Equipment for recovering and utilizing heat energy generated by phosphor combustion and system for preparing phosphoric acid by hot method

A technology of heat energy recovery and yellow phosphorus, which is applied in the recovery and utilization of heat energy and the recovery and utilization of yellow phosphorus combustion heat energy in the production of thermal phosphoric acid. Water-cooled wall heat transfer and other issues, to achieve the effect of increasing economic and social benefits, improving waste heat recovery efficiency, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

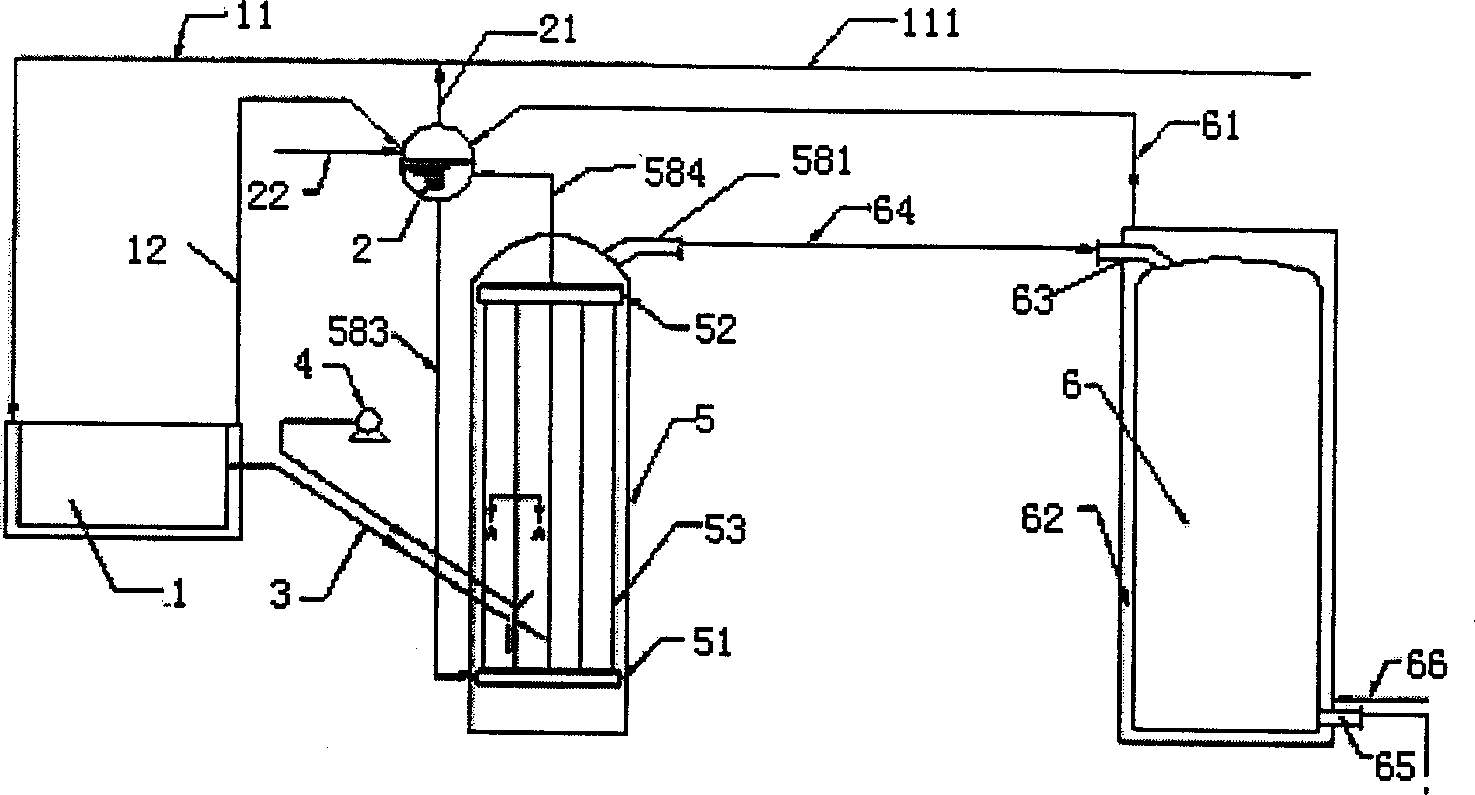

[0033] Yellow phosphorus combustion heat energy recovery and utilization device and thermal process phosphoric acid production system embodiment of the present invention design are described in detail as follows in conjunction with accompanying drawing:

