Heat-conducting electric-insulating epoxy resin potting adhesive and preparation method thereof

An epoxy resin, heat conduction and insulation technology, applied in the direction of epoxy resin glue, chemical instruments and methods, adhesives, etc., can solve the problems of affecting the efficiency and life of electronic components, not conducive to the heat dissipation of electrical components, and poor insulation of finished products. Achieve effective heat conduction and insulation, improve the elimination of cracking, and improve the effect of brittleness

Active Publication Date: 2014-12-03

LIMING RES INST OF CHEM IND

View PDF3 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although metal materials have high thermal conductivity, they can also be used as fillers for thermally conductive polymer composite materials. However, due to the electrical conductivity of metal materials, the finished products have poor insulation and are easy to break down, which affects the efficiency and life of electronic components.

The thermal conductivity of silica micropowder commonly used in inorganic thermally conductive fillers is low, and the thermal conductivity of potting materials filled with silica micropowder is also low, less than 0.6W / (m K), which is not conducive to the heat dissipation of electrical components

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

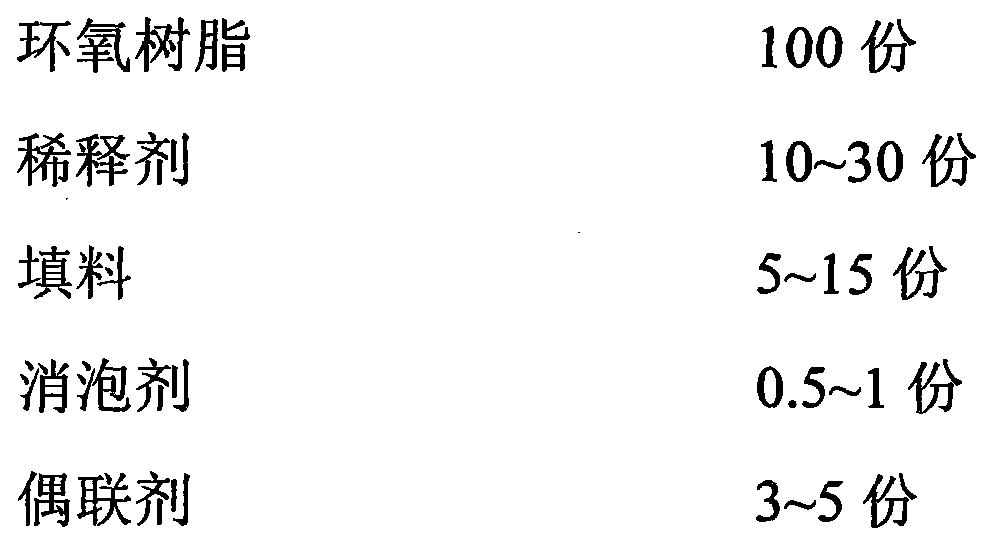

[0033] A component:

[0034]

[0035]

