Surfactant/polymer water repellent identification composite oil displacement agent and preparation method thereof

A technology of surfactant and combined oil displacement, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of loss, surfactant is easy to be absorbed by the formation, and the synergistic effect is not obvious, so as to achieve friction Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

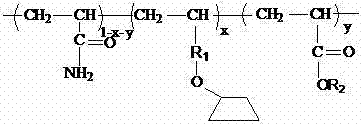

[0012] The preparation method of grafted cyclodextrin acrylamide polymer comprises the following steps.

[0013] Add 6mL of acrylamide (AM) with a concentration of 0.5g / mL and a concentration of 3mL of 0.5g / mL acrylic acid, the molar ratio of acrylamide, acrylic acid and allyl cyclodextrin or maleic anhydride modified cyclodextrin or acrylic acid modified cyclodextrin is 69.2~84.2:30~15: 0.8; then add 1 mL of 0.5 g / mL disodium edetate chelating agent, 1 mL of 0.5 g / mL potassium persulfate oxidizing agent and 0.5 mL of 1.0 g / mL sodium bisulfite reducing agent ; After mixing evenly, fill with nitrogen gas for 20-40 minutes to remove oxygen, then react at 30-50°C for 6-8 hours, neutralize the pH with NaOH solution to 6-7, and obtain grafted cyclodextrin acrylamide polymer;

Embodiment 1

[0015] Take 1 mL of cetyltrimethylammonium chloride solution with a concentration of 800 mg / L and a grafted cyclodextrin acrylamide polymer (R 1 for CH 2 , R 2 is Na, the molar percentage of X is 5%, and the molar percentage of Y is 8%) 300mL are mixed, stirred for 36 hours, and the stirring temperature is 40°C. A surfactant / polymer hydrophobic recognition composite oil displacement agent is obtained. The simulated core displacement test results show that the oil recovery rate is 87.2%;

Embodiment 2

[0019] Take the concentration of 800mg / L sodium dodecylbenzenesulfonate solution 1mL and the concentration of 1200mg / L grafted cyclodextrin acrylamide polymer (R 1 for CH 2 , R 2 is Na, the molar percentage of X is 5%, and the molar percentage of Y is 8%) 300mL are mixed, stirred for 36 hours, and the stirring temperature is 40°C. A surfactant / polymer hydrophobic recognition composite oil displacement agent is obtained. The simulated core displacement test results show that the oil recovery rate is 92.1%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com