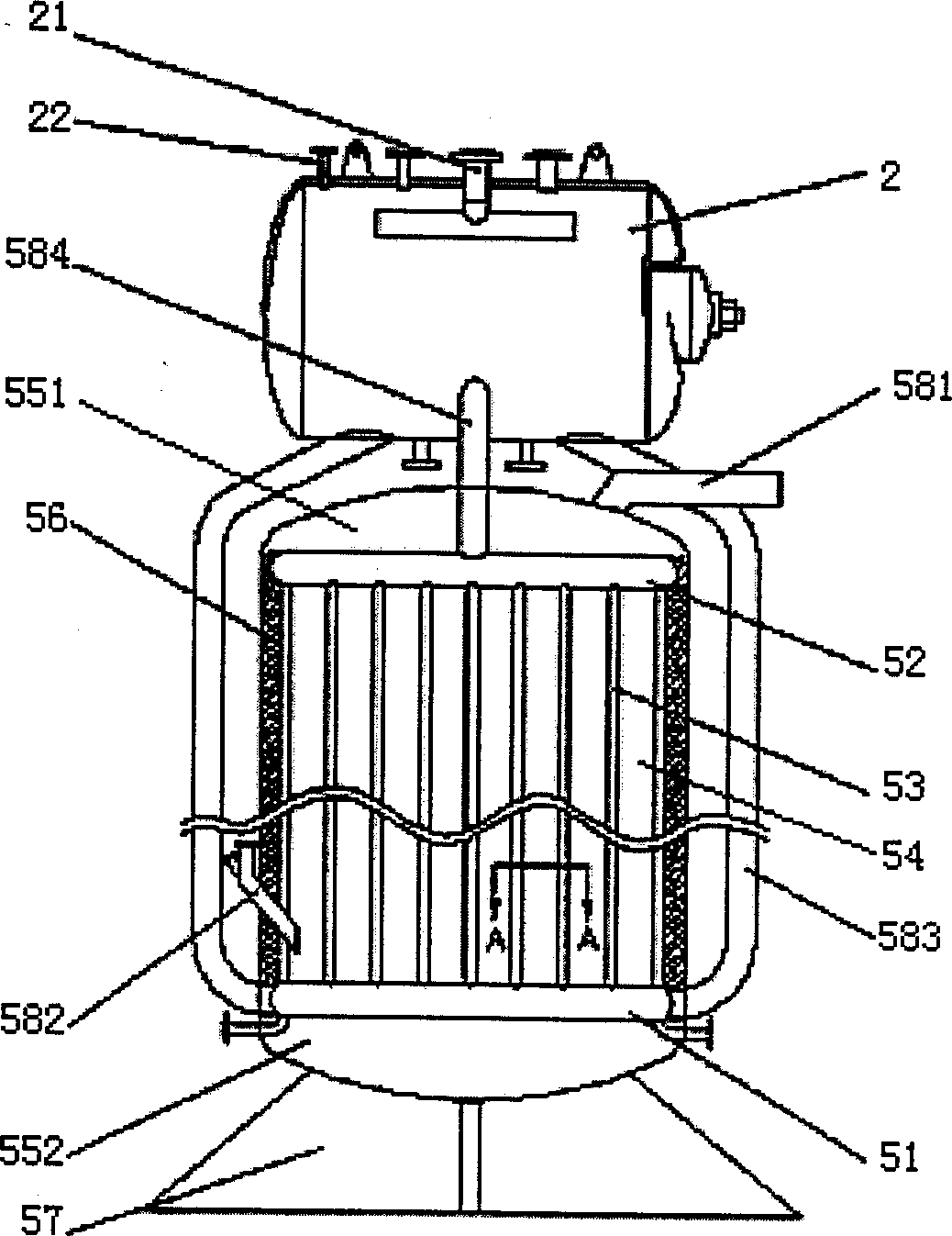

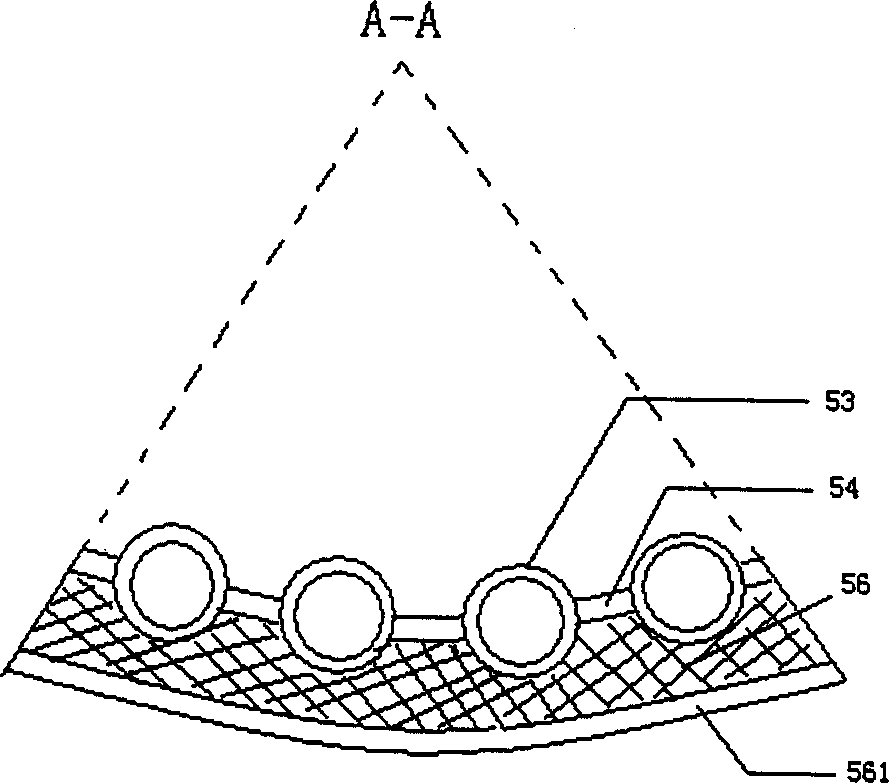

[0034] The structure of the yellow phosphorus combustion heat energy recovery and utilization device in this embodiment is as follows figure 1 , 2 As shown, it is made up of a steam drum 2 and a combustion tower 5 with heat energy recovery function; the combustion tower includes: a plurality of riser tubes 53 and enhanced heat exchange fins 54 connected between each tube form a ring with a hollow cavity Membrane heat exchanger; an annular upper header 52 and a lower header 51 arranged on the upper and lower ends of the heat exchanger and connected to the riser pipe; an upper head 551 installed on the upper and lower ends of the upper and lower headers , the lower head 552; a closed shell 561 formed by the insulation layer 56...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com