Hydrogenation catalyst and preparation method and application thereof in heavy oil suspended bed hydrotreatment

A hydrogenation catalyst and hydrotreating technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problems of metal aggregation, low utilization rate of active metals, boron There is little room for improvement in content and active component content, so as to achieve the effect of good hydrodesulfurization, wide adjustment range and easy adjustment of surface acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

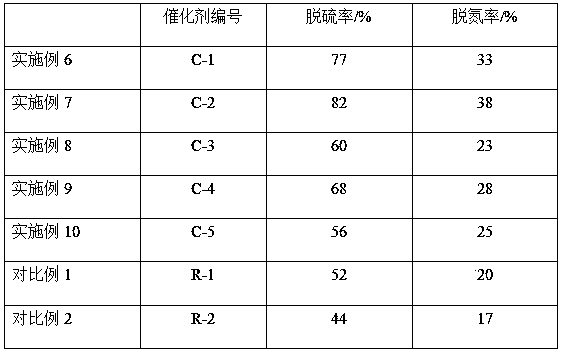

[0021] Weigh 20.3g of aluminum isopropoxide, uniformly disperse in 130g of deionized water to make a slurry, then add 9.5g of aqueous solution containing 15% boric acid, and react at 85°C for 2 hours to obtain mixture A. Weigh 3.7 g of ammonium molybdate tetrahydrate and 3.0 g of nickel nitrate hexahydrate, and prepare solutions with 10 mL of deionized water respectively, add them to mixture A in turn, and react at 90°C for 6 hours to obtain the catalyst precursor.

[0022] The catalyst precursor was aged at 25°C for 8 days, then dispersed in liquid paraffin, and heat-treated at 320°C for 5 hours to obtain catalyst C-1.

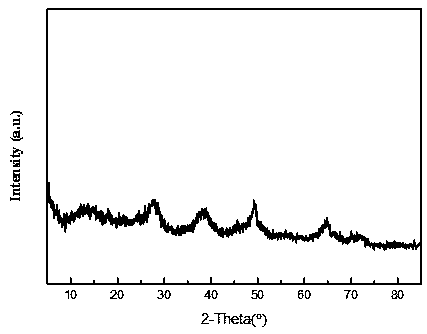

[0023] The XRD characterization results of catalyst C-1 are as follows figure 1 As shown, the characteristic diffraction peaks of incomplete crystal AlOOH are presented, which proves that the catalyst support is pseudo-boehmite. at 2θ=26 o MoO does not appear when 3 The characteristic peaks indicate that the supported active metals are well dispersed on th...

Embodiment 2

[0025] Weigh 18.8g of aluminum isopropoxide, uniformly disperse in 160g of aqueous solution containing 40% isopropanol to make a slurry, then add 10.0g of aqueous solution containing 40% boric acid, and react at 85°C for 2 hours to obtain mixture A. Weigh 3.7 g of ammonium molybdate tetrahydrate and 3.0 g of nickel nitrate hexahydrate, and prepare solutions with 10 mL of deionized water respectively, add them to mixture A in turn, and react at 90°C for 6 hours to obtain the catalyst precursor.

[0026] The catalyst precursor was aged at 40°C for 5 days, then dispersed in liquid paraffin, and heat-treated at 280°C for 8 hours to obtain catalyst C-2.

Embodiment 3

[0028] Weigh 21.1g of aluminum sulfate, uniformly disperse in 160g of aqueous solution containing 40% isopropanol to make a slurry, then add 1.4g of aqueous solution containing 40% boric acid, and react at 85°C for 2 hours to obtain mixture A. Weigh 2.5 g of ammonium molybdate tetrahydrate and 2.0 g of nickel nitrate hexahydrate, and prepare solutions with 10 mL of deionized water respectively, add them to mixture A in turn, and react at 90°C for 6 hours to obtain the catalyst precursor.

[0029] The catalyst precursor was aged at 40°C for 5 days, then dispersed in liquid paraffin, and heat-treated at 280°C for 8 hours to obtain catalyst C-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com