Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170results about "Storage discharge welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

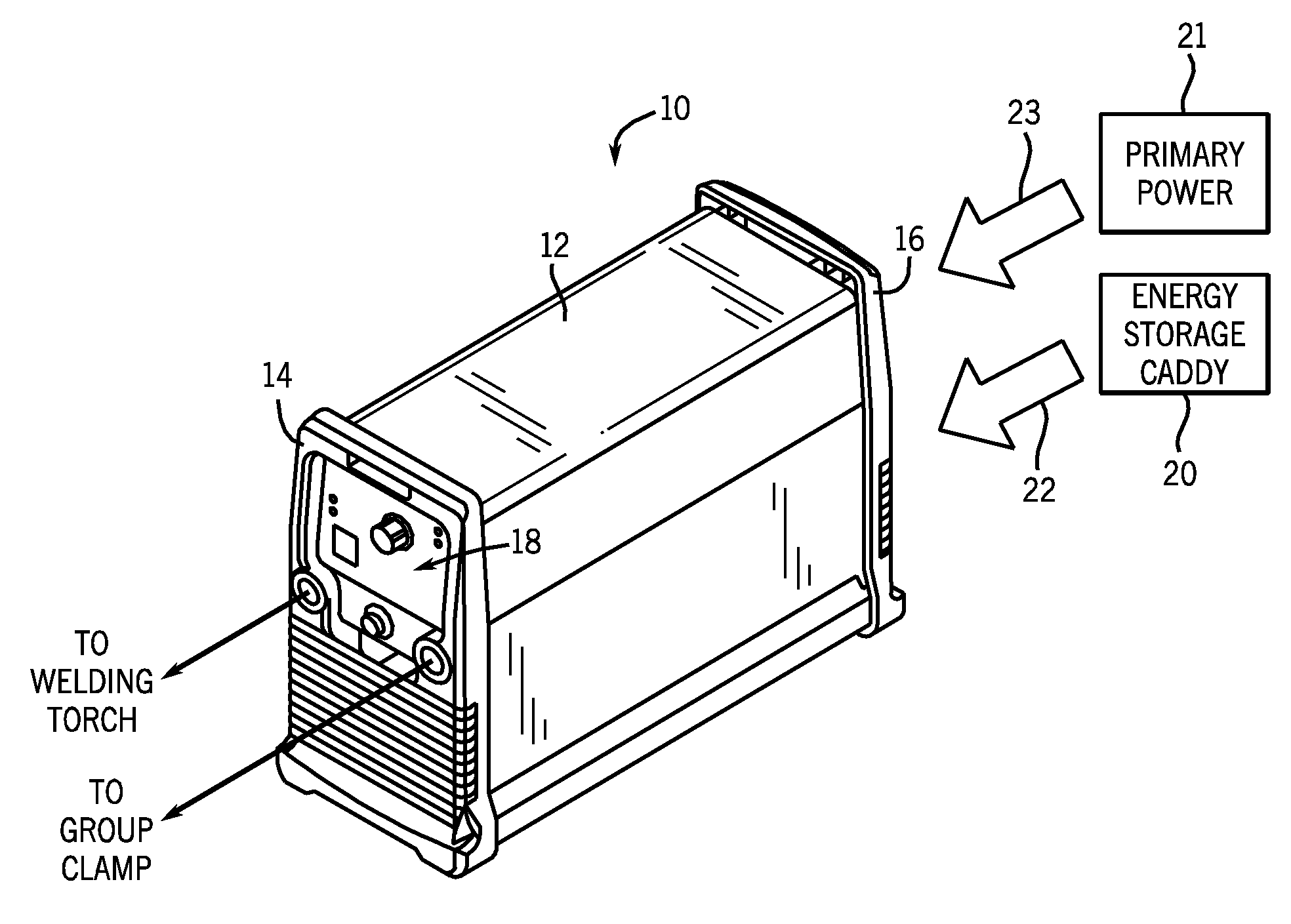

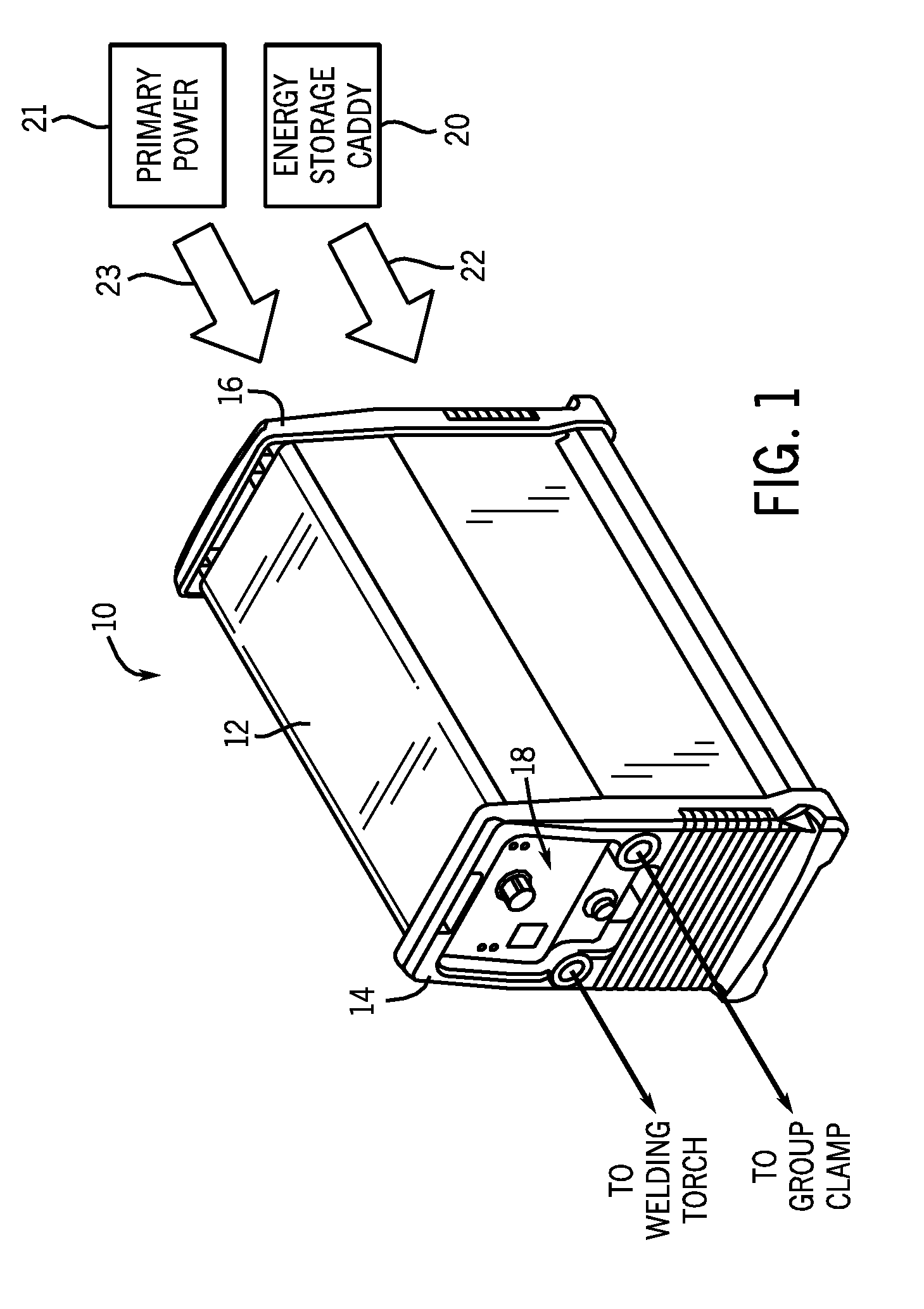

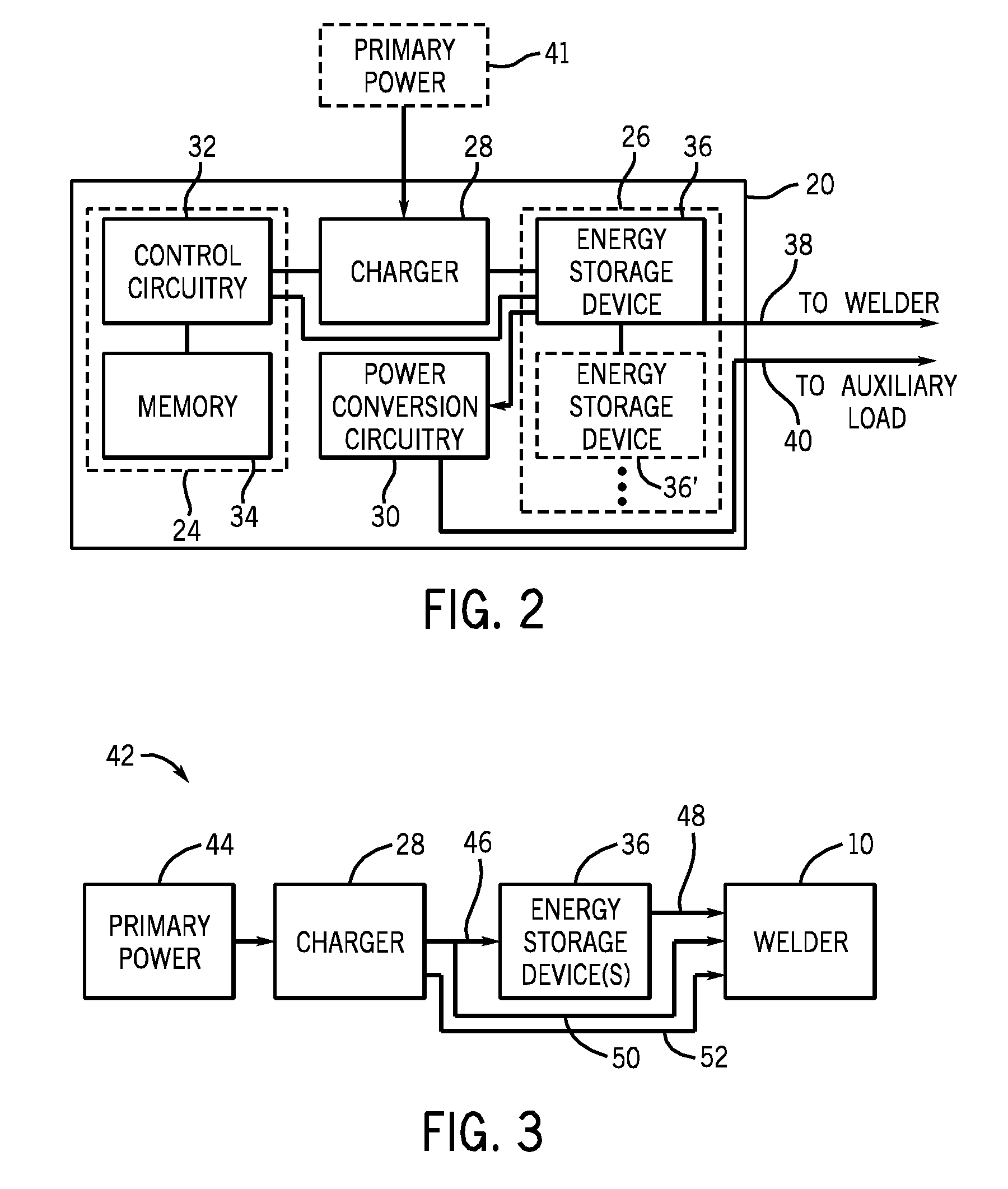

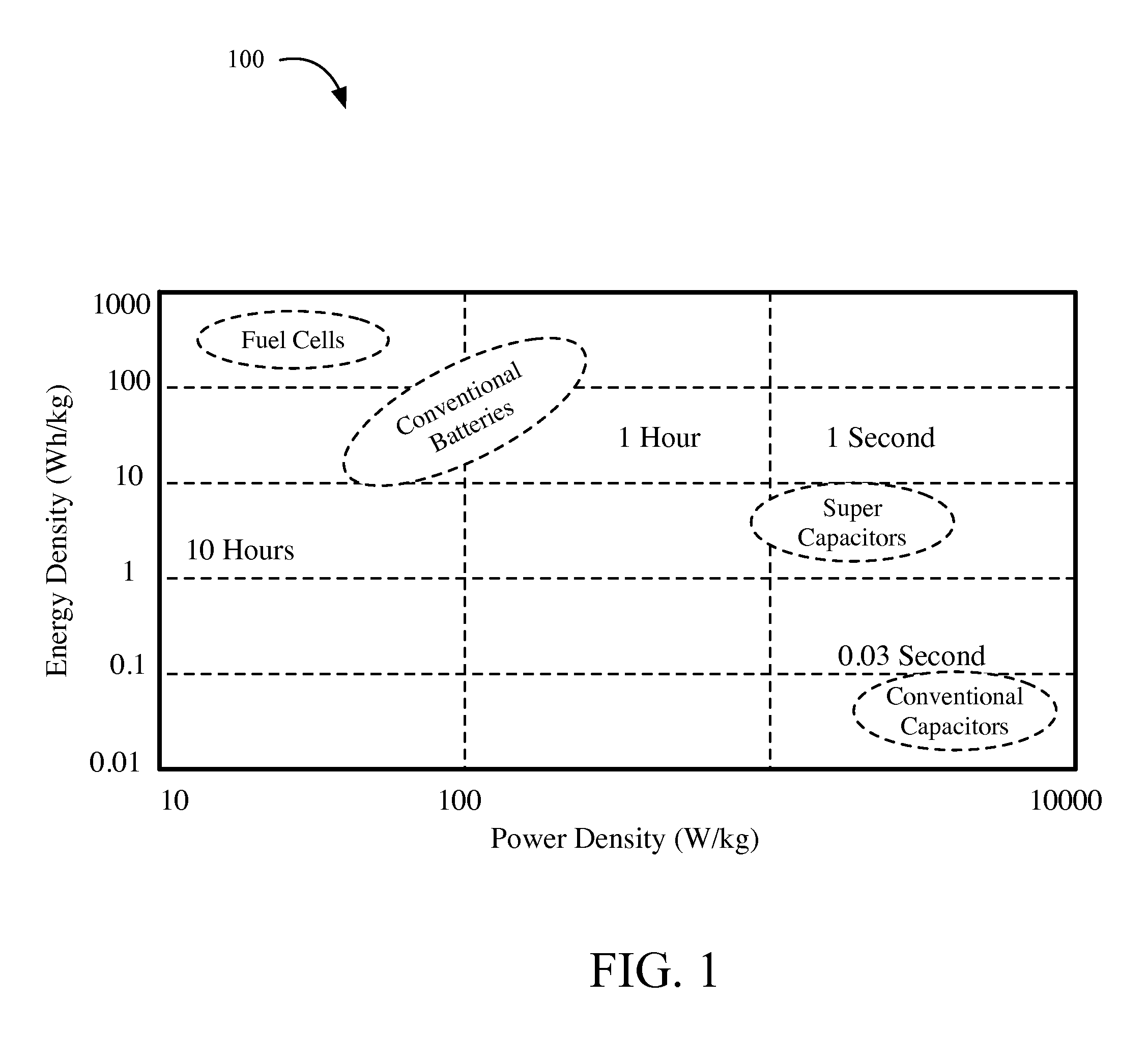

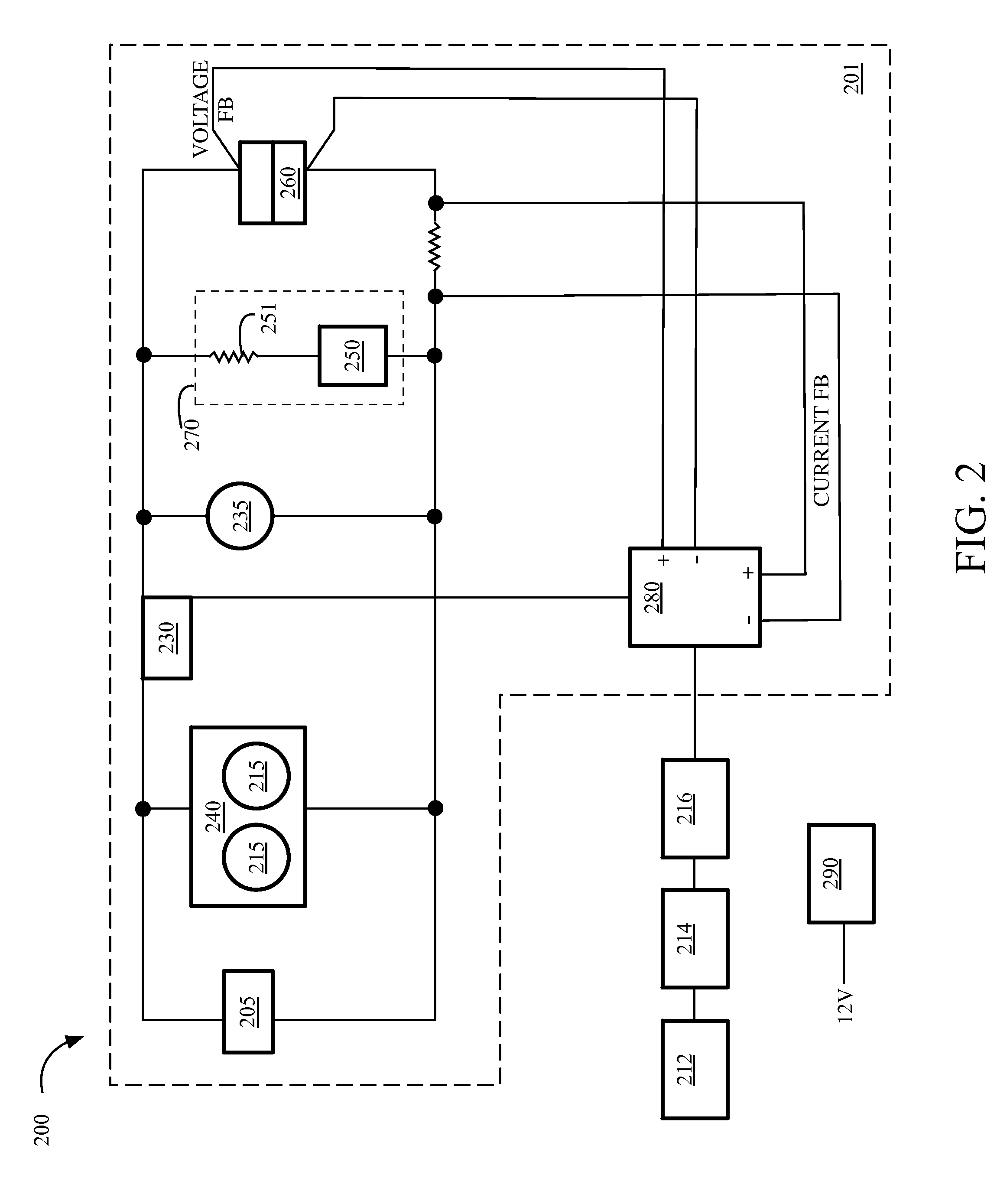

Energy storage caddy for a welding system

ActiveUS20110114608A1Circuit monitoring/indicationDifferent batteries chargingWelding power supplyControl circuit

Embodiments of energy storage caddies adapted to couple to a welding power supply are provided. The energy storage caddies may include an energy storage device, a charger, control circuitry, and power conversion circuitry. Certain control circuitry may be adapted to control the energy storage device to discharge to provide a direct current (DC) voltage output to the welding power supply when a weld load demand is detected, to monitor a charge level of the energy storage device, and to alert a user to an error when the charge level of the energy storage device falls below a predetermined limit.

