Hydrodesulfurization catalyst and preparation method thereof

A hydrodesulfurization and catalyst technology, applied in the fields of hydrodesulfurization catalyst and its preparation, low-temperature hydrodesulfurization catalyst for benzene hydrogenation and its preparation, can solve the problems of high reaction temperature and pressure, and achieve weak and good saturation selectivity Hydrodesulfurization performance and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

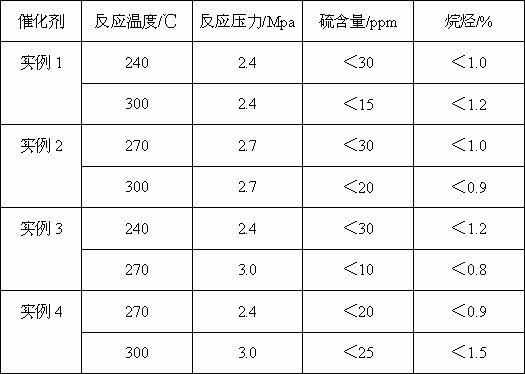

Embodiment 1

[0018] Weigh 61.8g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 58.2gCo(NO 3 ) 2 ·6H 2 O was dissolved in deionized water to prepare a salt solution, then weighed 44.56g of alumina and immersed in the salt solution, baked at 100°C for 10h, roasted at 600°C for 10h, and cooled naturally. Then weigh 11.2gKNO 3 , 24.4gH 3 PO 4 Dissolve the compound solution prepared in deionized water, immerse the cooled catalyst in the compound solution, bake at 100°C for 10h, roast at 600°C for 10h, and cool naturally to obtain the target catalyst. Wherein the mass percentage content of the active component is 10%, and the mass percentage content of the auxiliary agent is 1%.

Embodiment 2

[0020] Weigh 69.3gNi(NO 3 ) 2 ·6H 2 O, 68.8g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 20.1gCe(NO 3 ) 2 6H 2 O was dissolved in deionized water to prepare a salt solution, and then 45.13g of titanium oxide was weighed and immersed in the salt solution, baked at 150°C for 4 hours, roasted at 650°C for 4 hours, and cooled naturally. Then weigh 71.2g (NH 4 ) 10 W 12 o 41 ·xH 2 O was dissolved in deionized water to prepare the compound solution, and the cooled catalyst was immersed in the compound solution, baked at 150°C for 4 hours, calcined at 650°C for 4 hours, and cooled naturally to obtain the target catalyst. Wherein the mass percentage content of the active component is 20%, and the mass percentage content of the auxiliary agent is 5%.

Embodiment 3

[0022] Weigh 53.7g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 4.2gPdCl 2 Dissolve the salt solution prepared in deionized water, then weigh 4.31g of alumina and immerse in the salt solution, bake at 120°C for 5h, bake at 500°C for 10h, and cool naturally. Then weigh 6.3gMg(NO 3 ) 2 6H 2 O, 36.2g (NH 4 ) 10 W 12 o 41 ·xH 2 O was dissolved in deionized water to prepare the compound solution, the cooled catalyst was immersed in the compound solution, baked at 120°C for 5h, calcined at 500°C for 10h, and cooled naturally to obtain the target catalyst. Wherein the active component mass percentage content is 10%, and the auxiliary agent mass percentage content is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com