Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Good hydrodesulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

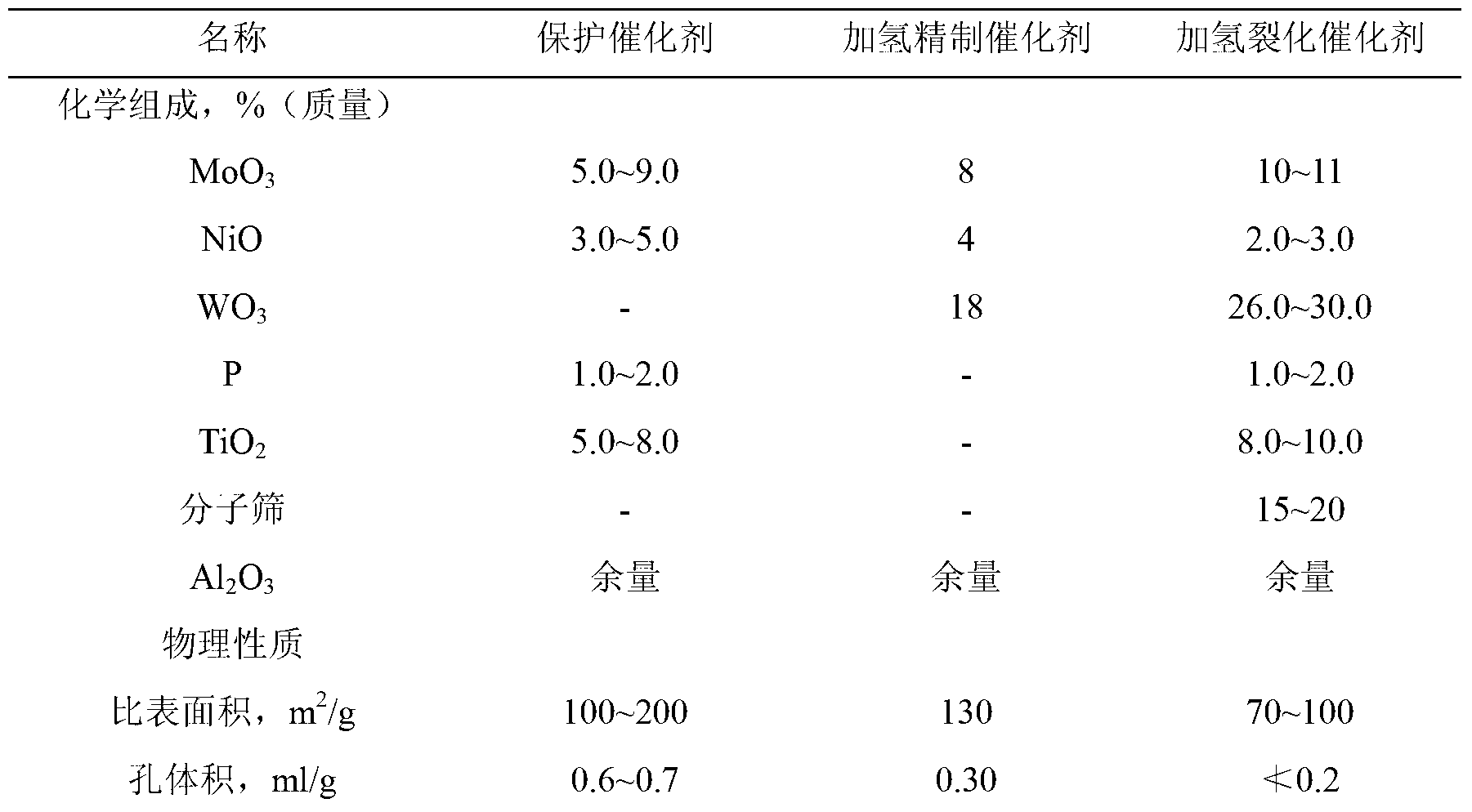

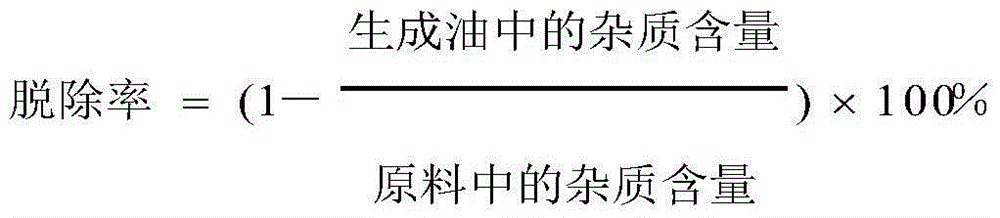

Coal tar hydrogenating modification catalyst and its prepn and application

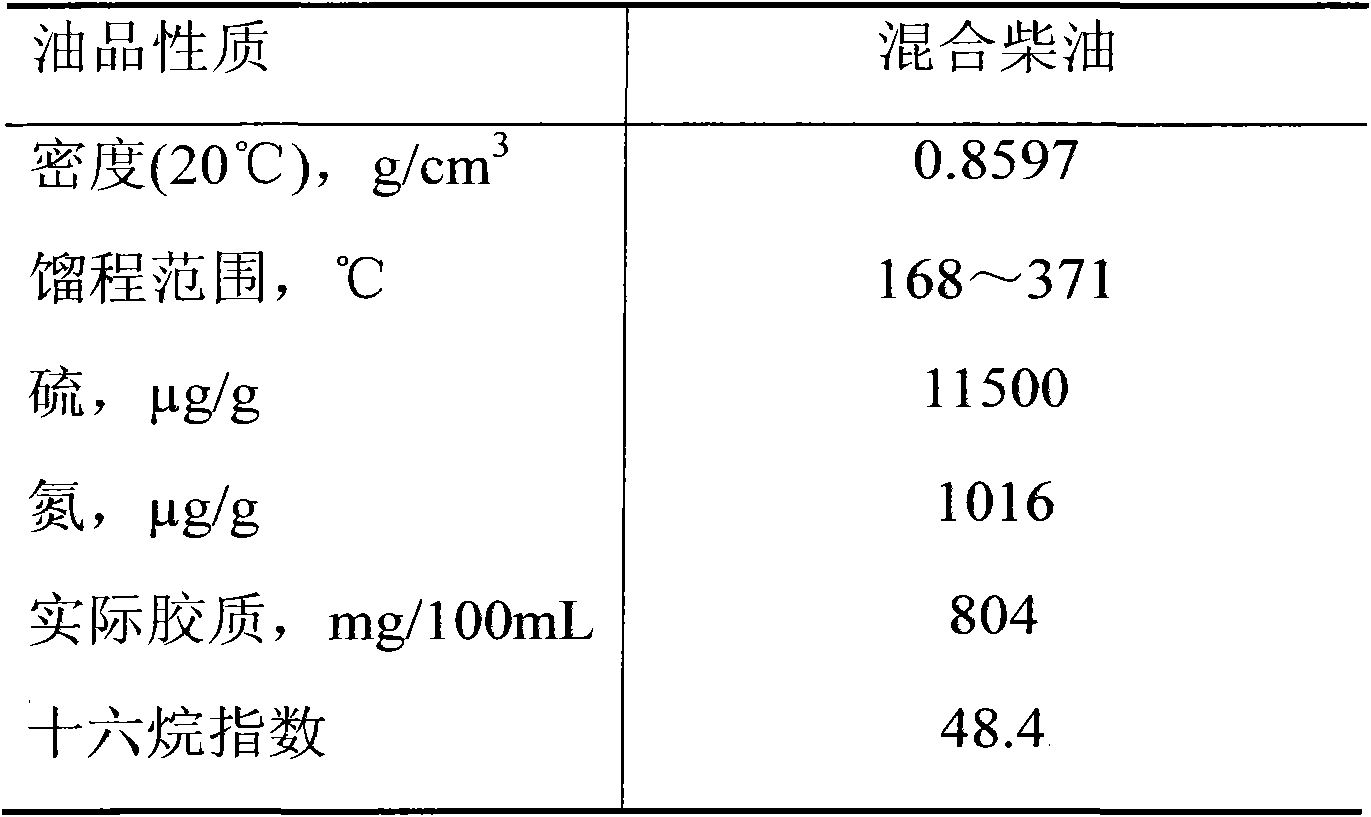

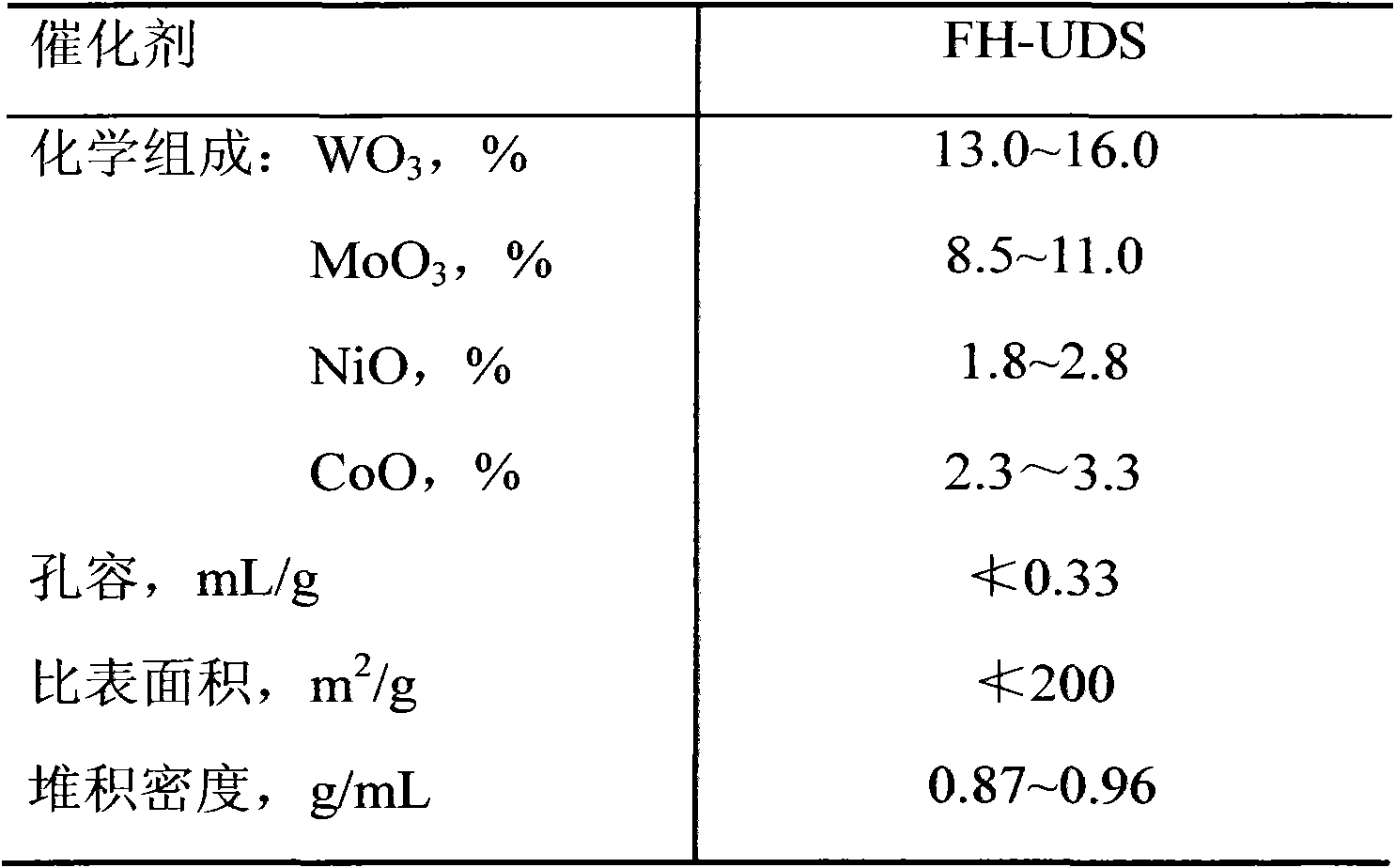

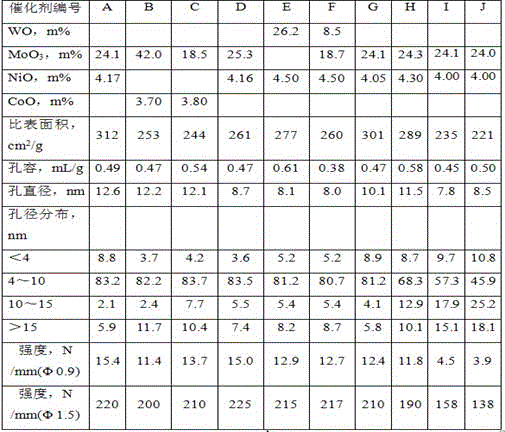

InactiveCN1772846AGood hydrodesulfurizationStrong aromatic saturation and ring-opening abilityWorking-up tarHydrocarbon oils refiningMolecular sieveZirconium nitrate

The coal tar hydrogenating modification catalyst consists of carrier and active component. The active component is the mixture of WO3, MoO3 and NiO, or the mixture of WO3 and NiO and accounts for 29-35 wt% of the catalyst; and the carrier consists of silica, alumina and modified type-Y molecular sieve, which is modified with zirconium nitrate and / or ammonium salt of phosphorus in the amount of 1-10 wt% of the modified molecular sieve, and accounts for 65-71 wt% of the catalyst. The catalyst has proper pore volume, pore size, hydrogenating center and acid center, relatively high mechanical strength and water resistance. Using the catalyst in hydrogenating modification of coal tar friction oil can eliminate its impurity S, N, gum, asphaltene and saturated arene component and open ring of partial arene.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

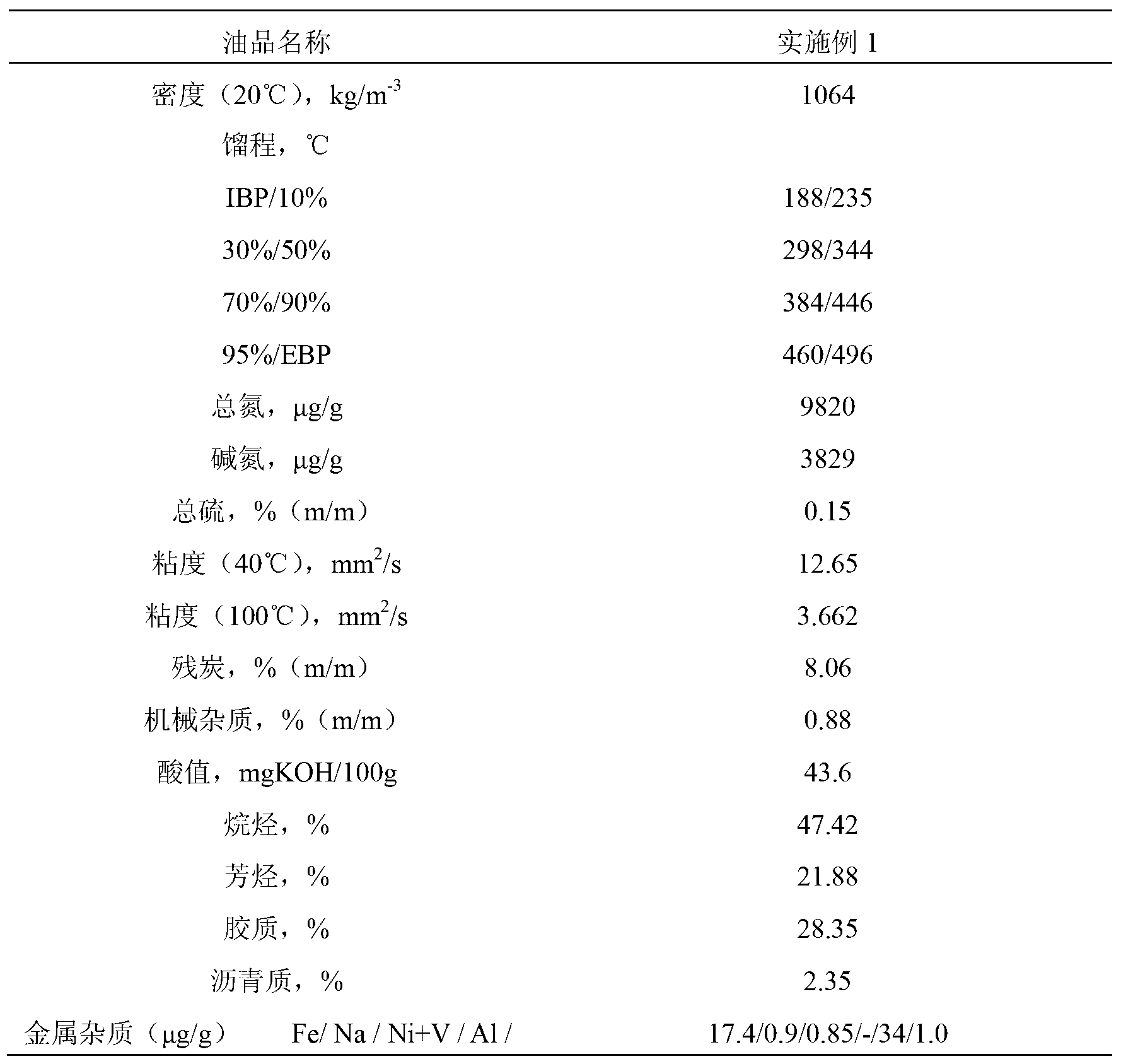

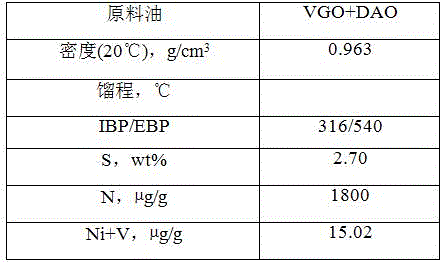

Residual oil hydrogenation catalyst and preparation method and use thereof

ActiveCN101491764AIncrease acidityImprove cracking capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationStrong acids

