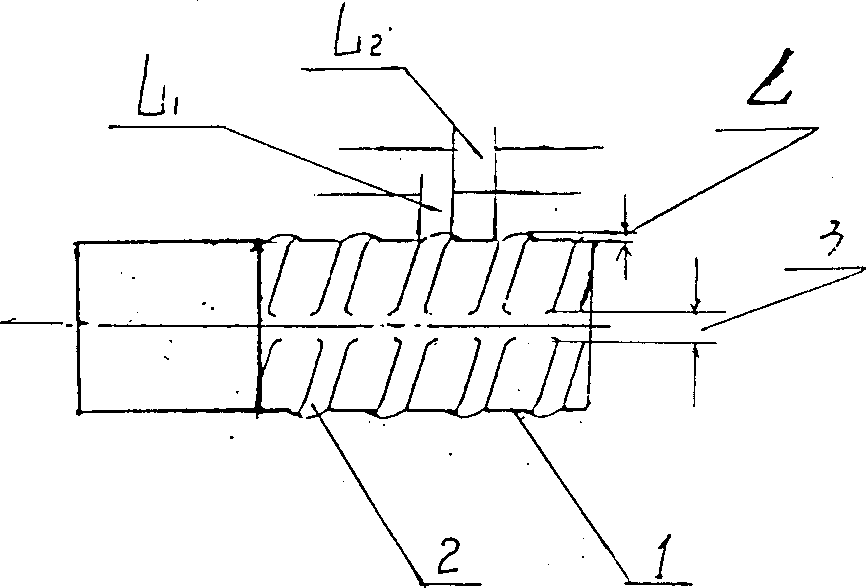

Cold-pressing technology for making equistrength archor arm and its end

A cold-pressed equistrength archor rod for supporting gallery has rod body and end part, and is made through cold (rolling) pressing the rolled rod body with axial spiral ribs to remove the ribs at head part and become a cylinder, and screwing the cylindrical head part. Its advantages are high strength, strong anchor power, and no stress concentration.

Owner:孔祥清

Low-melt poly(amic acids) and polyimides and their uses

ActiveUS8623253B2Repair damageEliminate brittlenessLayered productsApparatus for heat treatmentElectricityElectric wire

Owner:NASA

Medium carbon-rare earth alloy strengthening cast steel shot/grit and preparation technology thereof

ActiveCN106337154AGranularityIncrease productionFurnace typesHeat treatment furnacesNiobiumGrain structure

The invention provides medium carbon-rare earth alloy strengthening cast steel shot / grit and a preparation technology thereof, and belongs to the technical field of metal abrasives. The medium carbon-rare earth alloy strengthening cast steel shot / grit is characterized by being prepared from, by mass, 0.30%-0.85% of C, 0.30%-1.50% of Si, 0.30%-1.50% of Mn, 0.10%-0.15% of Re, 0.10%-0.90% of Cr, 0.01%-0.04% of Nb, smaller than or equal to 0.05% of P, smaller than or equal to 0.05% of S and the balance Fe. According to the medium carbon-rare earth alloy steel, by adding rare earth, molten steel is purified, and a grain structure of steel is refined; the strength, the hardness and the wear resistance are improved through chromium; niobium forms a carbide, and therefore the hardness and the wear resistance are improved; by means of alloy elements, the eutectoid temperature of the steel is increased, and diffusion of carbon is prevented. Accordingly, increase of the quenching temperature is beneficial for conversion from pearlite to austenite and diffusion of carbon. A metallographic structure is converted into tempered martensite and tempered troostite.