Owner:ILLINOIS TOOL WORKS INC

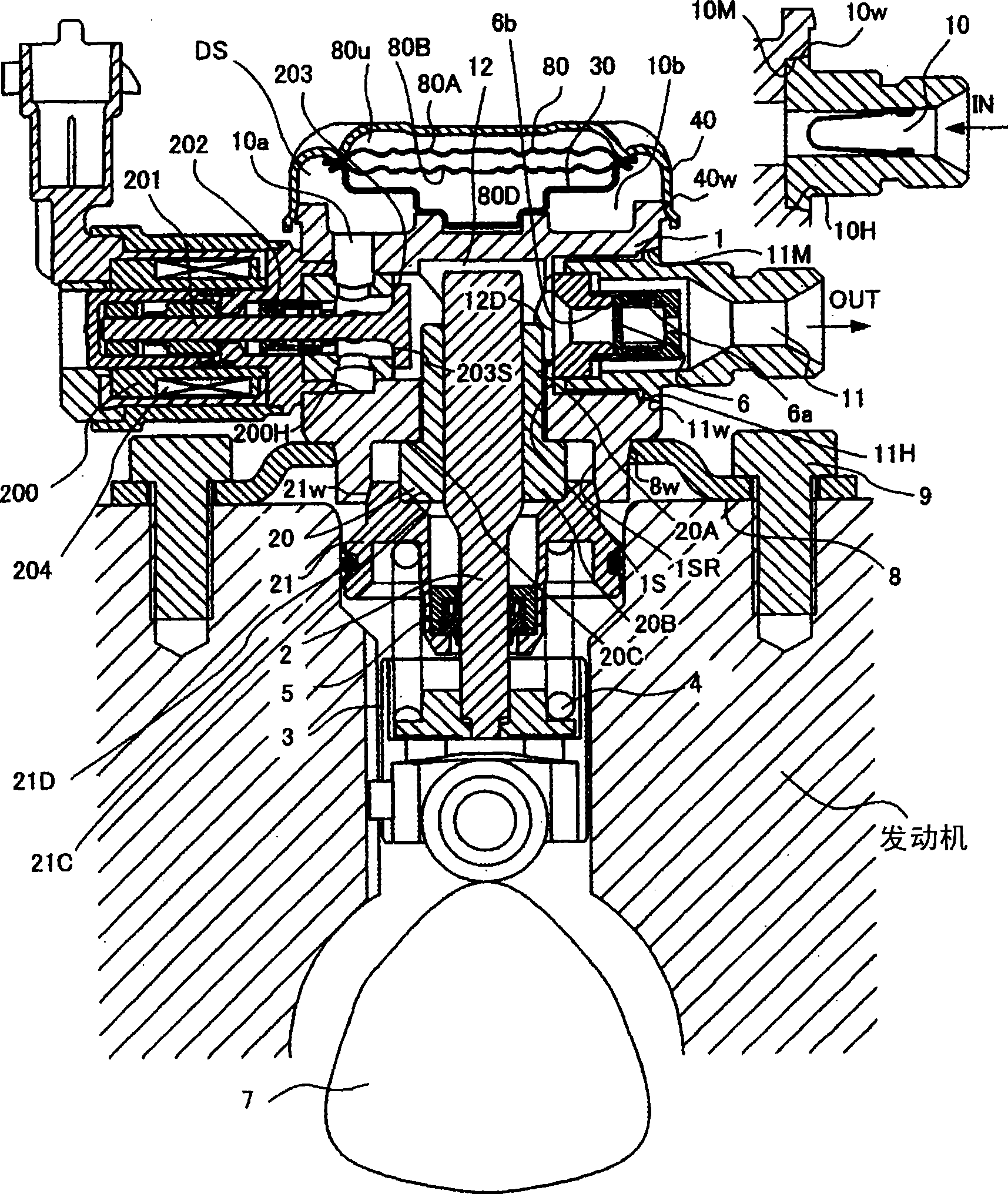

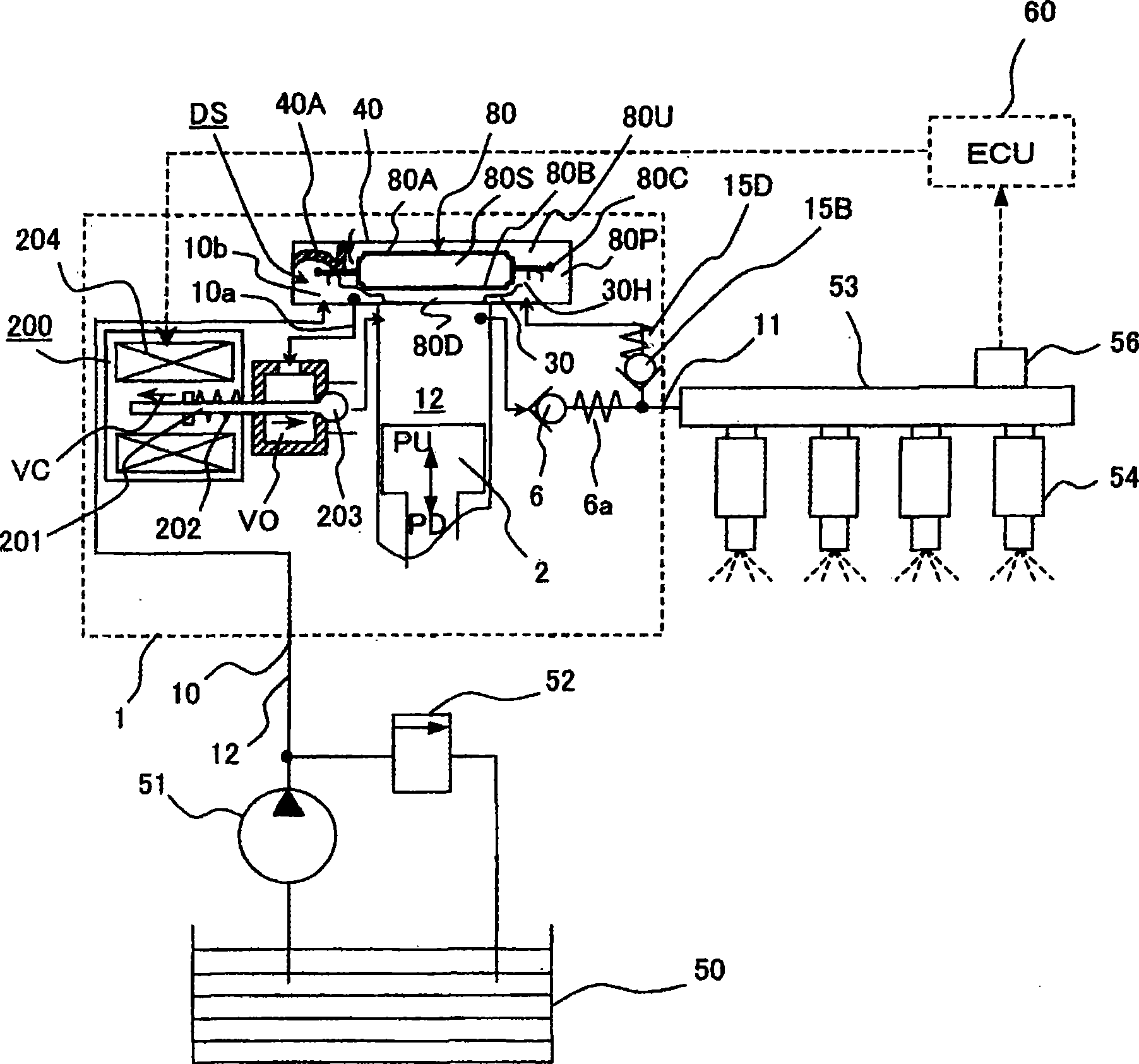

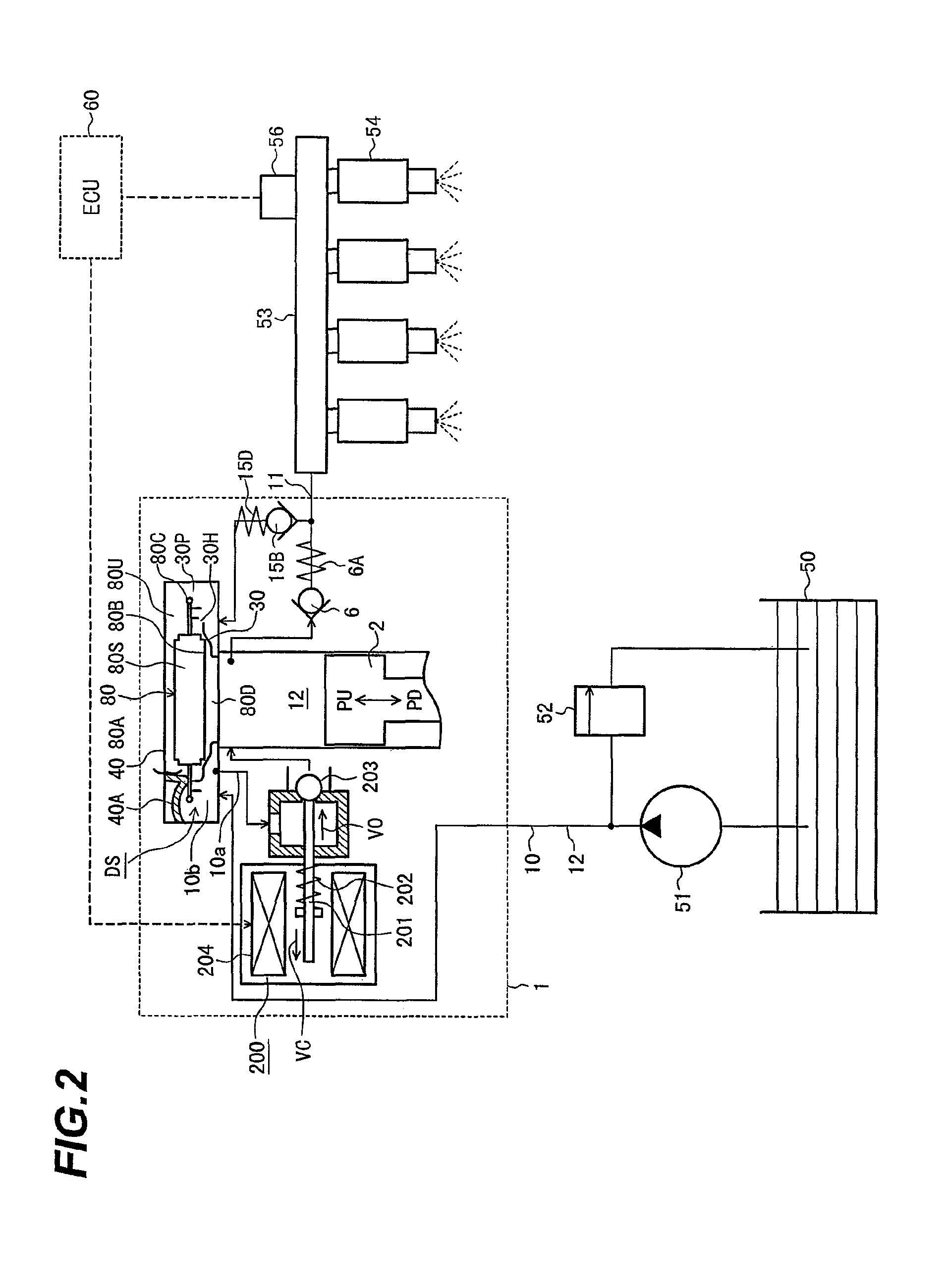

High-pressure fuel supply pump and the manufacturing method

InactiveCN101424235ARealize the joint functionRealize the sealing functionTubular articlesHollow articlesInlet valveMetallic materials

An object of this invention is to provide such a welded structure of and welding method for two metallic parts fitted together at a tubular section in a high-pressure fuel supply pump, that enables rapid joining of both metallic parts by staking (press-fitting included), screw fastening, and / or laser welding, offers high welding strength and sufficient fluid sealability, and keeps the metallic materials free from thermal changes in composition. While an electric current is supplied to any one of the welding connection surfaces formed between a pump housing and cylinder in a high-pressure fuel supply pump, between the pump housing and an installation flange, between the pump housing and an intake or discharge joint, between the pump housing and a pulsation-absorbing damper cover, between the pump housing and a relief valve mechanism, and between the pump housing and an electromagnetically driven intake valve mechanism, the particular two sections are pressed against each other to generate, along the connection surface, a plastic flow not causing melting or fusion due to heat, and form a diffusion-weld region at the connection surface by using the plastic flow and the application of the pressure.

Owner:HITACHI LTD

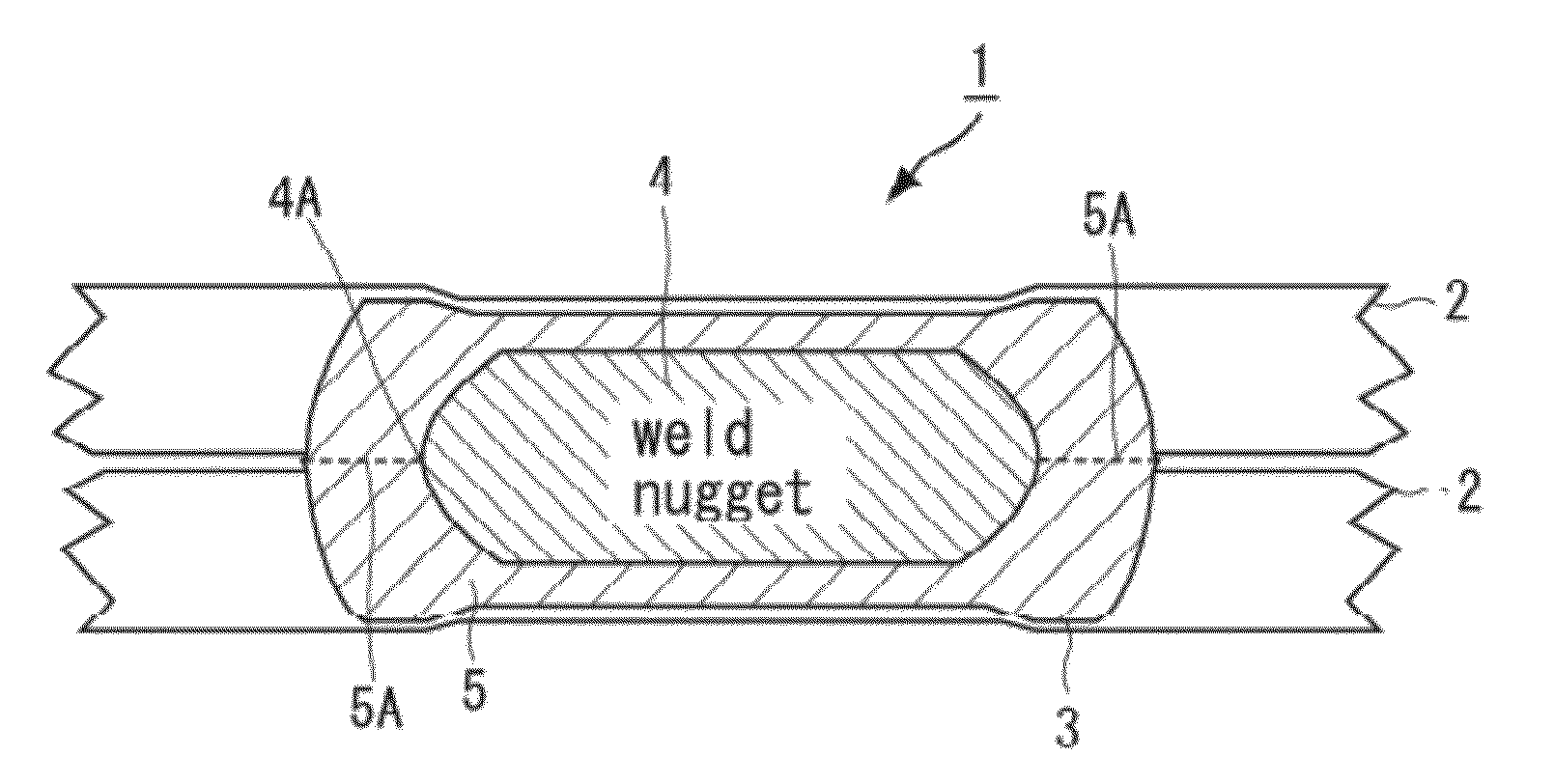

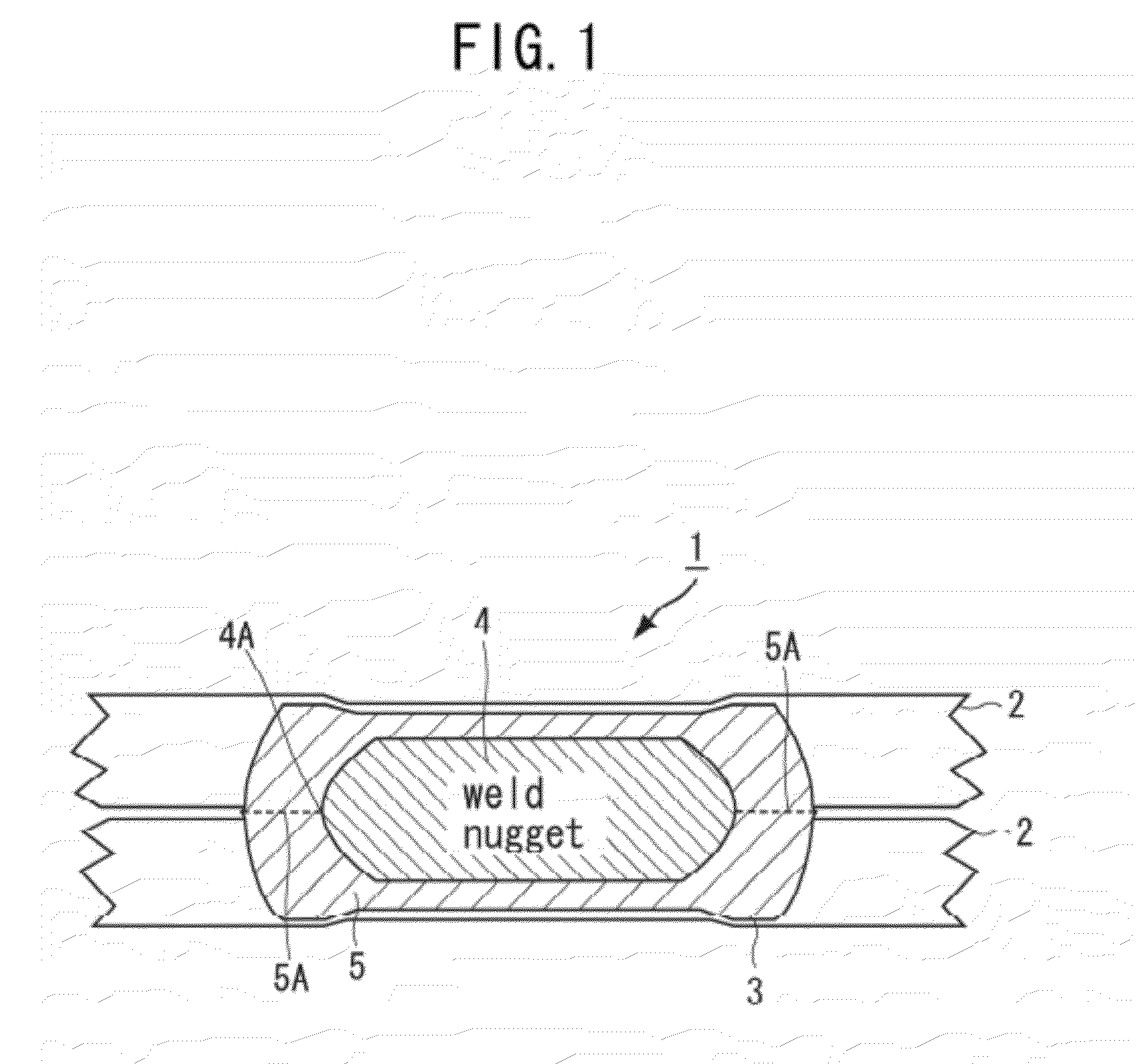

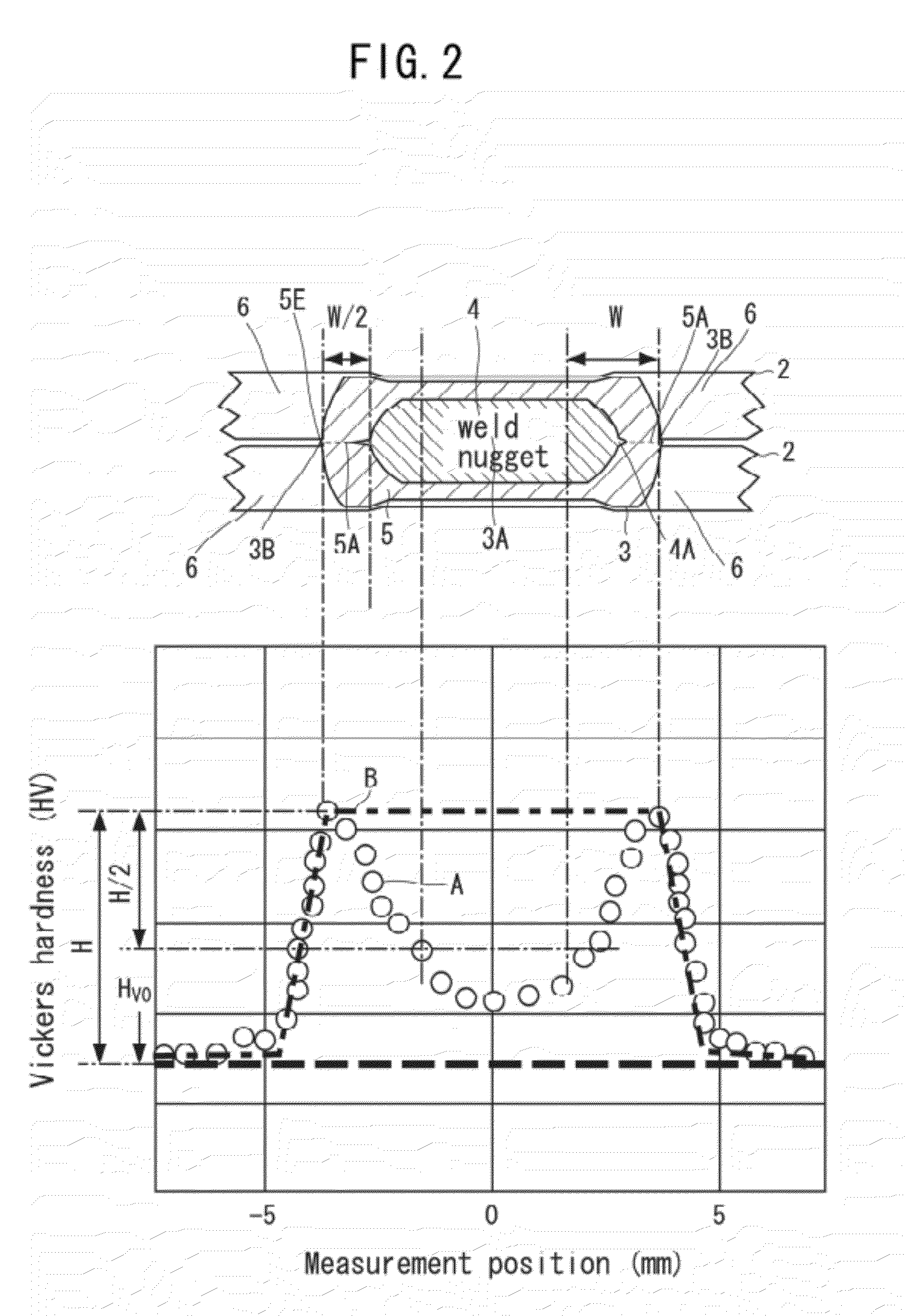

Welding structural part and welding method of the same

InactiveUS20120129006A1Highly strong and tough spot weld zoneHigh breaking strengthElectrode supporting devicesVehicle componentsHeat-affected zoneEngineering

A welding structural part 1 is manufactured by overlapping the surfaces of steel sheets 2, and forming a weld zone by spot welding. The weld zone 3 includes: a weld nugget 4; and a heat affected zone 5 surrounding the weld nugget 4, wherein the hardness in the weld zone increases along an exterior region 6 of the heat affected zone 5 toward the heat affected zone 5, and then decreases along the heat affected zone 5 toward the central region of the weld nugget 4. In the boundary region between the weld nugget 4 and the heat affected zone 5, the weld nugget 4 may have a convex portion 4A bulging into the heat affected zone 5 along the overlapped portion. The steel sheets 2 contain carbon in 0.15 mass % or more.

Owner:NETUREN CO LTD +1

Fusion welding method and welded article

A fusion welding method is provided for fusion welding at juxtaposed interface surfaces a first member, for example made of a first metal based on at least one of Ru, Rh, Pd, and Pt, with a second member made of a second metal, for example a high temperature alloy based on at least one of Fe, Co, and Ni, including at least one identified element, for example Al, that can form a continuous layer of a brittle intermetallic compound with the first metal that is free of such element. With the interface surfaces disposed in contact, energy is generated at the interface surfaces in a combination of an amount and for a first time selected to be sufficient to heat the interface surfaces to a fusion welding temperature. However, the first time is less than a second time that enables formation at the fusion welding temperature of the continuous layer of the brittle intermetallic compound at the interface surfaces. A welded article is provided with a fusion weld free of such continuous layer of the brittle intermetallic compound.

Owner:GENERAL ELECTRIC CO

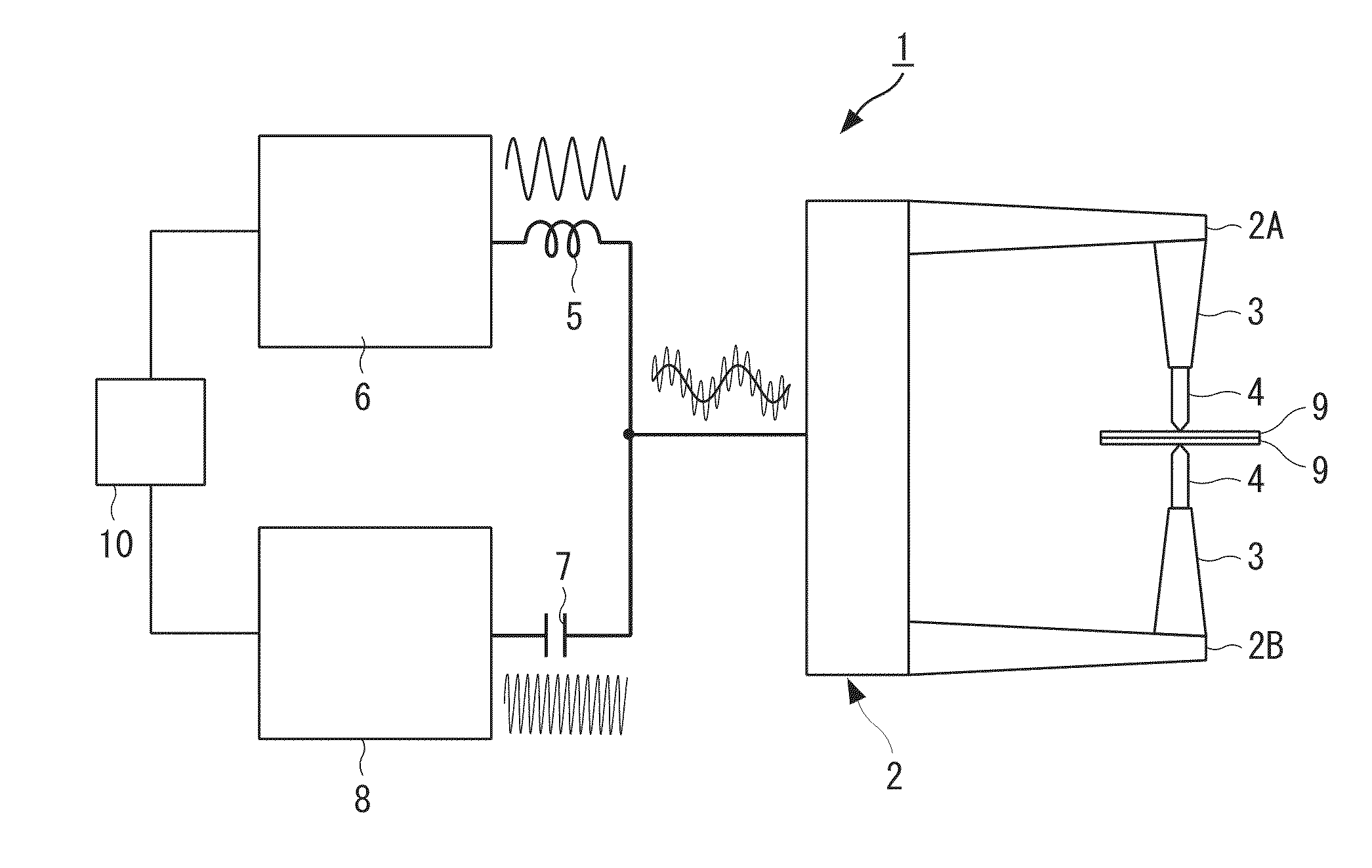

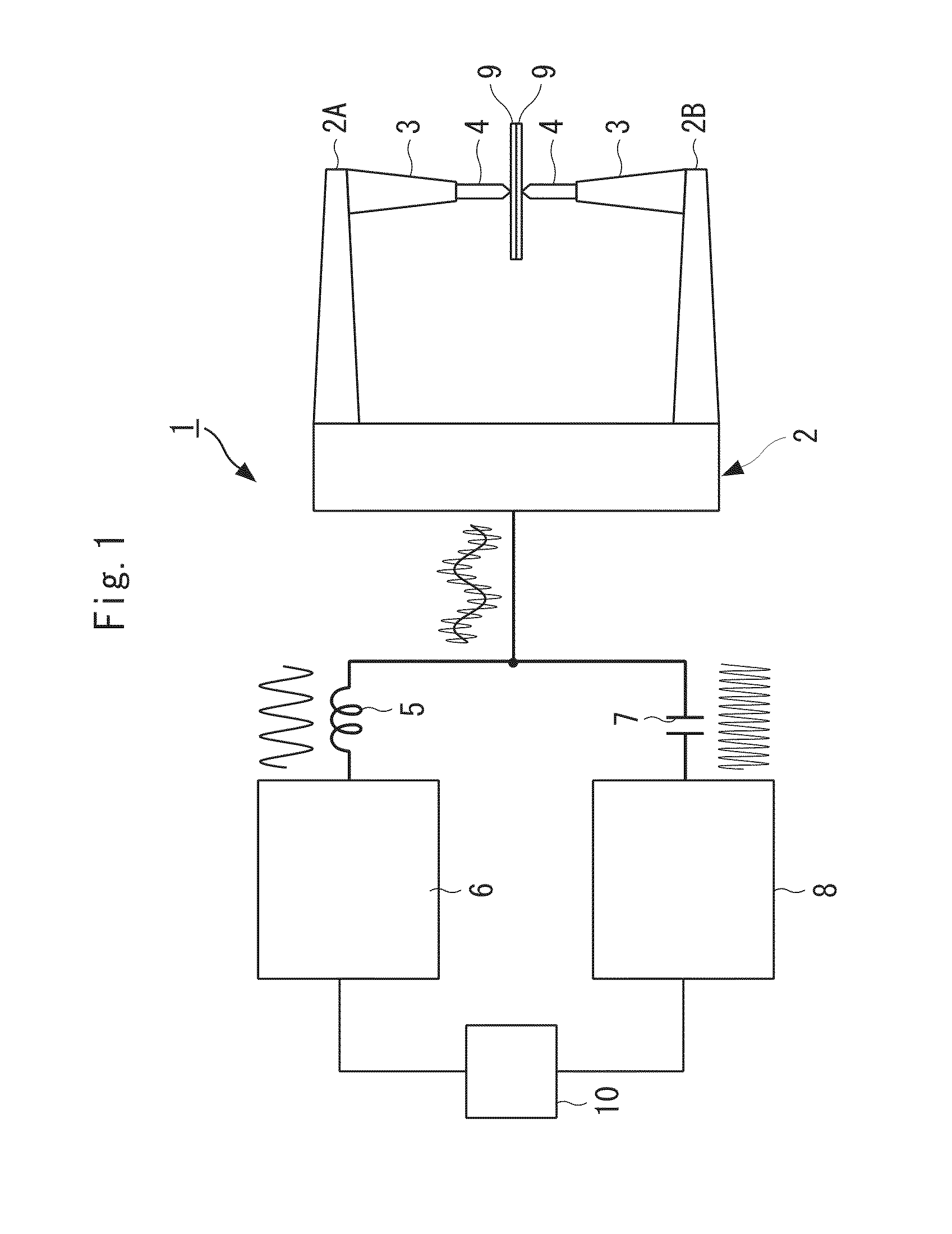

Welding equipment for metallic materials and method for welding metallic materials

InactiveUS20110303655A1Simple configurationFlexible heating treatmentArc welding apparatusWelding electric suppliesMetallic materialsSpot welding

A welding equipment for metallic materials capable of performing heat treatment such as tempering based on partial heating in spot welding is provided. The welding equipment 1 sandwiches metallic materials 9 with a pair of electrodes 4, 4, and heats different regions of the metallic materials 9 by energization, with the pair of electrodes 4, 4 maintained at the same position with respect to the metallic materials 9. The welding equipment includes a first heating means 6 connected to the pair of electrodes 4, 4 for heating and welding the internal region of the circle defined by projecting the cross-sectional area of the axis of the electrodes on the metallic materials by applying power having a low first frequency, a second heating means 8 for heating a ring-shaped region along the circle by applying power having a second frequency that is higher than the first frequency, and an energization control unit 10 for independently controlling the first and the second heating means 6, 8.

