Preparation method of hydrodesulfurization catalyst for high-nitrogen low-quality gasoline and diesel

A hydrodesulfurization and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve high dispersion, concentrated pore size distribution, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

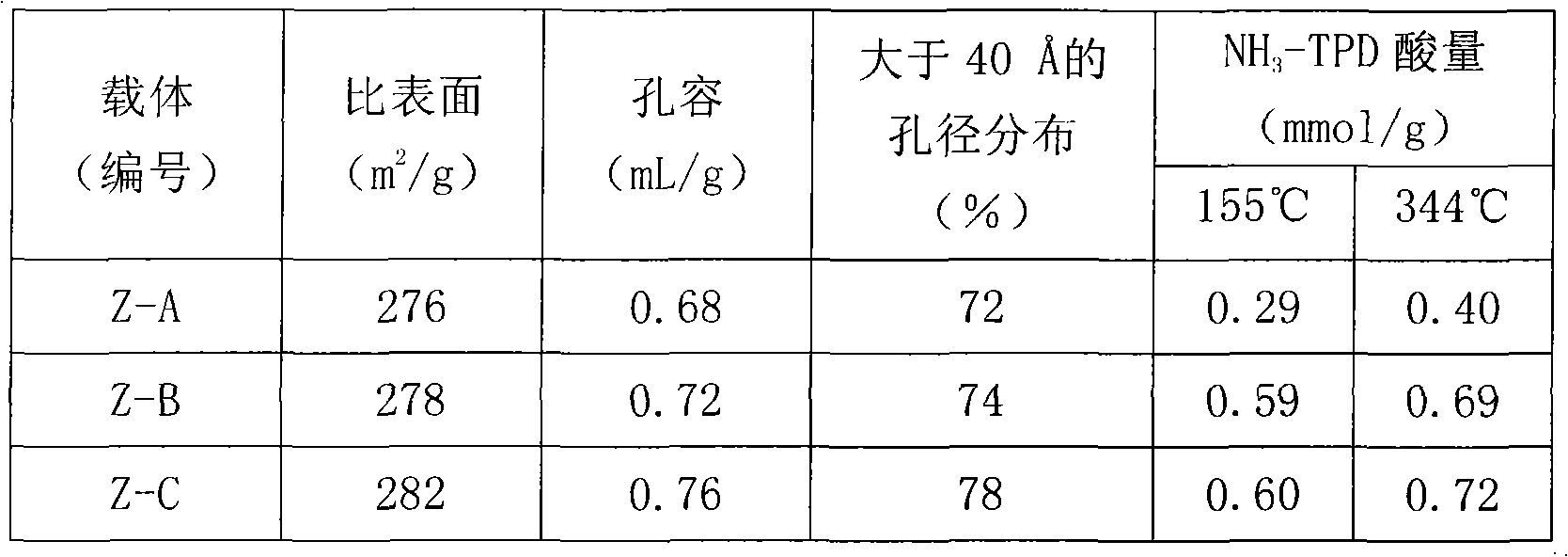

[0029] 240g of a macroporous aluminum hydroxide dry rubber powder, the alumina content of which is 70%, is mixed with 6g of scallop powder, 9g of 66% concentrated nitric acid and 10g of oxalic acid, added deionized water, kneaded and mixed in a kneader, Afterwards, the strips are extruded by an extruder to obtain clover strips with a diameter of 1.5 mm. After drying in an oven at 120°C for 12 hours and calcining in a muffle furnace at 500°C for 4 hours, carrier Z-A was obtained, and its properties are shown in Table 1.