The invention relates to a residual oil hydrogenation catalyst, a preparation method and application thereof. The residual oil hydrogenation catalyst contains modified kaolin; the process for modifying the kaolin mainly comprises the steps of roasting and treating raw kaolin, and then treating the raw kaolin with mixed acid of strong acid and weak acid; and the modified kaolin has larger aperture and proper surface property, and is properly used as a carrier material of the residual oil hydrogenation catalyst. The residual oil hydrogenation catalyst adopts an impregnation method to load active metal components of VIB and VIII families; and the prepared catalyst can be applied in the field of hydrogenation demetallization, hydrogenation desulfurization, hydrogenation conversion, and the like of heavy oil or residual oil, and has good using performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

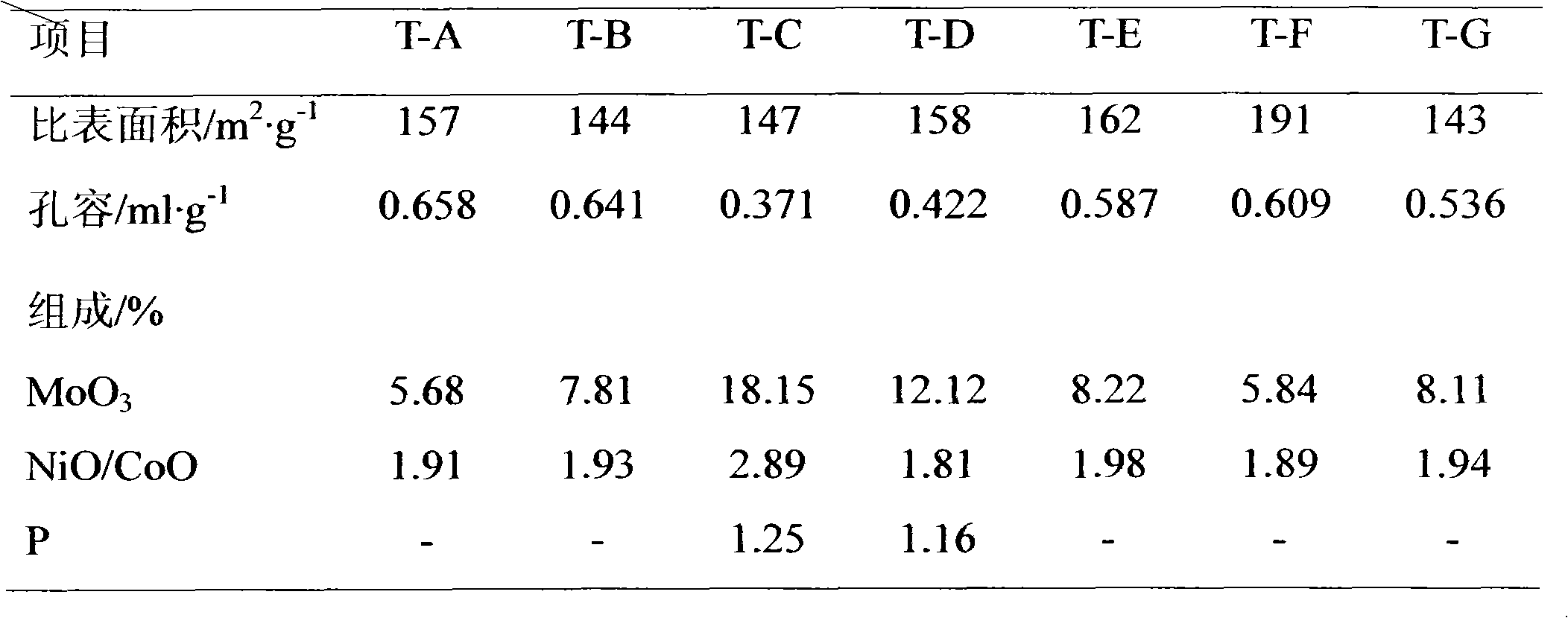

Preparation method of hydrodesulfurization catalyst for high-nitrogen low-quality gasoline and diesel

ActiveCN102151582ALarge specific surface areaGood dispersionPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrodesulfurizationGasoline

The invention relates to a preparation method of a hydrodesulfurization catalyst for high-nitrogen low-quality gasoline and diesel. The catalyst is characterized in that an A12O3-TiO2-SiO2 ternary oxide is taken as a composite carrier; the catalyst comprises the carrier, an auxiliary and active metals; the active metals comprise oxides of nickel, molybdenum and tungsten; the auxiliary is phosphorus; the carrier comprises aluminum oxide, titanium oxide and silicon oxide; based on the weight of the catalyst, nickel oxide accounts for 1-15 wt%, molybdenum oxide accounts for 2-12 wt%, tungsten oxide accounts for 12-35 wt%, phosphorus pentoxide accounts for 2-5% wt%, the titanium oxide accounts for 2-15 wt%, the silicon oxide accounts for 2-20 wt%, and the balance is aluminum oxide. In the method, a room-temperature complexation method is adopted for preparing W-Mo-Ni-P co-impregnation solution with stable dissolution performance, and then the step-by-step saturated impregnation technologyis adopted for loading the active metal components W-Mo-Ni and the auxiliary P on the carrier..

Owner:CHINA NAT OFFSHORE OIL CORP +1

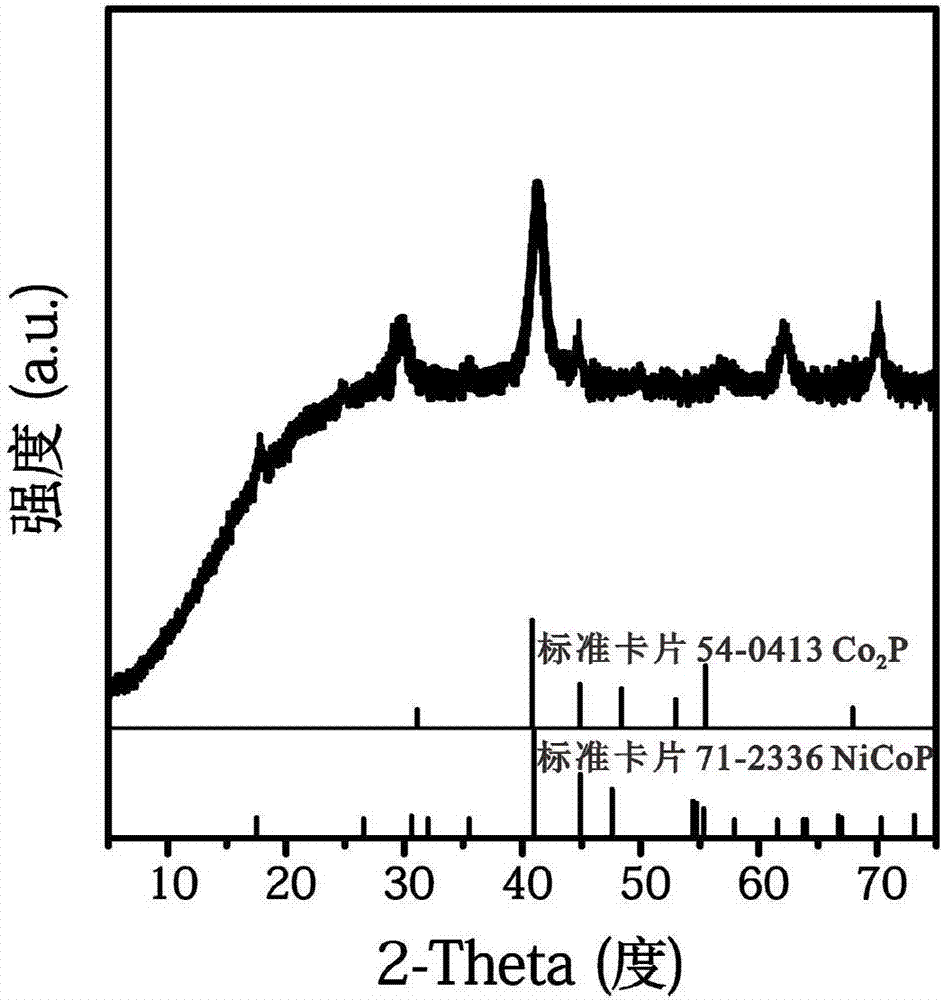

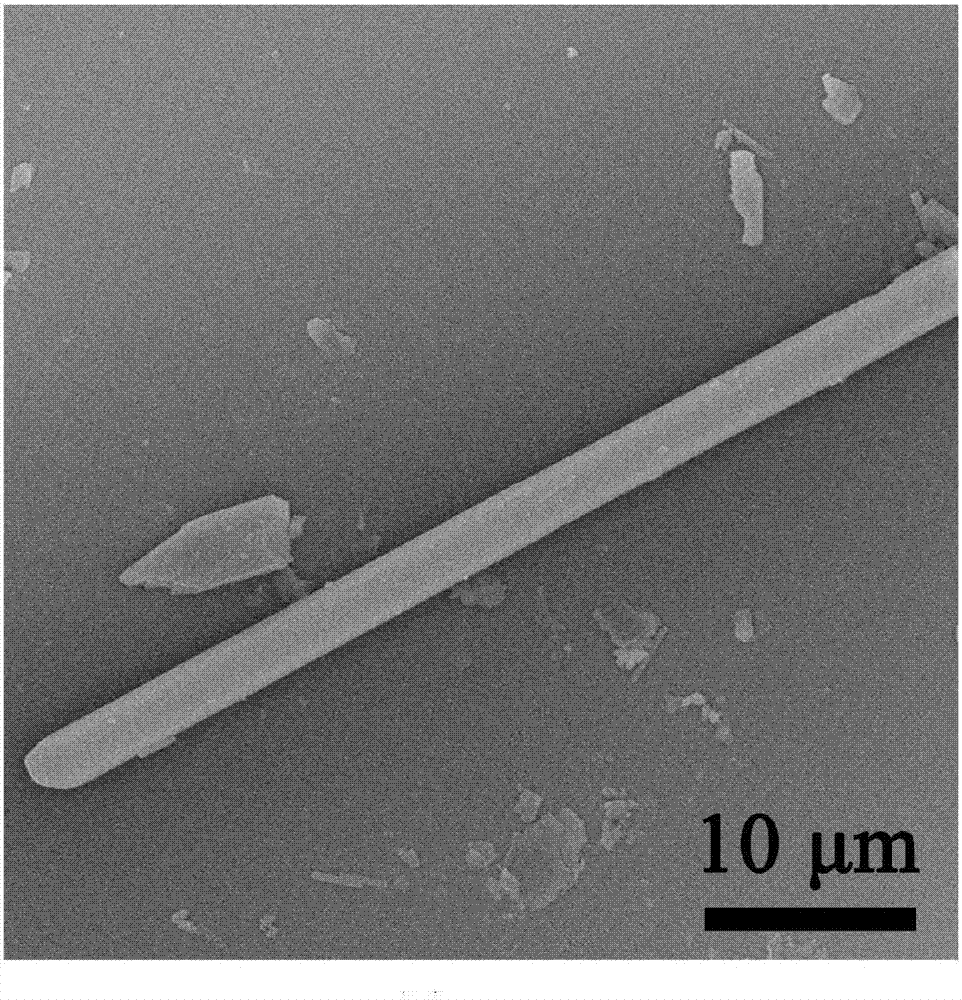

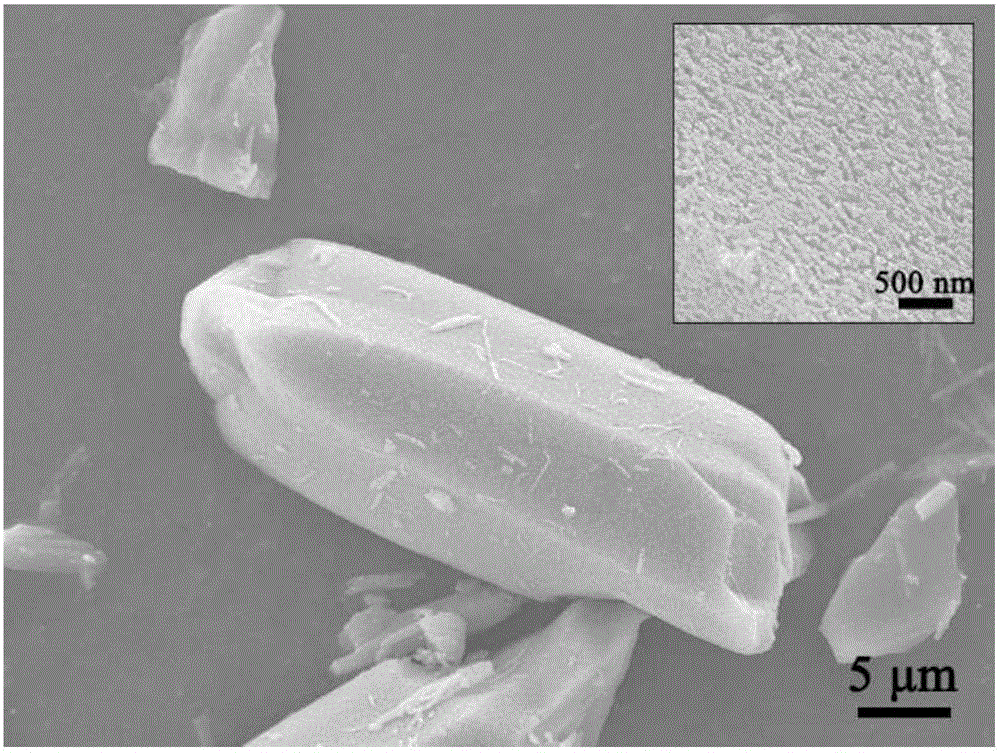

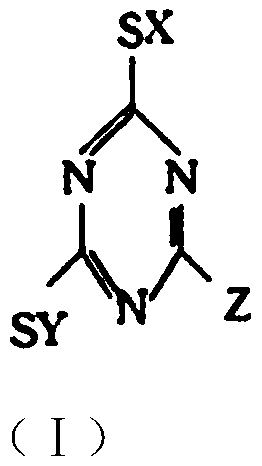

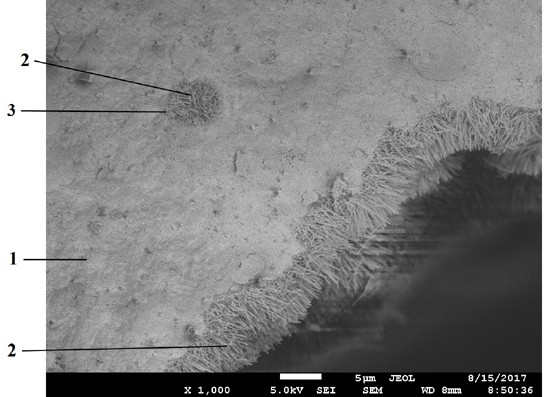

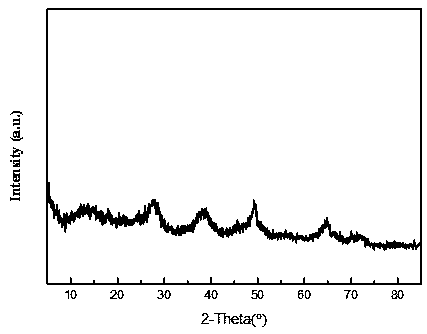

Multi-metal phosphide nanotube catalyst with evenly distributed catalytic centers and low-temperature preparation method