Owner:SHANDONG UNIV OF TECH +1

Low-carbon low-boron low-chromium alloy steel, and preparation method thereof

The invention discloses a low-carbon low-boron low-chromium alloy steel, and a preparation method thereof, and belongs to the technical field of alloy steel manufacturing. According to the preparationmethod, low-carbon low-boron low-chromium materials are combined with cerium rare earth, vanadium, tungsten, copper, tantalum, cobalt, niobium, and the like, technical target value determination, material preparation, melting, sampling adjusting, casting moulding, and heat treatment are carried out so as to obtain the low-carbon low-boron low-chromium alloy steel at last; the hardness is HRC42-52, the impact energy is as high as 11 to 20 joules. The preparation method is capable of guaranteeing the certain hardness of the alloy steel, and at the same time, improving the impact resistance, thetoughness, and the wear resistance greatly.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

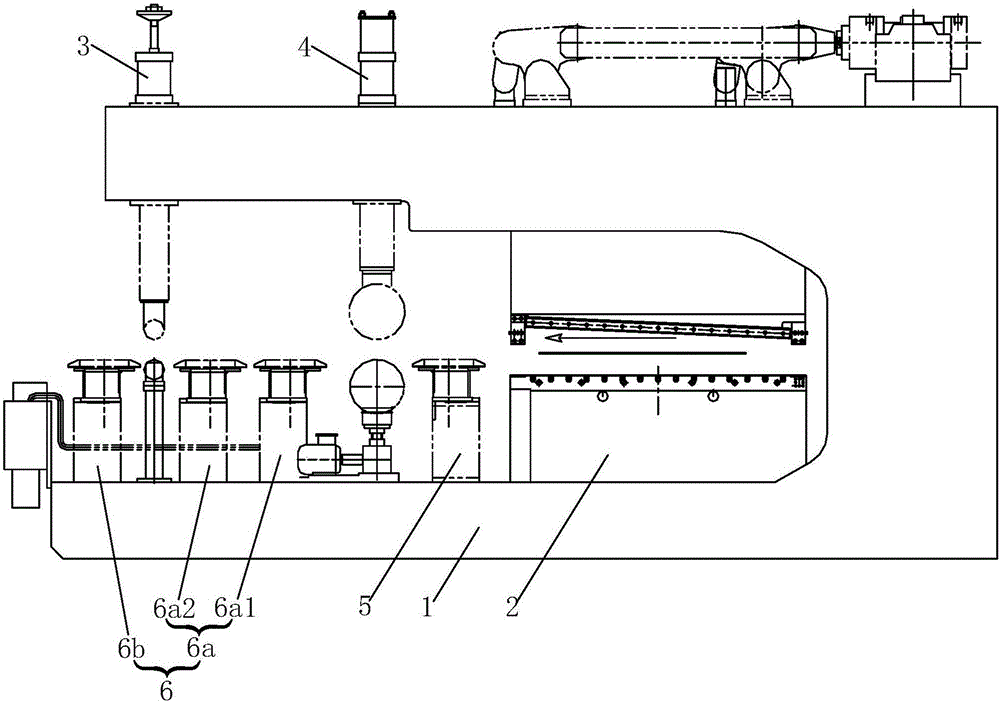

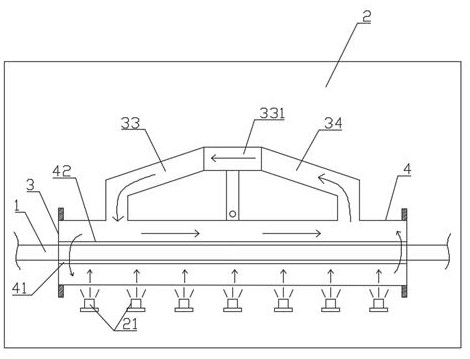

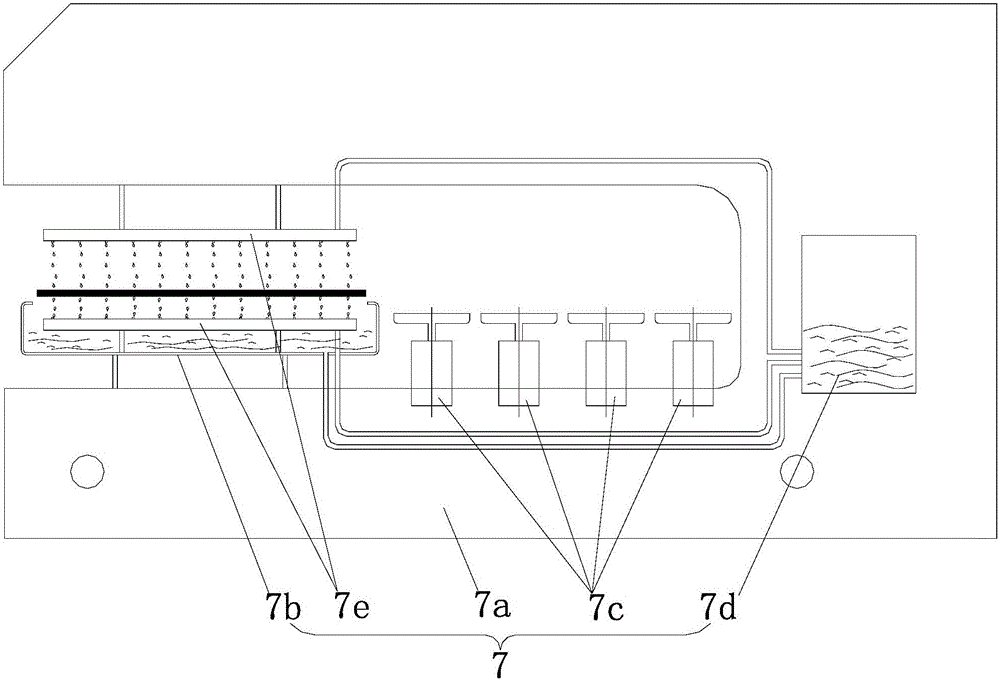

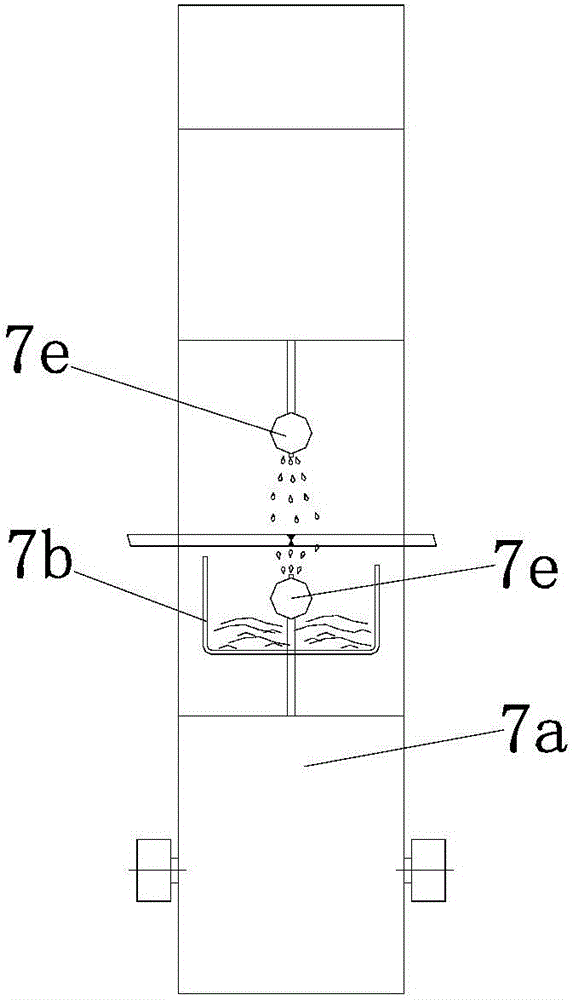

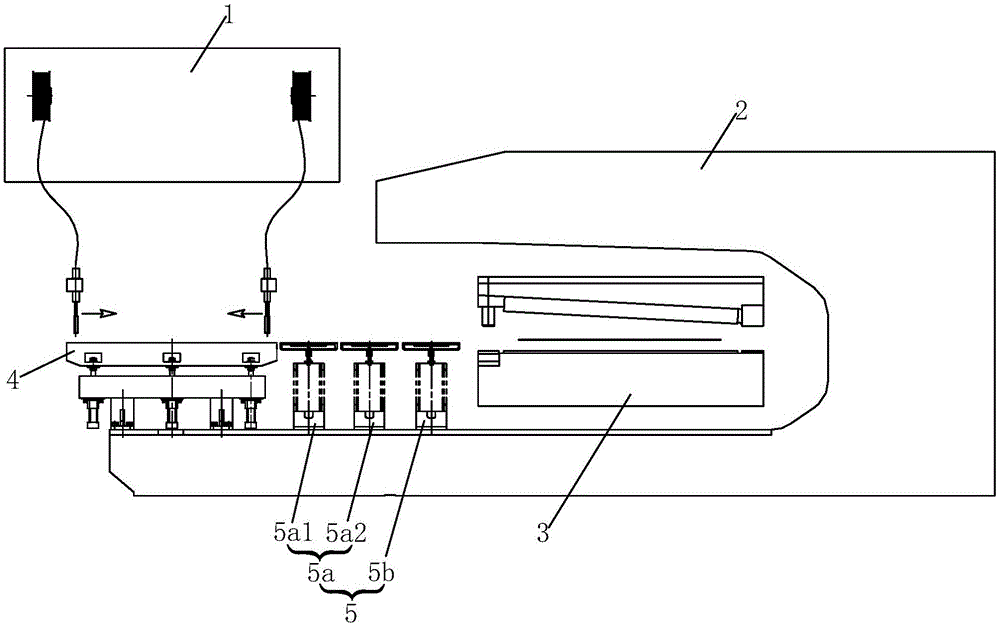

Resistance welding machine with online continuous weld heat treatment

InactiveCN106346260AReduce welding stressReduce welding strain rateOther manufacturing equipments/toolsEngineeringWater tanks

