A kind of hydrogenation treatment catalyst and preparation method thereof

A technology for hydrotreating and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Insufficient vulcanization of components and poor dispersion of active metals, etc., can solve the problems of rapid rise in bed temperature, shorten start-up time, and avoid metal aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

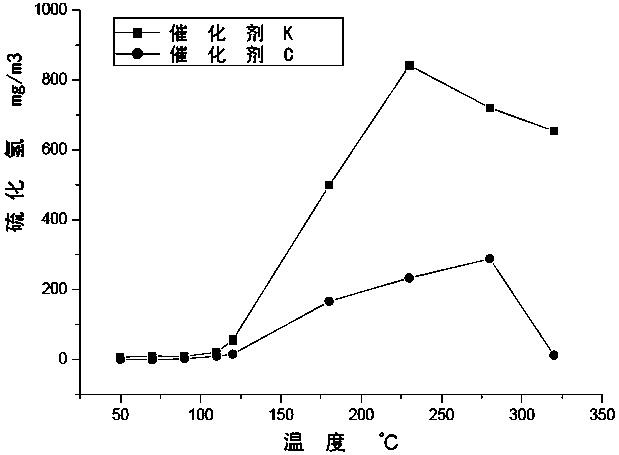

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 catalyst carrier

[0046] (1) Preparation of carrier A-1

[0047] Weigh 200g of macroporous pseudo-boehmite (dry basis: 73wt%), 4g of safflower powder, 6g of citric acid, 10mL of nitric acid (30wt%), and 80mL of deionized water, mix them evenly, and extrude them into 1.2mm clover on the extruder Strips, dried at 120°C for 4 hours, calcined at 800°C for 3 hours, crushed to obtain carrier a, weighed 700g of macroporous pseudo-boehmite (73wt% on a dry basis), 19g of squid powder, the above carrier a and 100 mesh quartz Mix 10g of sand, then take 32g of citric acid, 48mL of nitric acid (30wt%), 159mL of silica gel (containing 30wt% of silicon dioxide), 20g each of polystyrene and polyethylene glycol 2000, and 250mL of deionized water, mix evenly and spray mix The final powder, after rolling for 20 minutes, was extruded into 1.2mm clover strips on an extruder, dried at 120°C for 4 hours, and roasted at 600°C for 3 hours to obtain carrier A-1....

Embodiment 2

[0050] Example 2 Preparation of Hydrotreating Catalyst B

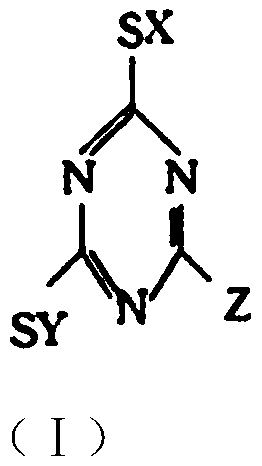

[0051] Weigh 18.7g of ammonium molybdate, 12g of nickel nitrate, and 30mL of ammonia water, and mix them with deionized water to 100mL to obtain impregnating solution I. Measure the impregnation solution I according to the water absorption rate of 100mL / 100g and spray the impregnation carrier A-1. After spraying, put the sample into the blast drying oven for the first low-temperature heat treatment. The first low-temperature heat treatment condition is: The temperature was raised to 120°C at a rate of °C / min, and the temperature was kept constant for 3 hours. Dissolve 10.6g of 2,4,6-trimercapto-s-triazine triammonium salt in 50mL of water to obtain impregnation solution II, spray the first low-temperature heat-treated sample with impregnation solution II, and put the sample into blast drying after spraying Carry out the second low-temperature heat treatment in the box, and the second low-temperature heat treatment con...

Embodiment 3

[0052] Example 3 Preparation of Hydrotreating Catalyst C

[0053] Take 15g of molybdenum oxide, 5g of basic nickel carbonate, 1.0mL of phosphoric acid, 50mL of deionized water and boil for 1 hour, add water to 100mL to obtain impregnation solution I, measure the impregnation solution I according to the water absorption rate of 100mL / 100g and spray carrier A-2, spray After showering, put the sample into the blast drying oven for the first low-temperature heat treatment. The conditions for the first low-temperature heat treatment are: the temperature is raised to 120°C at a rate of 3°C / min, and the temperature is kept constant for 3 hours. Then weigh 14.7g of 2,4-dimercaptotriazine diammonium salt and dissolve it in 50mL aqueous solution to obtain impregnation solution II. Spray and impregnate the sample of the first low-temperature heat treatment with impregnation solution II. After spraying, put the sample into the air blast The second low-temperature heat treatment was carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com