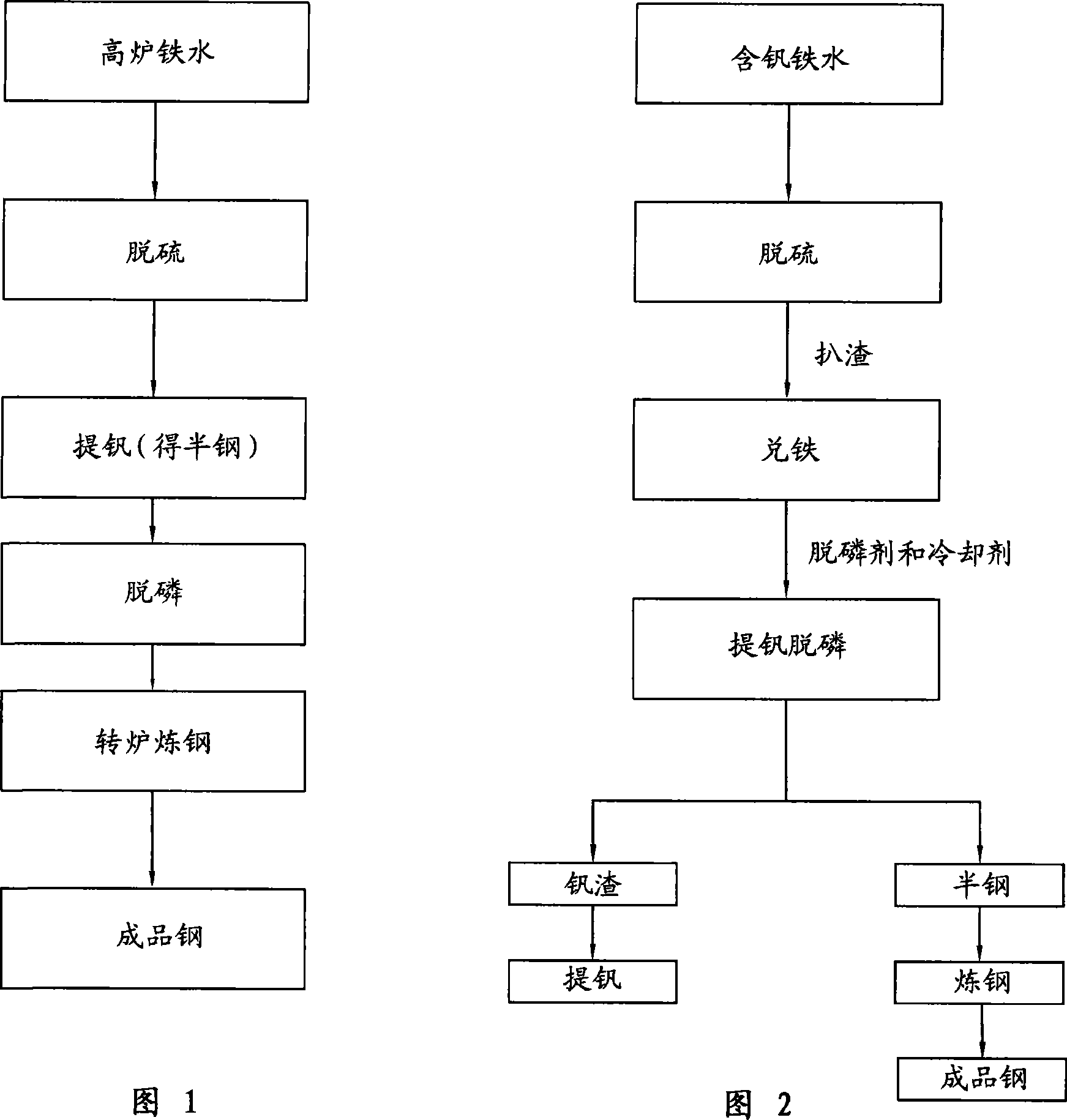

Method for extracting vanadium and removing phosphorus from vanadium-containing molten iron and steel-smelting technique using the same method

A technology for extracting vanadium dephosphorization agent and molten iron, which is applied in the field of steelmaking technology, can solve the problems of process complexity and reduction, and achieve the effect of reducing the pressure of dephosphorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Desulfurization of vanadium-containing molten iron: the vanadium-containing molten iron smelted in the blast furnace, after desulfurization and slag removal, the vanadium-containing low-sulfur molten iron is obtained, and its composition is: 4.23%C, 0.16%Si, 0.15%Mn, 0.28%V, 0.010%S , 0.060% P, 0.18% Ti, and the balance is Fe, all of which are percentages by weight, and the sum of the percentages is 100%;

[0023] 2) Dephosphorization while extracting vanadium: successively load Na 2 CO 3 and vanadium-containing low-sulfur hot metal, the charging amount of molten iron is 135t, Na 2 CO 3 The amount of addition is 2.5t, and then the converter is blown with oxygen; within 1 to 3 minutes of blowing with oxygen, add 600kg of iron oxide scale into the furnace as a coolant;

[0024] 3) Slag adjustment: after 5 minutes of blowing with oxygen, add 500kg of magnesia to the furnace for slag adjustment;

[0025] 4) Obtaining semi-steel and vanadium slag: then blowing with ox...

Embodiment 2

[0028] 1) Desulfurization of vanadium-containing molten iron: the vanadium-containing molten iron smelted in the blast furnace, after desulfurization and slag removal, the vanadium-containing low-sulfur molten iron is obtained, and its composition is: 4.42%C, 0.18%Si, 0.14%Mn, 0.24%V, 0.020%S , 0.077%P, 0.22%Ti, and the balance is Fe, all of which are percentages by weight, and the sum of the percentages is 100%;

[0029] 2) Dephosphorization while extracting vanadium: Add 140t of vanadium-containing low-sulfur molten iron into the 120t converter, and then carry out oxygen blowing to the converter; within 1 to 3 minutes of oxygen blowing, add 600kg of iron oxide scale into the furnace and Na 2 CO 3 2.5t;

[0030] 3) Slag adjustment: after 5 minutes of blowing with oxygen, add 350kg of magnesia to the furnace for slag adjustment;

[0031] 4) Obtaining semi-steel and vanadium slag: then blowing with oxygen supply for 0.5-1.0 minutes to stop the slag to produce semi-steel and ...

Embodiment 3

[0034] 1) Furnace low-sulfur molten iron for oxygen blowing: Use low-sulfur high-vanadium iron block (water) smelted in an electric furnace to extract vanadium and dephosphorize. The composition of the molten iron is: 4.08%C, 0.38%Si, 0.43%Mn, 1.24% V, 0.018% S, 0.118% P, 0.46% Ti, the balance is Fe, the above are weight percentages, and the sum of the percentages is 100%; 500kg of the molten iron is added to the medium frequency induction furnace for melting, or 500kg of the molten iron Blended into the intermediate frequency induction furnace for oxygen blowing;

[0035] 2) Dephosphorization while extracting vanadium: within 3 to 5 minutes of blowing with oxygen supply, add 13 kg of vanadium extracting and dephosphorizing agent Na 2 CO 3 (Na 2 CO 3 It not only has the function of vanadium extraction and dephosphorization, but also has the function of coolant, and no additional coolant can be added);

[0036] 3) To obtain semi-steel and vanadium slag: the total time of bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com