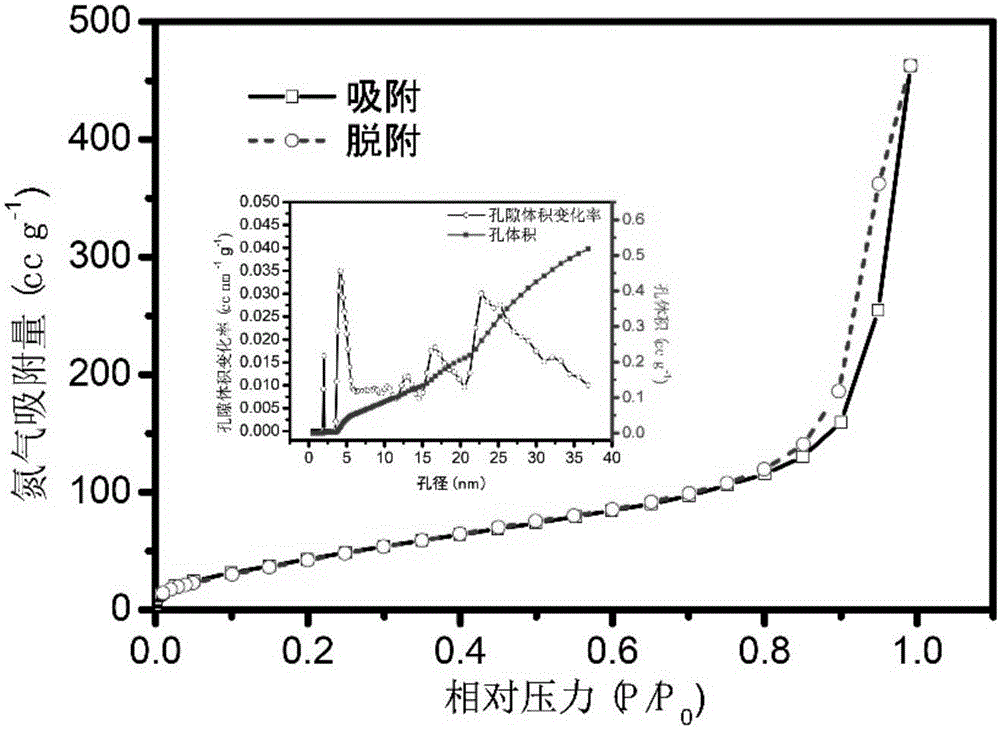

ActiveCN107252700ALow costIncrease the areaCatalyst activation/preparationPore distributionHydrodesulfurization

The invention relates to a multi-metal phosphide nanotube catalyst with evenly distributed catalytic centers and a low-temperature preparation method. The multi-metal phosphide catalyst composite material provided with a hollow nanotube structure, using carbon as the support and provided with the evenly distributed catalytic centers. The method uses a multi-metal metal organic framework material as the template and uses simple low-temperature phosphating reaction (200-350 DEG C) to obtain the multi-metal phosphide catalyst with the nanotube structure. The prepared multi-metal phosphide nanotube catalyst well keeps the morphology of precursors, has large specific surface area and pore volume, has hierarchical pore distribution, has an even and controllable metal doping proportion and phase, is beneficial to electrochemical catalyzing, hydrodesulfurization, selective hydrogenation and other hydrogenation reaction and is promising in application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

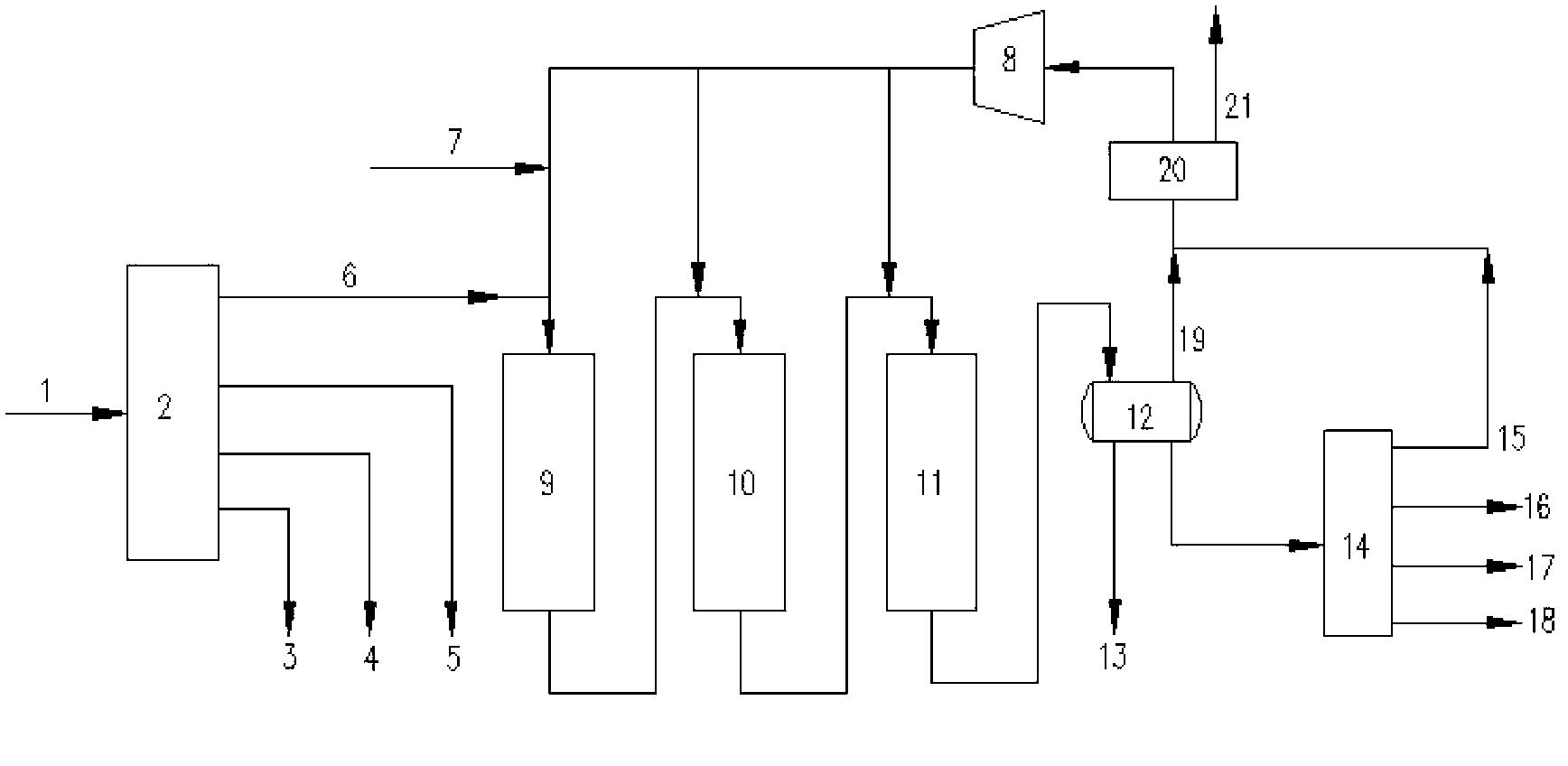

Combined process method of lightening residual oil/ medium and low temperature coal tar

ActiveCN103305271AHigh yieldImprove cracking performanceTreatment with hydrotreatment processesWaxHydrogenation reaction

The invention discloses a combined process method of lightening residual oil / medium and low temperature coal tar. Raw material oil enters a hydrotreating unit after being mixed with hydrogen to perform a hydrogenation reaction in the presence of a hydrogenation catalyst; all hydrogenation products enter a delayed coking unit without being separated to perform a thermal cracking reaction so as to prepare high quality coke; tower top oil gas obtained by a coke chamber of the delayed coking unit enters a fractionating system to be fractionated so as to separate out dry coking gas, gasoline, diesel oil, wax oil and heavy distillate oil; all wax oil enters a catalytic cracking unit to perform a catalytic cracking reaction, the catalytic cracking unit and the delayed coking unit share one fractionating system, and the oil gas obtained by catalytic cracking enters the fractionating system; and the dry coking gas enters a PSA purification unit after being desulfurized, and the obtained hydrogen is recycled in the hydrotreating unit. The method can be used for maximizing the production of light oil, obtaining clean finished product oil, producing high quality coke, simplifying the process procedures, saving the consumption of new hydrogen and reducing overall energy consumption.

Owner:SINOPEC NANJING ENG & CONSTR +1

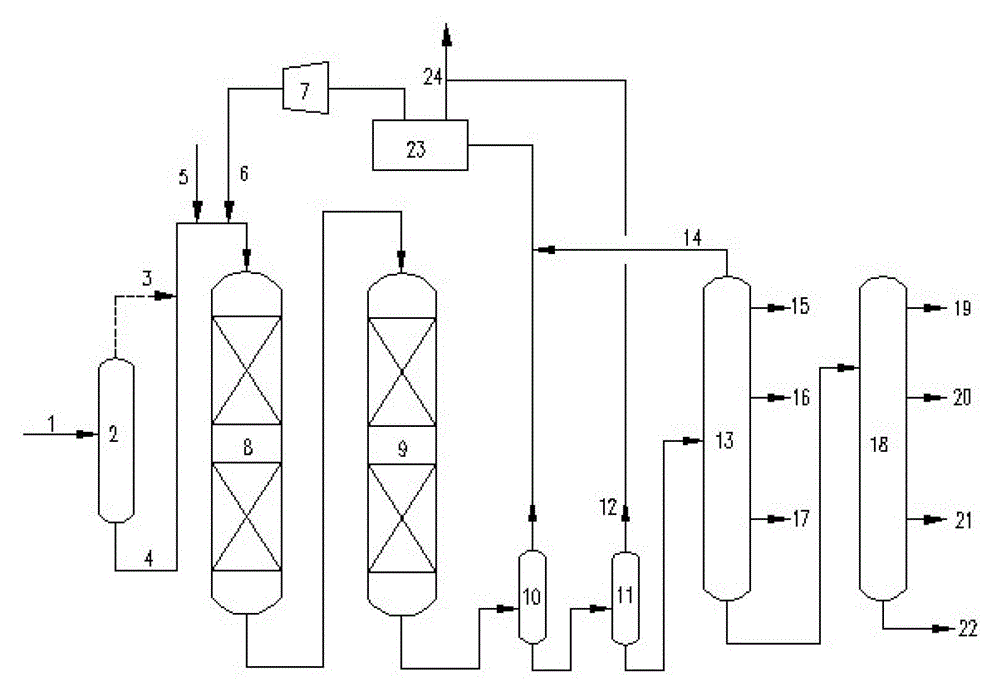

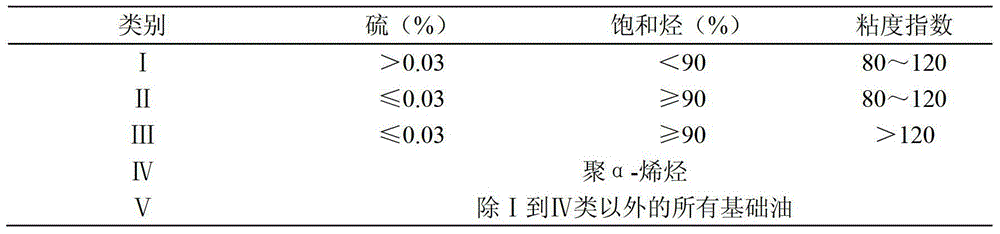

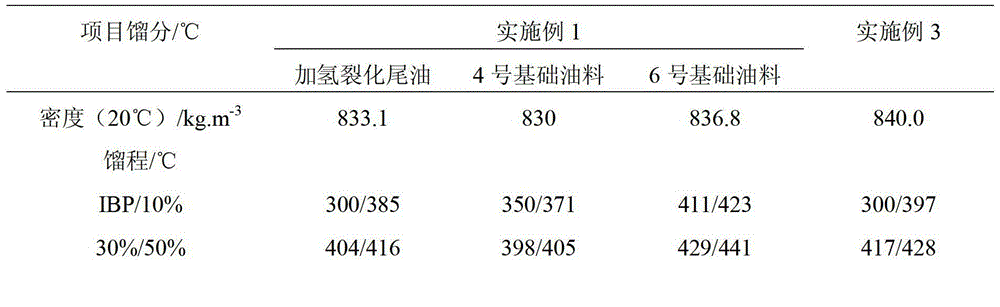

Combination method for producing high-grade lubricant base oil by hydrogenating hydrocracking tail oil

ActiveCN103289738AHigh selectivityIncreased production flexibilityTreatment with hydrotreatment processesDistillationProcess engineering

The invention discloses a combination method for producing high-grade lubricant base oil by hydrogenating hydrocracking tail oil. The combination method comprises the steps of: carrying out decompression and fractional distillation on the hydrocracking tail oil to obtain NO.4 base oil stock with end distillation point of less than or equal to 430 DEG C and NO.6 base oil stock with end distillation point of more than 430 DEG C; then by adopting a mode of switching feeding or a mode of respectively feeding, carrying out hydrogenated isodewaxing reaction and complement refining reaction together with hydrogen; firstly carrying out gas-liquid separation on the reaction product to obtain hydrogen-rich gas and low-distillate oil; feeding the low-distillate oil into an atmospheric and vacuum distillation device to obtain dry gas and high-grade lubricant base oil; mixing and feeding the hydrogen-rich gas and dry gas into a PSA (Pressure Swing Adsorption) purification unit for purifying and then recycling. The combination method is flexible in process flow, strong in raw material adaptability, good in product quality, and low in energy consumption, the produced base oil can achieve the requirement of API (American Petroleum Institute) II type and III type high-grade lubricant base oil, and the yield of the obtained API III type base oil is higher.

