Condenser discharge welder and use method thereof

A capacitor energy storage and welding machine technology, applied in the direction of energy storage discharge welding, welding power supply, etc., can solve the problem of inability to accurately control the moving distance of the upper and lower electrodes, the welding pressure, and the inability to monitor the operation of the welding machine throughout the welding parameters. Solve problems such as the gap in welding quality of weldments, achieve the effect of human-computer interaction, convenient operation of welding machines, and accurate welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

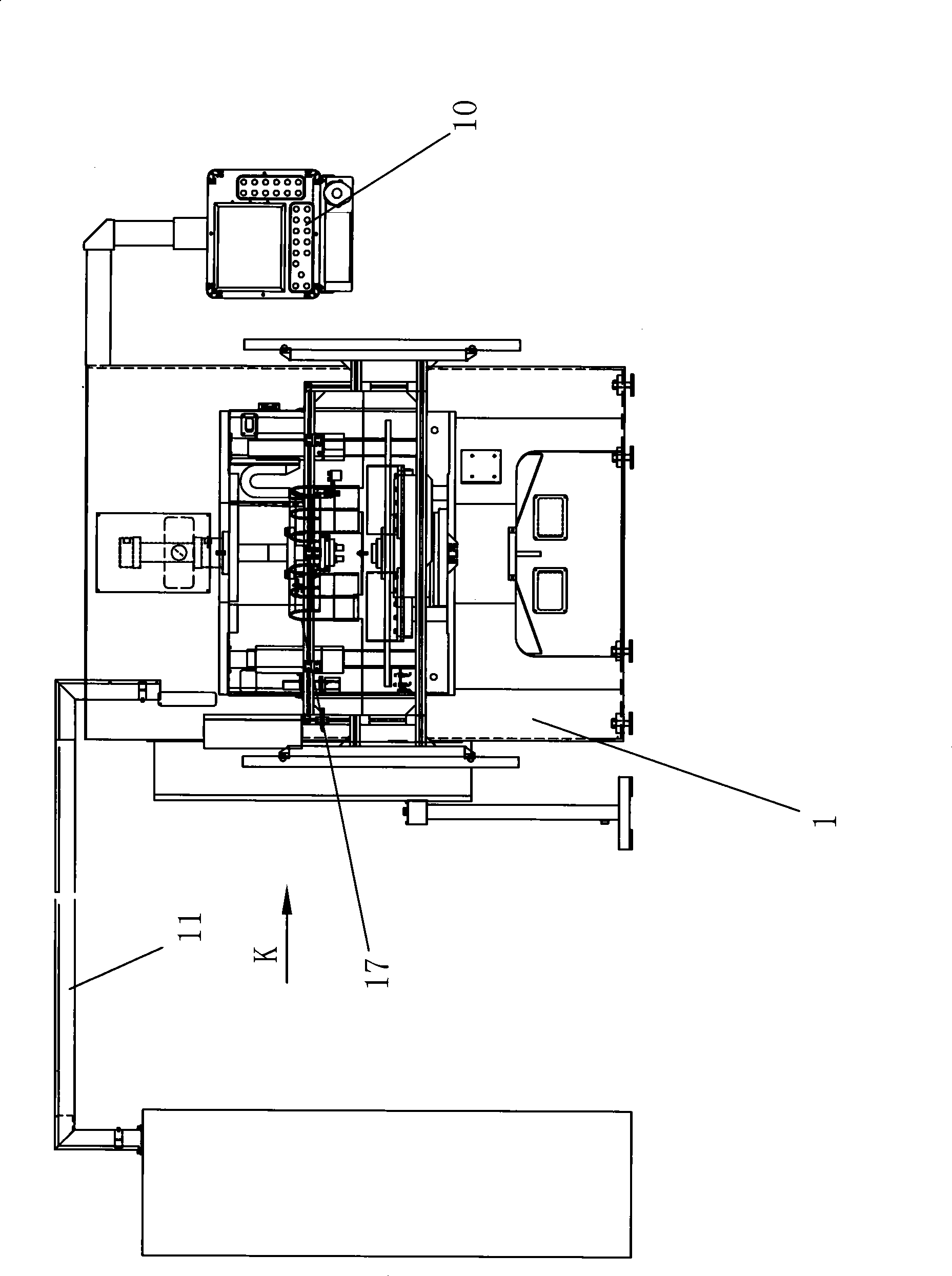

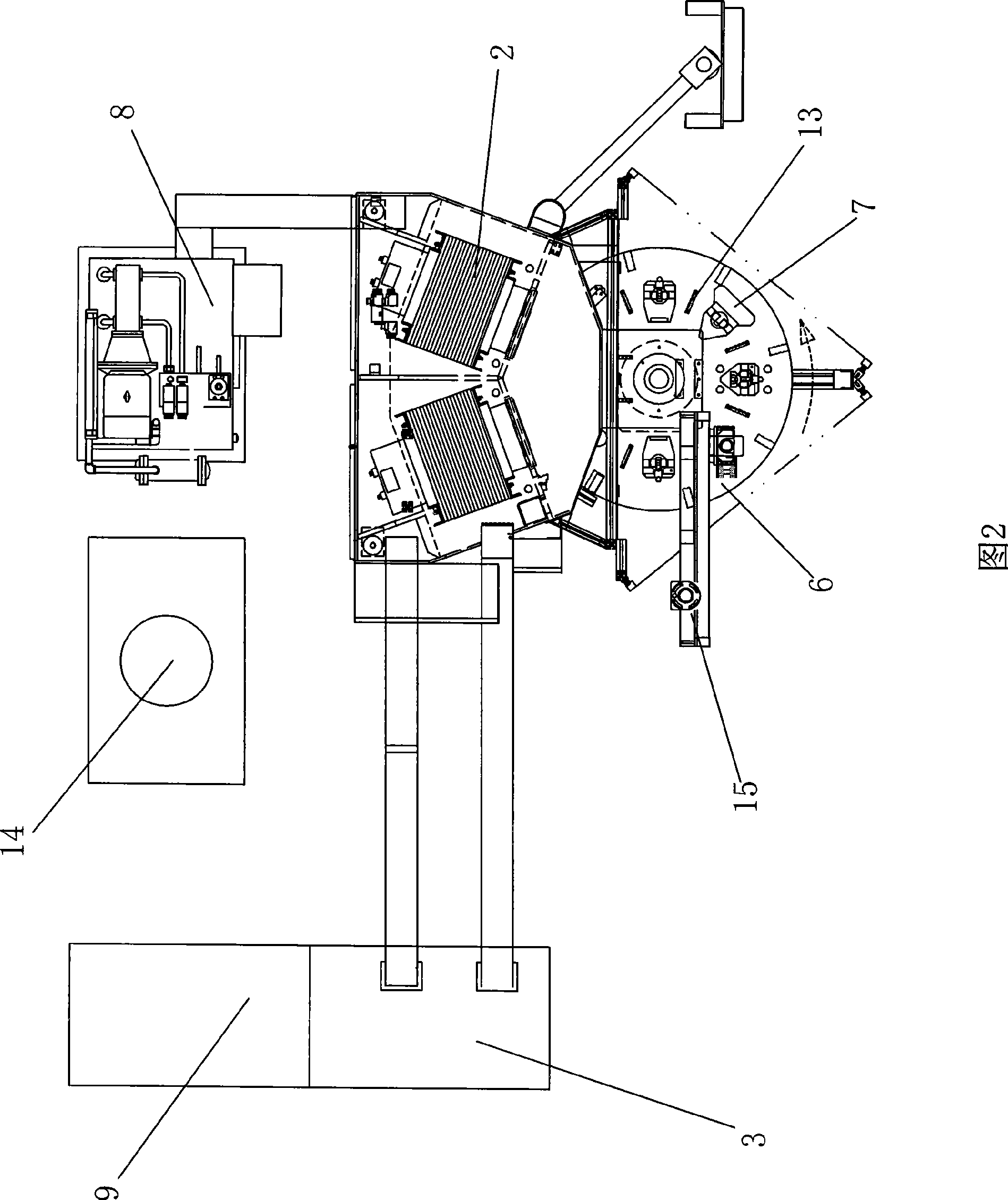

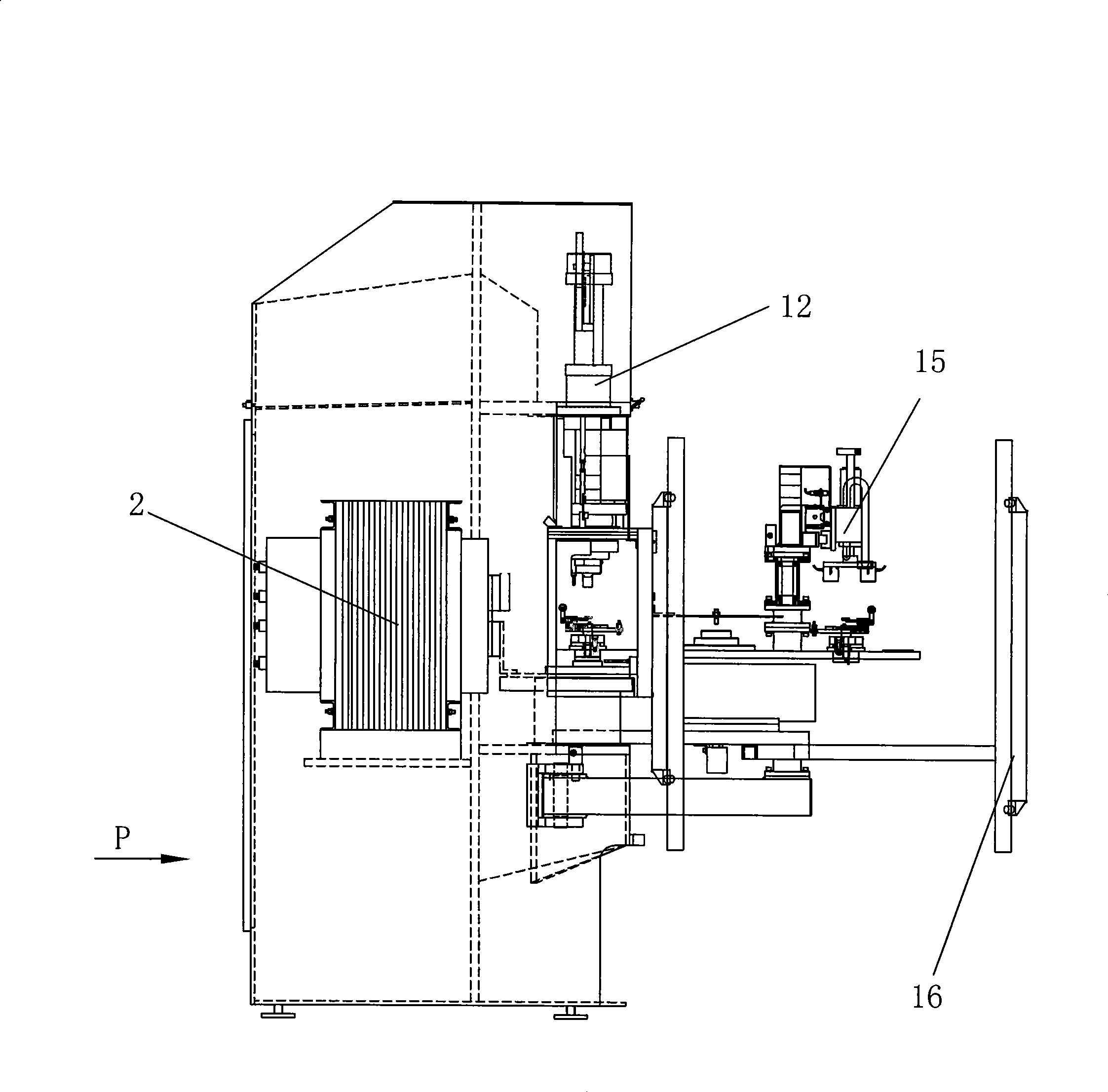

[0030] The capacitor energy storage welding machine of the present invention and its use method will be further described in conjunction with the accompanying drawings and specific embodiments.

[0031] Such as Figure 1 to Figure 4 As shown, the capacitor energy storage welding machine of the present invention includes a frame 1; a transformer 2, in the present embodiment, the transformer 2 is installed in the frame of the frame 1, greatly reducing the volume of the welding machine; the main electric cabinet 3; The upper electrode 4 and the lower electrode 5 on the frame 1, the upper electrode 4, the lower electrode 5 are electrically connected with the transformer 2 through a wire; A total of eight stations are provided, and a fixture 7 for clamping the weldment is provided corresponding to each station on the turntable 6; a drive mechanism 8 for driving the upper electrode 4 to move during the welding process , in this embodiment, the drive mechanism 8 is driven by hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com