Owner:NETUREN CO LTD +1

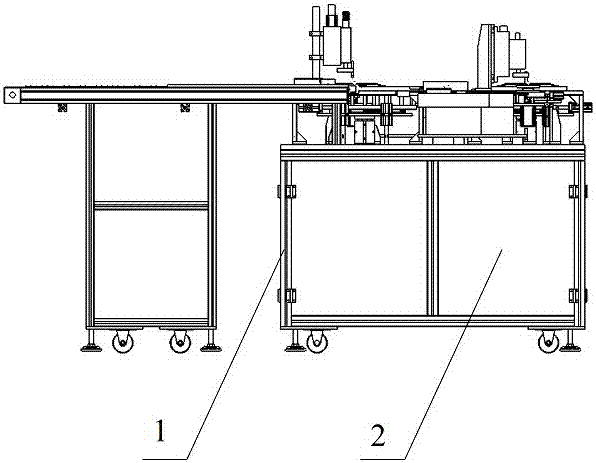

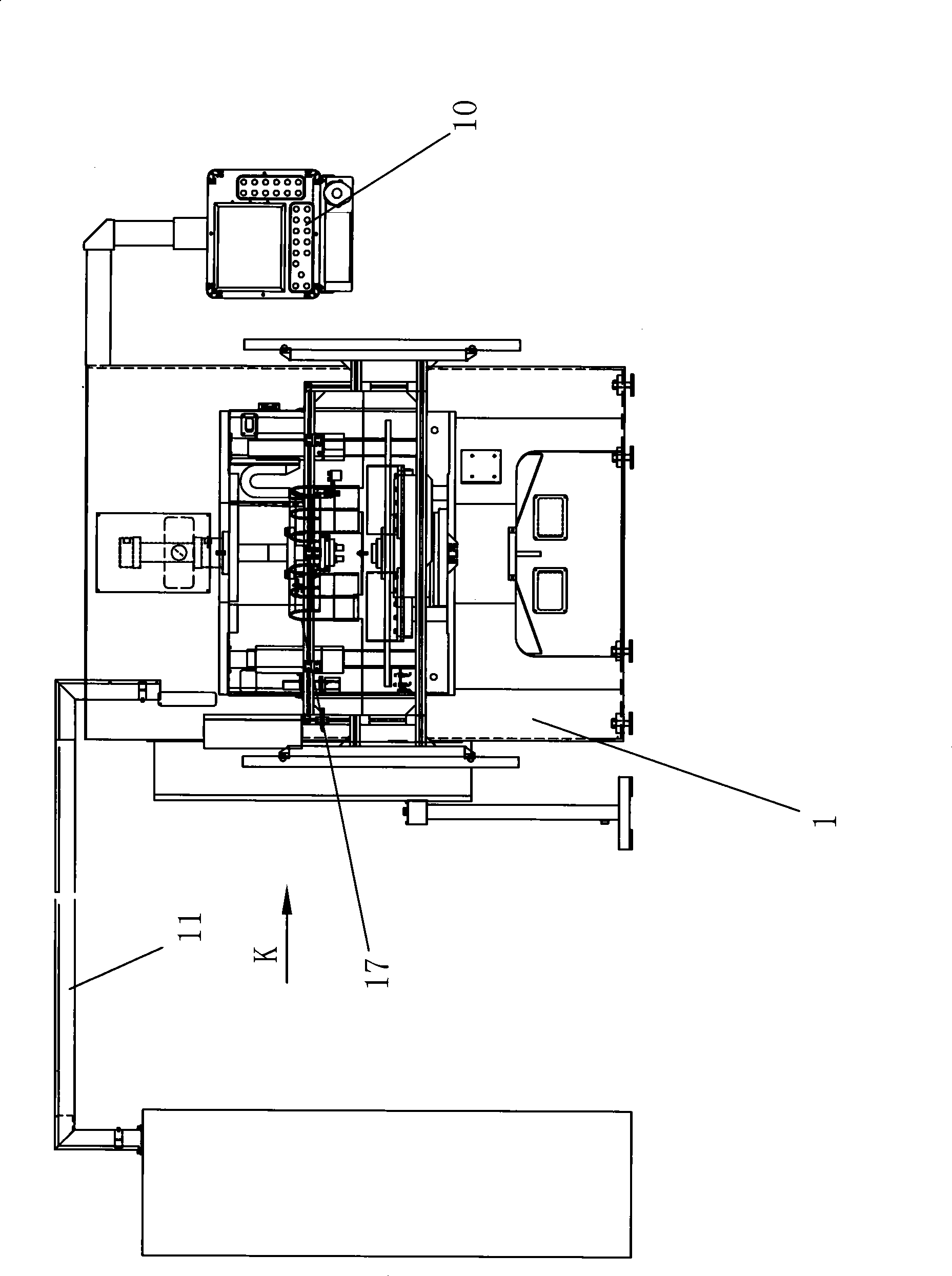

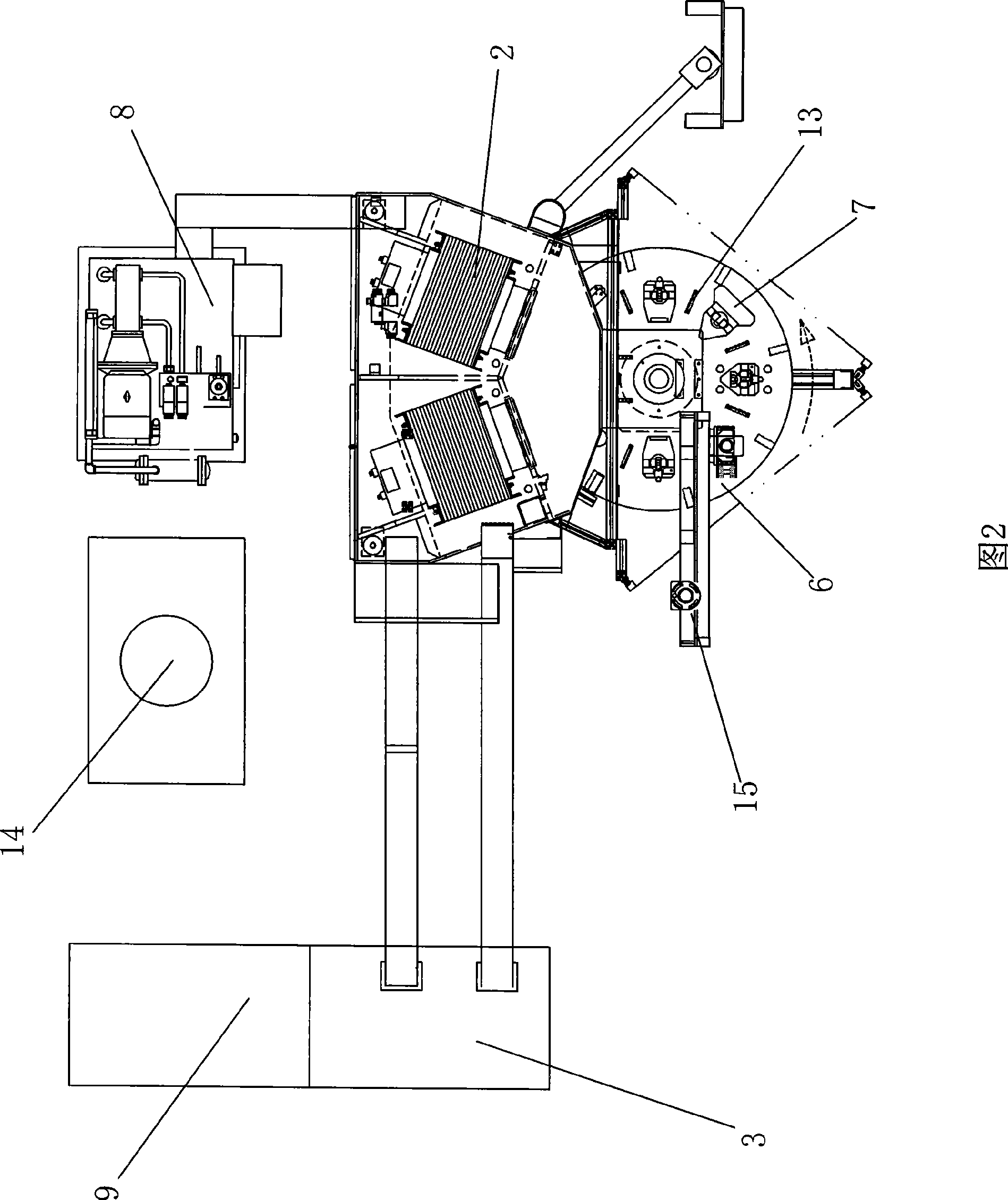

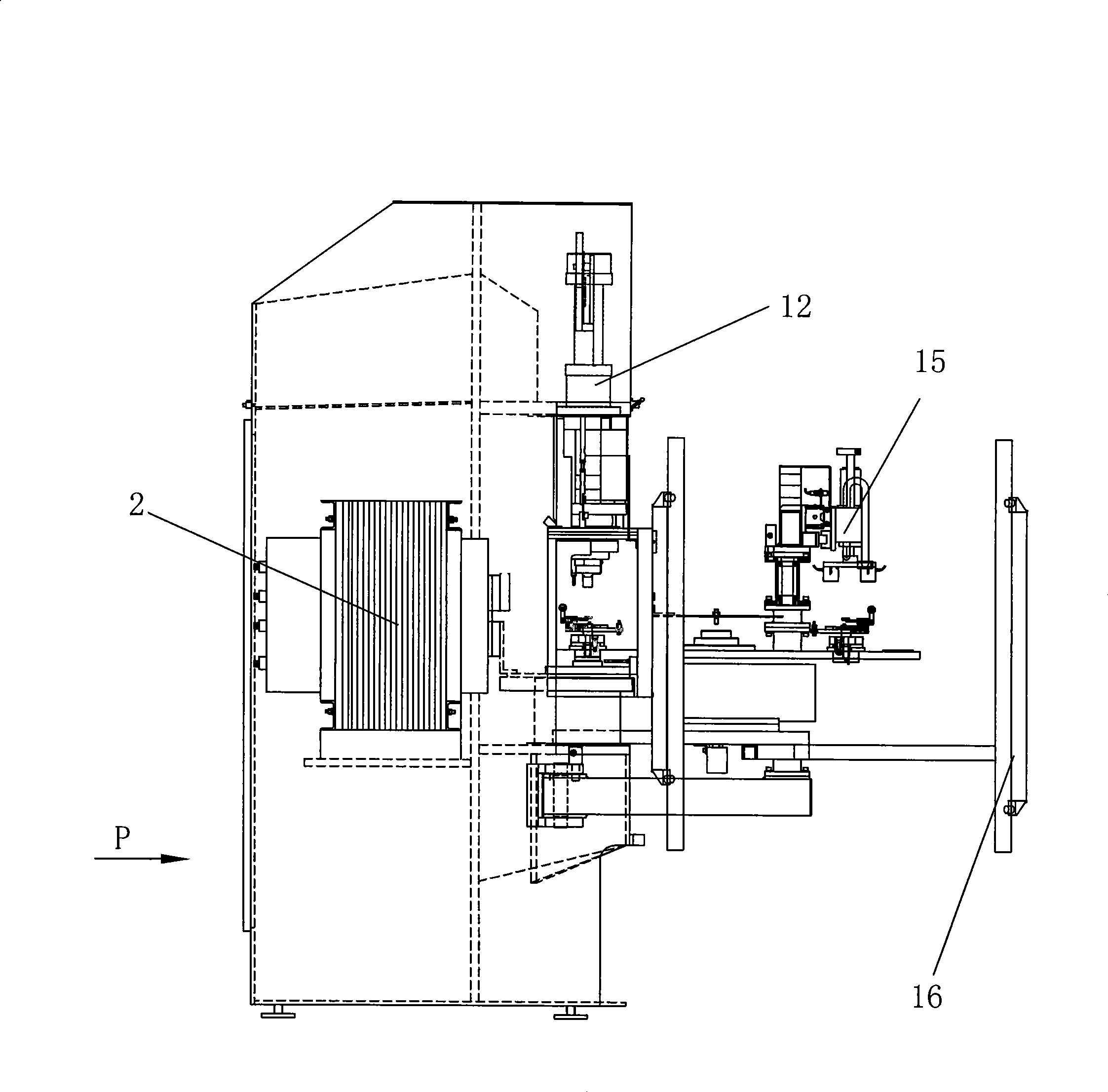

Automatic welding machine for lithium battery electrode lug

InactiveCN107414270AImprove welding efficiencyImprove welding qualityConductorsStorage discharge weldingLithium batteryElectrical and Electronics engineering

The object of the present invention is to provide a high-efficiency, high-quality lithium battery tab automatic welding machine. The lithium battery tab automatic welding machine can automatically weld the lithium battery and the tab, and at the same time, it can also automatically transport the welded lithium battery.

Owner:张亚平

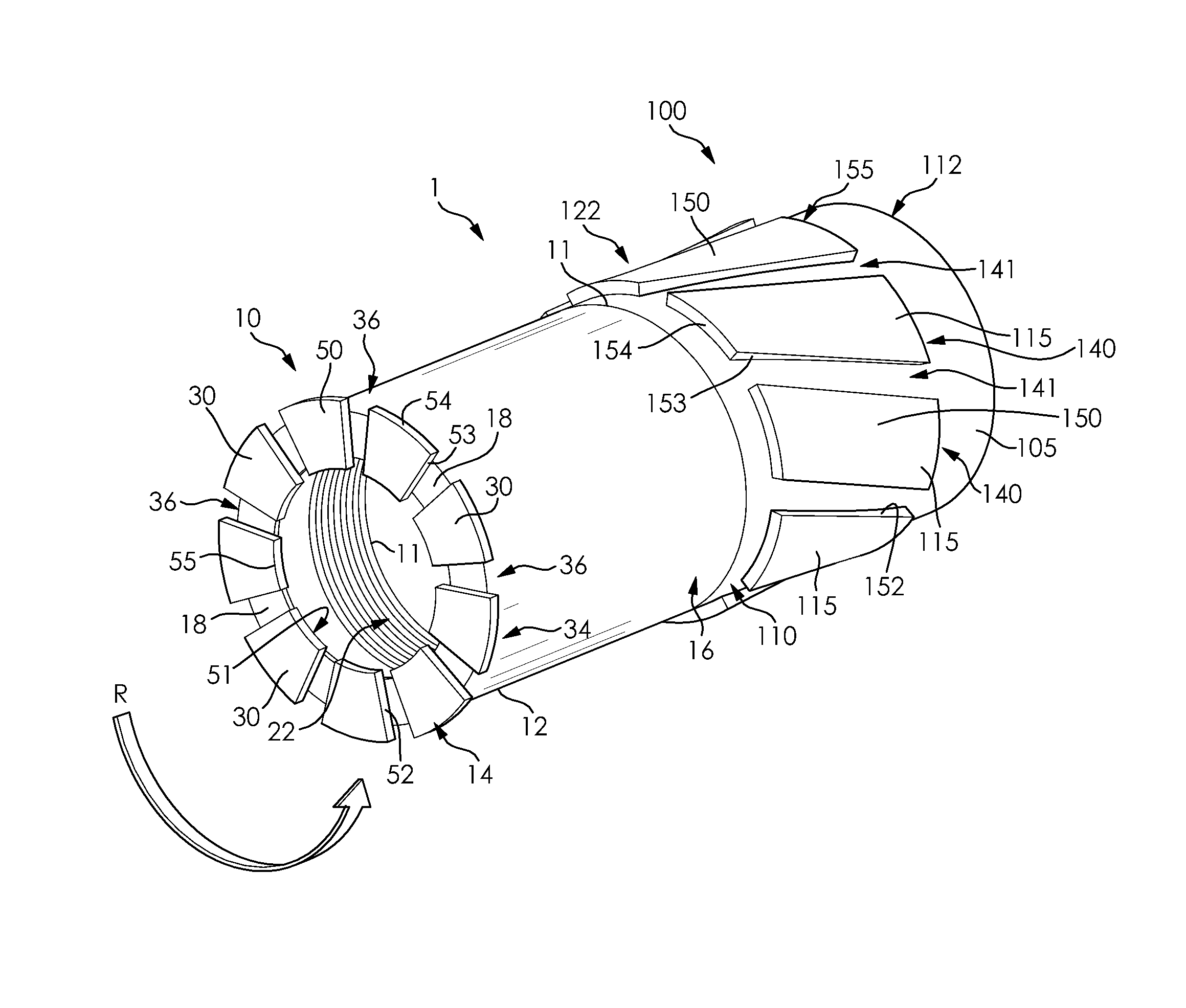

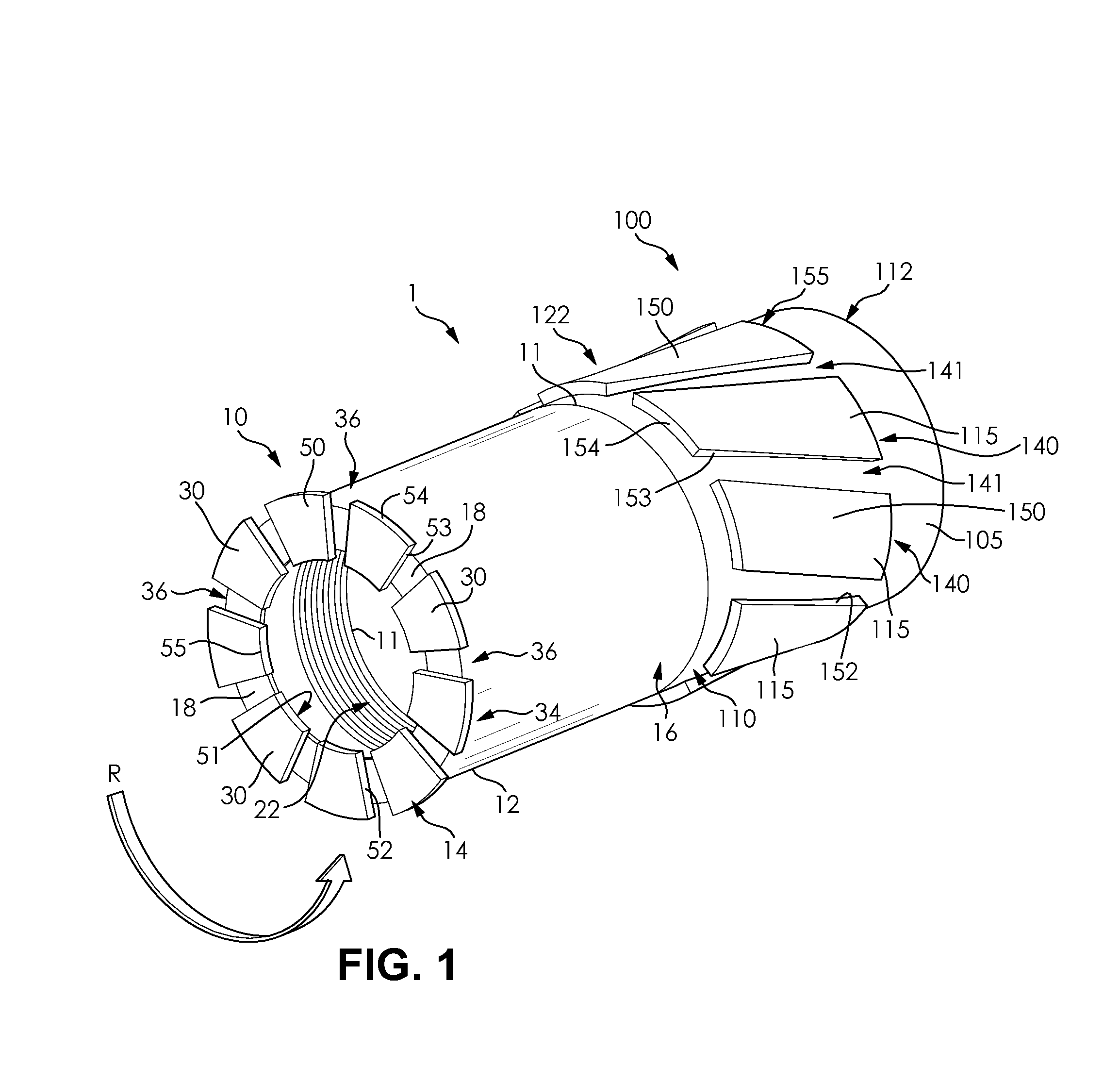

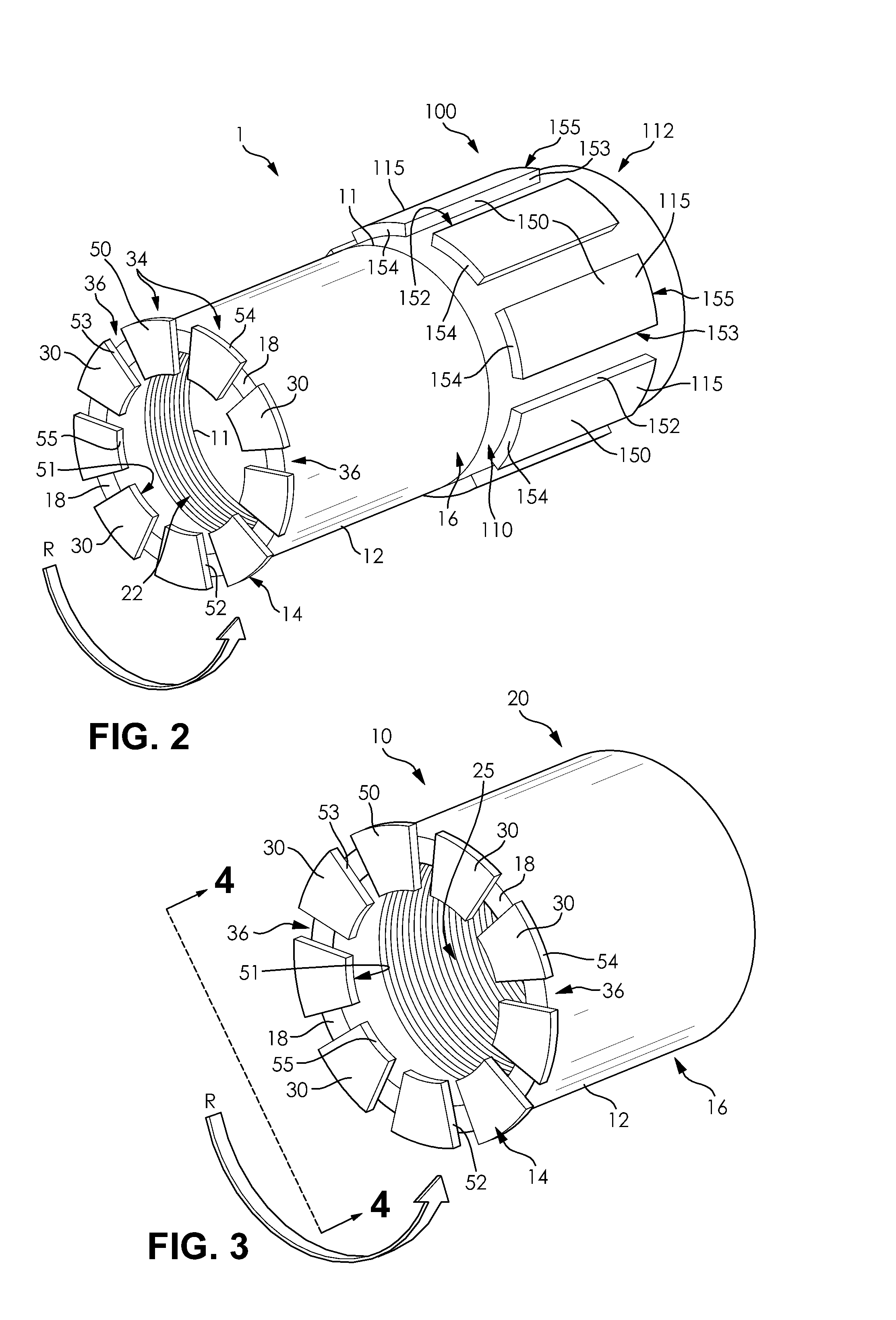

Method of making diamond mining core drill bit and reamer

A method of making a combination tool including a mining drill bit and reamer. The combination tool includes drill bit body having a plurality of cutting segments attached thereto, a reamer body having a plurality of reaming segments attached thereto, and the drill bit body and the reamer body being configured to selectively attach to the one another. The cutting segments and reamer segments being attached by laser welding to the drill bit body and reamer body, respectively.