Owner:SINOPEC NANJING ENG & CONSTR +1

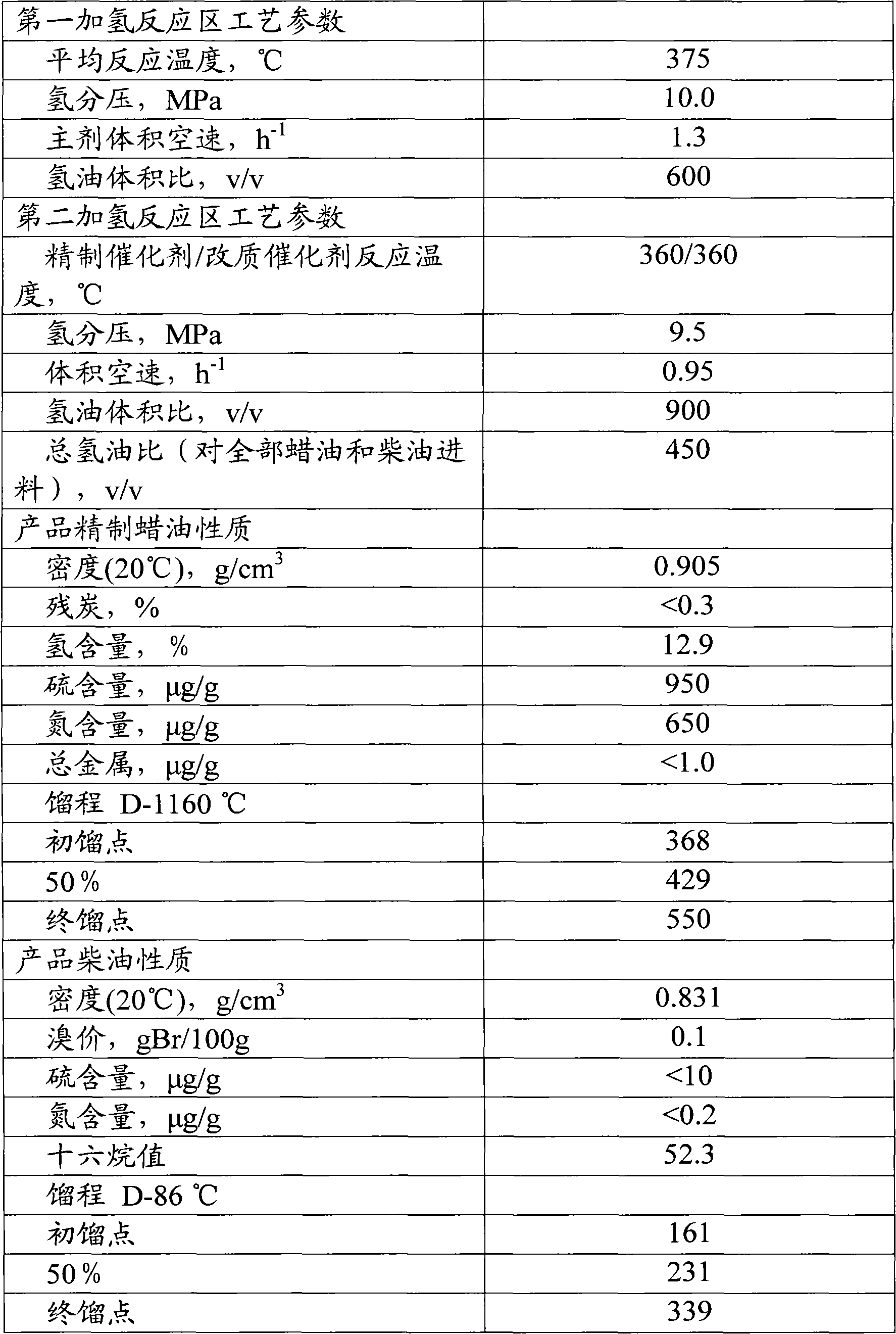

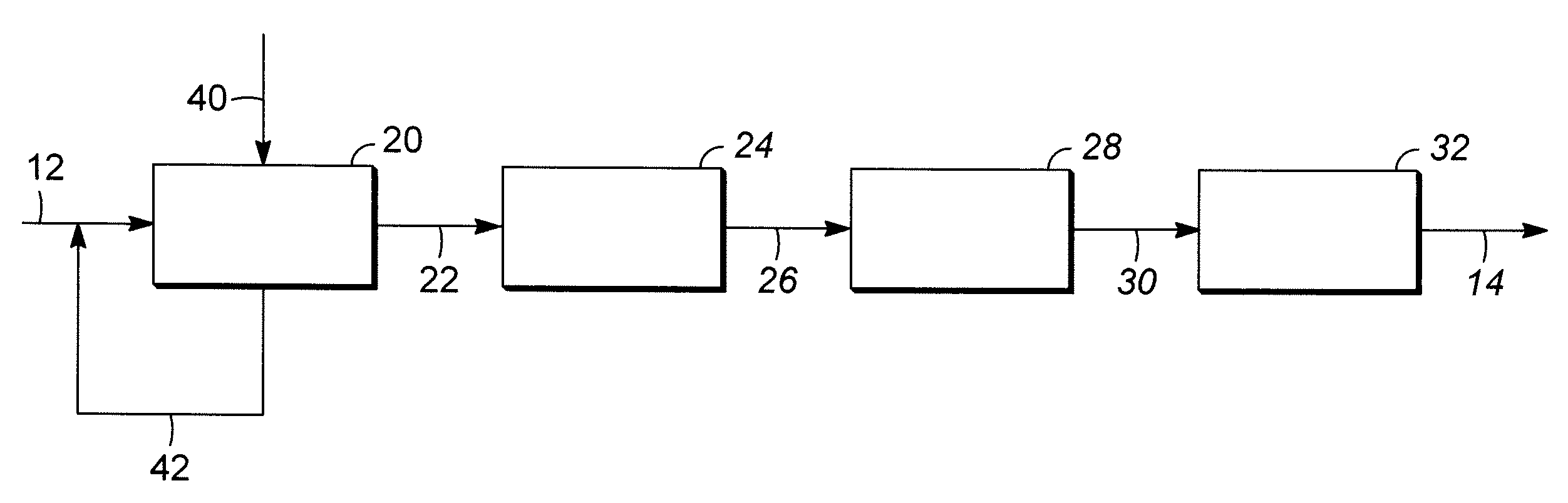

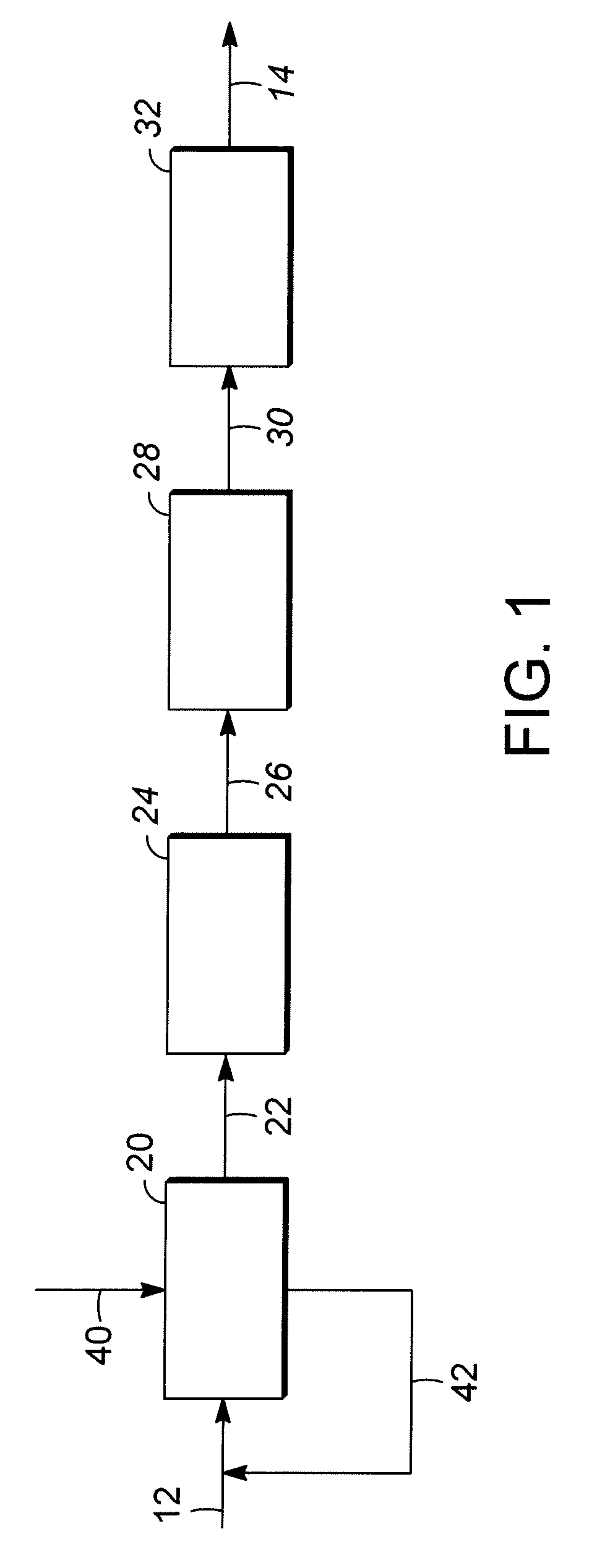

Combined hydrotreating method

InactiveCN103074103AIncrease cetane numberImprove energy efficiencyTreatment with hydrotreatment processesWaxProcess economics

The invention relates to a combined hydrotreating method. According to the method, a wax oil raw material enters a first hydrogenation reaction zone with an up-flow manner, such that a hydrotreating reaction is carried out; a reaction effluent from the first hydrogenation reaction zone enters a thermal high pressure separator; liquid-phase material flow from the bottom of the thermal high pressure separator is further separated by a thermal low pressure separator, such that dissolved gas is separated, and the material is directly used as a feed for a catalytic cracking device; hydrogen-rich gas and hydrocarbon fraction separated from the top of the thermal high pressure separator are mixed with a fresh diesel raw material; the mixture is subjected to a hydrogenation modification reaction in a second hydrogenation reaction zone; a reaction effluent from the second hydrogenation reaction zone is separated, such that a hydrogen-rich gas is obtained; and the hydrogen-rich gas is compressed, and is circulated back to the first hydrogenation reaction zone and the second hydrogenation reaction zone. With the method provided by the invention, device equipment investment and operation cost can be effectively reduced, and oil refining process economic efficiency can be improved to a maximal extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

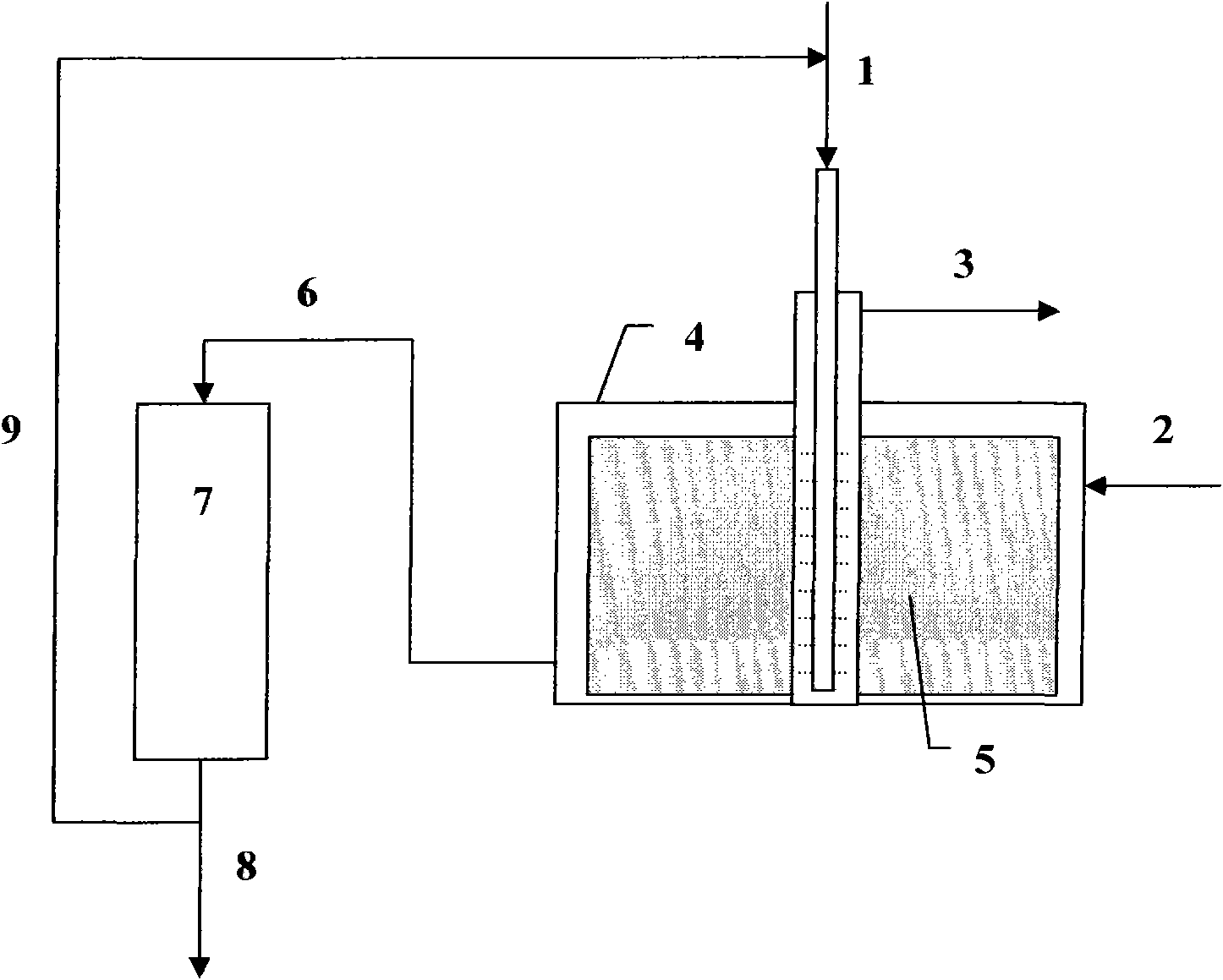

Liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer

ActiveCN102311791AEasy to operateLess investmentTreatment with hydrotreatment processesHydrocarbon oils refiningHydrodesulfurizationMixed materials

The invention discloses a liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer. The process flow adopted by the method comprises: part of hydrogenation circulating oil and a fresh raw material are mixed to form a liquid-phase mixed material to be filled into supergravity gas-liquid hydrogen dissolution equipment together with hydrogen; through the drive of the high-speed rotation of a feeding rotor, gas-liquid countercurrent full contact is formed; the mixed liquid-phase material in which hydrogen is dissolved is discharge out from the bottom of the supergravity gas-liquid hydrogen dissolution equipment and contacted with a catalyst to undergo a hydrogenation reaction, and part of a liquid phase obtained after reaction is circulated. Compared with the prior art, the method has the advantages that: the rotation of the feeding rotor in the gas-liquid hydrogen dissolution equipment forms a supergravity field, so the gas-liquid mass transfer efficiency is increased greatly, and the liquid phase material can fully dissolve hydrogen; meanwhile, gas impurities such as H2S and NH3 in a reaction system can be removed efficiently, so that the hydrodesulfurization, denitrification, aromatic saturation, cracking and other reactions are promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

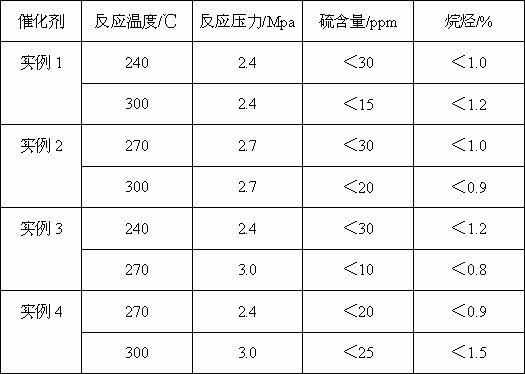

Method for producing gasoline and diesel by directly hydrogenating medium and low temperature coal tar

ActiveCN103305269AReasonable optimization of hydrogenation operation modeQuality improvementTreatment with hydrotreatment processesGasolineFuel oil

The invention discloses a method for producing gasoline and diesel by directly hydrogenating medium and low temperature coal tar. The method comprises the steps that the medium and low temperature coal tar is firstly subjected to dehydration and deslagging, and then the liquid phase is separated into heavy oil and hydrogenated raw oil after undergoing fractionation; the hydrogenated raw oil and hydrogen are hydrogenated by a hydrofining unit after being mixed, and the treated product is subjected to oil, water and gas three-phase separation to obtain a hydrogen-rich gas, sulfur and ammonium containing sewage and hydrofined oil; the hydrofined oil is fractionated to obtain a dry gas, a gasoline fraction, a diesel fraction and a liquefied gas; and the hydrogen-rich gas and the dry gas are sent to a PSA (pressure swing adsorption) purification unit to be treated after being mixed, and the hydrogen obtained after purification is returned to the hydrofining unit to be recycled. By adopting the method, coal tar resources can be fully utilized, and the coal tar is furthest converted to the light oil products, thus improving the utilization rate of the coal tar.

