Cold work roll steel for high-strength steel rolling, cold work roll and its manufacturing method

A technology of cold-rolled work rolls and manufacturing methods, which is applied in the direction of rolls, metal rolling, and manufacturing tools, and can solve problems such as poor wear resistance, insufficient strength of the roll body, and special carbides with low wear resistance, and achieve improved roll Body strength and wear resistance, the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

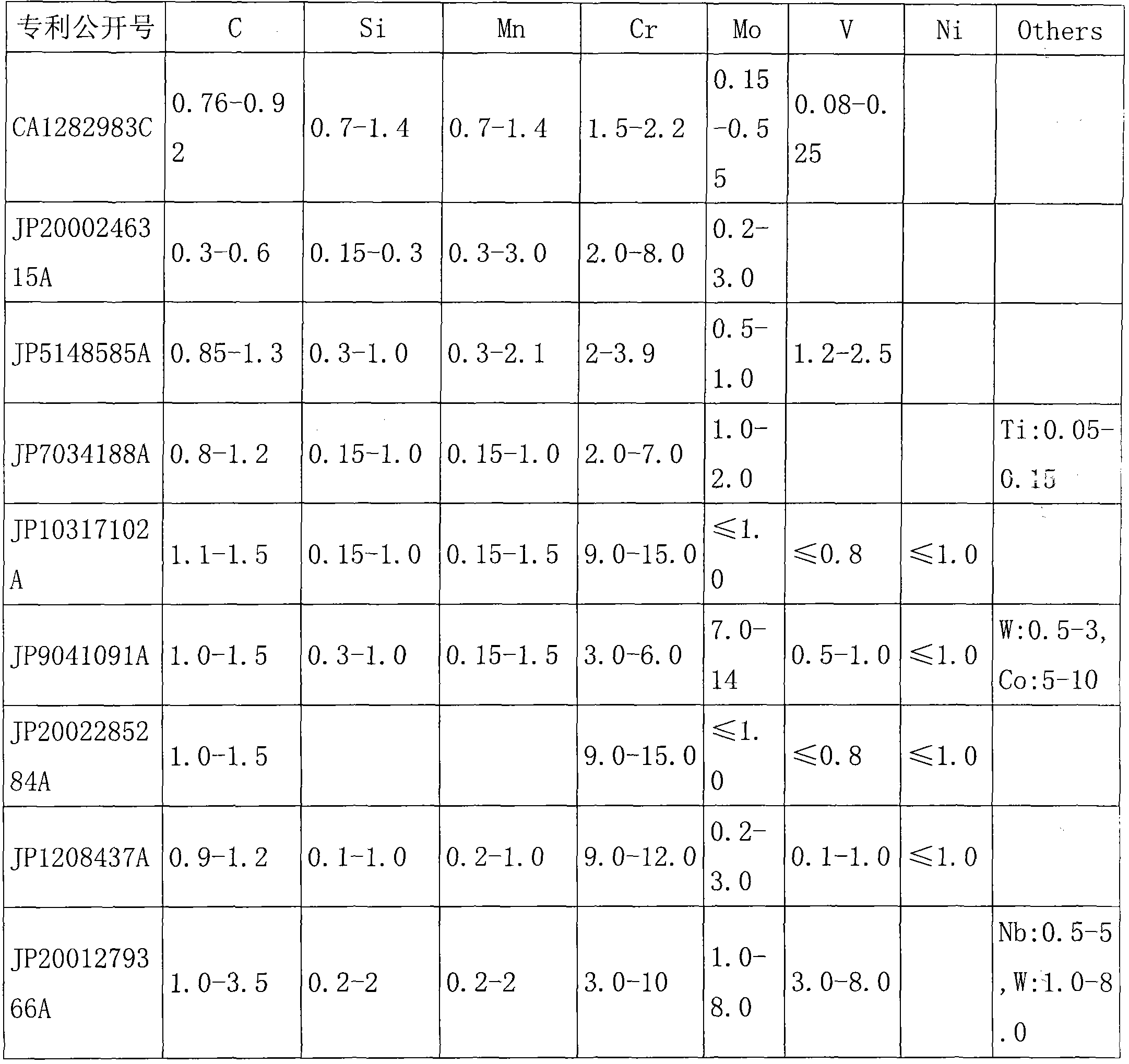

[0021] Now implement the novel cold rolling work roll steel and work roll of the present invention respectively by the chemical composition shown in table 2.

[0022] The chemical composition (wt.%) of table 2 cold rolling work roll of the present invention

[0023] C Si mn Cr Ni Mo V P S Control material 0.85 0.40 0.35 5.00 0.35 0.35 0.15 0.013 0.006 Example 1 0.78 0.68 0.63 5.21 - 1.03 0.47 0.012 0.005 Example 2 0.73 0.81 0.71 5.11 - 1.10 0.51 0.014 0.005 Example 3 0.76 0.90 0.73 5.55 - 1.22 0.53 0.012 0.007 Example 4 0.75 0.85 0.92 5.94 - 1.35 0.49 0.013 0.005 Example 5 0.69 0.83 0.81 5.76 - 1.47 0.41 0.014 0.006

[0024] The process route is as follows:

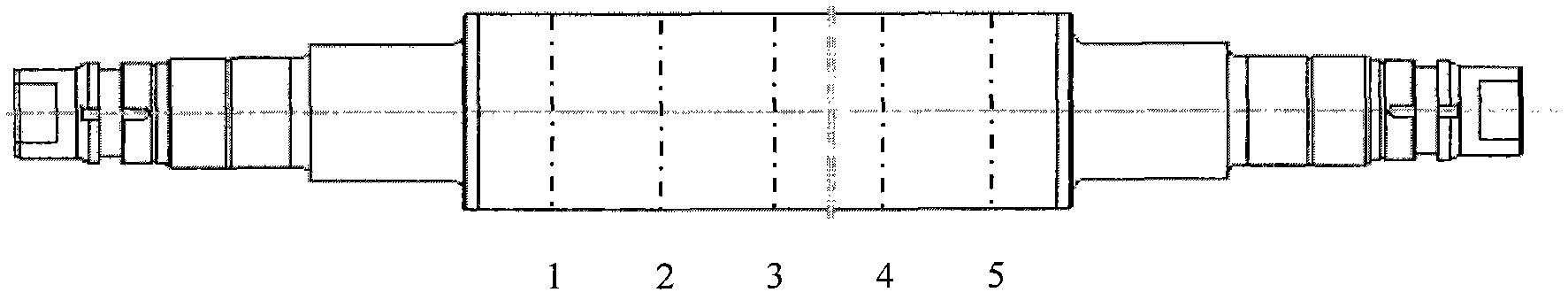

[0025] Electric furnace smelting→external refining→vacuum degassing→casting electrode rod→ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com