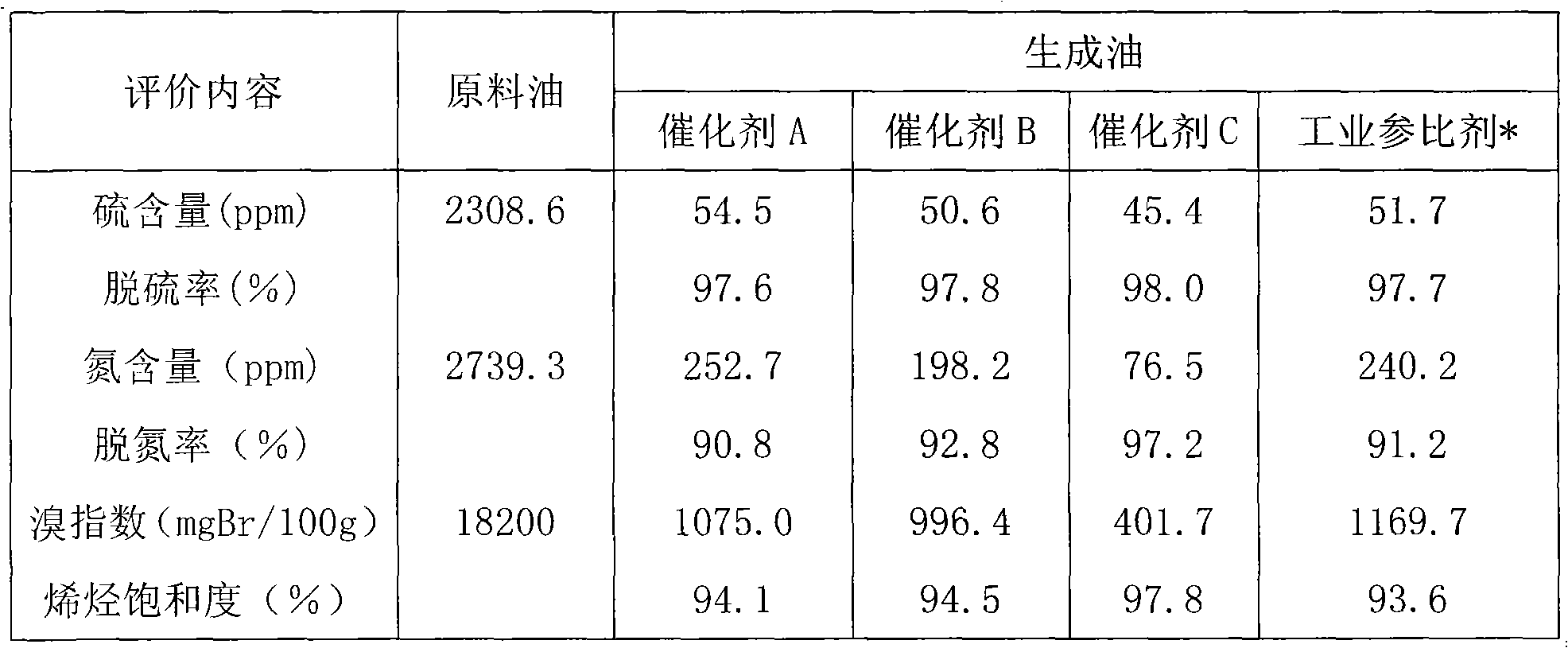

[0030] At room temperature, add 42g of ammonium metatungstate, 25g of ammonium heptamolybdate, 37g of nickel nitrate and 4g of citric acid into 120mL of deionized water, and stir evenly. Set aside. Take 120 g of the carrier strips prepared in the previous step in the dipping tank, add the above co-impregnation solution, and impregnate for 3 hours, then dry the wet strips in an oven at 120°C for 7 hours, and bake them in a muffle furnace at 400°C for 4 hours. ...

Embodiment 2

[0033] 240g of a macroporous aluminum hydroxide dry rubber powder, the alumina content of which is 70%, is mixed with 23g of metatitanic acid, 6g of scallop powder, 9g of 66% concentrated nitric acid and 10g of oxalic acid, added deionized water, and mixed in a kneader Knead and mix in middle, and then extrude and shape through extruder to obtain four-leaf clover strips with a diameter of 1.5mm. Dry in an oven at 120°C for 12 hours, and bake in a muffle furnace at 550°C for 4 hours to obtain carrier Z-B, whose properties are shown in Table 1.

[0034] At room temperature, add 7g of ethanolamine to 120mL of deionized water. After dissolving, add 46g of ammonium metatungstate, 25.5g of ammonium heptamolybdate, 35g of nickel nitrate and 5g of phosphoric acid. Divide the co-immersion solution into two parts of equal volume and set aside for later use.

[0035] Take 120 g of the carrier strips prepared in the previous step in the dipping tank, add one part of the co-immersion solu...

Embodiment 3

[0037] 240g of a macroporous aluminum hydroxide dry rubber powder, whose alumina content is 70%, is mixed with 24g of metatitanic acid, 63g of 25% silica sol, 6g of kale powder, 9g of 66% concentrated nitric acid and polyethylene glycol (Polymerization degree 2000) 10g, add deionized water, knead and mix in a kneader, and then extrude and shape through an extruder to obtain clover strips with a diameter of 1.5mm. Dry in an oven at 120°C for 12h, and bake in a muffle furnace at 550°C for 4h. The properties of the obtained carrier Z-C are shown in Table 1.

[0038] At room temperature, add 8g of aminotriacetic acid to 30mL of concentrated ammonia water, after dissolving, add deionized water until the volume of the solution is 120mL, add nitric acid dropwise until the pH is between 3 and 4, and then add 44g of ammonium metatungstate, 26g of heptamolybdenum ammonium nitrate, 36g nickel nitrate, 6g phosphoric acid, after they are completely dissolved, set the volume to 200mL to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com