Owner:SINOPEC NANJING ENG & CONSTR +1

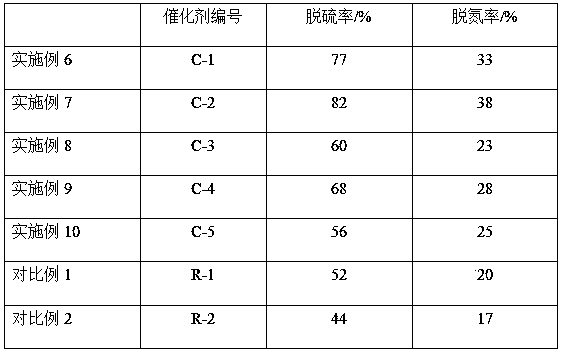

Hydrodesulfurization catalyst and preparation method thereof

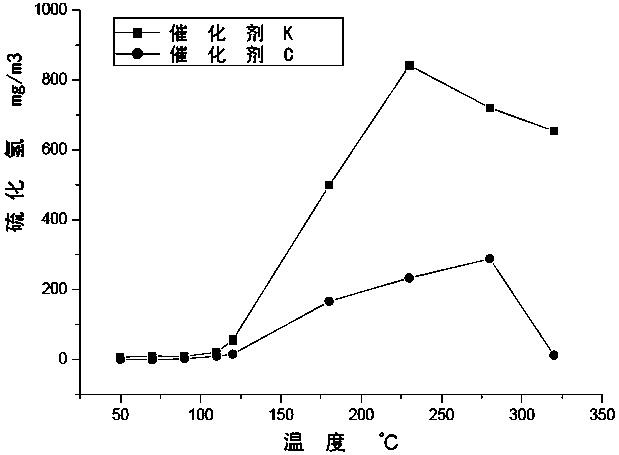

InactiveCN102423713AGood hydrodesulfurizationLow costMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationPotassium

The invention discloses hydrodesulfurization catalyst and a preparation method thereof, belongs to the technical field of catalyst, and particularly relates to hydrodesulfurization catalyst for benzene hydrogenation and a preparation method thereof. In the catalyst, at least two of oxides of nickel, molybdenum, cobalt, cerium, palladium and lanthanum metals are used as active ingredients; at least one of oxides of phosphorus, potassium, tungsten and magnesium is used as auxiliary agent; and the balance is a carrier. In the components, based on the mass of the catalyst, the catalyst comprises the components in percentage by mass: 10-20 percent of the oxides serving as the active ingredients, 1-5 percent of the oxide serving as the auxiliary agent and the balance the carrier. Aluminum oxide or titanium oxide is selected as the carrier. The invention provides the hydrodesulfurization catalyst; good hydrodesulfurization property can be kept under lower pressure and at lower temperature; the cost is reduced; and the saturation selectivity to aromatic hydrocarbon is weaker.

Owner:NANJING UNIV OF TECH

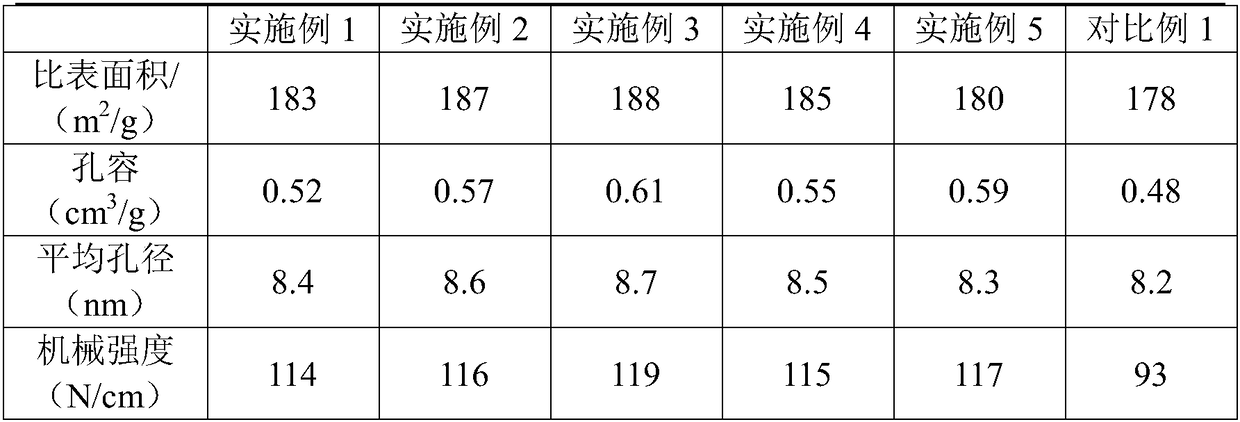

Preparation method of vulcanized hydrogenation catalyst

ActiveCN108067271AHigh catalytic activityReduce manufacturing costPhysical/chemical process catalystsHydrocarbon oils treatmentPore diameterSlurry

The invention discloses a preparation method of a vulcanized hydrogenation catalyst. The method comprises the steps as follows: (1) a vulcanizing agent, a vulcanizing aid, an emulsifier and additive particles are uniformly mixed, the mixture is subjected to a constant-temperature reaction, then, an aqueous solution containing hydrogenation active metal is added, the mixture reacts for 5-60 min, the additive particles are removed by separation, and a liquid mixture I is obtained; (2) a peptizing agent, water and urea are uniformly mixed and a liquid mixture II is obtained; (3) an aluminum source is added to an acidic aqueous solution for slurry making, the liquid mixtures I and II are added, and the slurry is mixed uniformly; (4) the slurry in the step (3) is subjected to quick evaporativeconcentration to form concentrated slurry, slow drying treatment is performed, and a semi-dried material is obtained; (5) the semi-dried material obtained in the step (3) is ground, subjected to extrusion molding and roasting, and the vulcanized hydrogenation catalyst is obtained. The catalyst preparation and vulcanizing processes are completed simultaneously, and the catalyst has uniform pore diameter distribution, is simple to prepare and has wider market application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

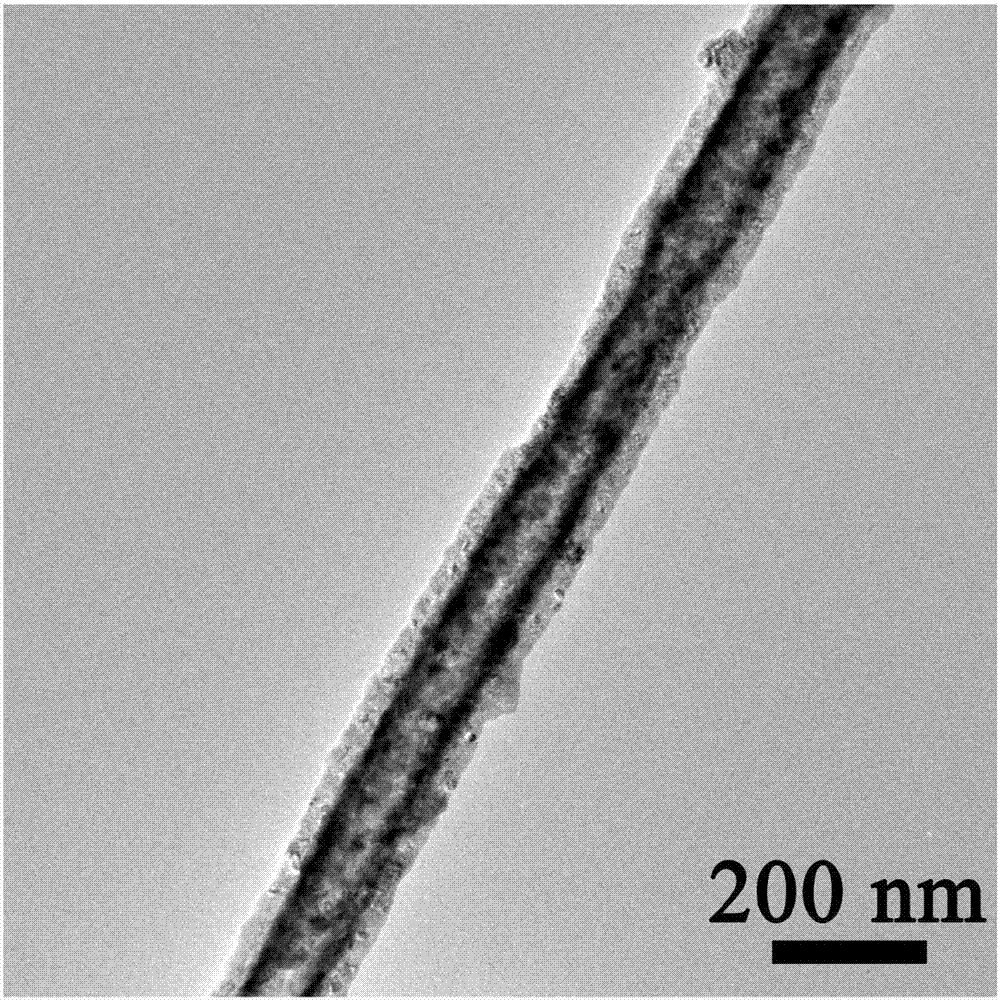

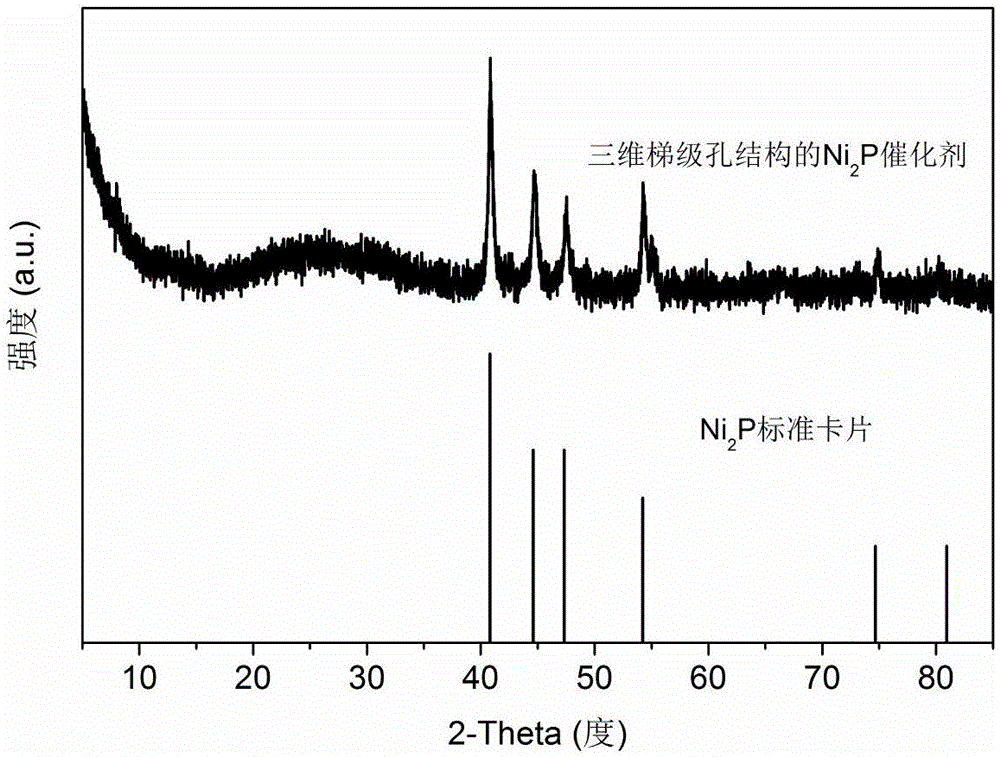

Method for preparing Ni2P catalyst with three-dimensional cascade pore structures at low temperature

ActiveCN106475122AMild preparation conditionsSimple processPhysical/chemical process catalystsHydrocarbon oils treatmentHydrogenation reactionHydrodesulfurization

The invention relates to a method for preparing a Ni2P catalyst with three-dimensional cascade pore structures at low temperature. Under the protection of inert gas, nickel-based metal organic framework materials and hypophosphite are conducted heat treatment at 200-350DEG C for 1-500 min, obtaining a Ni2P catalyst with a three-dimensional cascade pore structure. The method does not need a catalyst or a solvent, the preparation condition is mild, the craft is simple and the method is suitable for industrial production. The prepared Ni2P catalyst has a higher specific surface area(174 m<2> / g) and a bigger pore volume. The internal pore size distribution is 1-50 nm, which distributes as cascade pores. The internal cascade pores are favorable for electrochemical catalysis, hydrodesulfurization, selective hydrogenation and other hydrogenation reactions, and have broad application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A combined method for producing high-grade lubricating oil base oil by hydrogenation of hydrocracking tail oil

ActiveCN103289738BHigh selectivityIncreased production flexibilityTreatment with hydrotreatment processesThermodynamicsProcess engineering

The invention discloses a combination method for producing high-grade lubricant base oil by hydrogenating hydrocracking tail oil. The combination method comprises the steps of: carrying out decompression and fractional distillation on the hydrocracking tail oil to obtain NO.4 base oil stock with end distillation point of less than or equal to 430 DEG C and NO.6 base oil stock with end distillation point of more than 430 DEG C; then by adopting a mode of switching feeding or a mode of respectively feeding, carrying out hydrogenated isodewaxing reaction and complement refining reaction together with hydrogen; firstly carrying out gas-liquid separation on the reaction product to obtain hydrogen-rich gas and low-distillate oil; feeding the low-distillate oil into an atmospheric and vacuum distillation device to obtain dry gas and high-grade lubricant base oil; mixing and feeding the hydrogen-rich gas and dry gas into a PSA (Pressure Swing Adsorption) purification unit for purifying and then recycling. The combination method is flexible in process flow, strong in raw material adaptability, good in product quality, and low in energy consumption, the produced base oil can achieve the requirement of API (American Petroleum Institute) II type and III type high-grade lubricant base oil, and the yield of the obtained API III type base oil is higher.

Owner:SINOPEC NANJING ENG & CONSTR +1

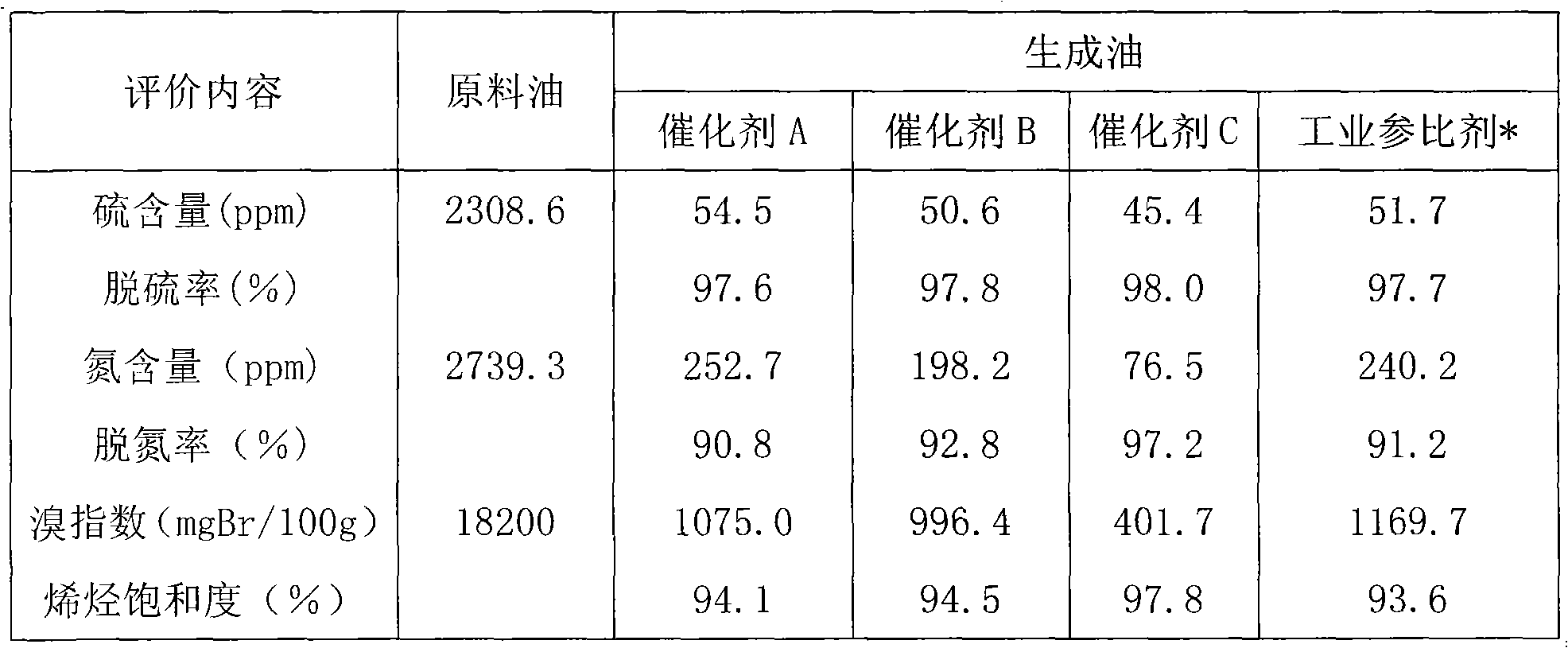

Coal tar hydrodenitrification catalyst and preparation method thereof

InactiveCN108906118AAvoid the problem of difficult complete conversion to sulfideHigh activityMolecular sieve catalystsHydrocarbon oils refiningNitrogenDry basis

The invention discloses a coal tar hydrodenitrification catalyst and a preparation method thereof. The coal tar hydrodenitrification catalyst includes active ingredients, an auxiliary and a carrier. The active ingredients include the following components in parts by weight: 13-15 parts of tungsten trisulfide, 5-8 parts of nickel oxide and 3-4 parts of molybdenum trisulfide; the auxiliary includesthe following components in parts by weight: in terms of elementary substance, 1-2 parts of phosphorus, and 1-4 parts of fluorine; and the carrier includes the following components in parts by weight:in terms of the dry basis of the carrier, 45-55 parts of alumina, 5-10 parts of H[beta] zeolite and 10-15 parts of titanium dioxide. The beneficial effects of the present invention are that the catalyst has excellent activity for hydrodenitrification of coal tar.