Owner:DIAMOND PROD

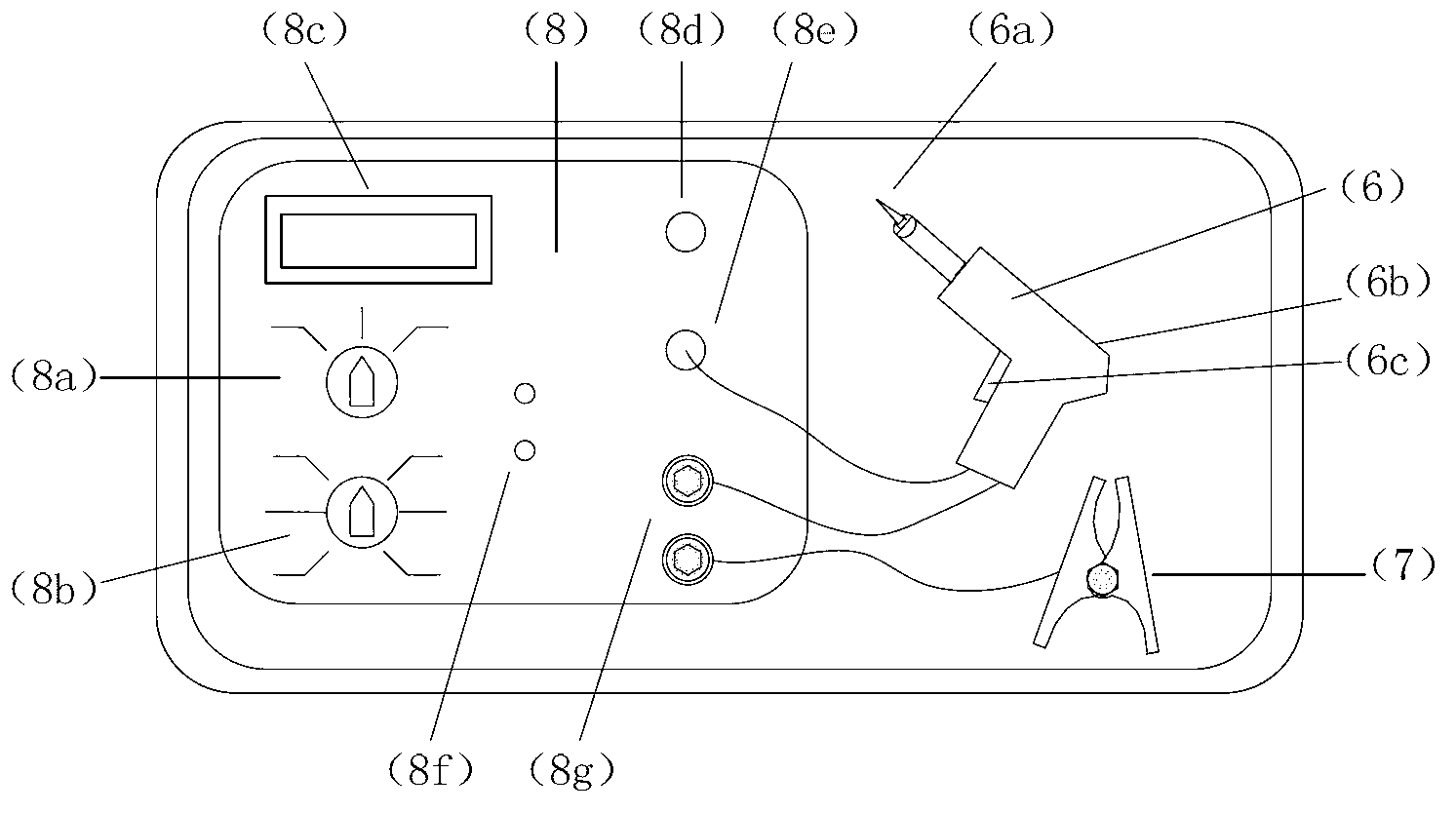

Portable miniature energy-storing spot welding machine

InactiveCN103252569ASimple structureSolve the problem of quick installation on siteStorage discharge weldingEnergy regulationEngineering

The invention provides a portable miniature energy-storing spot welding machine. The portable miniature energy-storing spot welding machine comprises a nickel-metal hydride battery pack (1) equipped with a charger, a spot welding control circuit module (2), an energy-storing charging switch (3), a Farad-level energy-storing capacitor (4), a spot welding discharging switch (5), a spot welding gun (6) provided with a manual control switch, a grounding clamp (7) connected with the welding machine through a cable, and an energy regulation and display panel (8), wherein the nickel-metal hydride battery pack (1), the spot welding control circuit module (2) and the energy-storing charging switch (3) are connected mutually, the spot welding control circuit module (2) is further connected with the spot welding discharging switch (5), the spot welding gun (6), the grounding clamp (7) and the energy regulation and display panel (8), the energy-storing charging switch (3) is connected with the Farad-level energy-storing capacitor (4), the Farad-level energy-storing capacitor (4) is connected with the spot welding control circuit module (2), the energy-storing charging switch (3), the spot welding discharging switch (5) and the energy regulation and display panel (8), the spot welding discharging switch (5) is connected with the spot welding gun (6), the spot welding gun (6) is connected with the energy regulation and display panel (8), and the grounding clamp (7) is connected with the energy regulation and display panel (8). The portable miniature energy-storing spot welding machine is designed for welding thin / ultra-thin steel plates or delicate and miniature parts, and can be used for solving the problem of fast on-site installation of some sensors.

Owner:BEIJING UNIV OF TECH

Fusion welding method and welded article

InactiveUS20050092717A1Avoid insufficient heatingTurbinesArc welding apparatusChemical compoundSuperalloy

A fusion welding method is provided for fusion welding at juxtaposed interface surfaces a first member, for example made of a first metal based on at least one of Ru, Rh, Pd, and Pt, with a second member made of a second metal, for example a high temperature alloy based on at least one of Fe, Co, and Ni, including at least one identified element, for example Al, that can form a continuous layer of a brittle intermetallic compound with the first metal that is free of such element. With the interface surfaces disposed in contact, energy is generated at the interface surfaces in a combination of an amount and for a first time selected to be sufficient to heat the interface surfaces to a fusion welding temperature. However, the first time is less than a second time that enables formation at the fusion welding temperature of the continuous layer of the brittle intermetallic compound at the interface surfaces. A welded article is provided with a fusion weld free of such continuous layer of the brittle intermetallic compound.

Owner:GENERAL ELECTRIC CO

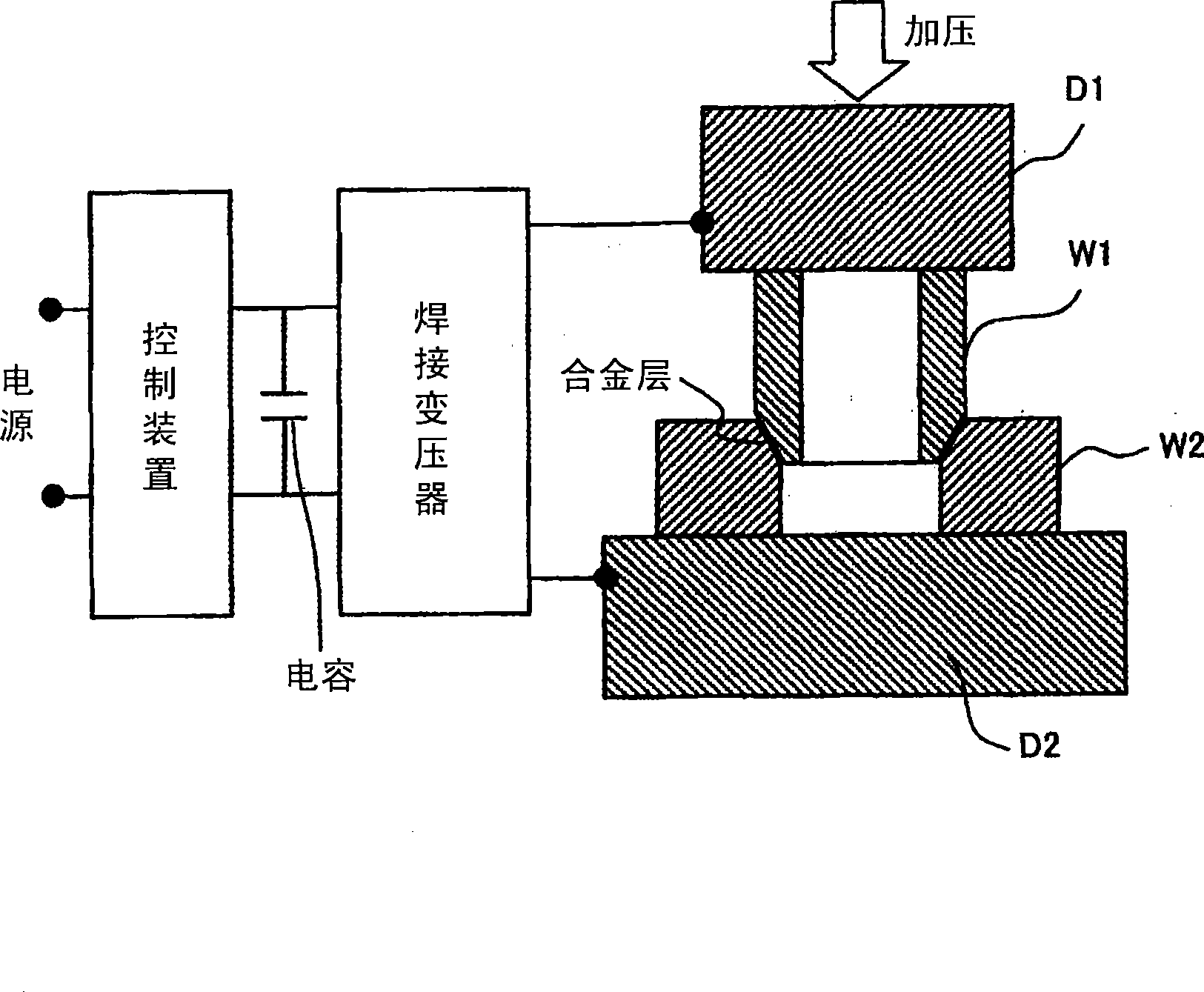

Projection welding method of double pulse high capacity capacitance for energy storage

InactiveCN1736649AImprove toughnessEliminate brittlenessStorage discharge weldingCapacitanceTransformer

Disclosed is a method for double-pulse high capacity condenser energy storage projection welding in the field of welding technique, which contains: overlapping and locating the two low-alloy steel workpieces on the static lower-electrode, the upper-electrode down to compact the joint of workpieces, charging the condenser bank to Uc1, after first-time discharging to welding transformer by the closure of the commutator and the trigger of thyristors which are controlled by a program, breaking the commutator; cooling, and charging the condenser bank to Uc2, and generating the second-time discharging to welding transformer by the closure of the commutator and the trigger of thyristors; breaking the commutator after the energisation, releasing the upper-electrode after constant pressure-maintaining, and the welding process being completed. The invention realizes welding and tempering double-pulse welding in the energy storage resistance projection welding, especially applies to the point welding (projection welding) of thick low-alloy steel, and it has a key action to the joint strength, the joint tenacity and the surface quality. And, compared with other resistance welding power, it decreased the capacity requirement to the power of live wire entanglement.

Owner:SHANGHAI JIAO TONG UNIV

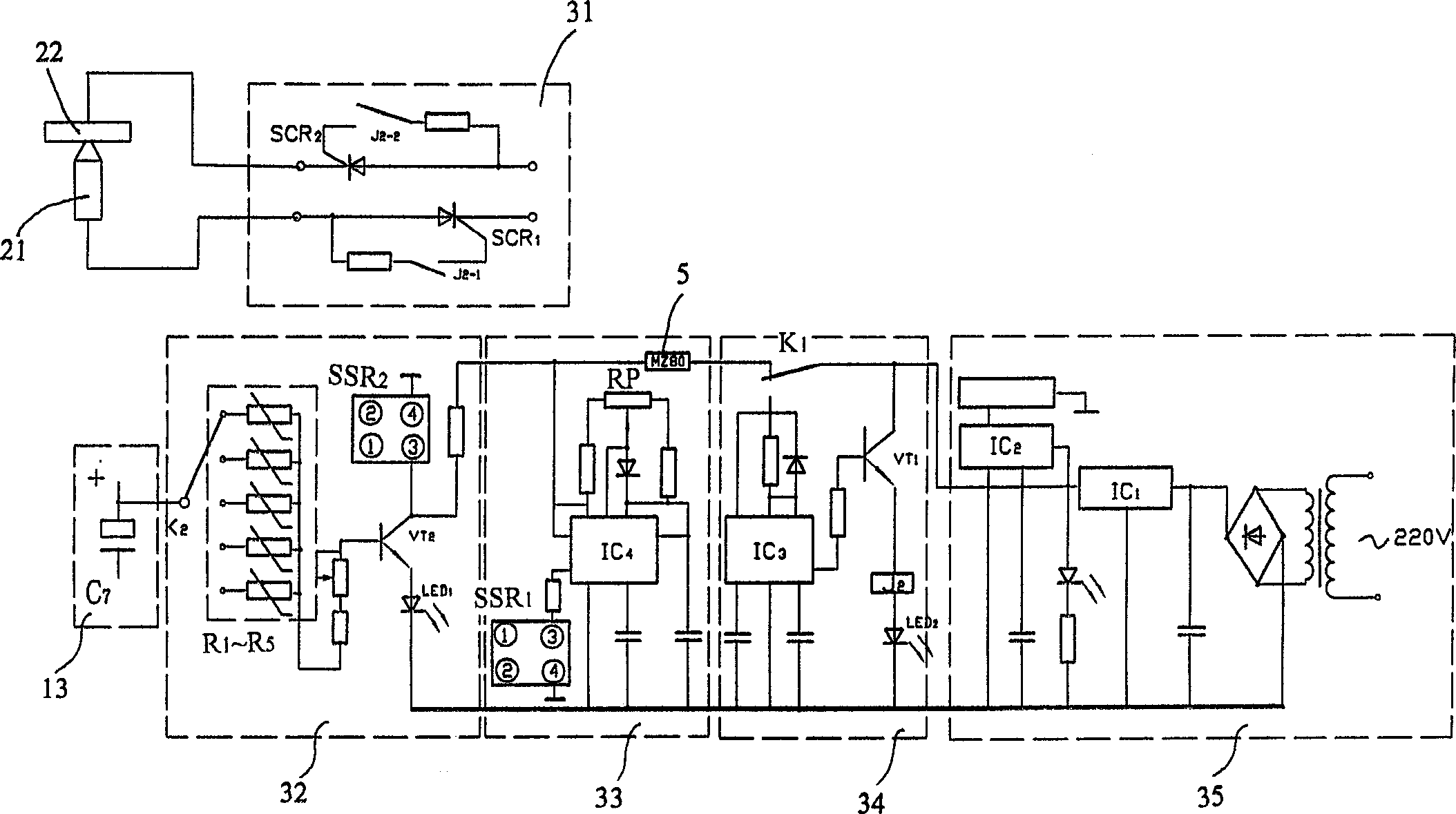

Energy-storing multifunctional welding machine

In the energy-storing multifunctional welding machine, the charge voltage of the energy-storing capacitors is selected via controlling the on-off of the AC zero-crossing solid relay, instead of voltage regulation of main transformer. At the same time, one sensitive and reliable voltage monitoring negative feedback system is designed to ensure the DC voltage fluctuation of energy-storing capacitors less than 0.2 %. The energy-storing multifunctional welding machine includes energy-storing capacitors, proportional voltage regulating system, welding output loop with thyristor switching assembly,voltage monitoring negative feedback system, thyristor triggering control system and power supply system. it may be used with various kind of welding guns.

Owner:俞岳皋

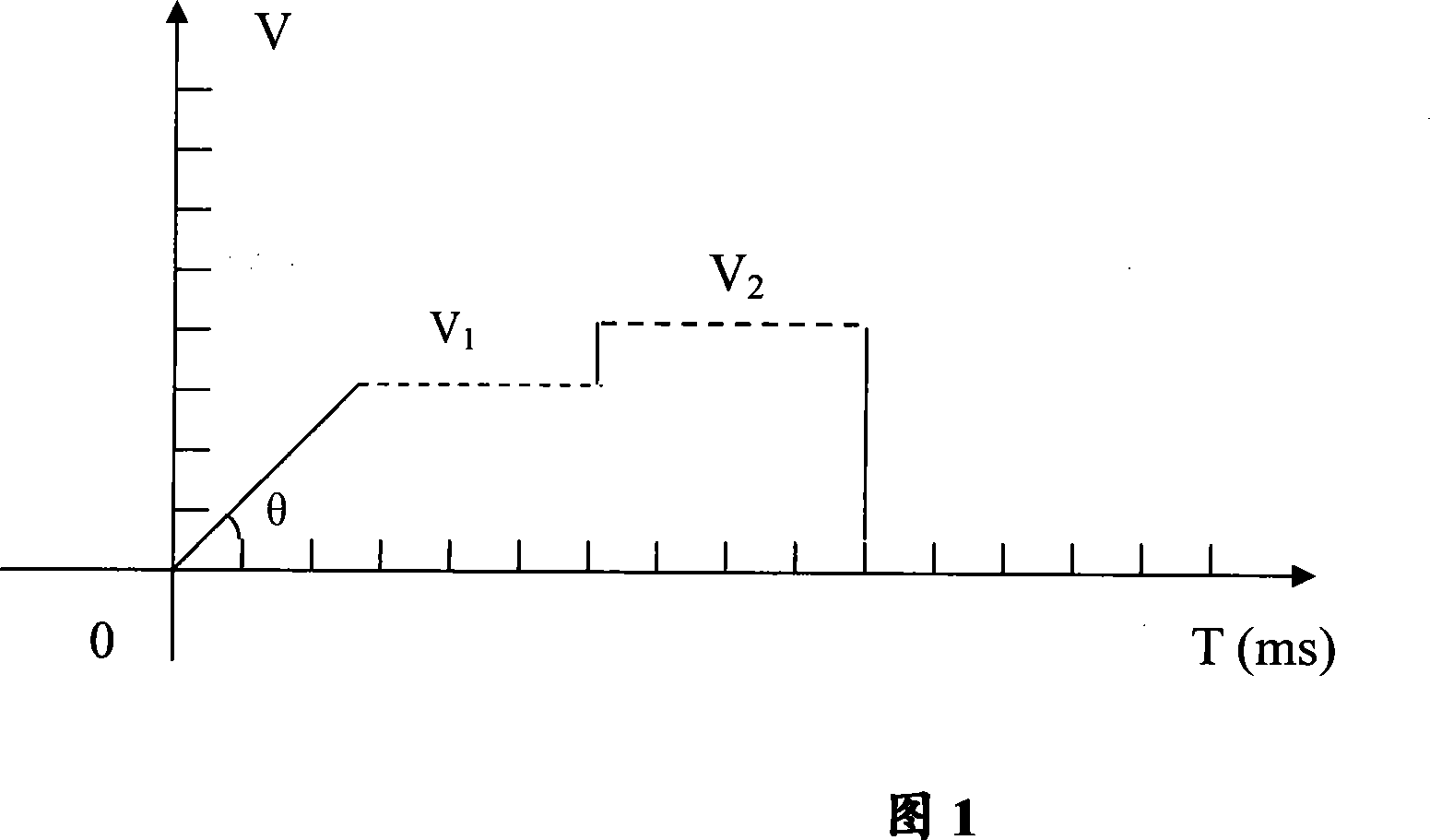

Precision resistance welding spot welding machine

InactiveCN101234452AAvoid damageExtended service lifeLine/current collector detailsStorage discharge weldingElectrical resistance and conductanceTransformer

The invention relates to a precision resistant welding spot-welder which is mainly used for welding enamel wire extraction contacts and minimal work pieces in the manufacturing of electric elements with small coils and comprises main power supply, a welding head and a die; among which, the main power supply which comprises a resistant welding transformer and a power supply control device provides step wave pulse output and outputs suitable current for welding through the power supply control device; the die connects the welding head and the output through the resistant welding transformer and provides welding power. The resistant welding spot welder output by the step wave of the invention reduces the damages to the welding head caused by excessive current which is used for burning the insulating varnish of the enamel wire and prolongs the service life of the welding head.

Owner:杨仕桐

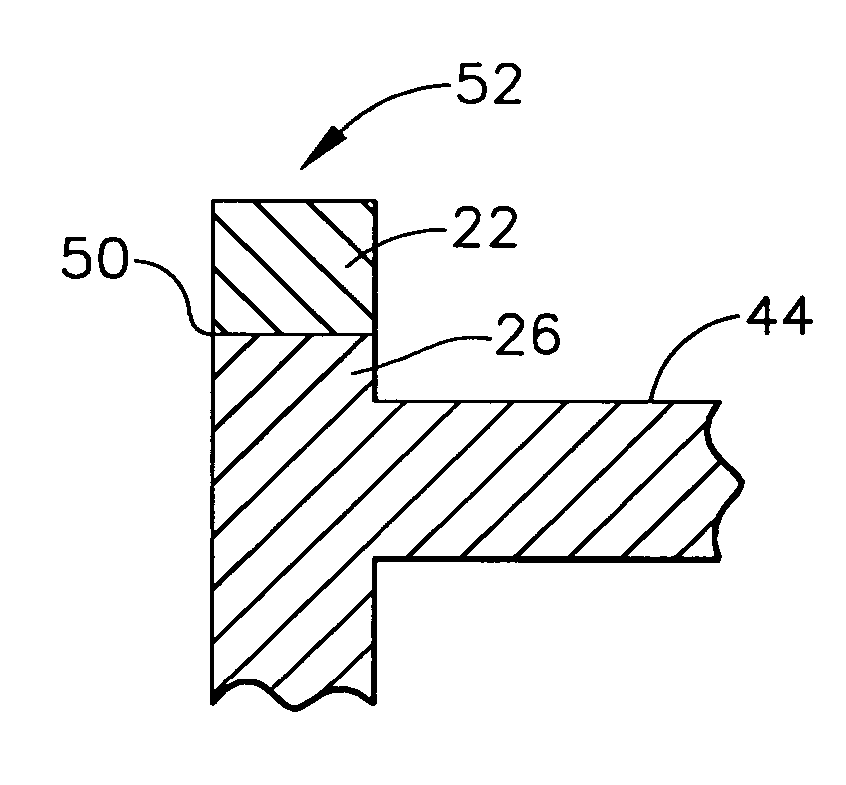

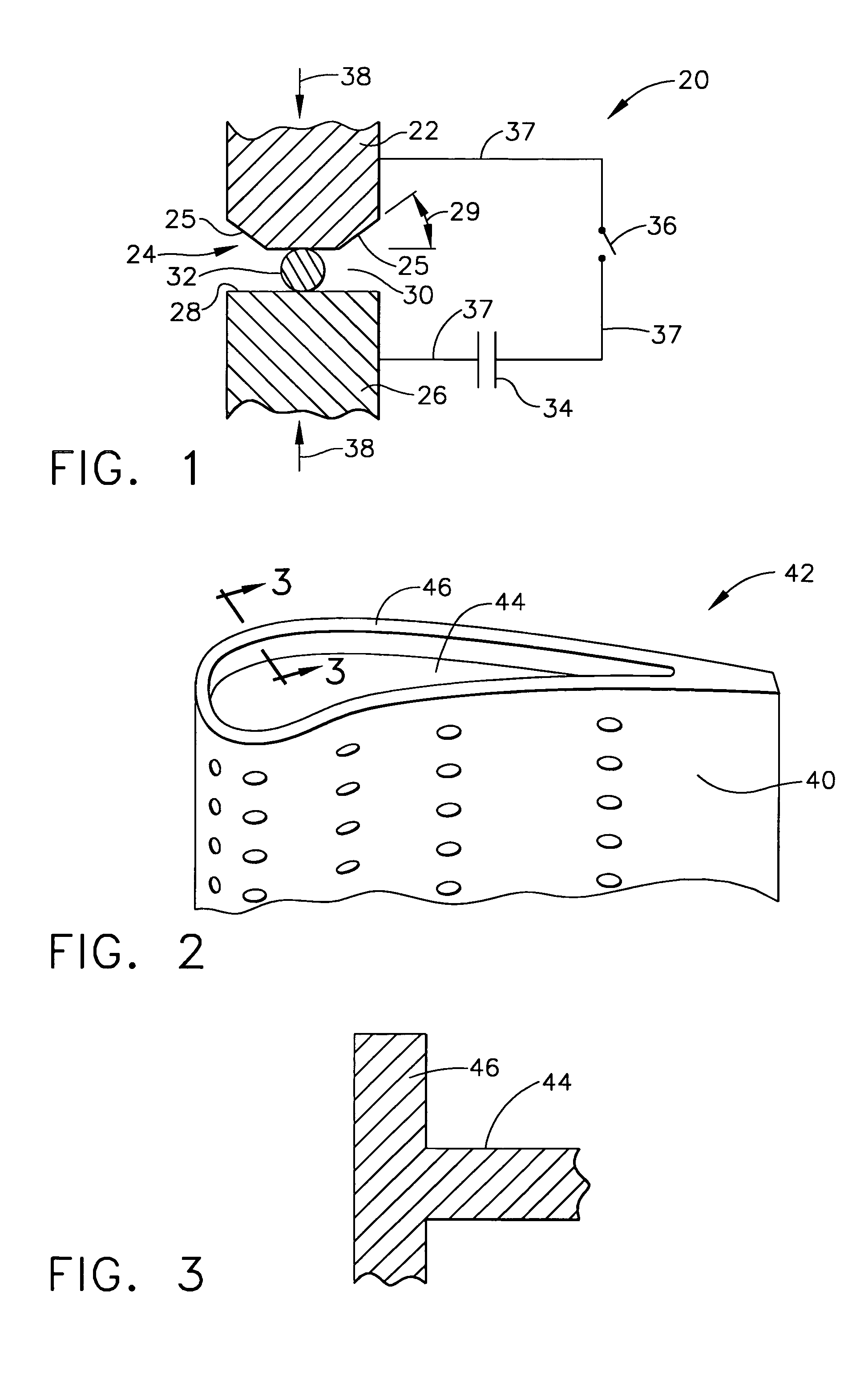

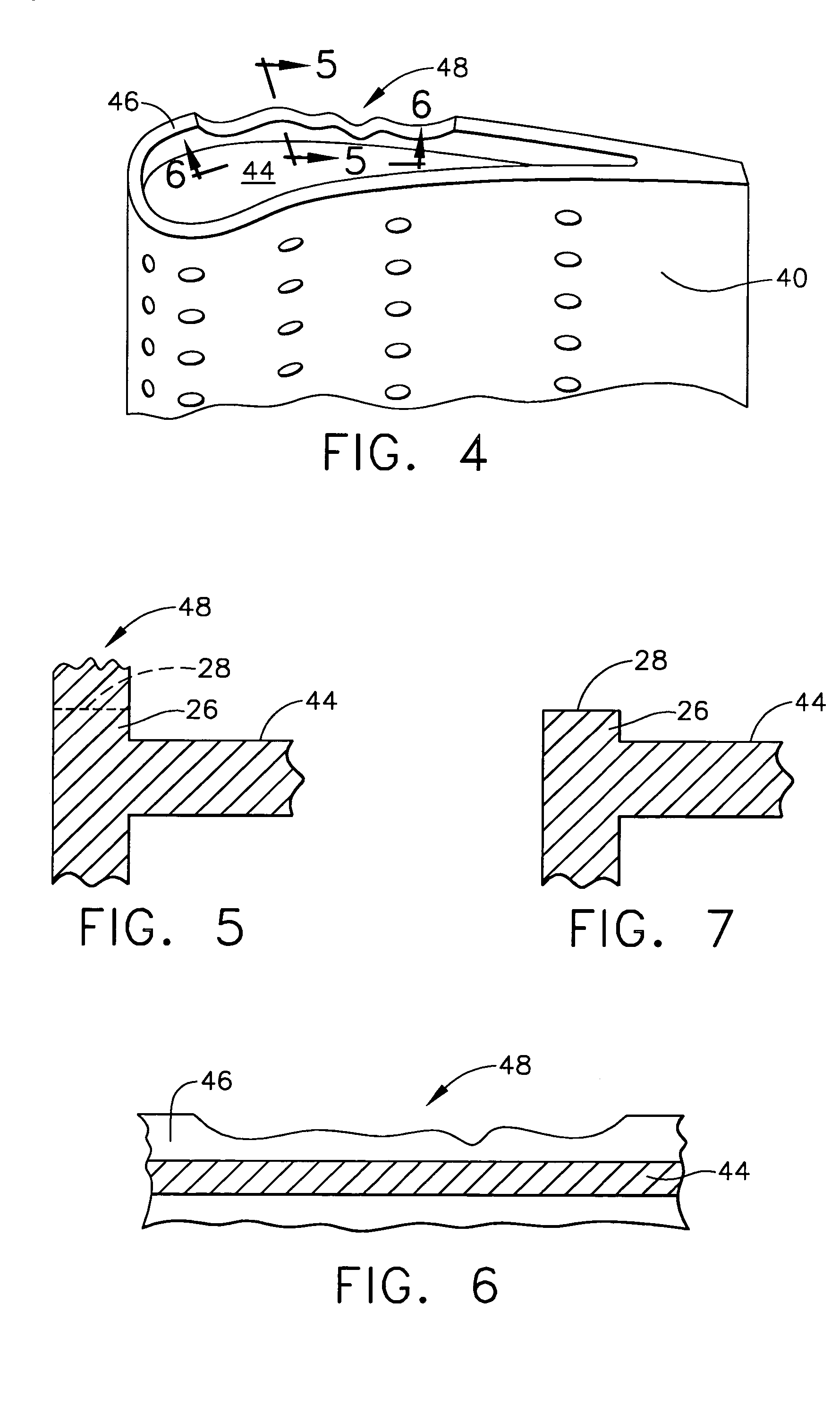

Method of manufacturing electrolyzer unit, and method and system for welding electrolyzer unit and electrolyzer unit rib

InactiveUS20040007458A1Keep for a long timeReduce in quantityCellsWelding/soldering/cutting articlesEngineeringFlange

The invention has an object of facilitating the detection of defective welds and improving the efficiency of manufacturing electrolyzer units. A a method of manufacturing an electrolyzer unit comprises a step of arranging a partition member on a front surface of a cathode pan and welding a top side and a left side of the cathode pan to the partition member to form a gas-liquid separation chamber, a step of performing a similar step on an anode pan, a step of arranging cathode ribs on a front surface of the cathode pan and clad plates on a back surface of the cathode pan at positions corresponding to the cathode ribs, welding them at the same time, putting a back surface of the anode pan over the back surface of the cathode pan and arranging anode ribs on a front surface of the anode pan at positions corresponding to the clad plates, a step of simultaneously performing on the anode pan a similar step of arranging anode ribs on a front surface of the anode pan at positions corresponding to the clad plates, and a step of inserting frame members into spaces formed between flange portions of the cathode pan and flange portions of the anode pan.

