Preparation method of sulfurized type hydrogenation catalyst

A hydrogenation catalyst and vulcanization-type technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of poor interaction between active metal components and elemental sulfur, unfavorable active metal components Severe vulcanization reaction, active metal components are difficult to interact with each other, achieve broad market application prospects, reduce preparation costs, and concentrate the pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

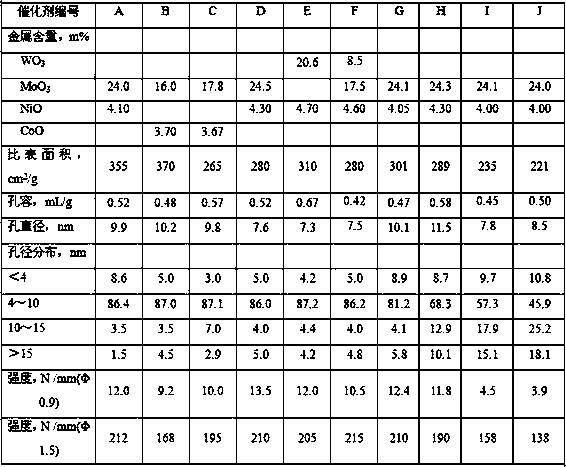

Examples

Embodiment 1

[0039] 1. Add 50ml of clean water into the preparation container, start the agitator, slowly add 57.2 g of molybdenum oxide, 22.4 g of basic nickel carbonate, and finally slowly add 1.27 g of phosphoric acid, to avoid carbon dioxide bumping due to the decomposition of basic carbonate by heating. Close the lid tightly, then heat up to >100°C, and keep the temperature constant for 1-2 hours until the molybdenum oxide and basic nickel carbonate are all dissolved, and the Mo-Ni-P solution is prepared. Mo-Ni-P solution concentration is MoO 3 , 57.1g / 100ml; NiO, 9.8 g / 100ml; P, 4.0 g / 100ml; take 70ml of Mo-Ni-P solution, and keep the temperature at 320°C for 150min to obtain the Mo-Ni active metal precursor;

[0040] 2. Mix the Mo-Ni active metal precursor, 10.9g of elemental sulfur, 2g of kerosene, and 22g of rapeseed oil for 15 minutes, and keep the temperature at 120°C for 25 minutes to obtain mixture I;

[0041] 3. Take 50ml of water, add 4.6ml of concentrated nitric acid to di...

Embodiment 2

[0047] 1. First, add 25ml of clean water into the preparation container, start the mixer, slowly add 9.8g of basic cobalt carbonate, 14g of citric acid, then heat up to >100°C, keep the temperature for 10-20min, and naturally cool to room temperature to obtain Co- Citric acid solution, the concentration is CoO 14.5g / 100ml; add Co-citric acid solution to ammonium heptamolybdate, 16.0g of ammonia solution (density 0.940) 67ml to obtain Co-Mo-ammonia citrate solution, and keep the temperature at 200℃ 240min to obtain the Mo-Co active metal precursor;

[0048] 2. Mix the Mo-Co active metal precursor, 15.6g of dimethyl disulfide, 2g of diesel oil, 22g of soybean oil, and 3g of glycerin for 5 minutes, and keep the temperature at 120°C for 25 minutes to obtain the mixture I;

[0049] 3. Take 50ml of water, add 4.6ml of concentrated nitric acid to dilute to obtain dilute nitric acid; then add 5g of citric acid and 4g of urea, and then add 20g of silica sol, stir well to obtain liquid ...

Embodiment 3

[0055]1. First add 25ml of clean water to the preparation container, start the agitator, slowly add 9.8g of basic cobalt carbonate, 14g of citric acid, then heat up to >100°C, keep the temperature for 10-20min, and naturally cool to room temperature, the solution volume is 35ml . A Co-citric acid solution was prepared. Add ammonium heptamolybdate 18.2g then, add ammoniacal liquor (0.94g / ml specific gravity) 50ml again, prepare Co-Mo citric acid solution concentration and be MoO 3 , 21.1g / 100ml; CoO, 3.90g / 100ml; take 30ml of Co-Mo citric acid solution, and keep the temperature at 270°C for 300min to obtain the Mo-Co active metal precursor;

[0056] 2. Mix the Mo-Co active metal precursor, 12.9g of elemental sulfur, 2.2g of white oil, and 24g of lard for 15 minutes; keep the temperature at 120°C for 25 minutes to obtain the mixture I;

[0057] 3. Take 52ml of water, then add 5g of citric acid and 4g of urea, stir well to obtain liquid mixture II;

[0058] 4. Take 200ml of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com