Laser welding machine provided with on-line continuous heat-treatment for welding seam

A laser welding machine and laser welding technology, applied in heat treatment furnaces, heat treatment equipment, other manufacturing equipment/tools, etc., can solve the problems of easy welding stress, hydrogen-induced cracks, high degree of hardening, etc., to reduce the degree of hardening, Effect of reducing welding strain rate and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

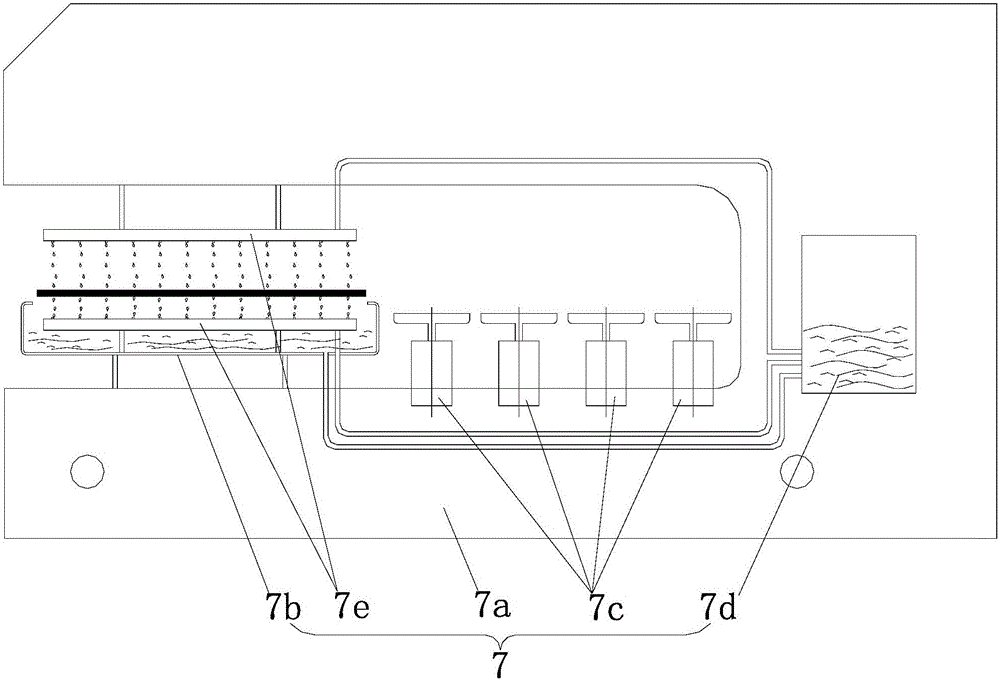

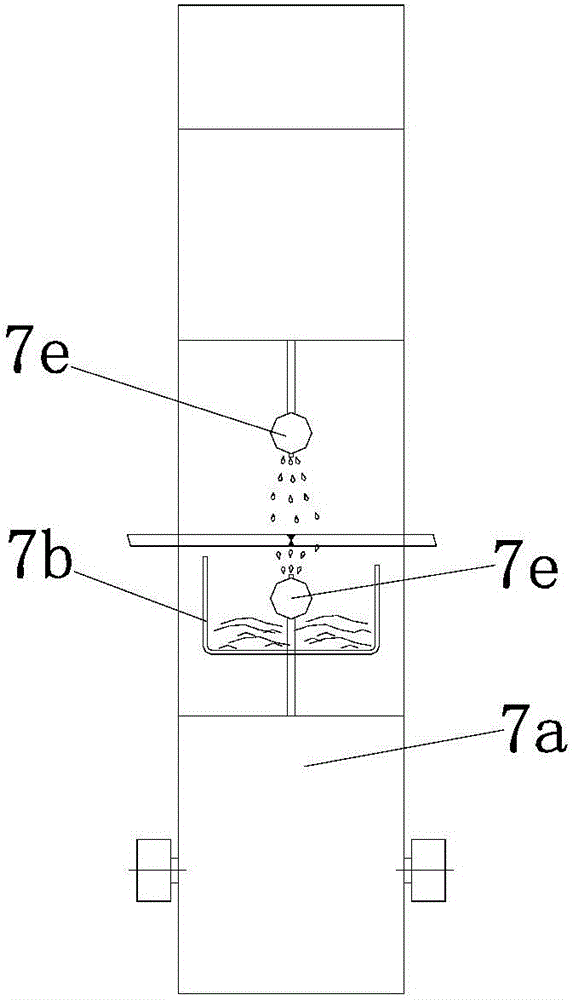

[0035] A laser welding machine with on-line continuous welding seam heat treatment, comprising a welding trolley 1, and a shearing device 2, a laser welding device 3 and a rolling device 4 which are sequentially installed on the welding trolley 1, on the welding trolley 1 Corresponding to the position in front of the laser welding device 3 is provided with a preheating device 5 capable of continuously raising and preheating the welding area online, and the preheating device 5 is arranged between the shearing device 2 and the laser welding device 3, The welding trolley 1 is provided with a heat treatment device 6 that can perform on-line continuous welding seam heat treatment on the welding seam area at a position corresponding to the rear of the laser welding device 3. By preheating the welding area before welding, it can not only reduce the welding stress, but also reduce the welding strain rate, which is beneficial to avoid welding cracks and the escape of diffused hydrogen in...

Embodiment 2

[0040] Embodiment 2 (for high-strength alloy steel and high-phosphorus steel, etc., of course, 400 series stainless steel can also adopt the scheme of this embodiment, but it is easy to produce brittleness):

[0041] A laser welding process with on-line continuous weld heat treatment, including the following steps:

[0042] 1) On-line strip steel is cut and seamed through the cutting device 2 at the cutting station of the welding process;

[0043] 2) After the shearing and splicing is completed, the welding area of the online strip is continuously heated and preheated to 100-200°C through the preheating device 5 at the preheating station of the welding process;

[0044] 3) After warming up and preheating, the online strip is welded by the laser welding device 3 at the welding station of the welding process;

[0045] 4a1) After the welding is completed, the weld area of the on-line strip is normalized once through the primary normalizing mechanism 6a1 at the primary normalizing stati...

Embodiment 3

[0051] Example 3 (specially for 400 series stainless steel):

[0052] A laser welding process with on-line continuous weld heat treatment, including the following steps:

[0053] 1) On-line strip steel is cut and seamed through the cutting device 2 at the cutting station of the welding process;

[0054] 2) After the shearing and splicing is completed, the welding area of the online strip is continuously heated and preheated to 100-200°C through the preheating device 5 at the preheating station of the welding process;

[0055] 3) After warming up and preheating, the online strip is welded by the laser welding device 3 at the welding station of the welding process;

[0056] 4a1) After the welding is completed, the weld area of the on-line strip is normalized once through the primary normalizing mechanism 6a1 at the primary normalizing station of the welding process, and the primary normalizing temperature is 600~ 800°C;

[0057] 4a2) After the primary normalization is completed, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com