Owner:FUJITA WORKS +1

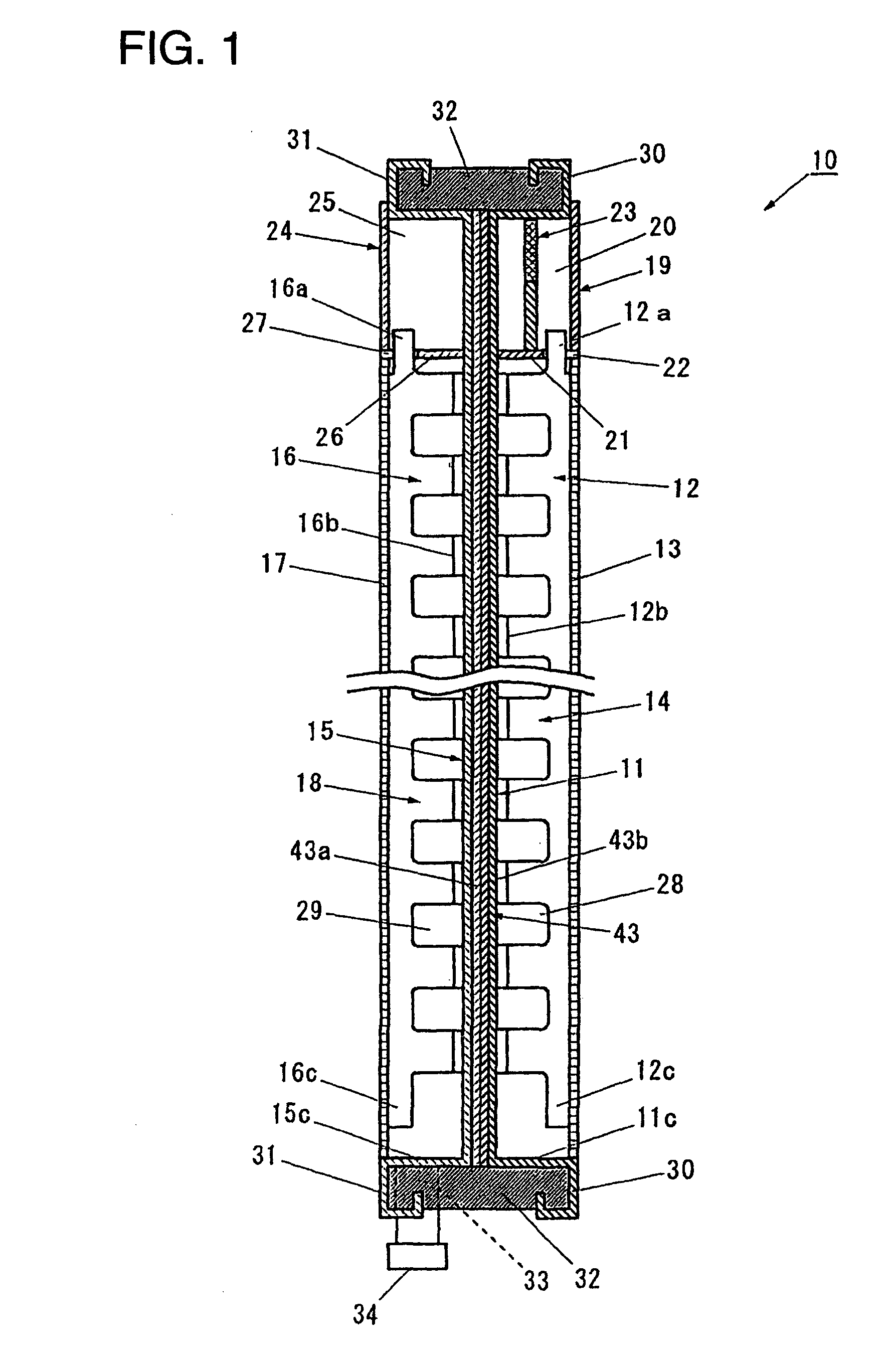

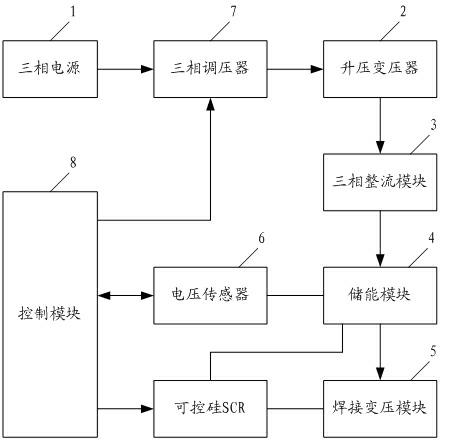

Medium-voltage capacitive energy storage welding machine

The invention discloses a medium-voltage capacitive energy storage welding machine, which comprises a three-phase power source, a step-up transformer, a three-phase rectifier module, an energy storage module and a welding transformation module, wherein the step-up transformer is connected with three-phase alternate current to perform step-up treatment on input alternate current; the three-phase rectifier module is connected with the step-up transformer and the energy storage module respectively; the alternate current which is stepped up is rectified into direct current by the three-phase rectifier module and is charged to the energy storage module; the voltage value of the direct current is 500-1,000V; the energy storage module comprises a plurality of energy storage capacitors; the energy storage capacitors are metal thin film non-polar capacitors, and the withstand voltage of the energy storage capacitors is more than 1,000V; and the welding transformation module is connected with an output end of the energy storage module. The medium-voltage capacitive energy storage welding machine provided by the invention is safe in operation and is cost-saving.

Owner:HERON INTELLIGENT EQUIP CO LTD

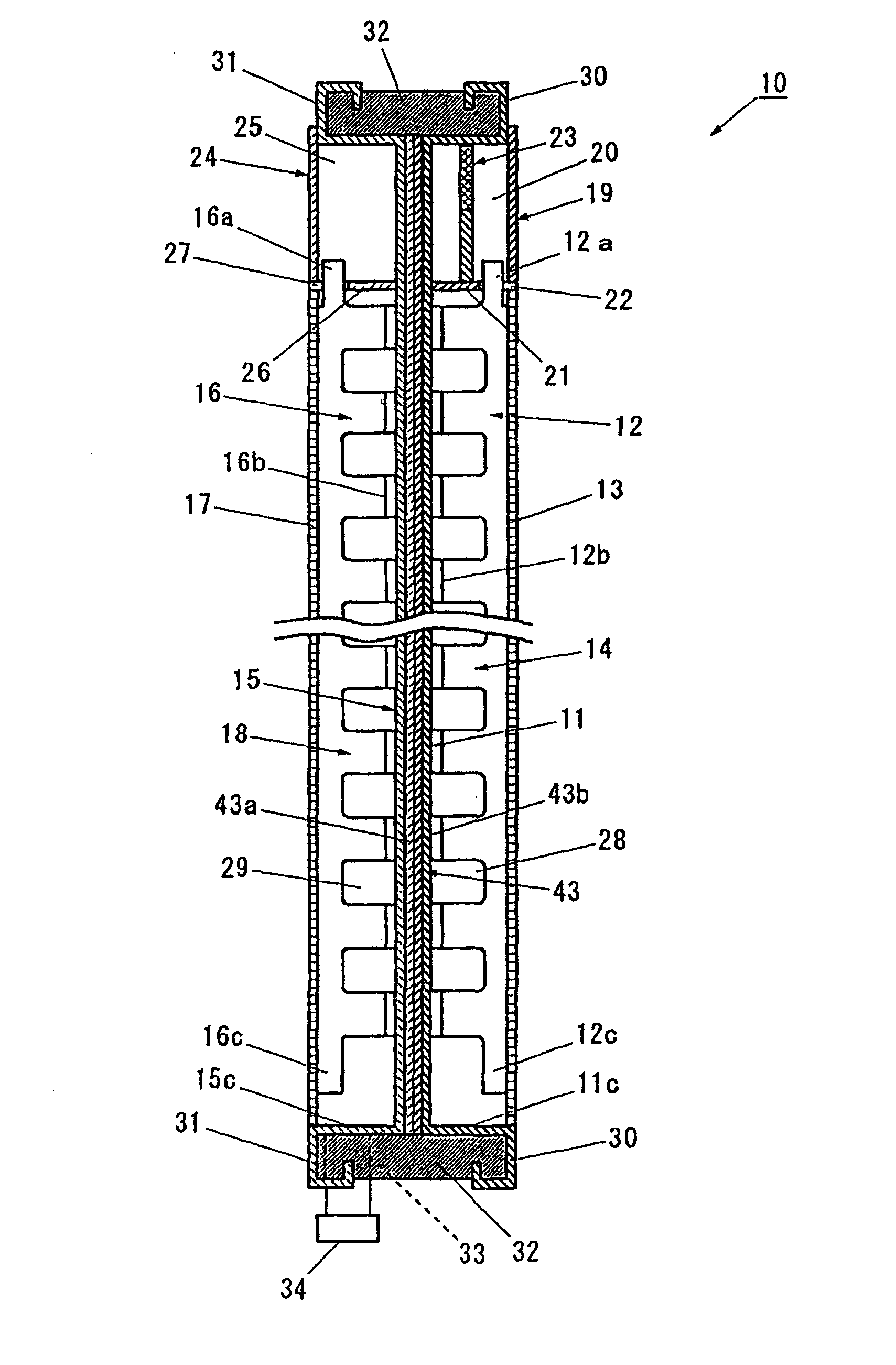

High-pressure fuel supply pump and the manufacturing method

InactiveUS8672652B2Large welding forceIncrease frictional resistanceSuction devicesTubular articlesInlet valveEngineering

In order to provide a welded structure of and welding method for two metallic parts fitted together at a tubular section in a high-pressure fuel supply pump, an electric current is supplied to any of the welding connection surfaces formed between a pump housing and cylinder in a high-pressure fuel supply pump, between the pump housing and an installation flange, between the pump housing and an intake or discharge joint, between the pump housing and a pulsation-absorbing damper cover, between the pump housing and a relief valve mechanism, and between the pump housing and an electromagnetically driven intake valve mechanism. The two sections are pressed against each other to generate, along the connection surface, a plastic flow not causing melting or fusion due to heat, and form a diffusion-weld region at the connection surface by using the plastic flow and the application of the pressure.

Owner:HITACHI LTD

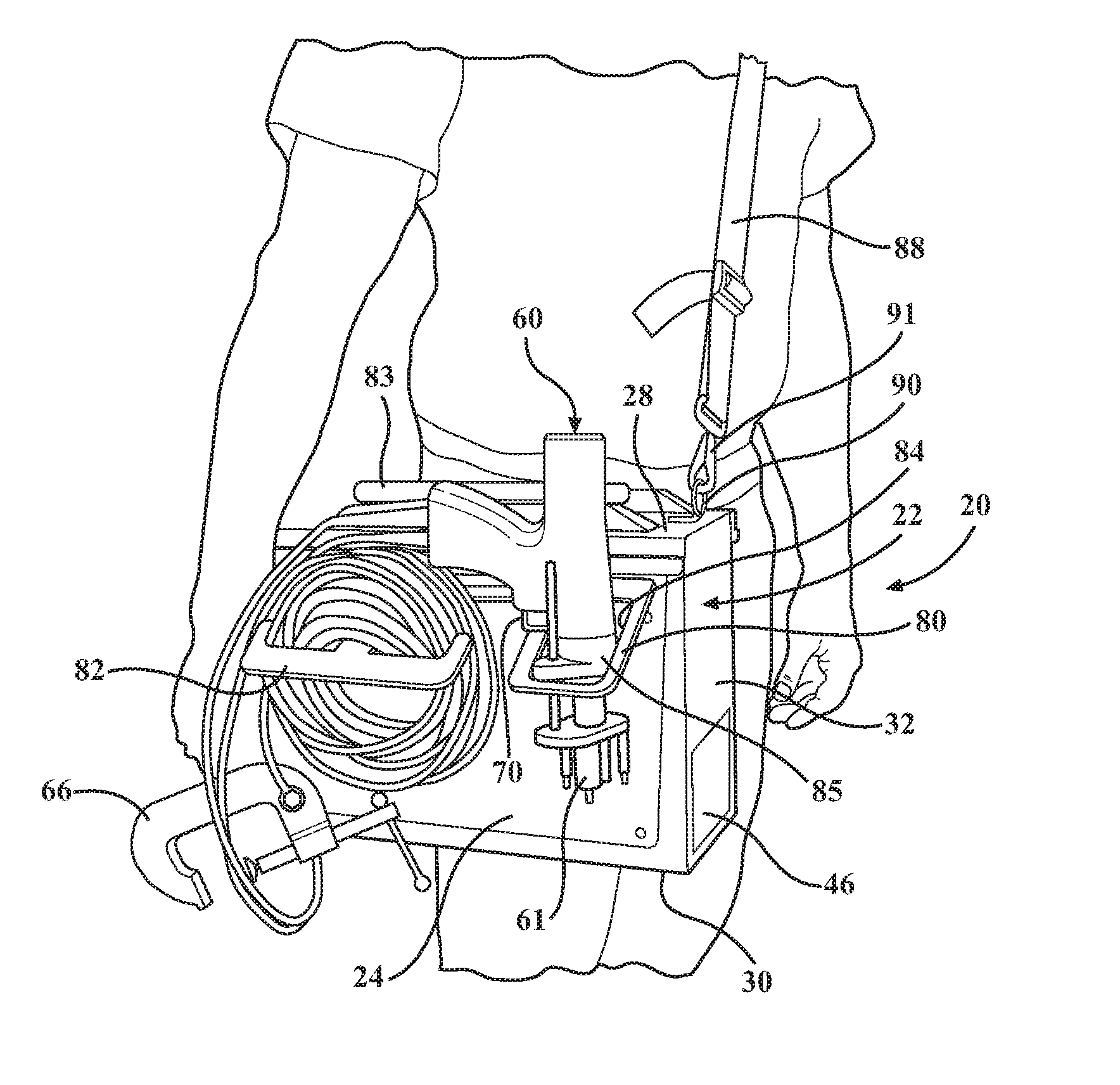

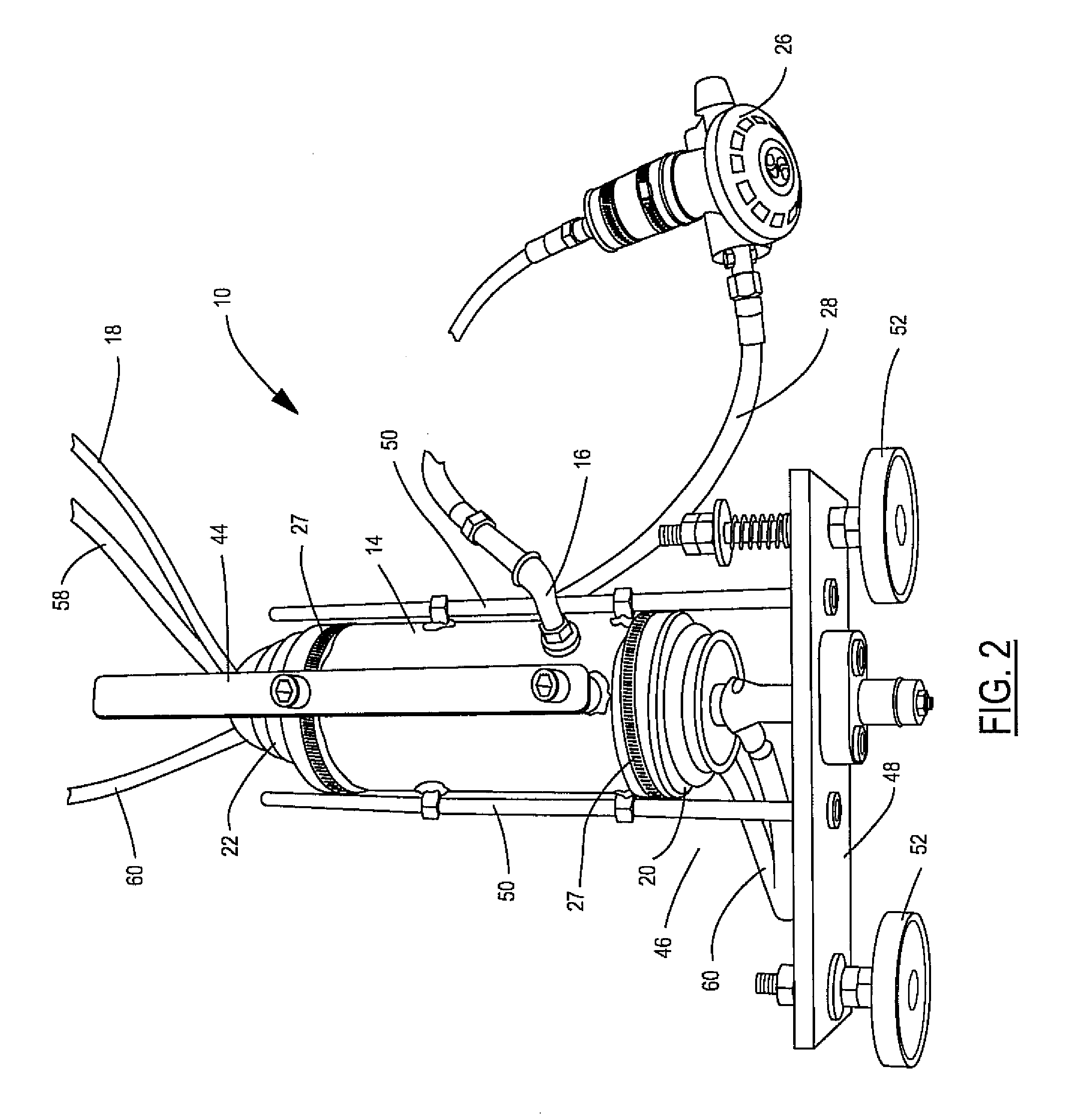

Light weight cordless stud welder

ActiveUS20170050259A1Easy to operateEasy to transportBatteries circuit arrangementsSecondary cellsElectricityLithium

A portable stud welder apparatus is provided for welding a stud onto a work piece. The portable stud welder apparatus includes a housing and an energy storage device. A weld stud gun that is configured to hold a weld stud is electrically connected to the energy storage device for receiving energy from the energy storage device to pass a current through the stud and the work piece to form a weldment. At least one battery of the lithium ion type that is removeably coupled to the housing to establish an electrical connection with said energy storage device and provide energy to the energy storage device.

Owner:NELSON STUD WELDING

Two-level electric resistance welding method for damping clad plate oil sump

Disclosed is a method for double-skin resistance welding of oil sump of vibration-damping clad plate in the welding art, which contains: locating the fuel outlet plane of oil sump of vibration-damping clad plate on the location seat of welder, and locating the fuel outlet double-screw bolt on the fuel outlet and aligning. The two upper-electrodes decreasing at the same time, the first upper-electrode pressed on the fuel releasing double-screw bolt, the second upper-electrode pressed on the outer ring of the fuel outlet of the oil sump and near the double-screw bolt, the energy storage capacitor one- time discharging by energy storage welding transformer after the two electrodes are compacted, the second upper-electrode being released after energisation, at the same time the three lower-electrodes of point welding lifting and contacting with the lower steel plate of the fuel outlet of the oil sump and being compacted, energizing by alternating resistance welding transformer to complete the welding of doubling plate, keeping forcing, the second upper-electrode and the three lower-electrodes of point welding being released at the same time, the welding is completed, and finally the sealing and strength connection of fuel releasing double-screw bolt and doubling vibration-damping clad plate is formed. The welding has a high output rate, the sealing of the joint is good and the strength high, and the damage to the intermediate insulating layer of the vibration-damping clad plate is small.

Owner:SHANGHAI JIAO TONG UNIV

Once flattening and energy storage capacitor welding method for broad band type thin steel plate connection

InactiveCN1586784AGood workmanshipExcellent welding current waveform with excellent process performanceStorage discharge weldingCapacitanceTransformer

The once flattening and energy storing capacitor welding process for connecting wide thin steel bands includes vertical overlapping two steel bands to be welded on the planar lower electrode, lowering the upper electrode to densify the overlapped area, once discharging of the energy storing capacitor via the welding transformer in the designed parameters, maintaining the pressure after finishing discharge to complete once welding and form weld seam. The present invention is suitable for common cold rolled low carbon steel plate and galvanized steel plate. The present invention has high welding efficiency and welded joint has high strength and toughness.