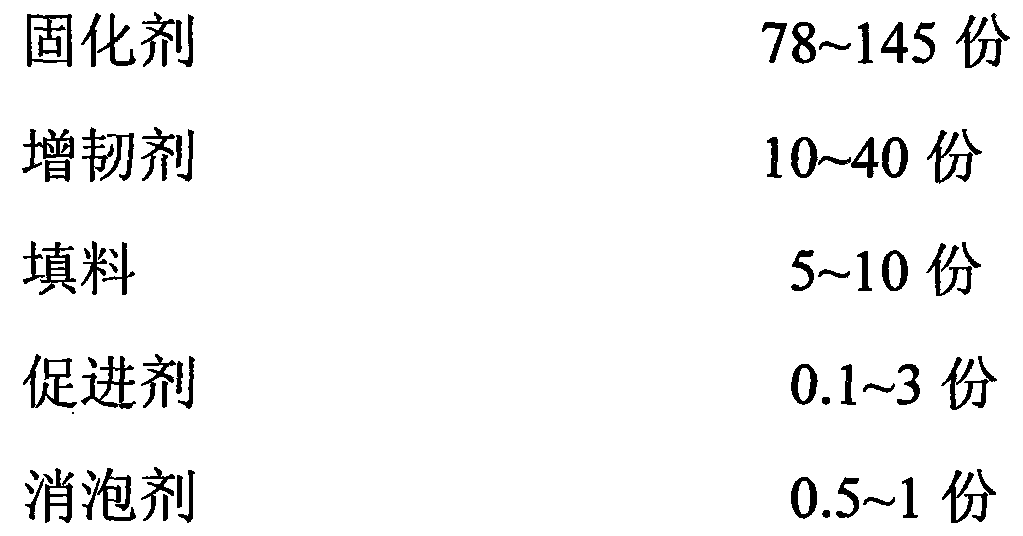

[0036] B component:

[0037]

Embodiment 2

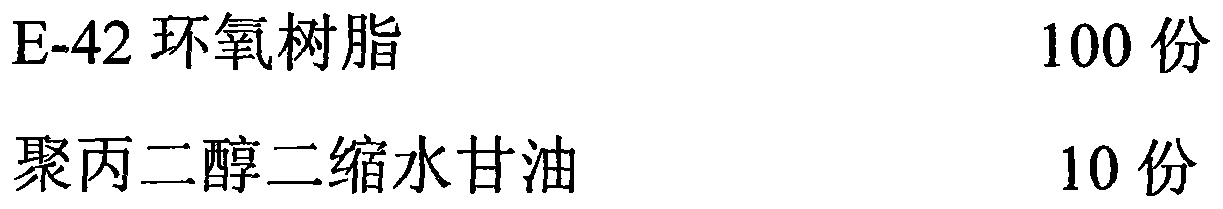

[0039] A component:

[0040]

[0041] B component:

[0042]

Embodiment 3

[0044] A component:

[0045]

[0046] B component:

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a heat-conducting electric-insulating epoxy resin potting adhesive which is composed of an epoxy resin, a curing agent, a toughener, a diluter, a filler, an accelerator and a defoaming agent. The component A is composed the following components in parts by weight: 100 parts of epoxy resin, 10-30 parts of diluter, 5-15 parts of filler, 0.5-1 part of defoaming agent and 3-5 parts of coupling agent. The component B is composed the following components in parts by weight: 78-145 parts of curing agent, 10-40 parts of toughener, 5-10 parts of filler, 0.1-3 parts of accelerator and 0.5-1 part of defoaming agent. The A / B weight ratio is 1:1. The toughener is epoxy hydroxyl-terminated polybutadiene acrylonitrile. The filler is composite powder composed of nano magnesium silicon nitride, nano silicon carbide, nano aluminum nitride, nano boron nitride, high-sphericity nano aluminum oxide and nano silicon nitride with different particle sizes, and the average particle size is 40-60nm. The potting adhesive has the advantages of favorable thermal conductivity and favorable electric insulating property.

Description

technical field [0001] The invention relates to the technical field of adhesive preparation, in particular to a thermally conductive and insulating epoxy resin potting adhesive and a preparation method thereof. Background technique [0002] Epoxy resin potting glue is a kind of thermosetting polymer composite material with good adhesion, corrosion resistance, electrical insulation, high strength and other properties. Indispensable basic material in many industrial fields. [0003] With the development of microelectronics and integrated circuits in the direction of high speed, high density, miniaturization, and light weight, the volume of electronic components and logic circuits is continuously compressed, and the heat generated per unit volume of electronic equipment increases sharply, so the thermal conductivity will decrease. Affect the life and reliability of electronic components and electronic equipment. In order to ensure the normal operation of electronic components...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J163/00C09J11/04C09J11/06C09J11/08C09K3/10

Inventor 王勃袁伟于文杰吴强赵传富

Owner LIMING RES INST OF CHEM IND

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com