Reduced pressure ultrasonic combined extraction device

An extraction device and ultrasonic technology, applied in the field of combined extraction devices, can solve the problems of low extraction efficiency of the decompression extraction device, and achieve the effects of saving solvent, easy dissolution, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

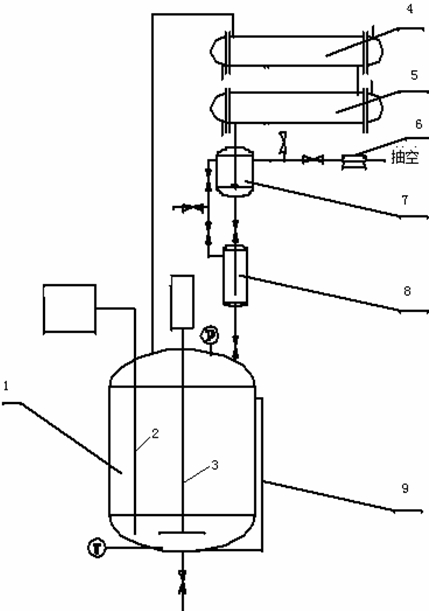

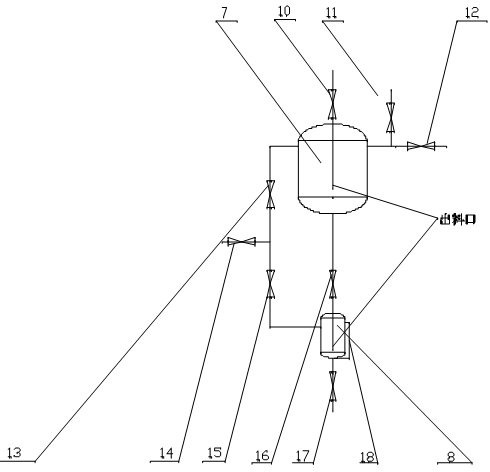

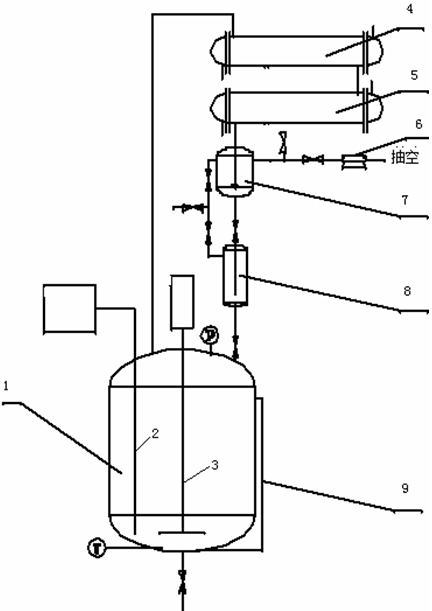

[0019] A decompression ultrasonic combined extraction device, comprising an extraction tank 1, a condenser 4, a cooler 5, a gas-liquid separation device for keeping the extraction tank 1 in a vacuum state, an extraction tank 1, a condenser 4, a cooler 5, The gas-liquid separation devices are connected end to end and form a circulation loop through pipelines. The extraction tank 1 is provided with an ultrasonic generator 2 and a stirring device 3 under the liquid surface in the tank. The invention can not only keep the extraction always carried out under the low-temperature boiling state with a certain degree of vacuum and concentration, so as to ensure the product quality, but also improve the extraction rate of natural products and shorten the extraction time by using the ultrasonic modern extraction technology. The extraction tank 1 is equipped with an ultrasonic generator and a stirring device, and the ultrasonic vibrator and the stirring paddle are arranged under the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com