Owner:SHANGHAI JIAO TONG UNIV

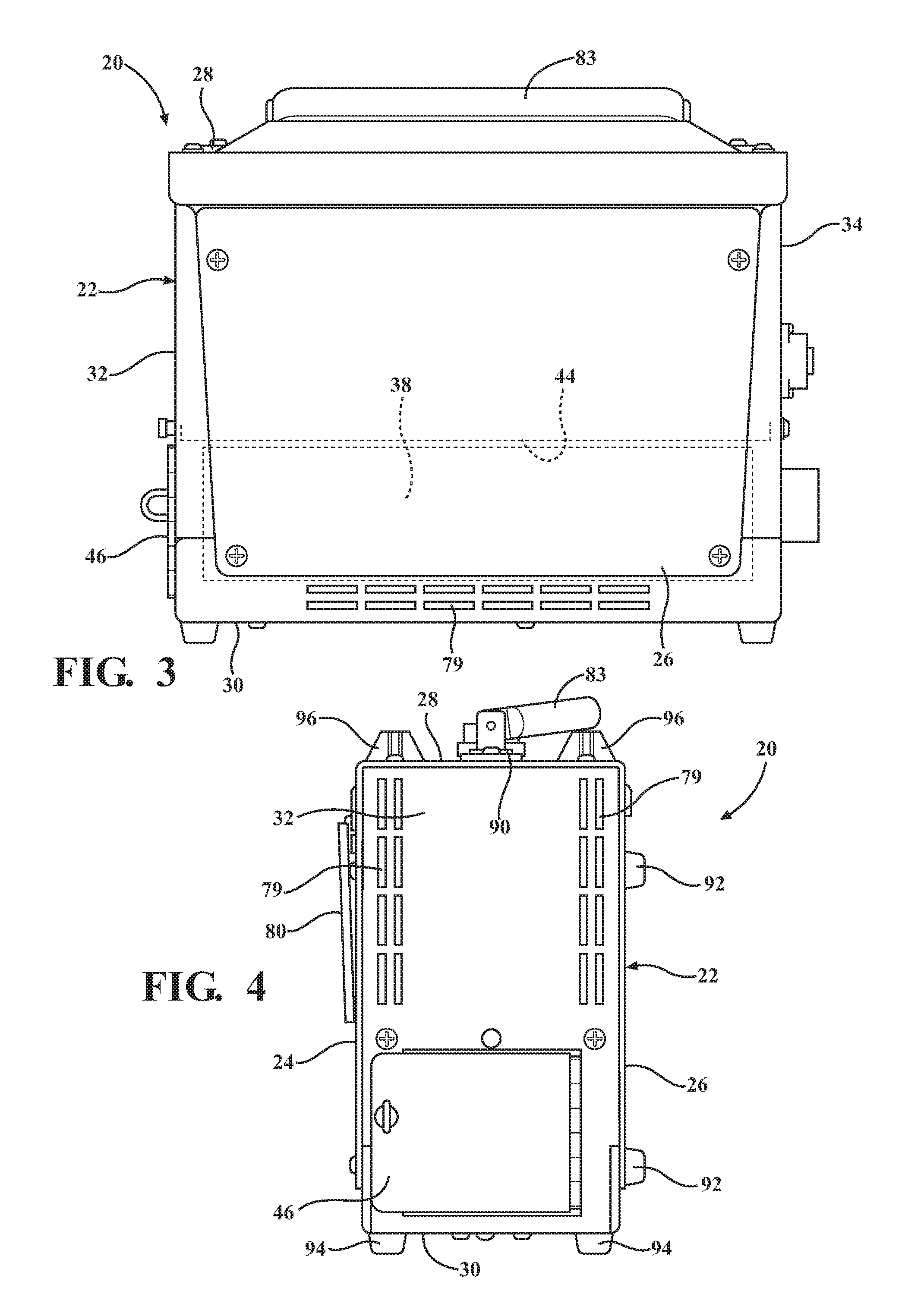

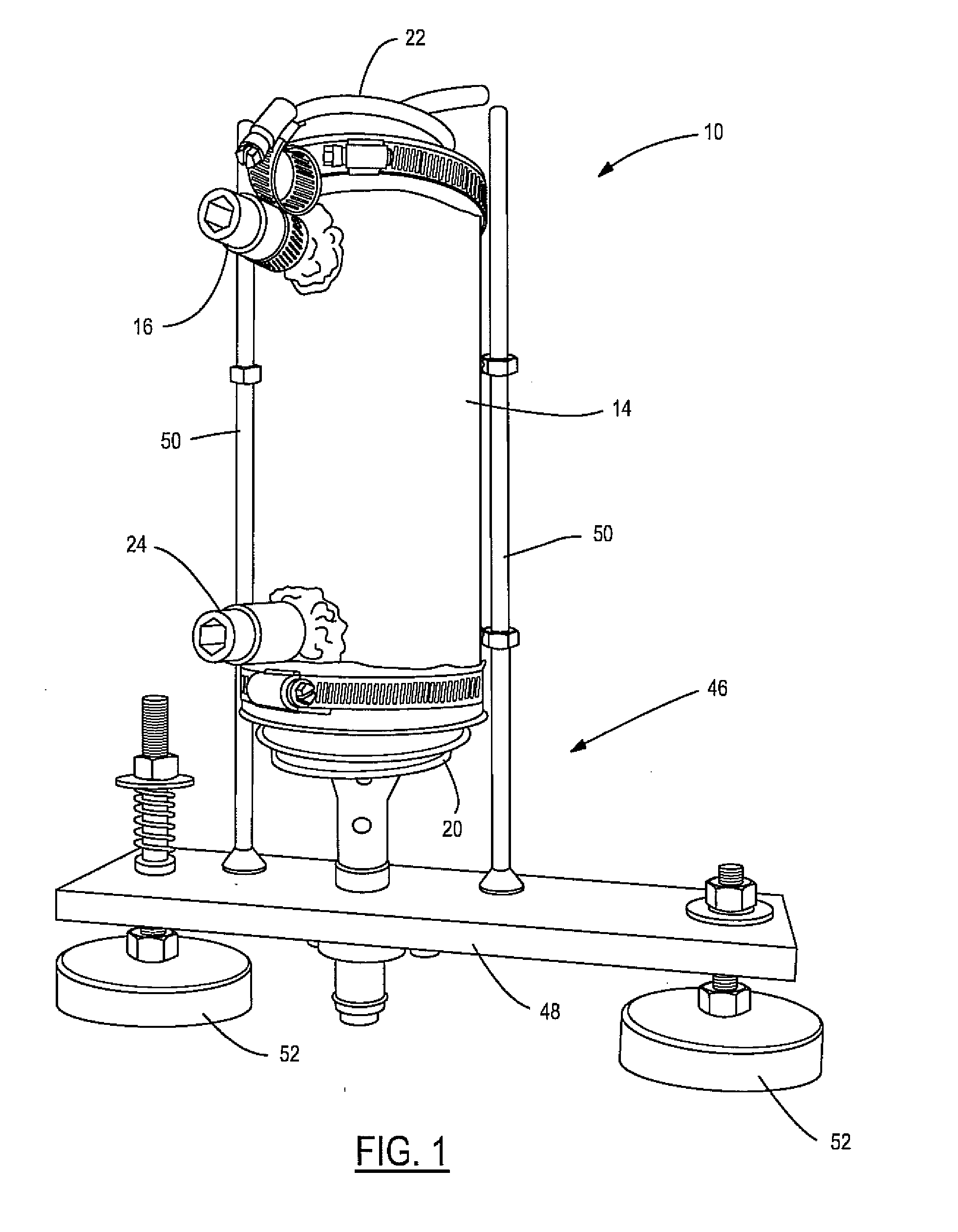

Thermal Management for a Super Capacitor Power Supply

InactiveUS20150306698A1Protecting/adjusting hybrid/EDL capacitorWelding/cutting auxillary devicesCapacitanceThermal management system

A power supply assembly, suitable for use in conjunction with a capacitive discharge welder, comprises an integrated thermal management system. The housing of the power supply assembly allows the integration of ultra-capacitor thermal management with electrical connectivity and mechanical modularity. In the most preferred embodiments of the present invention, aluminum (or other conductive material, such as copper, etc.) channels are shaped and arranged to both act as thermal fin elements for the removal of waste heat while simultaneously serving as an electrical path with a relatively low electrical resistance. The thermal fin assembly may comprise self-isolating insulation elements or the thermal fin elements may be electrically isolated from each other by an electrically insulating material. Airflow within the housing may be directed via fan or other method into the ultra-capacitor wind tunnel to remove heat from the capacitor cylinder itself as well as the thermal conductive fin elements.

Owner:SUNSTONE ENG

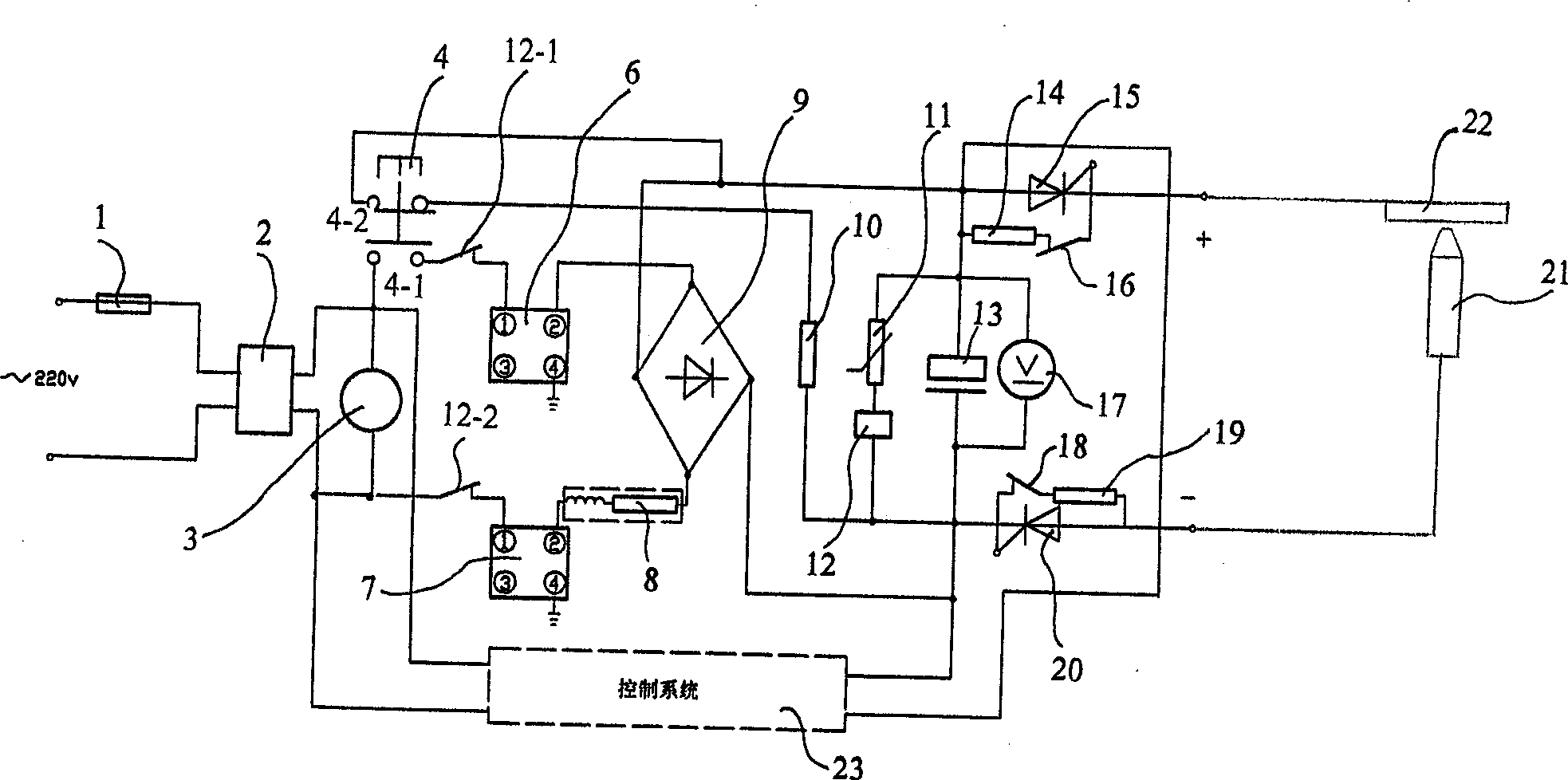

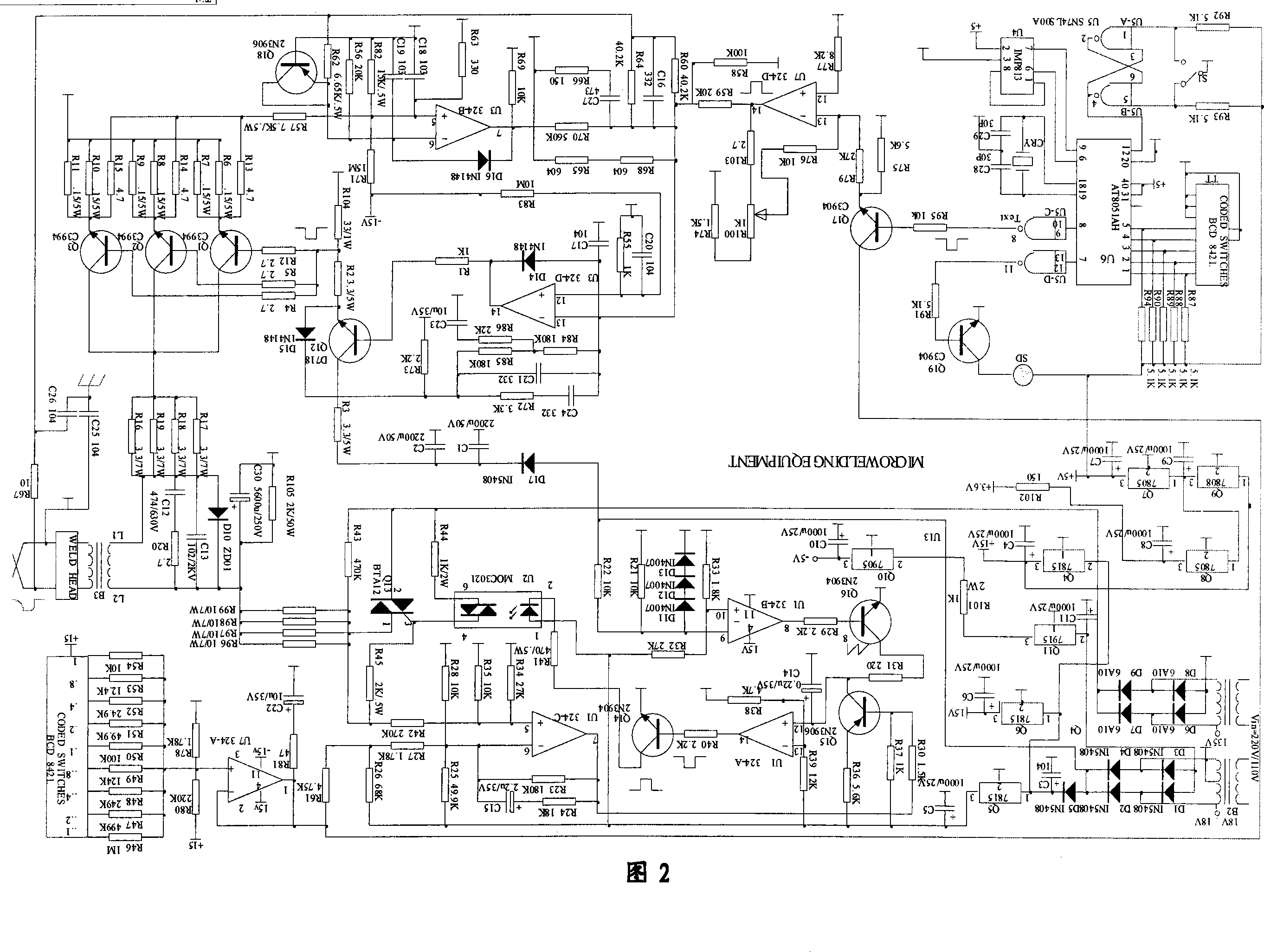

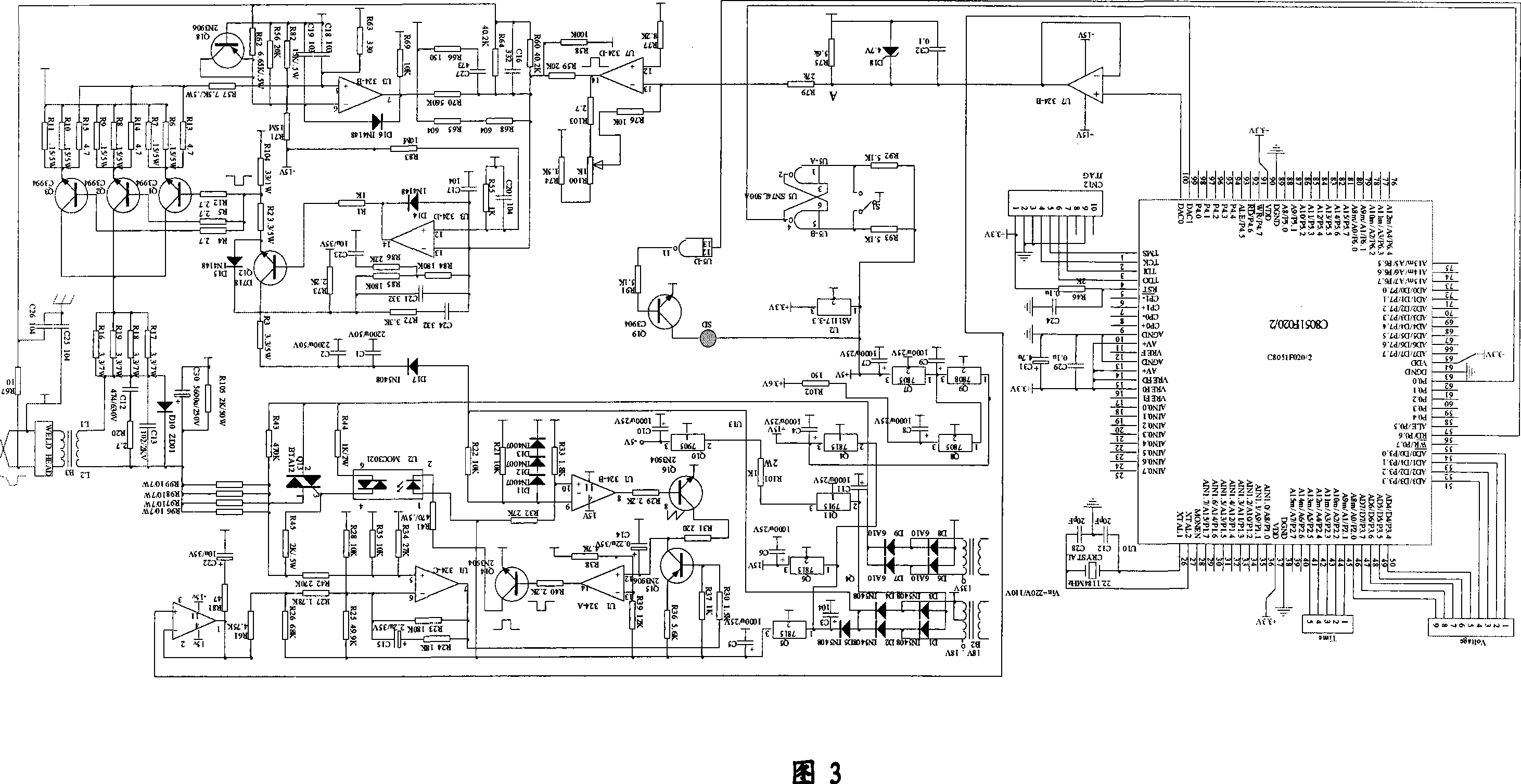

Condenser discharge welder and use method thereof

ActiveCN101386107AEasy to operateRealize human-computer interactionStorage discharge weldingCapacitanceMicrocomputer

The invention relates to a capacitance energy storing welder and a using method thereof, wherein, the capacitance energy storing welder is characterized in that the welder is provided with a microcomputer and an operation panel; the microcomputer is used for controlling a device that is electrically connected by a main electric cabinet, and the operation panel is used for sending commands to the microcomputer and displaying the working status of the whole capacitance energy storing welder. In welding process, all welding parameters are set precisely, and specific operating actions of all parts of the welder can be controlled, thereby realizing better welding quality. Meanwhile, a display panel connected with the microcomputer can display all welding parameters and specific situation of all parts of the welder in the welding process so that operators can monitor the welding process more visually. When the welding parameters need to be changed, human-computer interaction is realized by direct operation of the display panel, which facilitates the operators to operate the welder.

Owner:HERON INTELLIGENT EQUIP CO LTD

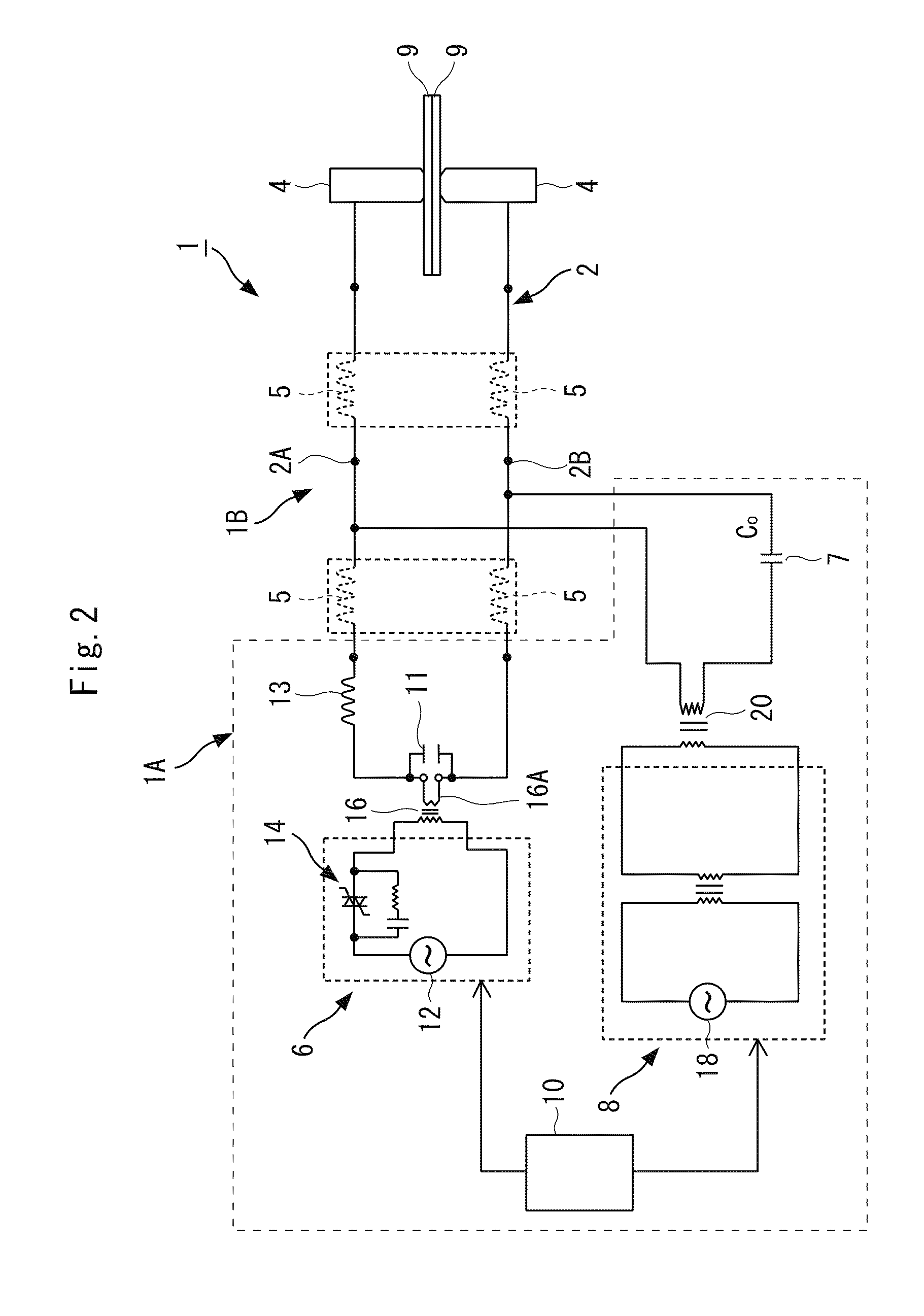

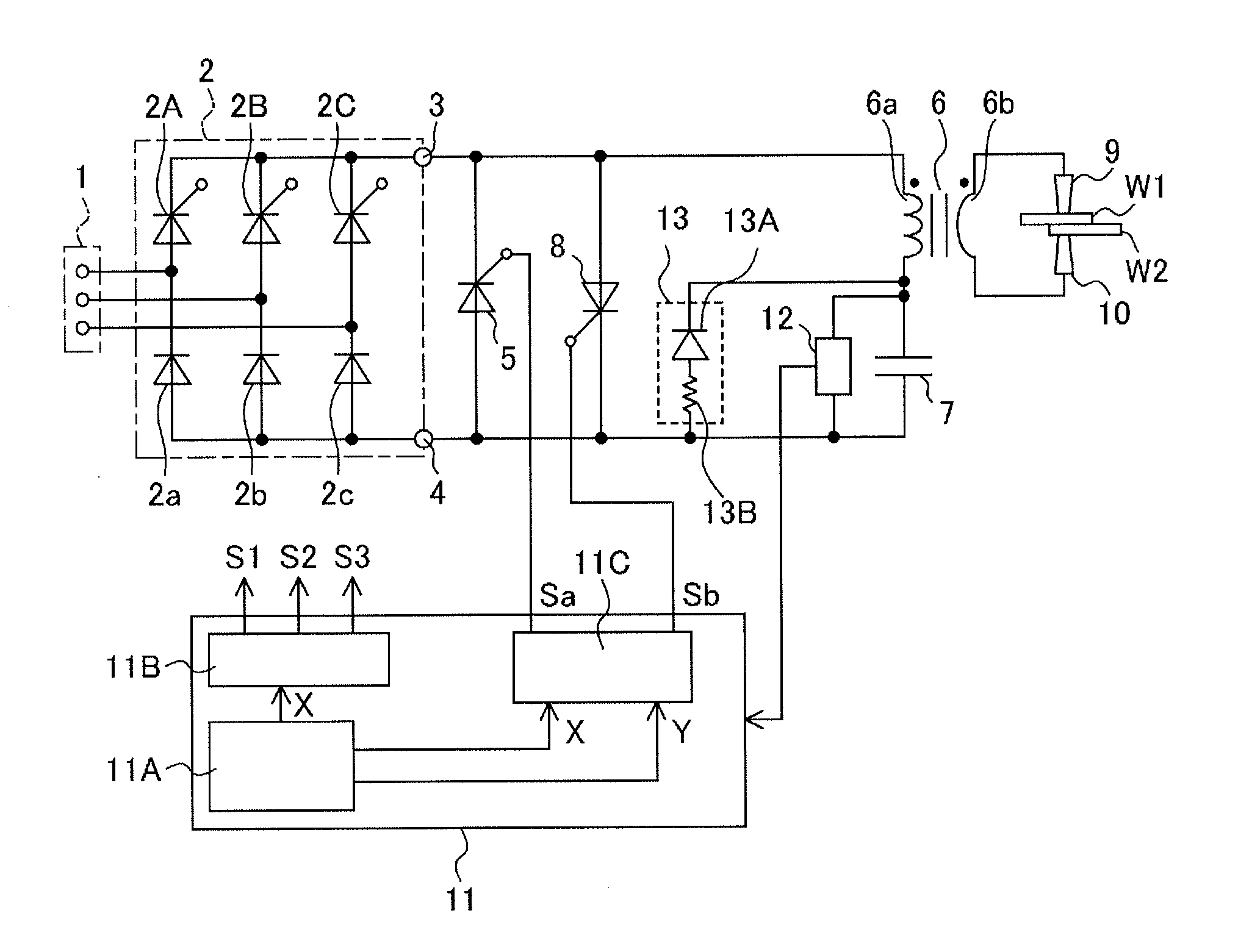

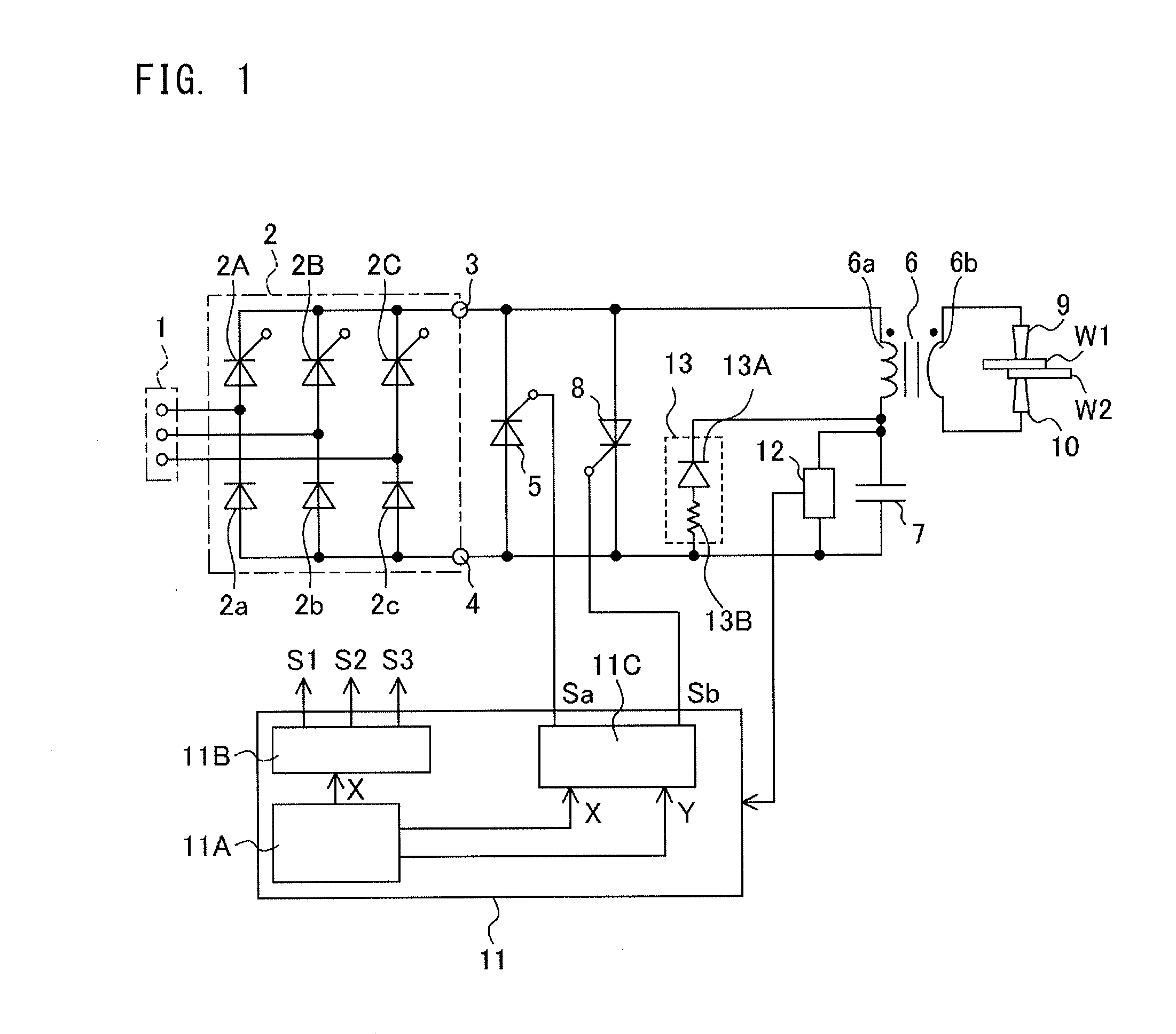

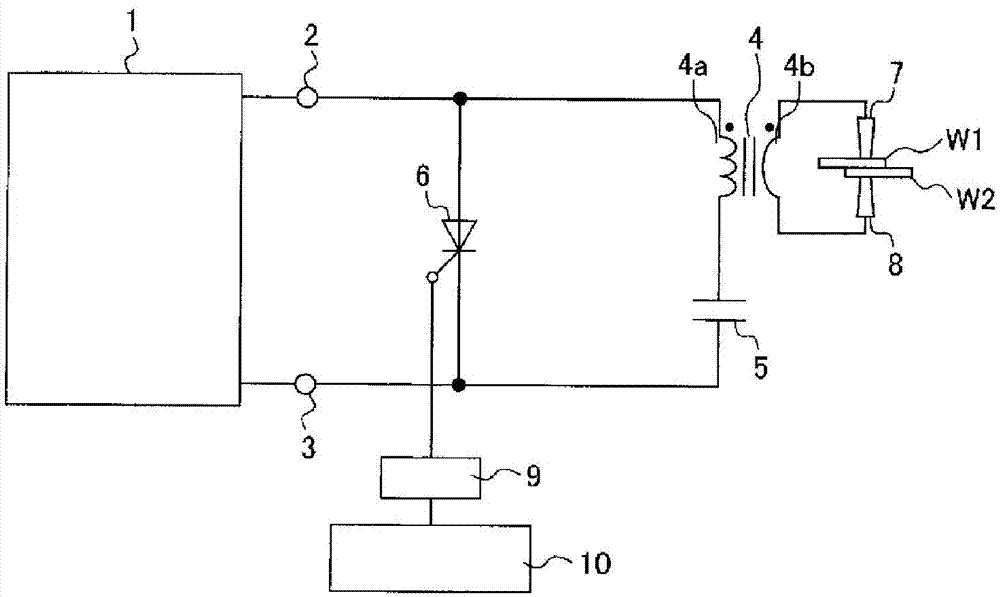

Capacitor-type welding device and capacitor-type welding method

ActiveUS20140374389A1Reduce power lossLow costArc welding apparatusWelding electric suppliesEngineeringInductor