The invention discloses a resistance welding machine with online continuous weld heat treatment, including a welding carriage, a shearing device, a resistance welding device and a rolling device. The welding carriage is provided with a preheating device and a heat treatment device. The next step after the process of welding is a brittle processing procedure, and the position of the brittle processing procedure is provided with a brittle processing device. The brittle processing device includes an auxiliary trolley, and a water tank, an annealing mechanism and a circulating water cooler, and they are arranged on the auxiliary trolley in order. A rapid cooling nozzle which can quickly cool down the both sides of the welding area of the online strip steel is arranged in the water tank and on the upper portion of the water tank which the auxiliary trolley corresponds to. The rapid cooling nozzle is connected with the outlet of the circulating water cooler. The heat treatment device includes a normalizing mechanism and a tempering mechanism. The normalizing mechanism is provided between the resistance welding device and the rolling device, and the tempering mechanism is provided behind the rolling device. The resistance welding machine with online continuous weld heat treatment is suitable for welding machine.

Owner:WUHAN KAIQI SPECIAL WELDING EQUIP

Steel wire heat treatment quenching process

PendingCN113416834AImprove performanceSuitable for drawingFurnace typesHeat treatment furnacesPhysicsPearlite

The invention discloses a steel wire heat treatment quenching process. The steel wire heat treatment quenching process comprises the following steps of leading out a steel wire through a roller of a pay-off machine, horizontally outputting the steel wire after passing through a positioning device, and heating the steel wire to 900-950 DEG C to convert the structure into austenite; quenching and preserving heat the austenite in molten lead or salt (a mixture of sodium nitrate and potassium nitrate or calcium chloride, sodium chloride and potassium chloride) with the temperature of 480-550 DEG C for a period of time to enable the austenite to be subjected to isothermal transformation into fine pearlite, heating the wire to the temperature above a critical point, preserving heat for a certain time, and quickly cooling to a standard value temperature; the heat preservation time is long enough to form a required spheroidized structure; heating to the temperature above the upper critical point, quickly cooling to the temperature which is about 30 DEG C higher than the standard value, and cooling to the temperature below the lower critical point (about 650 DEG C) at the speed of 5 DEG C / h; heating to a lower critical point or a slightly lower temperature, preserving heat for enough time to form a required spheroidized structure (generally 8-12 hours), and heating the steel wire to 30-50 DEG C above the lower critical point.