Owner:宁波敬业控股集团有限公司

Heavy raw oil hydrogenating treatment catalyst and its preparing method

InactiveCN1211464CNot easy to losePhysicochemical property adjustmentHydrocarbon oil crackingRefining to eliminate hetero atomsNitrogenCatalyst support

The present invention discloses one kind of catalyst for the hydrotreatment of heavy material oil and its preparation. The catalyst consists of fluorine 0.5-15 wt%, assistant M in oxide 1.0-30 wt%, VIB metal oxide 15-35 wt%, VIII metal oxide 2.0-10 wt% and alumina the rest. It features the simultaneous modification of catalyst carrier with both fluorine and assistant M, and this can not only regulate the physical and chemical property of catalyst but also avoid the loss of fluorine in the catalyst, which will lower the activity of the catalyst, corrode the downstream apparatus and pollute environment. The catalyst is used in hydrotreatment of heavy material oil and has excellent hydrodesulfurizing, hydrodenitrifying and arene saturating performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy raw oil hydrogenating treatment catalyst and its preparing method

InactiveCN1448477ANot easy to losePhysicochemical property adjustmentHydrocarbon oil crackingRefining to eliminate hetero atomsNitrogenCatalyst support

The present invention discloses one kind of catalyst for the hydrotreatment of heavy material oil and its preparation. The catalyst consists of fluorine 0.5-15 wt%, assistant M in oxide 1.0-30 wt%, VIB metal oxide 15-35 wt%, VIII metal oxide 2.0-10 wt% and alumina the rest. It features the simultaneous modification of catalyst carrier with both fluorine and assistant M, and this can not only regulate the physical and chemical property of catalyst but also avoid the loss of fluorine in the catalyst, which will lower the activity of the catalyst, corrode the downstream apparatus and pollute environment. The catalyst is used in hydrotreatment of heavy material oil and has excellent hydrodesulfurizing, hydrodenitrifying and arene saturating performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silicon-containing alumina and preparation method thereof

ActiveCN102029192BIncrease acidityImprove cracking capacityCatalyst carriersCatalyst activation/preparationStrong acidsResidual oil

The invention discloses a method for preparing silicon-containing alumina, which comprises the following steps of: preparing modified clay, roasting original clay at high temperature, and reacting the clay with mixed acid, wherein the mixed acid is a mixture of strong acid and weak acid; performing a gelling reaction of aluminum-containing acid solution and alkaline solution in modified clay size, ageing, filtering, washing, drying, roasting and the like to prepare the silicon-containing alumina, or drying to prepare silicon-containing alumina dry glue without roasting. Compared with that prepared by the conventional method, the silicon-containing alumina prepared by the method has the advantages of large pore diameter, proper pore structure and the like, and can be used for preparing heavy oil or residual oil hydrotreating catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrotreating method

ActiveCN105754641AGood hydrodesulfurizationGood demetallizationRefining to eliminate hetero atomsHydrodesulfurizationFuel oil

The present invention provides a heavy oil hydrotreating method, the method comprises contacting of heavy oil with a catalyst composition of a heavy oil hydrotreating catalyst I and a heavy oil hydrotreating catalyst II for heavy oil hydrotreating under heavy oil hydrotreating conditions, wherein first the heavy oil is contacted with the heavy oil hydrotreating catalyst I, and then contacted with the heavy oil hydrotreating catalyst II, by calculation of volume on the basis of the total volume of the catalyst composition as a reference, the content of the heavy oil hydrotreating catalyst I in the catalyst composition is 20-60v%, and the content of the heavy oil hydrotreating catalyst II in the catalyst composition is 40-80v%. Compared with conventional heavy oil hydrotreating methods, the heavy oil hydrotreating method has better hydrodesulfurization, demetalization and carbon residue removal effects when used in heavy oil hydrotreating.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sulfurized type hydrogenation catalyst

ActiveCN108067256AHigh catalytic activityReduce manufacturing costPhysical/chemical process catalystsHydrocarbon oils treatmentEvaporationSlurry

The invention discloses a preparation method of a sulfurized type hydrogenation catalyst. The method comprises the following steps: (1) preparing a solution containing a reactive metal complex, performing drying dehydration to obtain a reactive metal precursor, and preparing a semi-sulfurized material from the reactive metal precursor, a sulfurizing reagent and a sulfurizing aid by a mixed reaction; (2) uniformly mixing a peptizer, water and urea to obtain a liquid mixture; (3) adding an aluminum source to an acid aqueous solution, performing pulping, and then adding the semi-sulfurized material and the liquid mixture to the slurry; (4) performing rapid evaporation and concentration on the slurry to obtain concentrated slurry, and then performing slow drying treatment to obtain a semi-dried material; (5) performing rolling and extruding forming on the semi-dried material obtained in step (4), and performing roasting to obtain the sulfurized type hydrogenation catalyst. Catalyst preparation and sulfurization are finished simultaneously, pore size distribution of the catalyst is centralized, the preparation process is simple, and broader market application prospect is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

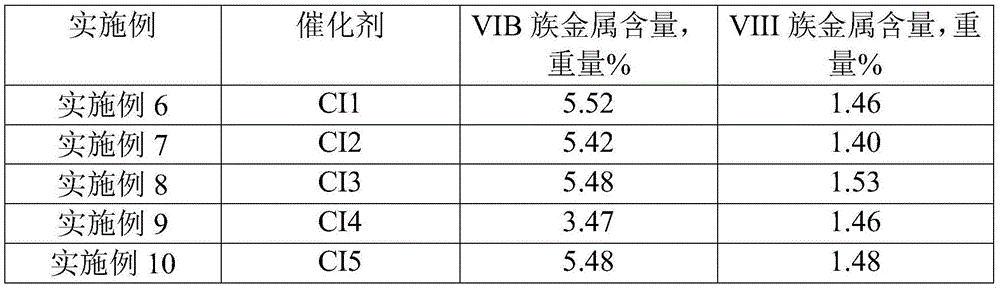

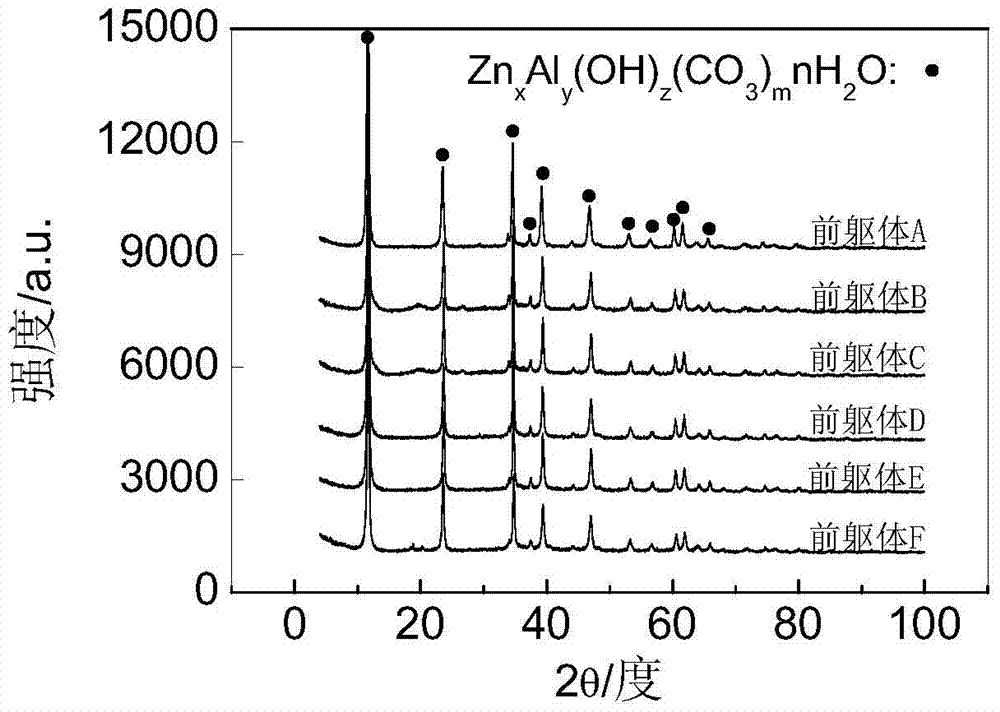

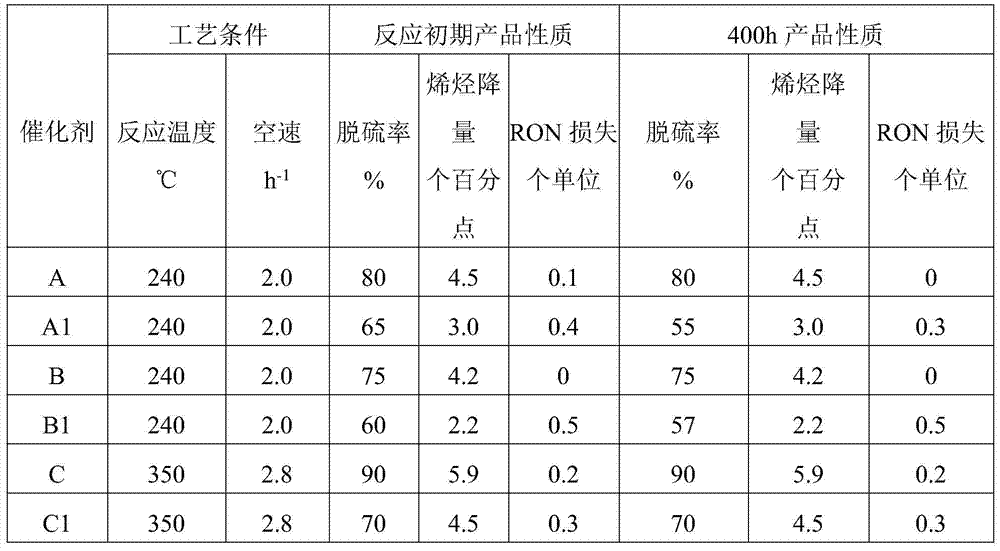

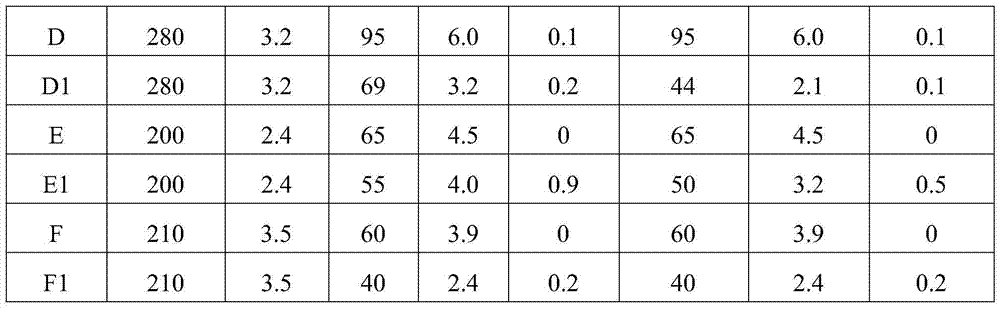

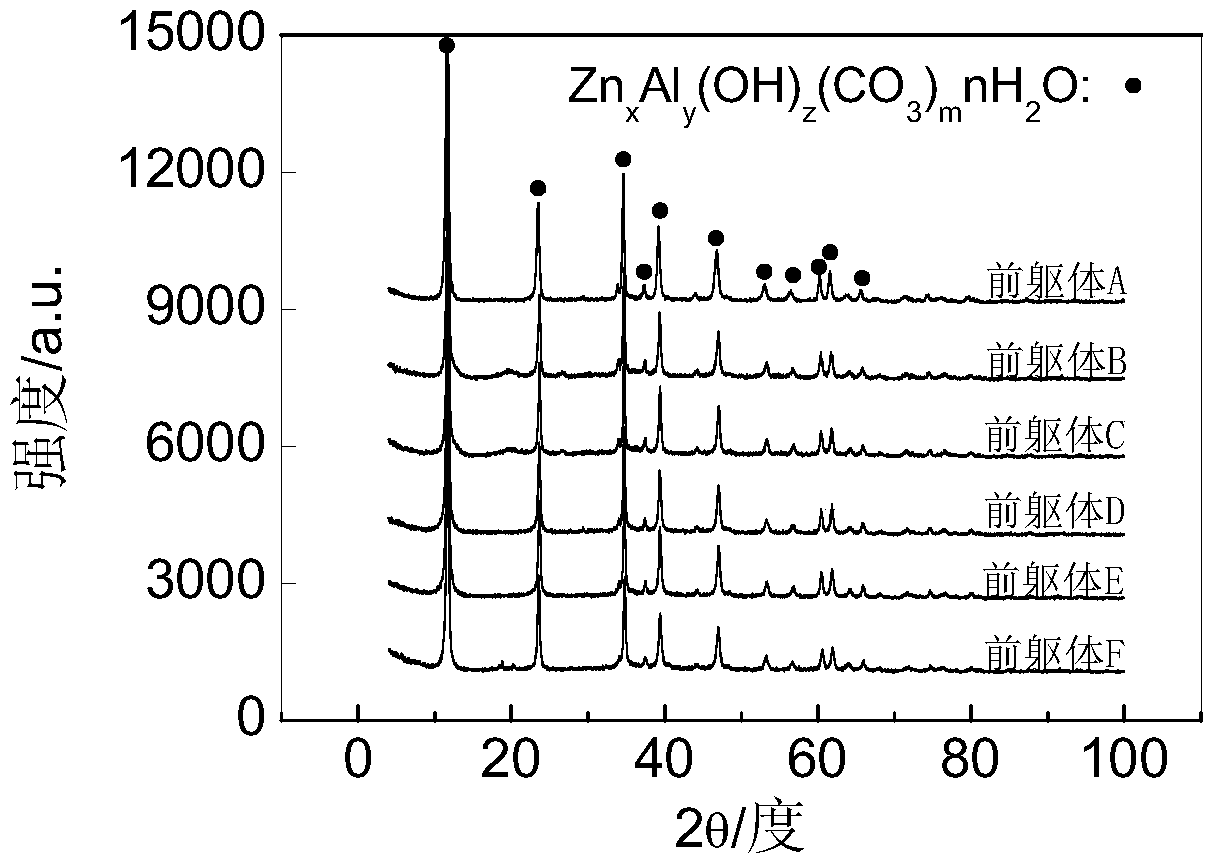

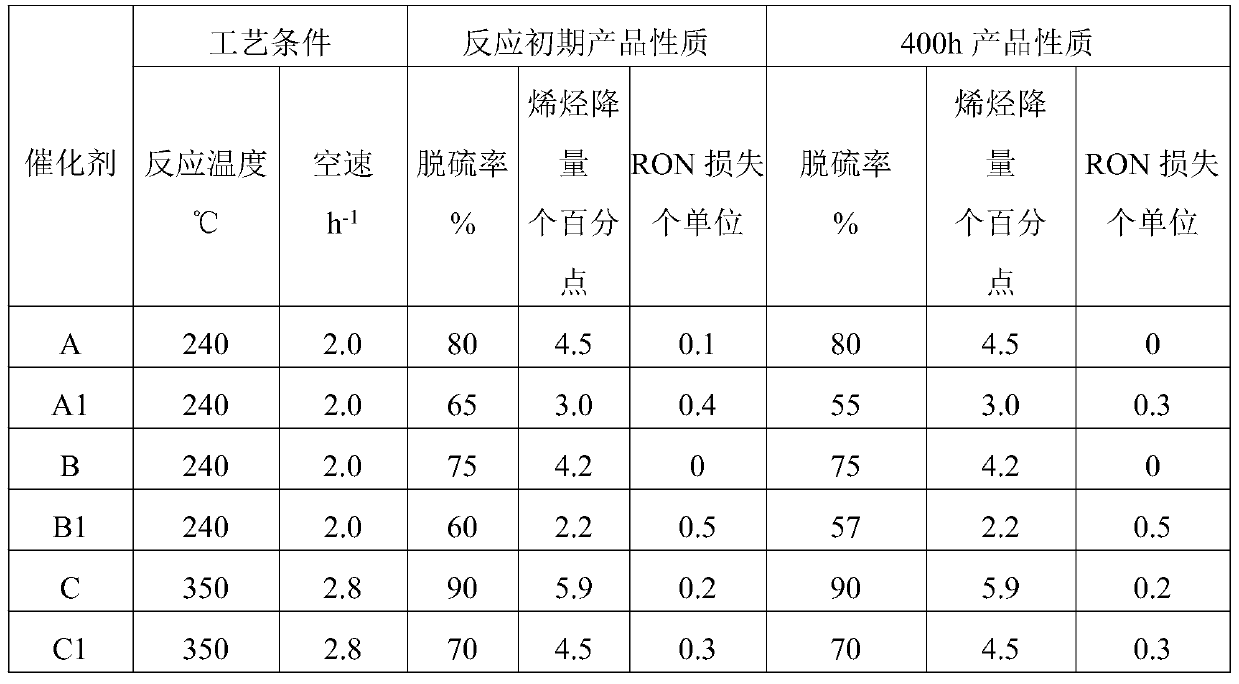

Sulfur-carrying hydrodesulfurization upgrading catalyst and preparation method

ActiveCN106925338AEvenly dispersedLarge specific surface areaMolecular sieve catalystsHydrocarbon oils treatmentMolecular sieveHydrodesulfurization

The invention relates to a sulfur-carrying hydrodesulfurization upgrading catalyst. On the basis of weight of the catalyst, content of a molecular sieve in the catalyst is 5-70wt%, VIB-family metal content is 2-10wt% calculated according to oxide, VIII-family metal content is 1-5wt% calculated according to oxide, sulfur content is 3-8wt%, content of a zinc-aluminum lamellar material prepared through non-constant pH alternate titration is 5-50%, and phosphorus content is 0-10wt% calculated according to oxide. The zinc-aluminum lamellar material in the catalyst has large specific surface area, and the sulfur-carrying hydrodesulfurization upgrading catalyst prepared by compositing the zinc-aluminum lamellar material with a molecular sieve material has good hydrodesulfurization and olefin-reducing performance.