An economical capacitor-type welding device and capacitor-type welding method that have a small power loss, that can be made compact, and that reliably control a charging circuit without being affected by the inductance of a charging path. In an exemplary capacitor-type welding device and an exemplary capacitor-type welding method of the invention, a bypass switching element having a forward-blocking function is connected in parallel to output terminals of a charging circuit, and the bypass switching element is brought into a conduction state to allow a backflow current, which is caused to flow by a magnetic energy stored in the inductance of a primary winding or an inductor included in the charging path, to bypass the charging circuit. A discharge switching element is brought into a conduction state after the bypass switching element enters the non-conduction state and recovers the forward-blocking function.

Owner:ORIGIN ELECTRIC CO LTD

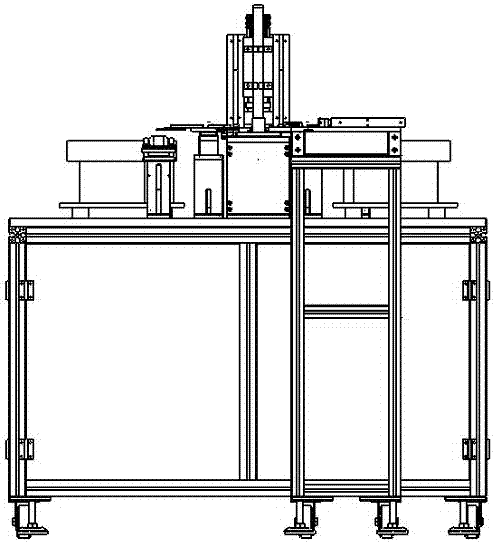

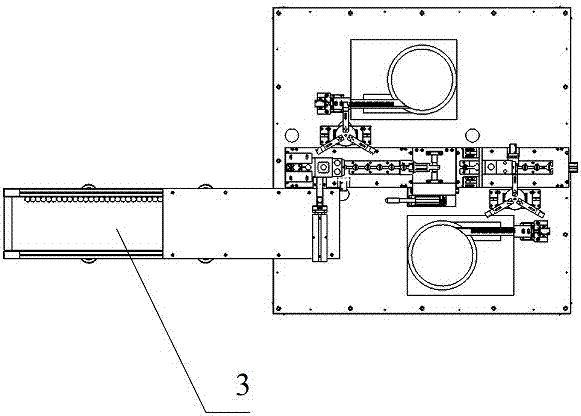

Automatic welding device for lower oil pans

ActiveCN106181008AHigh degree of automationAccurate retrievingStorage discharge weldingElectricityIntermediate frequency

The invention discloses an automatic welding device for lower oil pans. The device comprises an intermediate frequency energy storing welder, a feeding conveyor line, a discharging conveyor line, a nut feeding assembly, a robot, a robot electric cabinet, a control cabinet and a nut locating assembly, wherein the feeding conveyor line is used for conveying the oil pans to the position of the intermediate frequency energy storing welder; the robot is used for transferring the oil pans to the oil pan welding part of the intermediate frequency energy storing welder from the feeding conveyor line and is also used for transferring welded finished products to the discharging conveyor line, and the discharging conveyor line is used for outputting the finished products; the nut feeding assembly is arranged at one side of the intermediate frequency energy storing welder and used for conveying nuts to the position of the intermediate frequency energy storing welder; the nut locating assembly is arranged between the intermediate frequency energy storing welder and the nut feeding assembly and used for transferring the nuts from the nut feeding assembly to the oil pan welding part; and the intermediate frequency energy storing welder is connected with the control cabinet, and the intermediate frequency energy storing welder discharges electricity and finishes the welding of the oil pans and the nuts under the control of the control cabinet.

Owner:CHANGSHU JUNCHI SCI & TECH

Sealed and pressurized gun for underwater welding

InactiveUS20100065532A1Welding/cutting auxillary devicesArc welding apparatusMarine engineeringDepth level

An underwater fastener welding apparatus that includes a welding tool positioned within a watertight housing. The housing includes an inlet coupled to a source of pressurized gas. The housing is pressurized to balance a pressure internal to and external to the housing when the underwater welding apparatus depth level is changed.

Owner:NELSON STUD WELDING

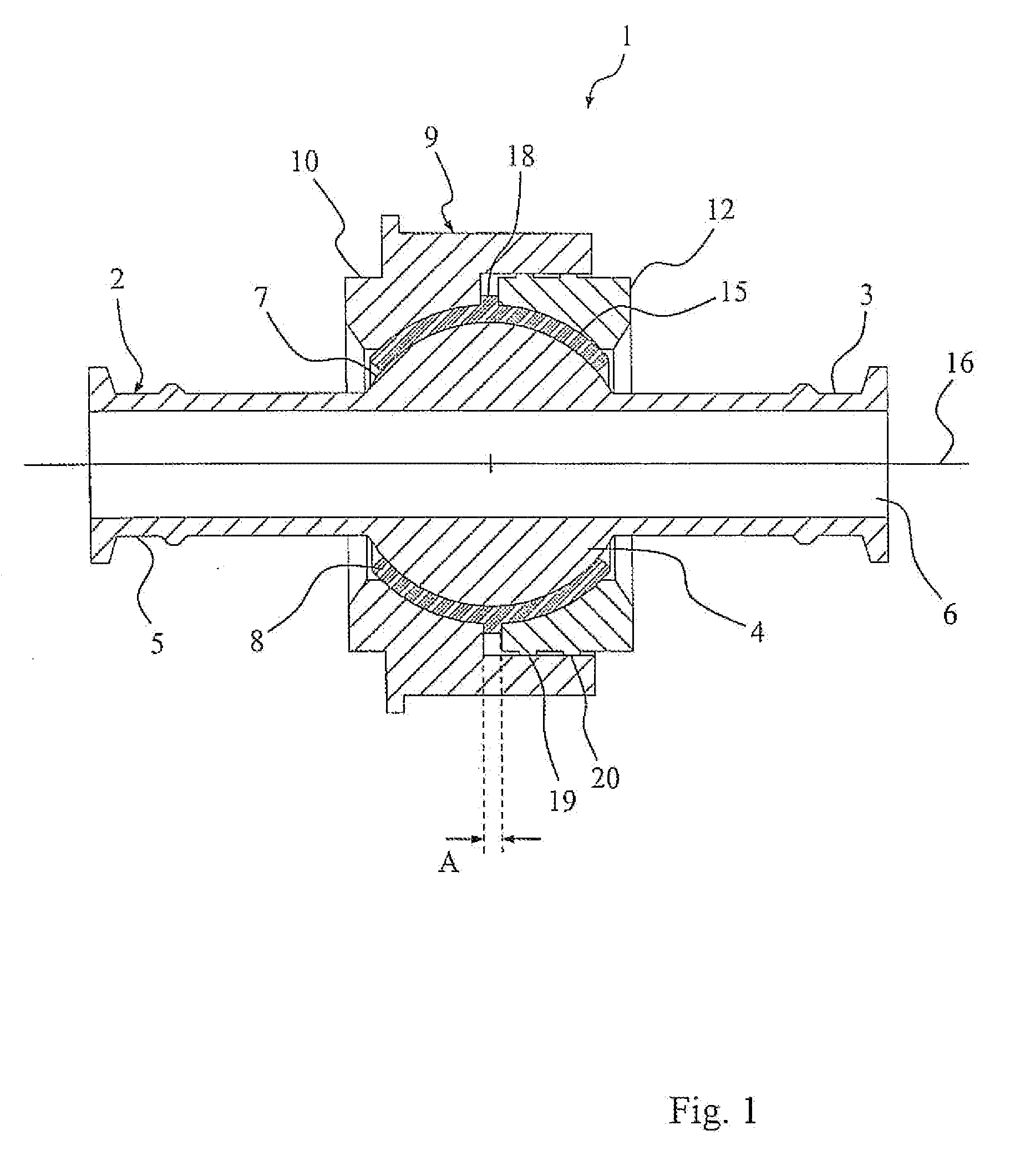

Ball and socket joint

InactiveUS20100040407A1Reduce riskBearing componentsCouplings for rigid shaftsEngineeringSpherical form

A ball and socket joint is provided for a vehicle. The ball and socket joint includes a housing (9), with a joint inner part (2), which is seated in the housing (9), extends from this and is mounted movably in the housing (9) with a bearing area (4) having a spherical surface or partial spherical surface (7) via the intermediary of a bearing shell (8). The housing has two housing parts (10, 12) meshing with one another, which are firmly connected to one another by means of at least one welded connection (19, 20), wherein the two housing parts (10, 12) are braced against one another in the radial direction to form a press fit.

Owner:ZF FRIEDRICHSHAFEN AG

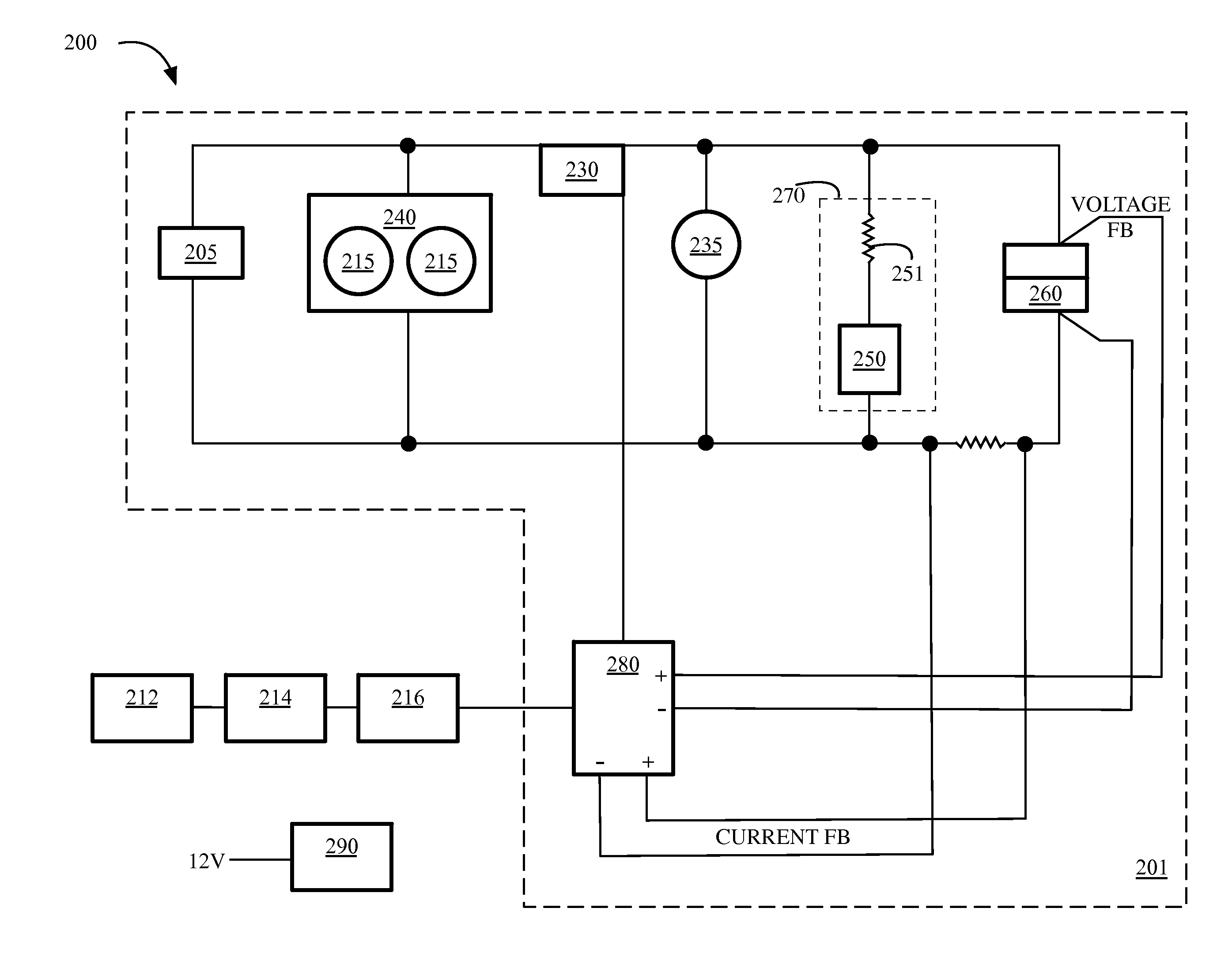

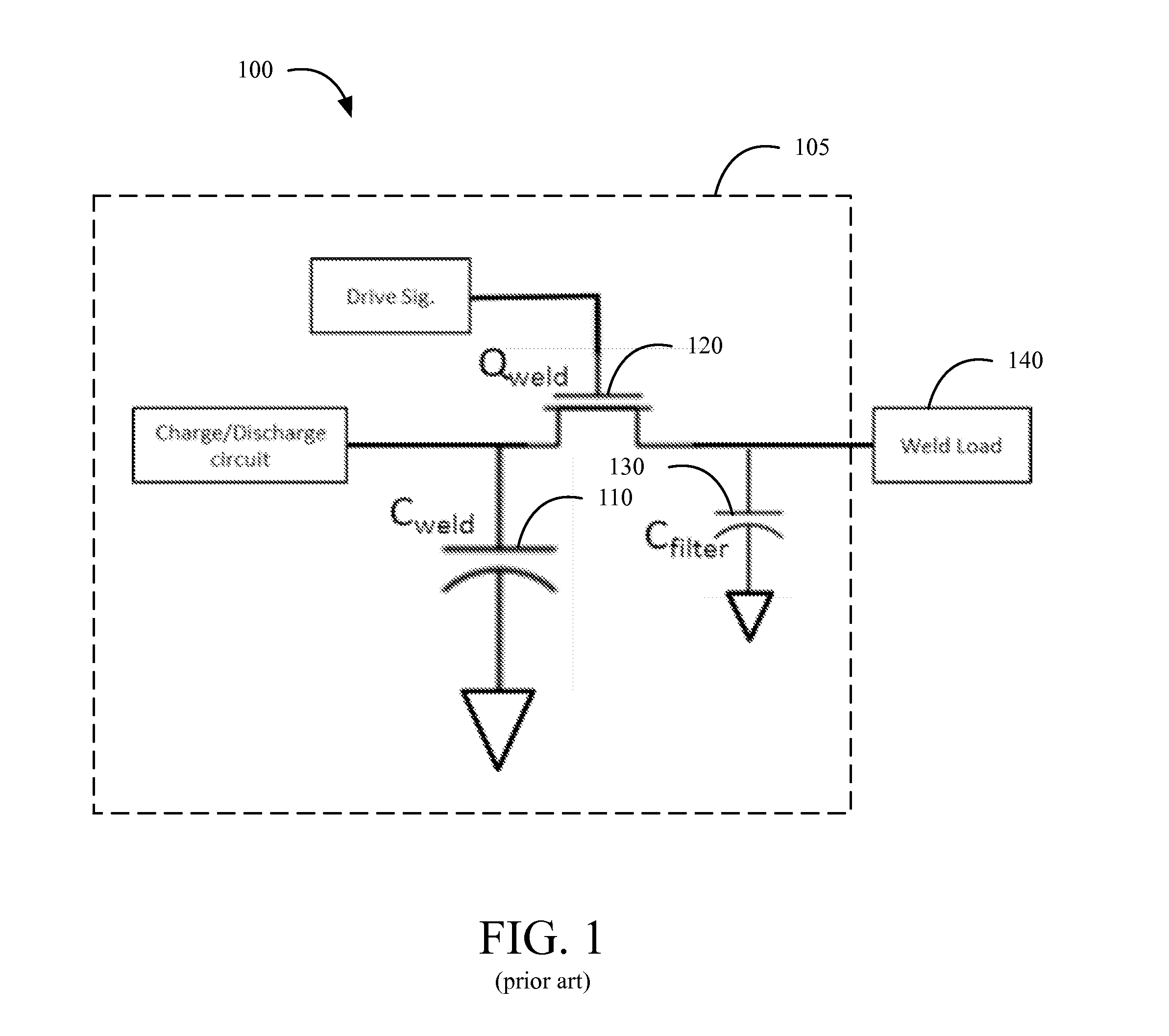

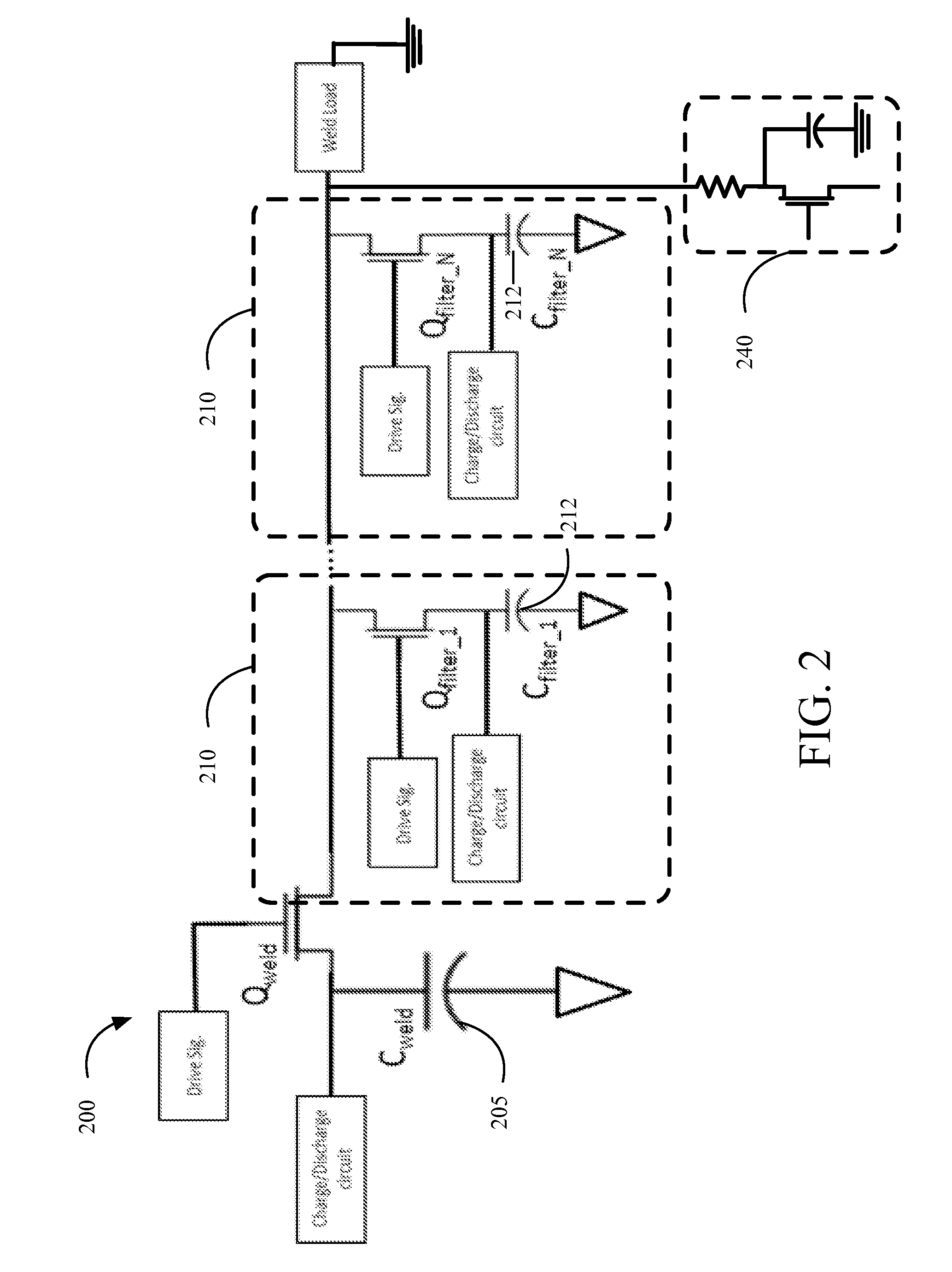

Welder With Active Linear DC Filtering Circuit

InactiveUS20150174693A1Arc welding apparatusWelding electric suppliesElectrical resistance and conductanceWelding process

A linear DC welder for enhanced welding capabilities comprises one or more active filtering circuits. The active filtering circuit(s) are capable of producing a variety of user-configurable and user-controllable custom waveforms for use in various welding applications. The custom waveforms may be created and combined via the use of overlay waveforms and, in at least some preferred embodiments of the present invention, include agitation waveforms. The overall operation of the welder, including the power supply and the active filtering circuit can be controlled via an integrated feedback cycle that provides for the monitoring and adjustment of multiple weld process parameters including volts, amps, power, resistance, and displacement. Additionally, a low current ignition (“LCI”) circuit may also be included to provide for additional welding options.

