Welding method of sealing opens of metal tube member

A technology for metal pipe fittings and welding methods, applied in welding power sources, welding equipment, energy storage discharge welding, etc., can solve the problems of a lot of smoke and harmful gases, slow welding speed, increase energy loss, etc., and achieve easy automation and welding speed. The effect of fast, short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

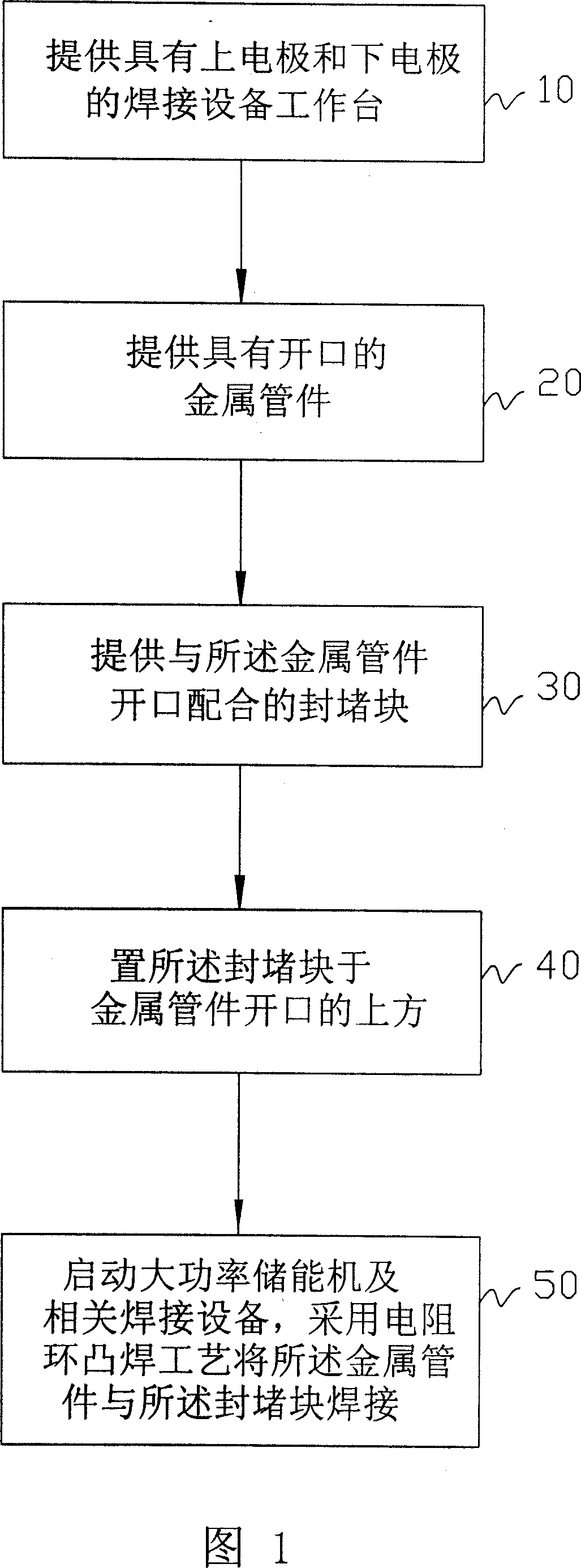

[0030] With reference to accompanying drawing 1, illustrated the step flow process of steel pipe seal welding method of the present invention, comprises

[0031] Step 10: providing a welding equipment table with an upper electrode and a lower electrode;

[0032] Step 20: providing a metal pipe with an opening;

[0033] Step 30: providing a blocking block matched with the opening of the metal pipe;

[0034] Step 40: placing the blocking block above the opening of the metal pipe;

[0035] Step 50: Start the high-power energy storage machine and related welding equipment, and use the resistance ring projection welding process to weld all

[0036] The metal pipe fitting is welded to the blocking block.

[0037] With reference to accompanying drawing 2, illustrate an embodiment of steel pipe seal welding method of the present invention, comprise processing pipe fitting 1, plugging block 2, upper electrode 3 and lower electrode 4; It is processed into an inclined cone surface, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com