Novel industrialization method for comprehensive utilization of vanadium ferrotitanium ore concentrate

A vanadium-titanium iron concentrate and industrial technology, which is applied in the field of comprehensive utilization of vanadium-titanium iron concentrate, can solve the problems of short service life of refractory containers, high labor intensity of loading and unloading materials, low production capacity of a single kiln, etc., and achieve low production cost, The best economic effect, technically sound and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

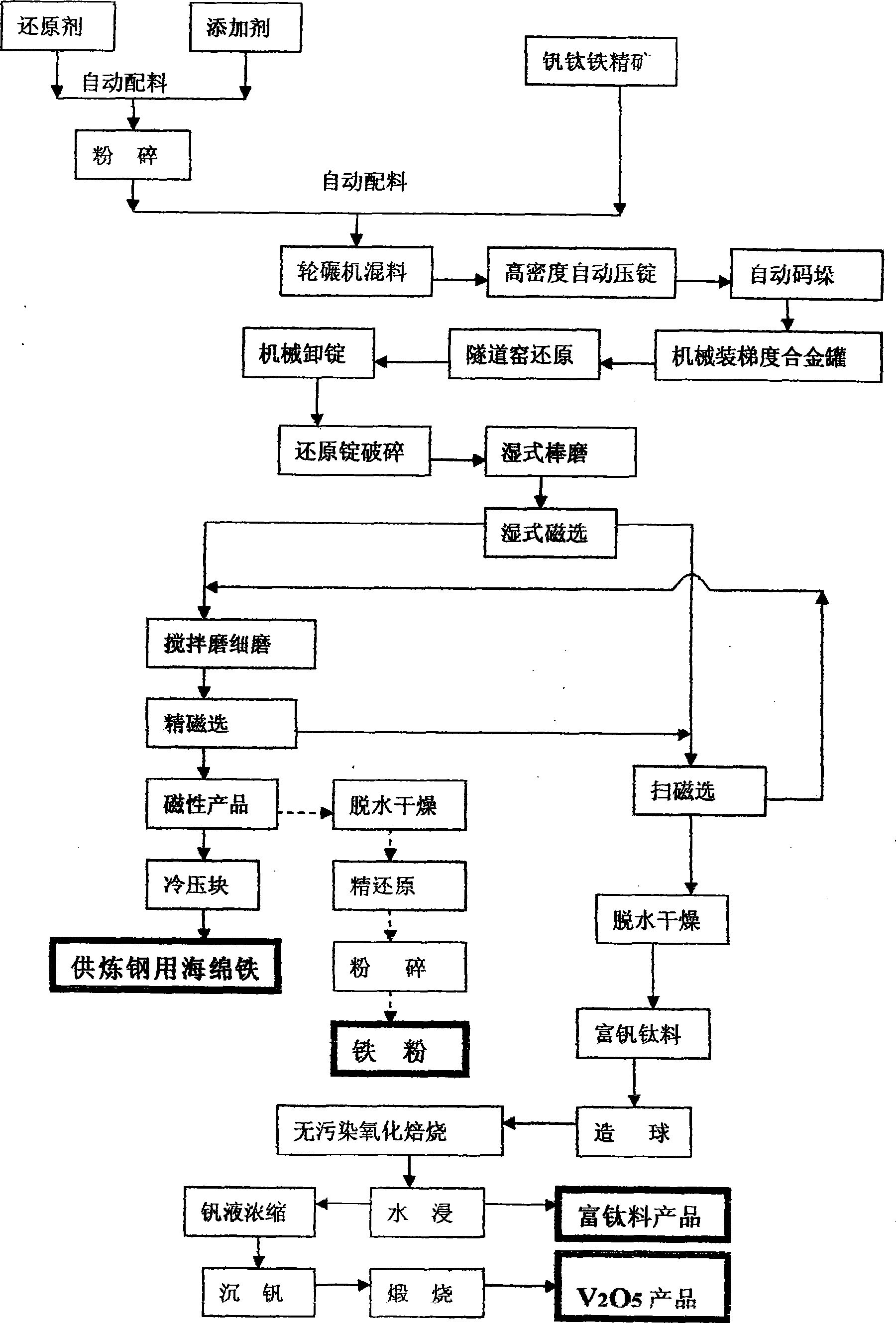

[0052] Attached figure 1 Process, mixing vanadium-titanium-iron concentrate with additive sodium salt and reducing agent through wheel mill, automatic ingot pressing, mechanical loading of gradient alloy tank, pushing into tunnel kiln for direct reduction, mechanical unloading of reduction ingot, crushing, grinding, magnetic separation , Separation of iron, titanium and vanadium.

