Repaired roller and method for repairing roller

A roll and roll surface technology, which is applied in the field of iron and steel production equipment, can solve the problems of increasing production costs, limiting the service life of rolls, and poor mechanical properties of rolls, and achieves the effects of increasing service life, improving mechanical properties, and uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

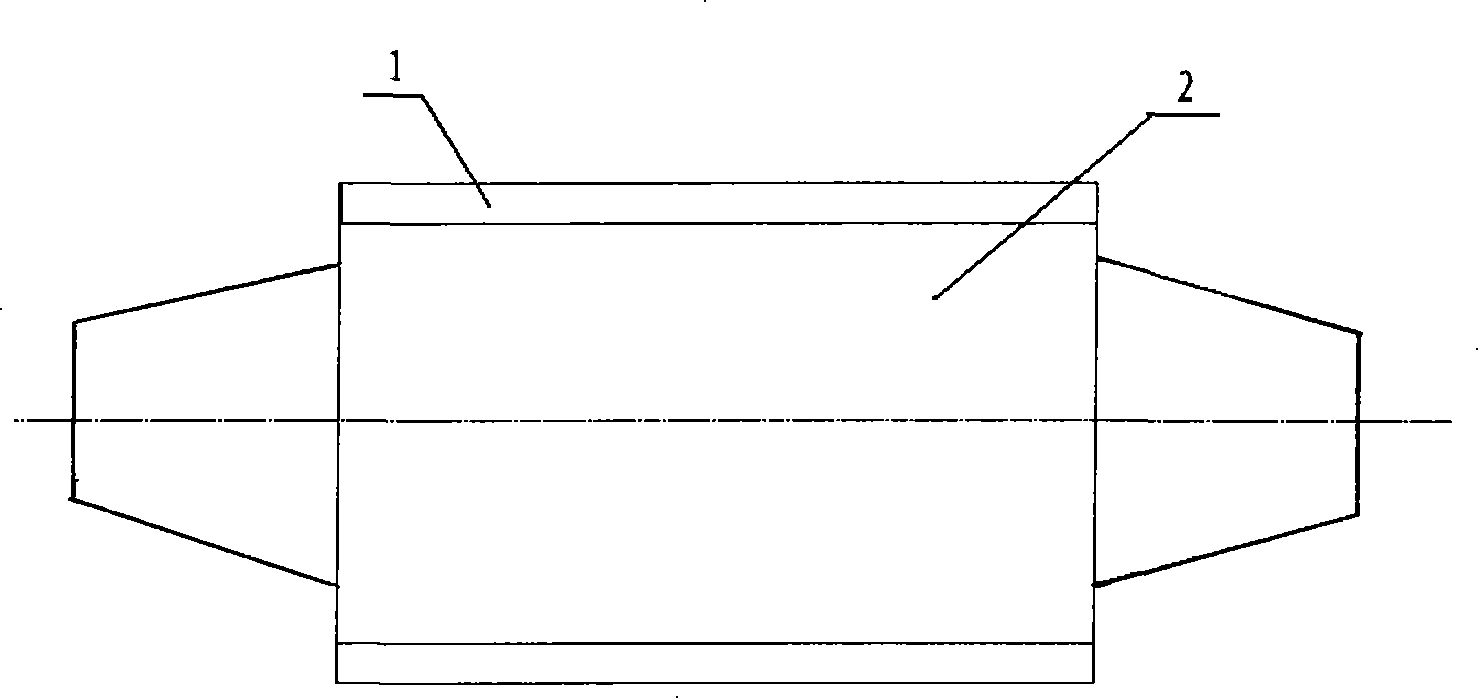

[0017] like figure 1 In the process, the waste roll that cannot be used after wear and tear is firstly cut off the wear layer along the outer surface of the roll by mechanical cutting method to obtain a roll core 2, and then the cladding agent coating material similar to or consistent with the base material is selected and sprayed On the surface of the roller core, it is melted together with a thin layer by laser irradiation to form a cladding layer 1 .

[0018] like figure 2 Among them, the laser cladding layer 1 is divided into a cladding surface layer 3 , a cladding middle layer 4 , and a cladding bottom layer 5 . The spot diameter during laser cladding is generally 5-15 mm, so the cladding surface can be regarded as a semi-infinite plane. The high-power laser beam irradiates the surface of the cladding layer with a constant power P, and moves along the direction of the roll body at a constant speed v. At the same time, the powder is directly fed into the molten pool by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com