Owner:陈冬英

Production method of non-loose steel wire rope

ActiveCN111621635AUniform internal organizationHigh tensile strengthRope making machinesFurnace typesWire rodMegasonic cleaning

The invention provides a production method of a non-loose steel wire rope. The production method comprises the steps of wire rod forming: selecting 304 stainless steel wires with diameter of 5.5mm; surface treatment: soaking the wires in dilute hydrochloric acid to remove an oxide film; wire drawing: drawing the wires with the diameter of 5.5mm into 1.5mm steel wires; stranding: stranding a plurality of layers of steel wires into rope strands; rope laying up: stranding the rope strands around the center line of a rope core on a laying-up machine into a steel wire rope; heat treatment: puttingthe laid-up steel wire rope strand in a heat treatment furnace for heat treatment, and carrying out ultrasonic cleaning and cooling after heat treatment; and inspection: calculating the safety factorof the steel wire rope. The production method provided by the invention is not used in the steel wire rope at present, and the produced steel wire rope has the advantages that all layers of steel wires inside the steel wire rope are in close contact with each other, the non-looseness performance is excellent, the fatigue resistance is good, the stability is good, and the service life is long.

Owner:江苏亚盛金属制品有限公司

Laser welding machine provided with on-line continuous heat-treatment for welding seam

InactiveCN106346255AAvoid the evolution of diffusible hydrogenReduce the degree of hardeningFurnace typesOther manufacturing equipments/toolsStrip steelWeld seam

The invention discloses a laser welding machine provided with on-line continuous heat-treatment for welding seam. The laser welding machine comprises a welding trolley, and the welding trolley is provided with a pre-heating device and a heat-treatment device, a shearing device, a laser welding device and a rolling device. The next step of welding process is the brittleness treatment process whose position is provided with a brittleness treatment devise. The brittleness treatment devise comprises an auxiliary engine trolley and a water tank, an annealing mechanism and a circulating water cooler, which are arranged on the auxiliary engine trolley in sequence. A rapid cooling sprayer which is used to cool rapidly the front and back of on-line strip steel welding area, is arranged on each position in the water tank and above the auxiliary engine trolley. The rapid cooling sprayer is communicated with the output port of the circulating water cooler. The water tank is communicated with the input port of the circulating water cooler. The heat-treatment device comprises a normalizing mechanism and a tempering mechanism. The normalizing mechanism is provided between the welding devise and the rolling device, and the tempering mechanism is arranged at the rear of the rolling device. The laser welding machine provided with on-line continuous heat-treatment for welding seam is suitable for welding machines.

Owner:WUHAN KAIQI SPECIAL WELDING EQUIP

Argon arc welding technique with online and continuous weld heat treatment

InactiveCN106346113AReduce the degree of hardeningUniform temperatureArc welding apparatusStrip steelWelding process

The invention discloses an argon arc welding technique with online and continuous weld heat treatment, which comprises the steps of shearing joint, preheating, welding, normalizing and tempering . (1)The online strip steel is sheared and pieced by shearing device on the shearing station of the welding process. (2)The welding area of the online strip steel carries out online and continuous preheating by heat-treating device on the heat-treating station of the welding process after being sheared and pieced. (3)The online strip steel carries out welding by argon arc welding car on the welding station of the welding process after being preheated. (4a)The welding area of the online strip steel carries out online and continuous normalizing treatment through normalizing mechanism on the normalizing station of the welding process after being welded. (4b)The welding area of the online strip steel carries out online and continuous tempering treatment through the tempering mechanism on the tempering station of the welding process after normalizing treatment, or the welding area of the online strip steel carries out online and continuous welding brittleness treatment by the brittleness treatment device in the place of the brittleness treatment process. The brittleness treatment process suitable for welding is the next process after welding.

Owner:WUHAN KAIQI SPECIAL WELDING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com