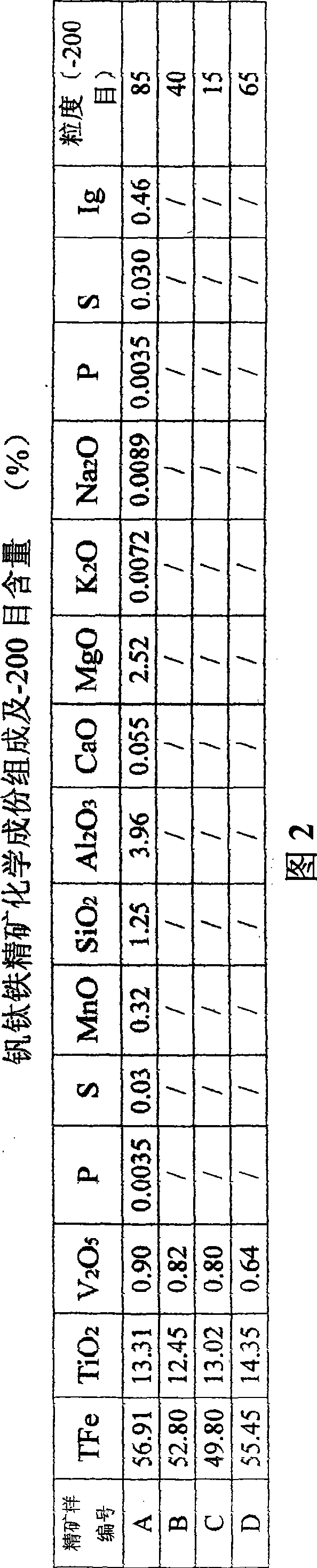

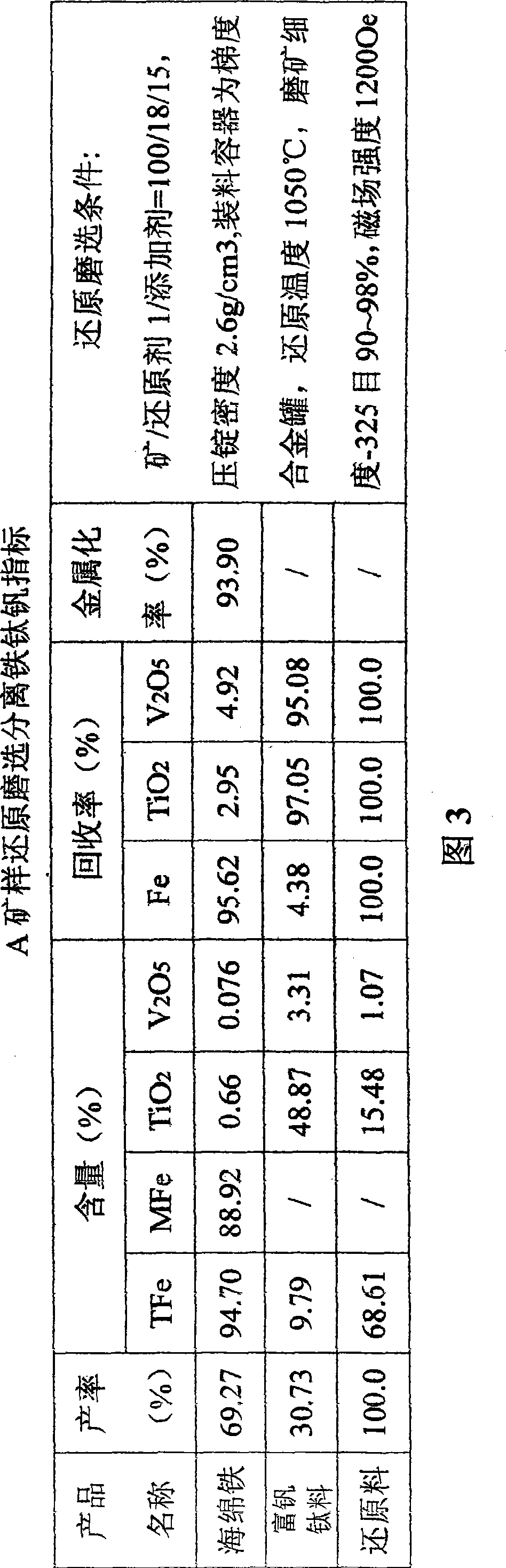

[0053] The chemical composition and -200 mesh content of four vanadium-titanium-iron concentrates with different grades A, B, C, and D are listed in Figure 2. The reduction grinding conditions and the separation indicators of iron, titanium, and vanadium are shown in Figure 3, respectively. Figure 4 table, Figure 5 table and Figure 6 table. From the results in Figures 3, 4, and 5, it can be seen that different grades of vanadium-titanium iron concentrates can obtain good iron, titanium, and vanadium separation indicators, but the higher the grade of the concentrate, the greater the yield of the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com