Owner:PETROCHINA CO LTD

Method for preparing macroporous vulcanization-type hydrogenation catalyst through one-step molding

ActiveCN106732666ALarge hole volumeHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPore distributionVulcanization

The invention provides a method for preparing a macroporous vulcanization-type hydrogenation catalyst through one-step molding. The method comprises (1) uniformly mixing a vulcanization agent, a vulcanization aid and additive granules, keeping the mixture at the constant temperature of 90-150 DEG C for 5-50min, adding an aqueous solution containing a hydrogenation active metal into the mixture, carrying out a reaction process at a temperature of 100-140 DEG C for 5-60min, and separating to remove the additive granules so that a liquid mixture I is obtained, (2) uniformly mixing a peptizing agent, water and urea to obtain a liquid mixture II, (3) carrying out mixing kneading on the liquid mixture I, the liquid mixture II and an aluminum source and extruding the mixture to obtain a wet material, and (4) carrying out ammonia treatment on the wet material, and then freezing, drying and calcining the treated wet material to obtain the vulcanization-type hydrogenation catalyst. The method realizes synchronization of catalyst preparation and vulcanization. The pore distribution of the catalyst is concentrated, the preparation process is simple, the catalytic activity of the catalyst is improved, the preparation cost of the catalyst is reduced, and the application prospect in the market is relatively broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

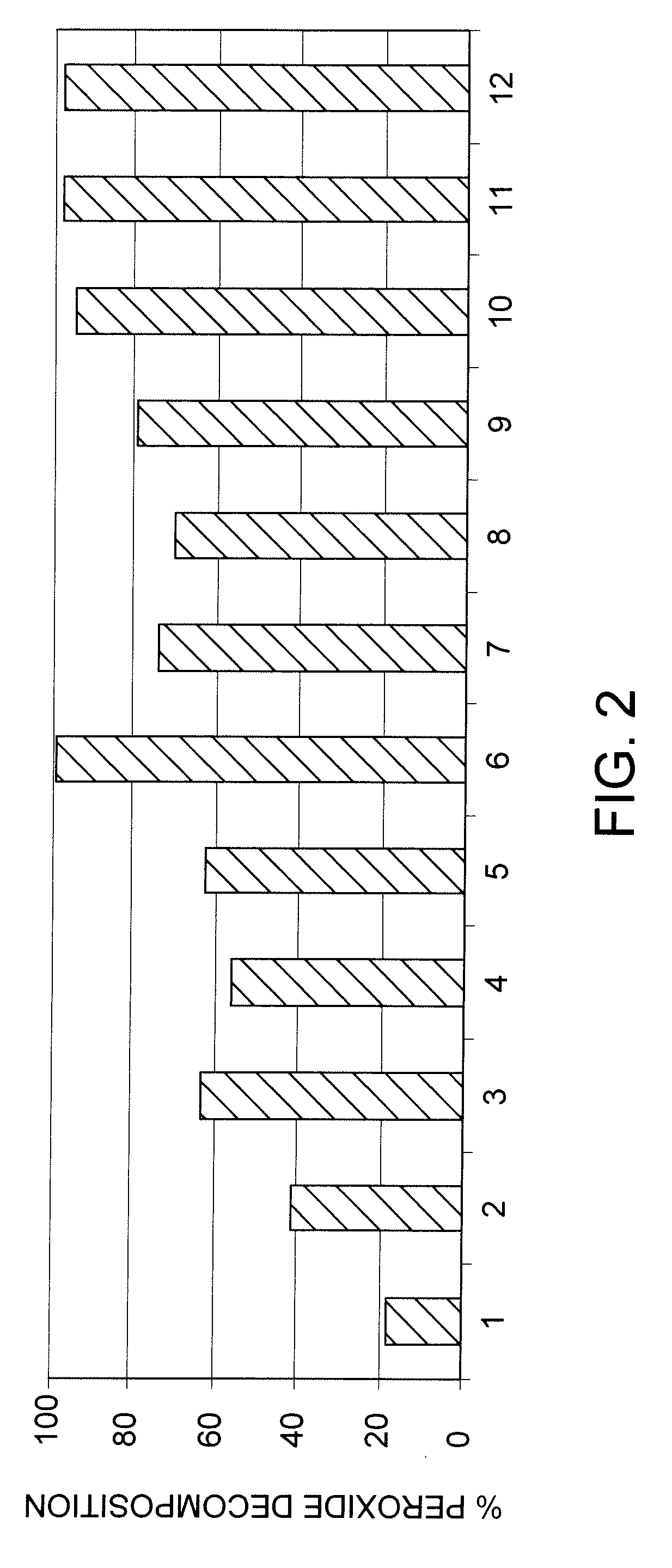

Decomposition of peroxides using iron-containing acidic zeolites

InactiveUS20090159502A1Easy to oxidizeIncrease capacityAluminium compoundsMolecular sieve catalystsAlcoholDecomposition

The present invention provides a catalyst particle for decomposing a peroxide compound into an alcohol compound, the catalyst particle having an acidic zeolite material having an iron containing material in the framework position or the non-framework position and being present in an amount by weight of the catalyst particle from 100 ppm to 10,000 ppm.

Owner:UOP LLC

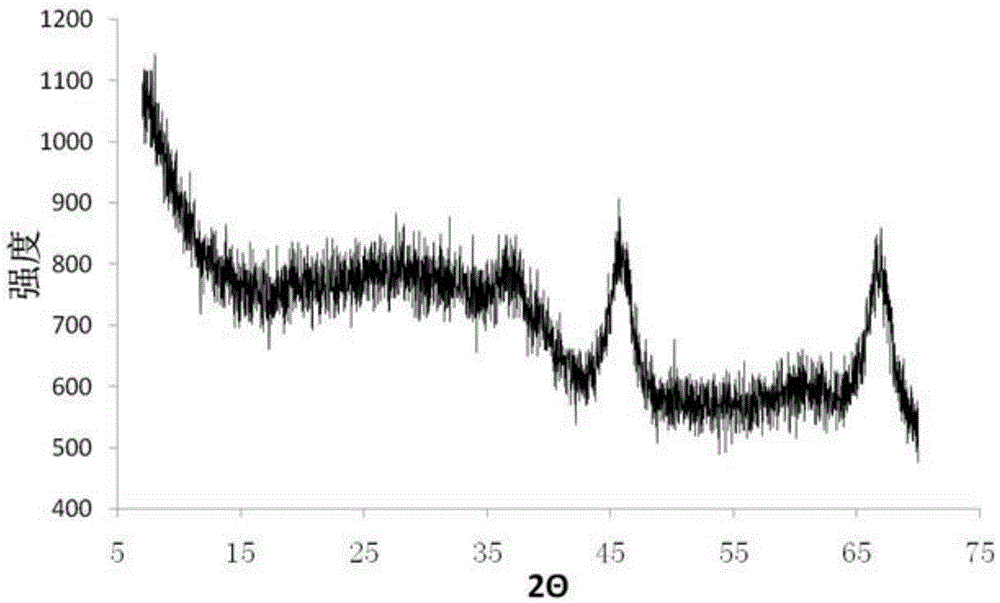

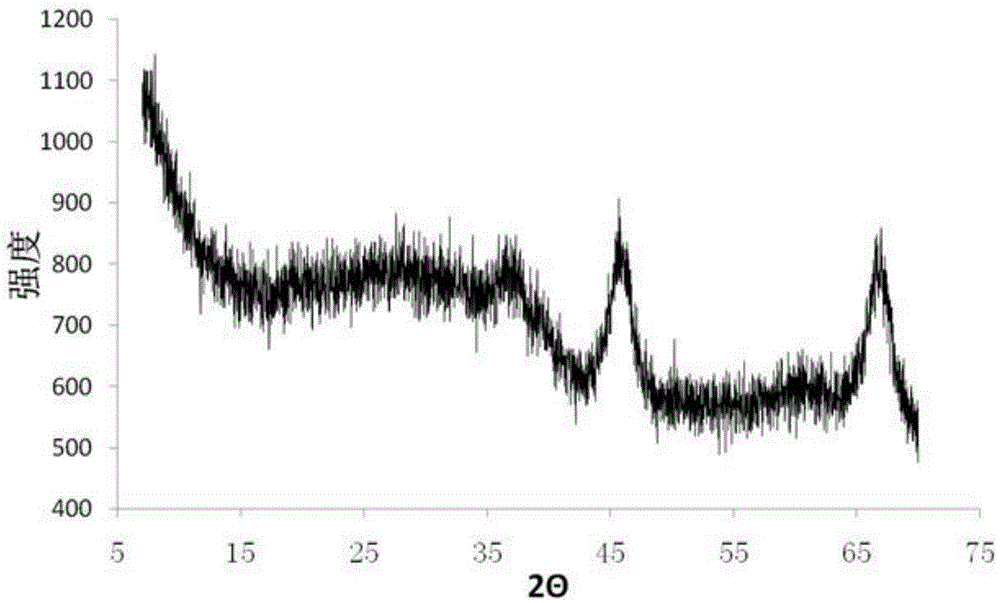

Heavy oil hydrogenation catalyst and application thereof

ActiveCN105772008AGood hydrodesulfurizationPromote denitrificationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationFuel oil

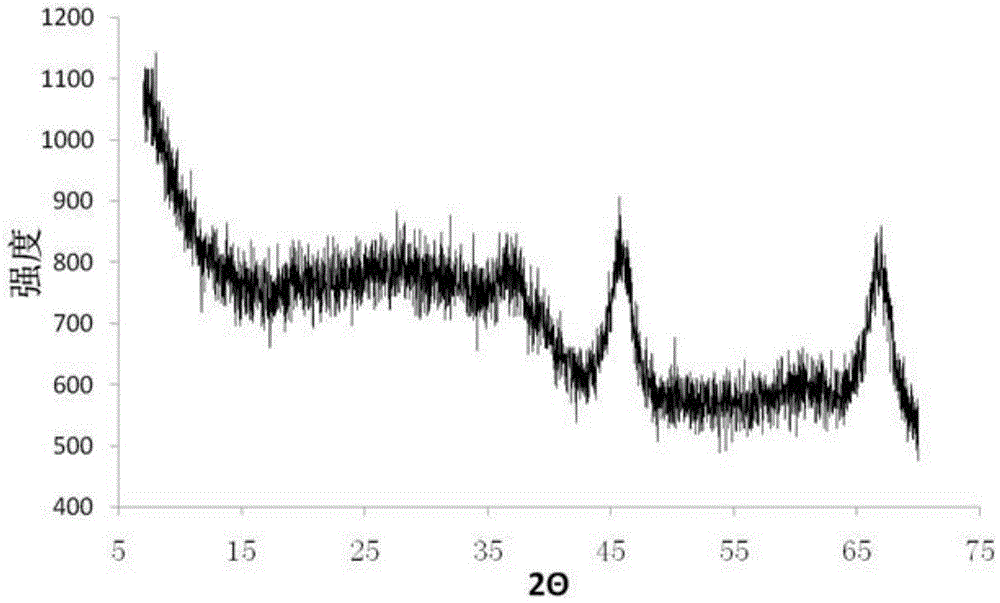

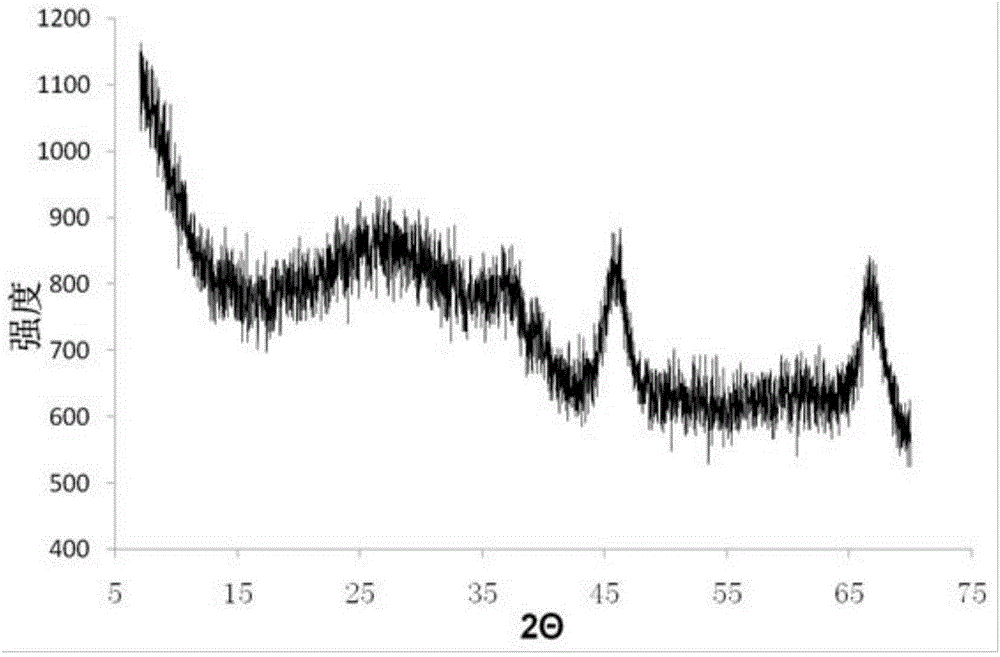

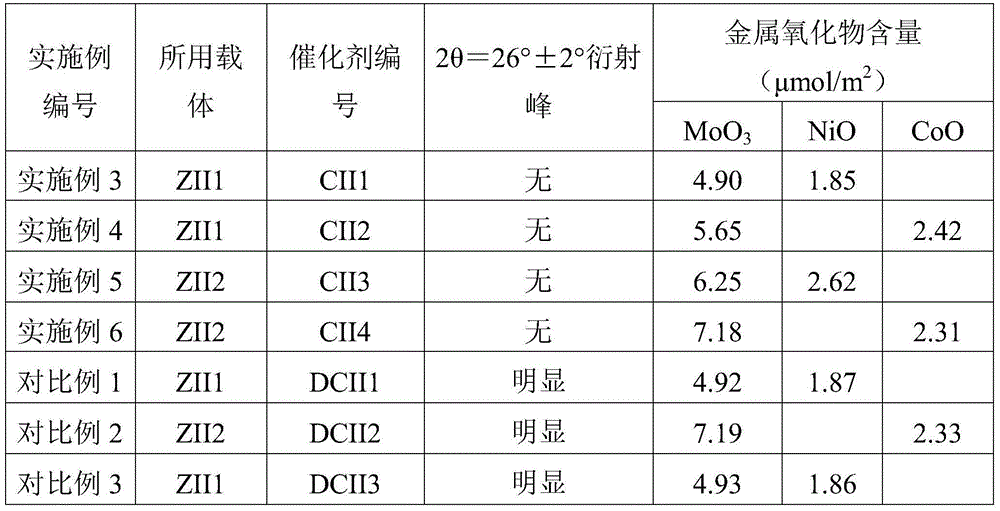

The invention provides a heavy oil hydrogenation catalyst. The catalyst comprises a titanium-containing molded alumina carrier, a metal component molybdenum and a metal component cobalt or nickel; the content of titanium (by oxide) in the titanium-containing molded alumina carrier used as a reference is 0.5-8wt%; the content of the metal component molybdenum (by oxide) in the catalyst with the unit carrier surface load as a reference is 4.8-9.0[mu]mol / m<2>, and the content of the metal component cobalt or nickel (by oxide) is 1.5-4.0[mu]mol / m<2>; and no MoO3 characteristic peak appears at a diffraction angle 2theta of 24-28DEG in the XRD characterization map of the catalyst. Compared with heavy oil hydrogenation catalysts, the heavy oil hydrogenation catalyst provided by the invention has better hydrodesulfurization, nitrogen removal and residual carbon removal effects in the heavy metal hydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrotreating method