Owner:ASTLE AARON +3

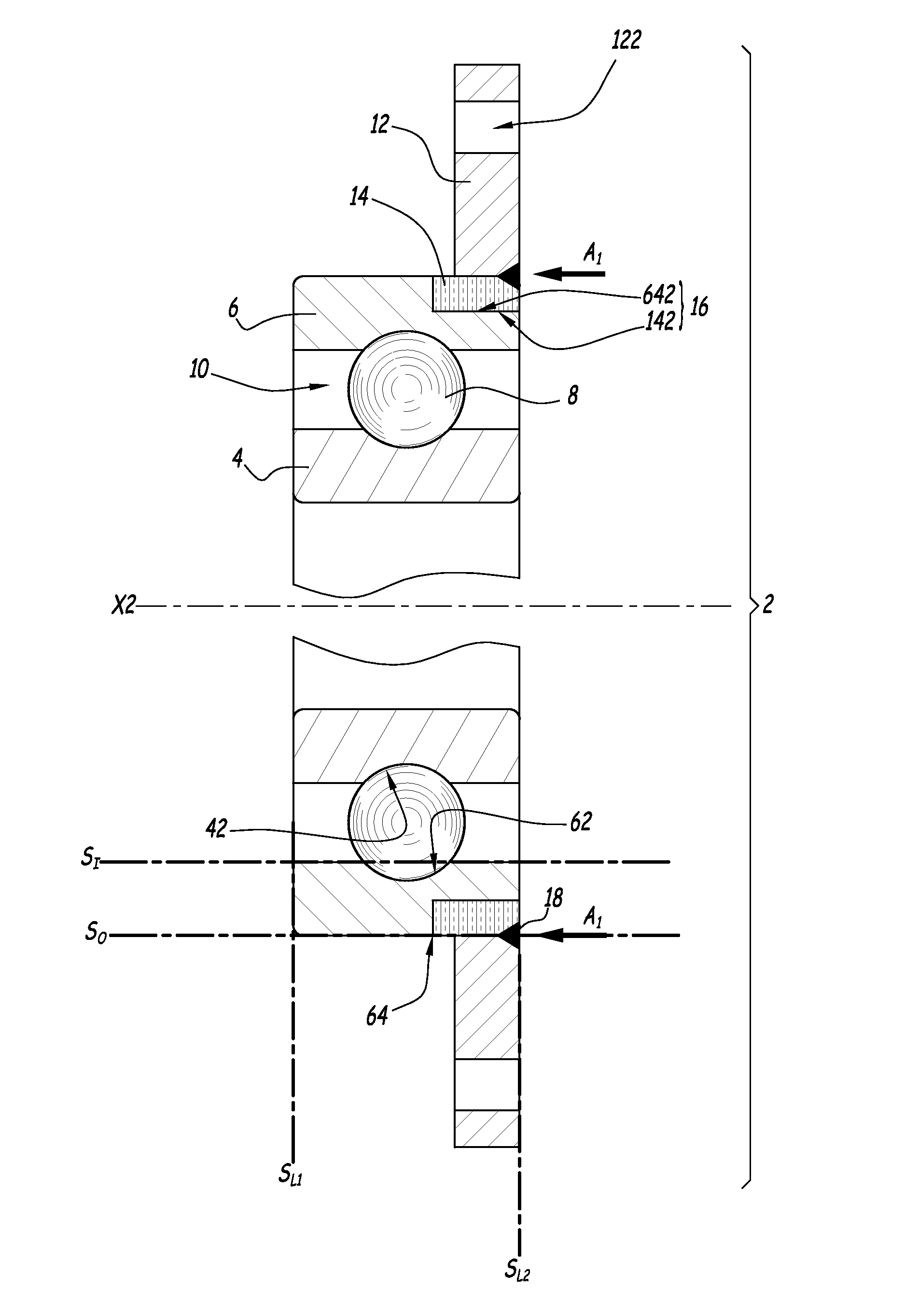

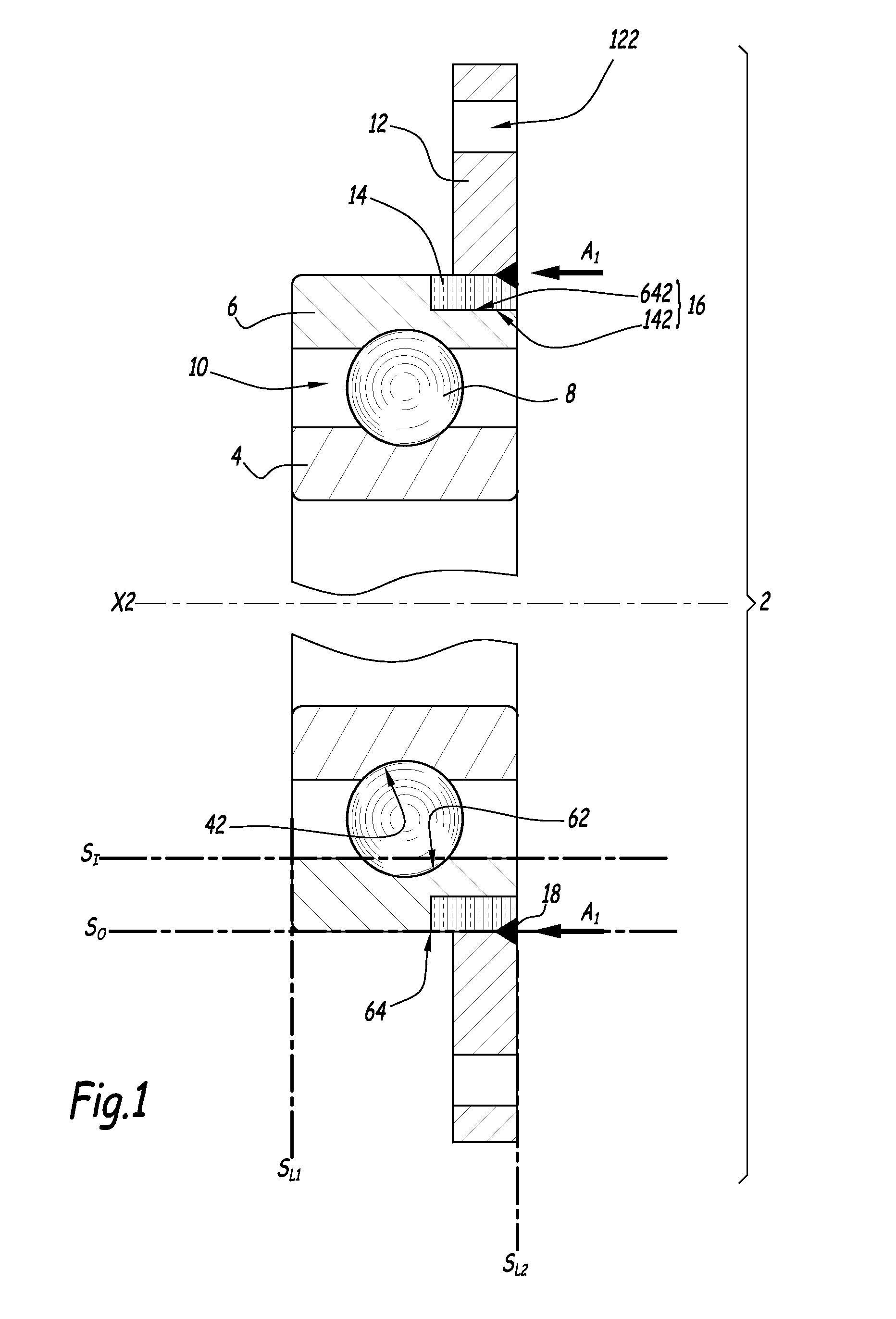

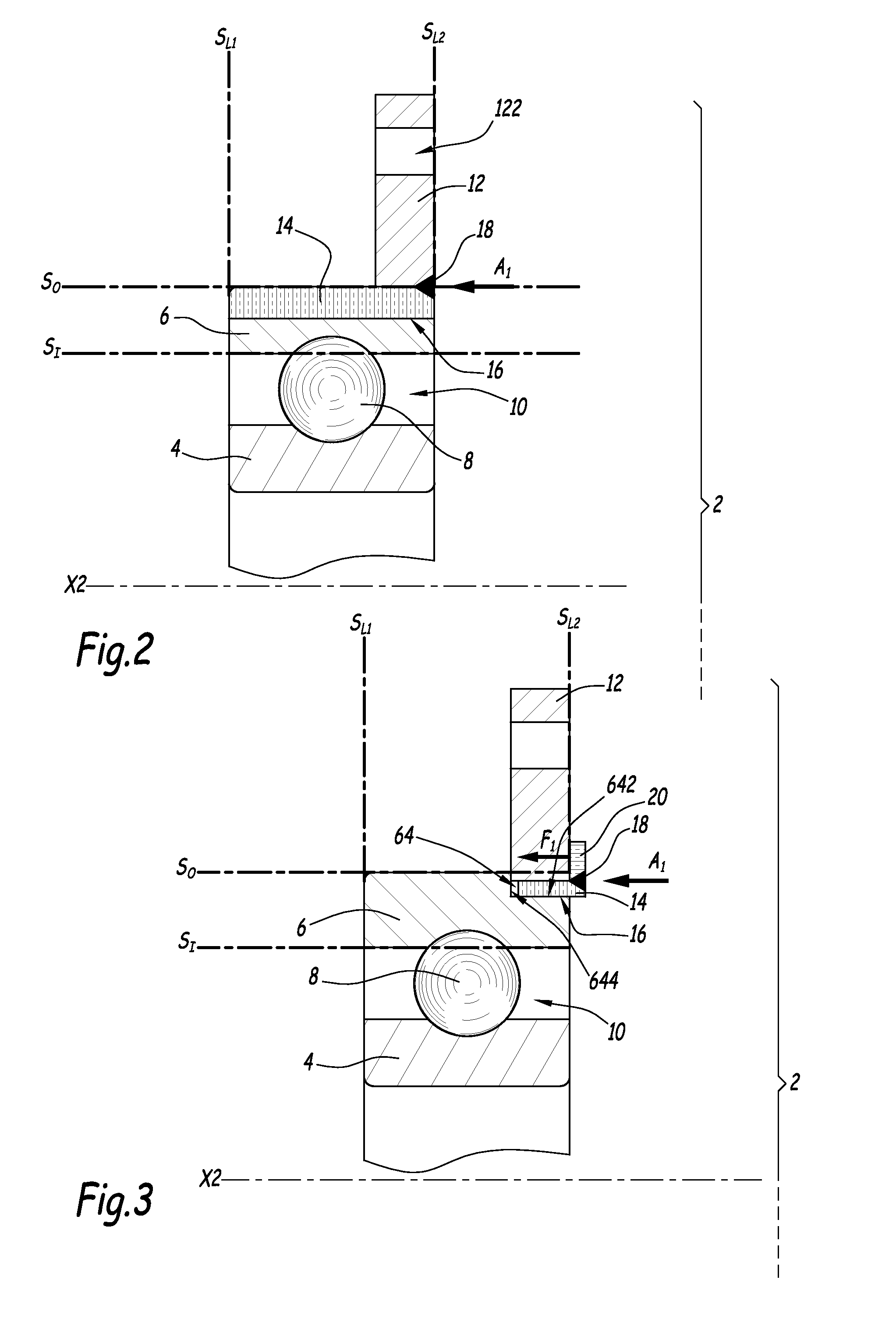

Method for manufacturing a rolling bearing and rolling bearing manufactured according to such a method

This method is for manufacturing a rolling bearing having a rotatable ring, a non-rotatable ring, rolling bodies and a flange coupled with a first ring amongst the rotatable ring and non rotatable ring. This method includes at least the following steps: forming the rings and the flange as three independent parts, immobilizing a weldable insert onto the first ring, by electro magnetic pulse technology (EMPT) or by capacitor discharge welding (CW), and welding together the insert and the flange or the insert and a flange holding member. The rolling bearing includes the insert immobilized on the first ring by magnetic pulse welding (MPW), magnetic pulse forming (MPF) or by capacitor discharge welding (CDW). Moreover, the flange or a flange holding member is welded on the insert.

Owner:AB SKF

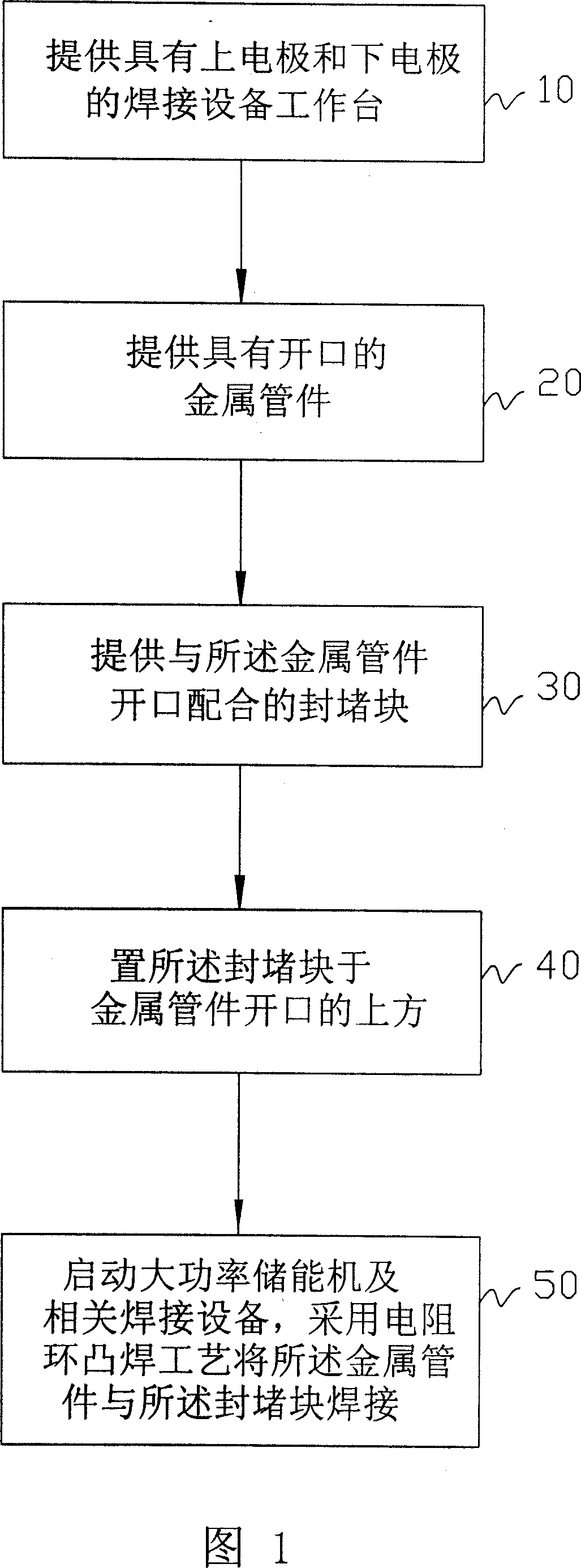

Welding method of sealing opens of metal tube member

InactiveCN101152683AFast welding speedImprove automationHeat exchange apparatusStorage discharge weldingHeat-affected zoneBlock match

The invention provides a welding method for sealing of opening of metal pipe casting and comprises the following steps: A. a welding equipment work platform is provided; B. a metal pipe casting with an opening is provided; C. a plugging block matched with the opening of the metal pipe casting is provided; D. the plugging block is arranged on upward side of the opening of the metal pipe casting; E. the welding equipment is started and the metal pipe casting and the plugging block are welded together; the welding method adopted by the welding equipment is resistance welding. The welding method provided by the invention has the advantages of high welding speed, no requirement for additive packing material, easy realization of automation and high working efficiency; short heating time and energy saving due to centralized heat lead to small heat affected field and small deformation and stress, moreover, calibration and heat treatment process are not necessary to be arranged after welding, with no flue and no requirement for numerous abrading and polishing; the invention is energy saving and environmental friendly while saving material.

Owner:HERON INTELLIGENT EQUIP CO LTD

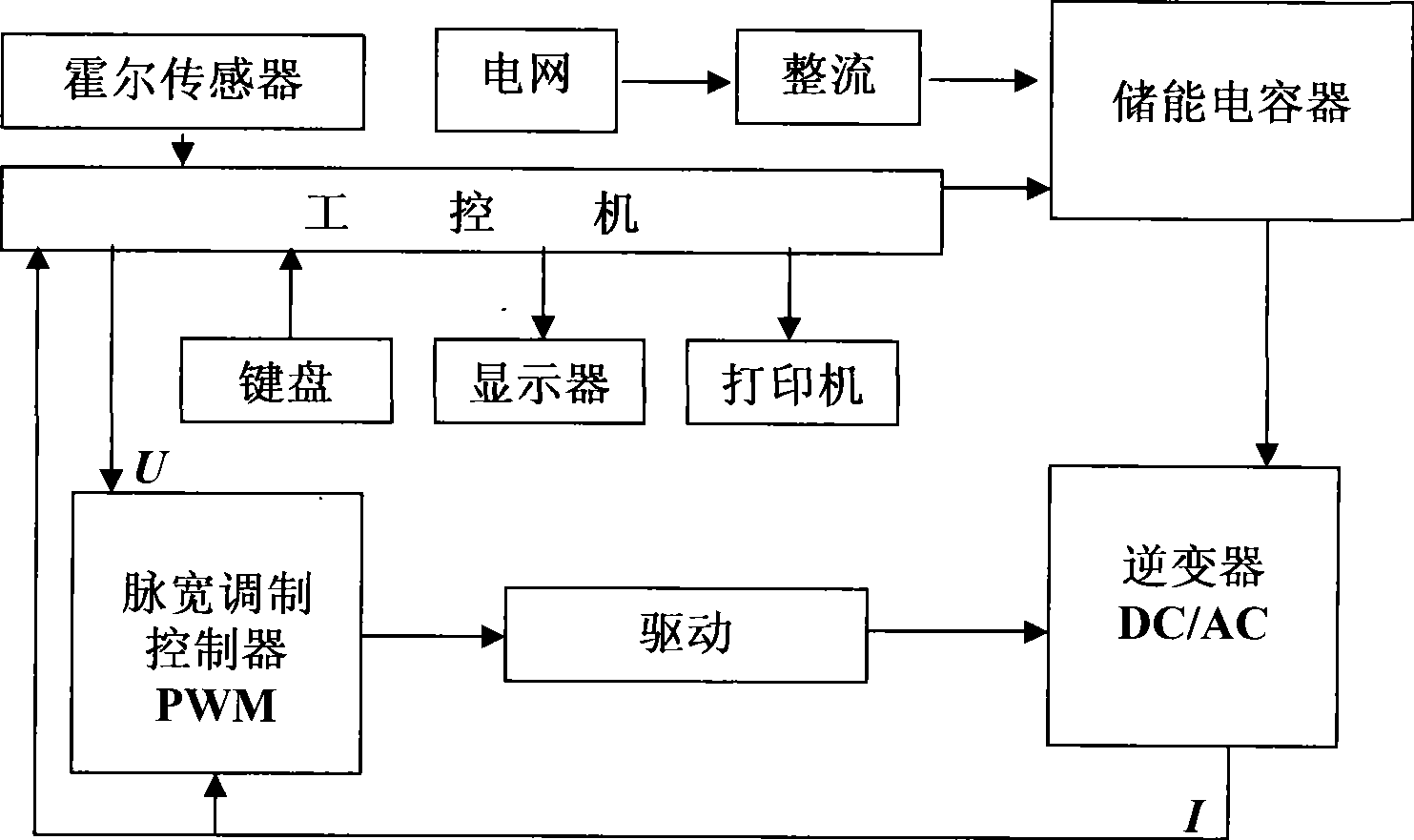

Capacitance energy storage type inversion spot welding method

InactiveCN101480754AMeet welding process requirementsEliminate "striking" phenomenonStorage discharge weldingCapacitanceTransformer

The invention relates to a capacitor energy-storage inverter spot welding method comprising the following steps: (1) rectifying alternating current to charge an energy storage capacitor; (2) sending a command from an industrial control computer to switch a switch to the discharge position for the welding when a welding is started; (3) receiving the starting command by a data acquisition card to output a preset current setting signal to a setting signal input terminal of a PWM controller to start welding; (4) after amplifying a PWM signal from the PWM controller in a driving circuit, triggering a main switching tube in an inverter to control the normal working thereof, and rectifying and outputting high-frequency pulse square wave voltage from a main transformer for achieving the welding of work pieces, and meanwhile, feeding back and adjusting welding current and acquiring waveform thereof to display and print. The invention adopts the combination of capacitor energy-storage welding and inverter techniques to fully meet the welding process requirement of bridge strip and eliminate the splatter and the spark of the welding.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

Capacitor type welding method and welding device

The purpose of the present invention is to prevent, with a simple circuit configuration, an after-flash from occurring and a large surge voltage from occurring in a primary winding when opening between welding electrodes between which excitation current is flowing. In a capacitor type welding method according to the present invention, electric charges charged on a welding capacitor are discharged and when the discharge current is brought into a state in which the discharge current does not substantially flow through a discharge switch, excitation current that has been flowing through the primary winding of a welding transformer is transferred to the secondary winding thereof. When opening between a first welding electrode and a second welding electrode while the transferred excitation current is flowing through the secondary winding, the discharge switch is brought into a state in which the discharge switch can be turned on by applying a drive signal thereto. Surge voltage occurring in the primary winding of the welding transformer when opening between the first and second welding electrodes is thereby flowed through the discharge switch to the welding capacitor as surge current.

Owner:ORIGIN CO LTD

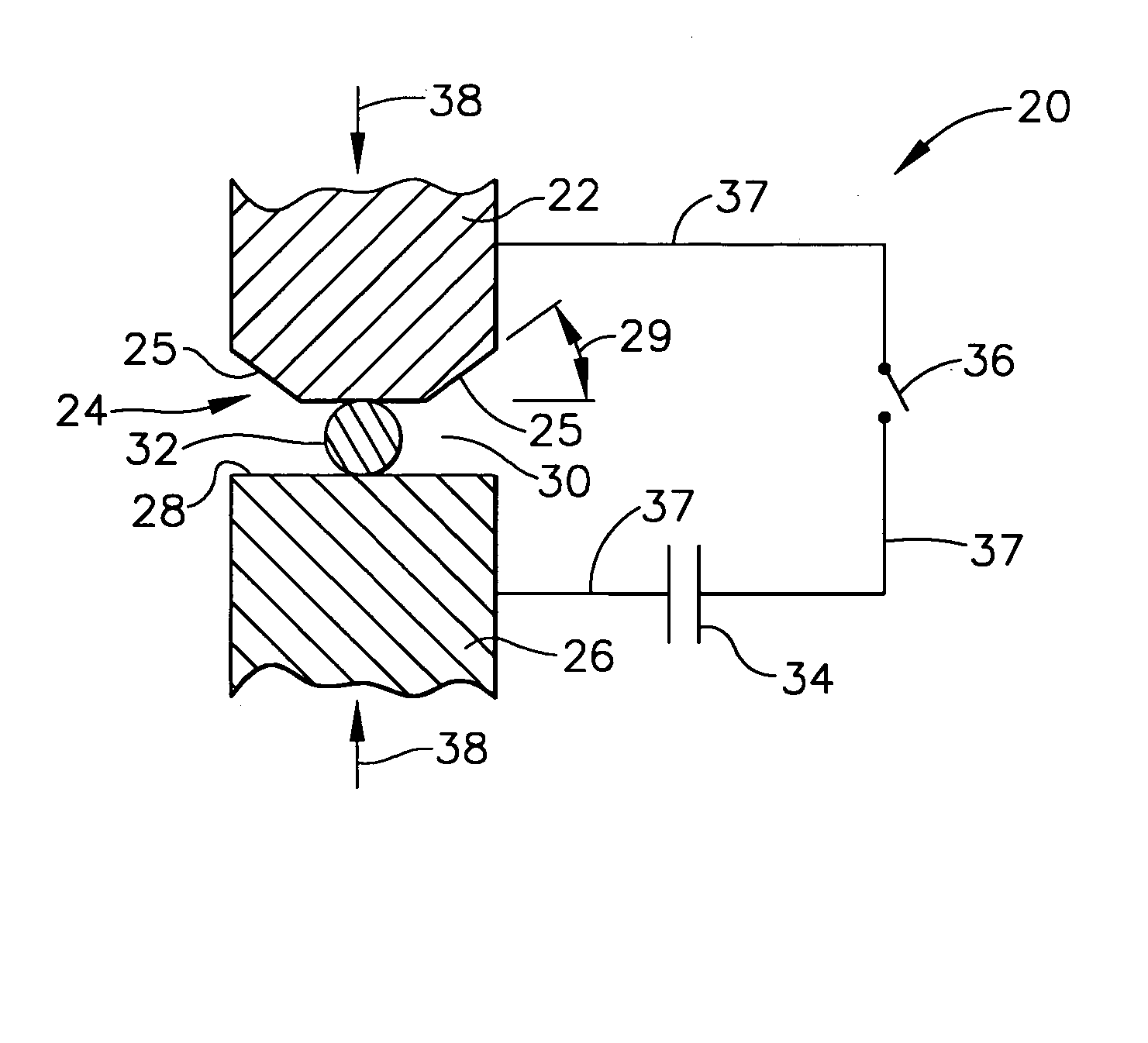

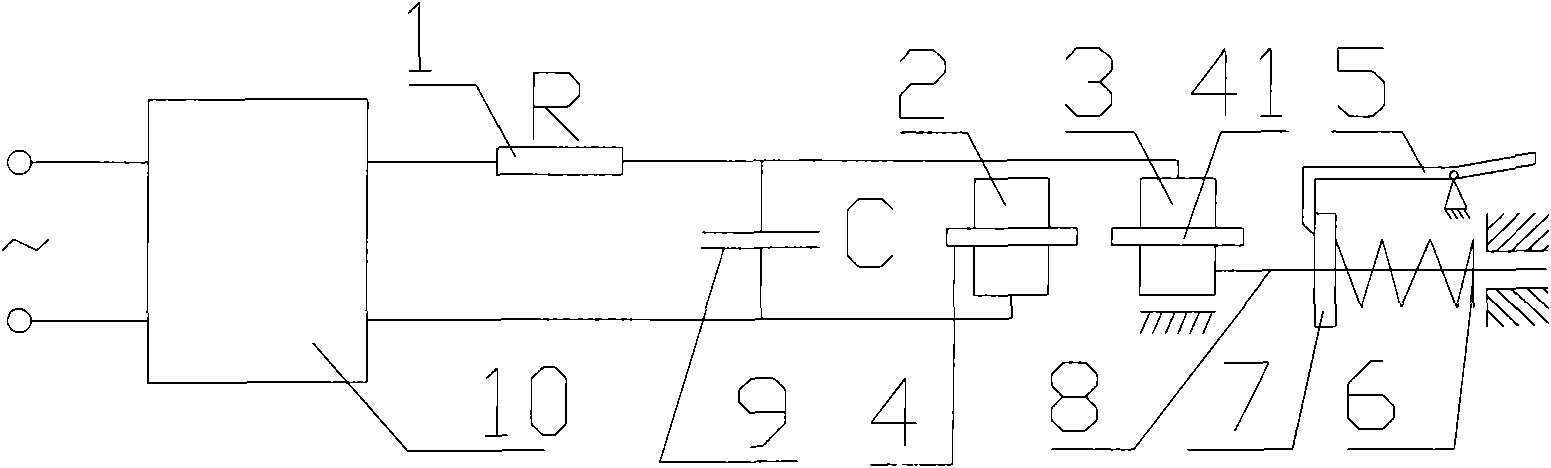

Welding device and method

InactiveCN101549434AEasy to operateHigh strengthWelding/soldering/cutting articlesStorage discharge weldingCapacitanceCurrent limiting

The invention relates to a welding device and a method; the welding device comprises a current-limiting resistor (1), a fixed clamp (2), a moving clamp (3), a capacitor (9) and a power supply and control system (10), wherein the power supply and control system (10) is connected with the current-limiting resistor (1) and the capacitor (9) so as to form a circuit; the capacitor (9) is connected with the fixed clamp (2) and the moving clamp (3) so as to from a circuit; a first welding piece (4) is clamped in the fixed clamp (2); and a second welding piece (41) is clamped in the moving clamp (3) and is connected with a position adjusting device (A) which is connected with a spring (6) and is provided with a clamping device (5). When in welding, the moving clamp (3) is pulled toward right and is hooked by the clamping device (5); the power supply is powered on and when the capacitor (9) is charged to working voltage, the clamping device (5) is released. The invention has simple welding device, convenient operation, high welding joint strength, corrosion resistance and high welding efficiency.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com