ActiveCN105754640AGood hydrodesulfurizationGood demetallizationRefining to eliminate hetero atomsHydrodesulfurizationFuel oil

The present invention provides a heavy oil hydrotreating method, the method comprises contacting of heavy oil with a catalyst composition of a heavy oil hydrotreating catalyst I and a heavy oil hydrotreating catalyst II for heavy oil hydrotreating under heavy oil hydrotreating conditions, wherein first the heavy oil is contacted with the heavy oil hydrotreating catalyst I, and then contacted with the heavy oil hydrotreating catalyst II, by calculation of volume on the basis of the total volume of the catalyst composition as a reference, the content of the heavy oil hydrotreating catalyst I in the catalyst composition is 20-60v%, and the content of the heavy oil hydrotreating catalyst II in the catalyst composition is 40-80v%. Compared with conventional heavy oil hydrotreating methods, the heavy oil hydrotreating method has better hydrodesulfurization, demetalization and carbon residue removal effects when used in heavy oil hydrotreating.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of silicon-containing alumina carrier

ActiveCN103769231BEasy to modifyIncrease acidityCatalyst carriersRefining to eliminate hetero atomsStrong acidsResidual oil

The invention discloses a preparation method of a silicon-containing alumina carrier. The preparation method comprises the following steps: mixing clay, which has been calcinated at a high temperature, with alumina or a precursor of alumina, orderly adding a weak alkali solution and a strong acid solution, carrying out a life-cultivating treatment in damp air, and then subjecting the life-cultivated material to processes of forming, drying, and burning so as to obtain the silicon-containing alumina carrier. In the preparation method, the weak alkali solution is added before the addition of the strong acid solution, and then a life-cultivating treatment is carried out so as to adjust the physical and chemical properties of the catalyst carrier, and finally a hydro-treatment catalyst, which has the advantages of reasonable pore structure and proper acidity, is obtained. The silicon-containing alumina carrier provided by the invention is especially suitable for being used as a carrier of a catalyst for heavy oil or residual oil hydro-treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrogenation treatment catalyst and preparation method thereof

ActiveCN106694053BReduce heatSolve the problem of rapid temperature riseOrganic-compounds/hydrides/coordination-complexes catalystsSimple Organic CompoundsVulcanization

The invention discloses a hydrotreating catalyst and a preparation method thereof. The hydrotreating catalyst comprises a hydrogenation activity metal component, a vulcanizing agent, a carrier, and an organic compound, wherein the carrier is provided with double-peak pore diameter distribution. The organic compound in the catalyst can replace part of vulcanizing agent, has no need to be subjected to generation reaction of hydrogen sulfide and vulcanization reaction of the hydrogen sulfide and active metal during vulcanization, and is subjected to direct chain scission so as to generate metal sulfide, so that the problem of rapid temperature rise during a catalyst vulcanizing process is solved, and the on-stream time can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A carrier, catalyst and preparation method for hydrodesulfurization

ActiveCN109718815BMaintain continuityImprove uniformityCatalyst carriersCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a carrier, a catalyst and a preparation method for hydrodesulfurization. The carrier is an auxiliary-containing alumina carrier. The auxiliary-containing alumina carrier includes main alumina and rod-shaped alumina. The main alumina is alumina with micron-scale pores, and at least part of the rod-shaped alumina is distributed in the main body. On the outer surface of the alumina and in the micron-sized pores, the auxiliary agent is phosphorus and / or boron. The preparation method of the carrier is as follows: a physical pore-enlarging agent is adsorbed to a solution containing an auxiliary agent, and then the pseudo-boehmite and the physical pore-enlarging agent of the adsorption auxiliary agent are kneaded and formed, and the molded product is dried and roasted to obtain a carrier intermediate; Then immerse the carrier intermediate in the ammonium bicarbonate solution, and then seal and heat treat the material. After the heat treatment, the material is dried and calcined to obtain the hydrogenation desulfurization catalyst carrier. The hydrodesulfurization catalyst is especially suitable for the hydrodesulfurization treatment process of residual oil, and has the characteristics of good macromolecular diffusion performance, strong metal-accommodating ability, and high desulfurization ability.

Owner:CHINA PETROLEUM & CHEM CORP +1

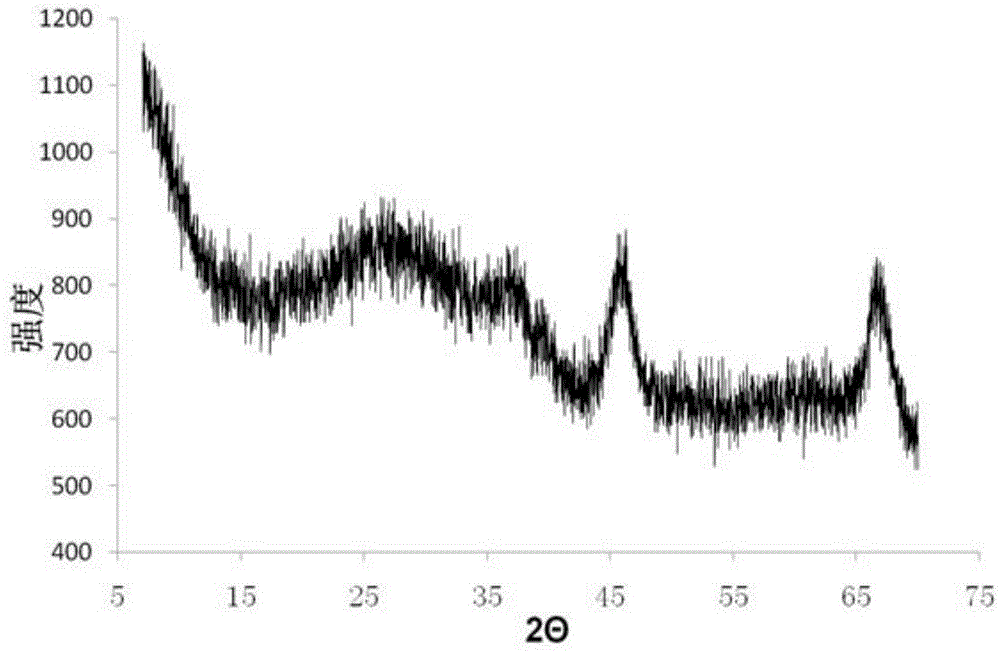

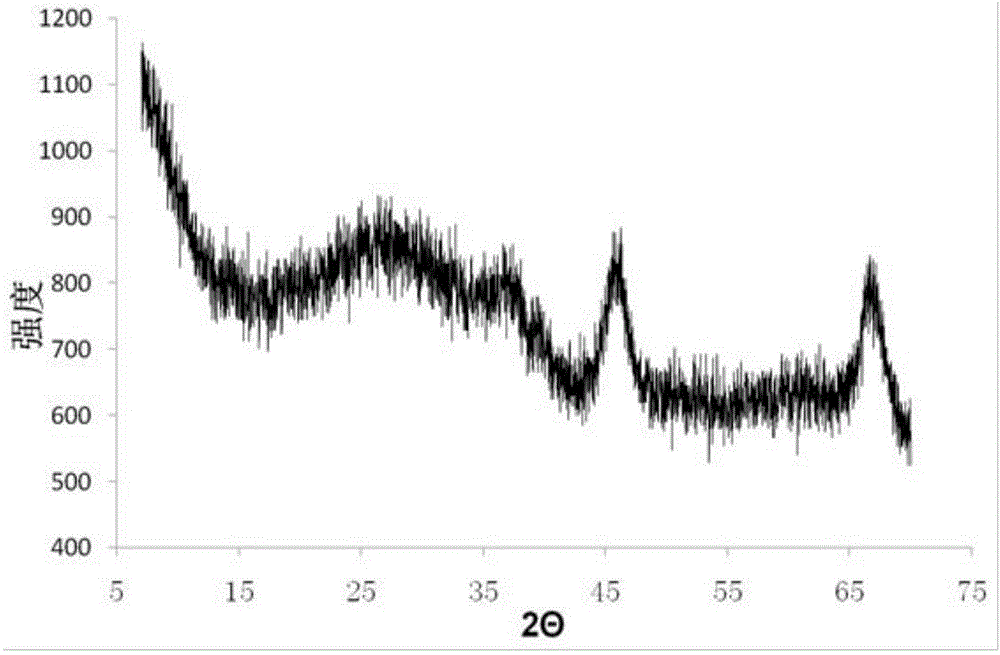

Hydrogenation catalyst and preparation method and application thereof in heavy oil suspended bed hydrotreatment

ActiveCN111420672ASurface acidity is easy to adjustLarge adjustment rangeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrodesulfurization

The invention discloses a hydrogenation catalyst and a preparation method and an application of the hydrogenation catalyst in heavy oil suspended bed hydrotreatment. The hydrogenation catalyst comprises a carrier, a metal component molybdenum, at least one non-noble metal component selected from group VIII, and an auxiliary agent component; the auxiliary agent component comprises boron or a composition of boron and phosphorus, the carrier is pseudo-boehmite, and the infrared total acid content of the catalyst at a temperature of 350 DEG C or more is 40-350 [mu]mol / g; when the catalyst is characterized by XRD, no MoO3 characteristic peak appears when 2[theta] is equal to 26 degrees. Compared with the prior art, the catalyst provided by the invention is used for carrying out suspended bed hydrotreatment on heavy oil, and has better hydrodesulfurization and denitrification effects.

Owner:TAIYUAN UNIV OF TECH

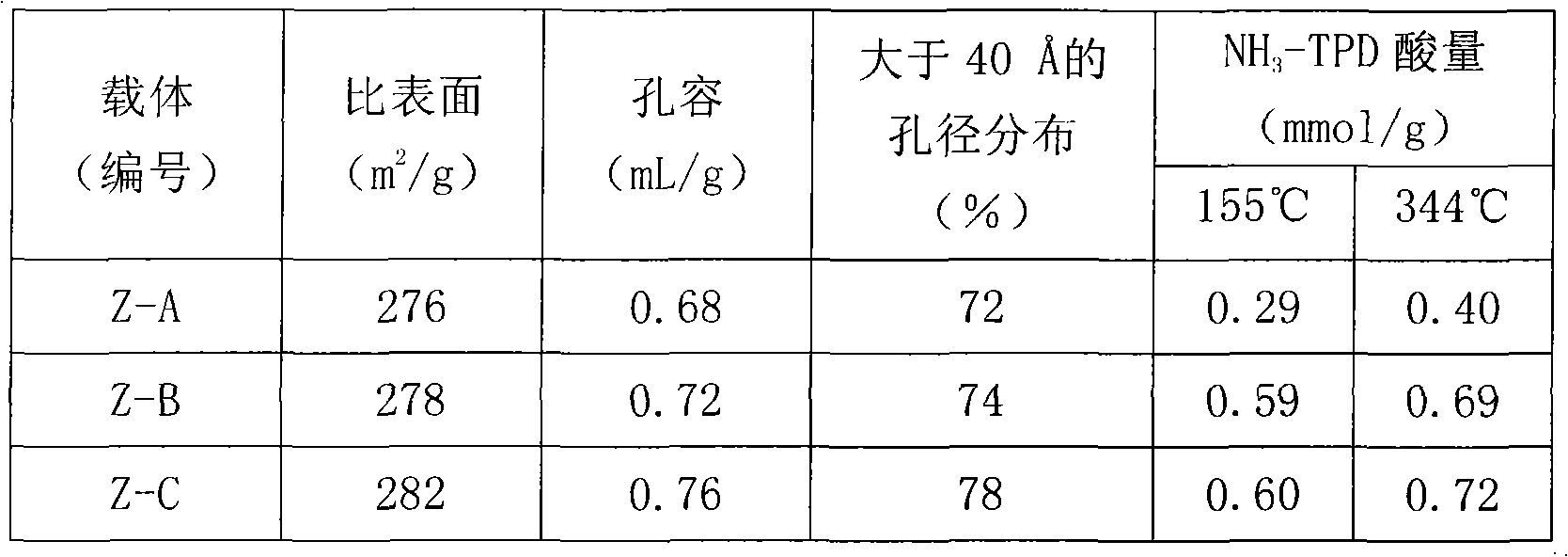

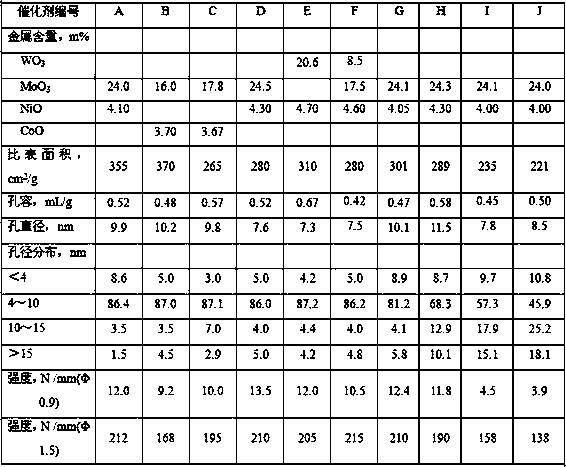

A kind of heavy petroleum distillate hydrogenation treatment catalyst and preparation method thereof

ActiveCN106925287BGood hydrodesulfurizationMeet the nature requirementsCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationAlumina composite

The invention relates to a highly active heavy petroleum fraction hydrotreating catalyst and a preparation method thereof. It proposes a method for preparing a catalyst using titanium-modified silicon-aluminum composite oxide as a carrier, in which mesoporous silicon prepared by a co-precipitation method is used. Aluminum composite oxide is the matrix material, and titanium oxide, titanium sulfate, titanium tetrachloride, titanium n-propoxide, titanium isopropoxide, or Isobutyl titanate, etc., to obtain a titanium modified carrier with a large specific surface area and pore volume. The specific surface area of the carrier is 200~310m 2 / g, pore volume is 0.5~1.2ml / g. The metal active components are loaded on the carrier using solution impregnation technology. The catalyst of the invention has good hydrodesulfurization and hydrodenitrification activities for heavy petroleum fractions.

Owner:PETROCHINA CO LTD

Sulfur-loaded hydrodesulfurization upgrading catalyst and preparation method

ActiveCN106925338BEvenly dispersedLarge specific surface areaMolecular sieve catalystsHydrocarbon oils treatmentMolecular sievePtru catalyst

The invention relates to a sulfur-carrying hydrodesulfurization upgrading catalyst. On the basis of weight of the catalyst, content of a molecular sieve in the catalyst is 5-70wt%, VIB-family metal content is 2-10wt% calculated according to oxide, VIII-family metal content is 1-5wt% calculated according to oxide, sulfur content is 3-8wt%, content of a zinc-aluminum lamellar material prepared through non-constant pH alternate titration is 5-50%, and phosphorus content is 0-10wt% calculated according to oxide. The zinc-aluminum lamellar material in the catalyst has large specific surface area, and the sulfur-carrying hydrodesulfurization upgrading catalyst prepared by compositing the zinc-aluminum lamellar material with a molecular sieve material has good hydrodesulfurization and olefin-reducing performance.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com