Special high-performance dual-curable UV coating for automotive interior decorative parts and preparation method thereof

A dual-curing technology for automotive interior parts, applied in the field of coatings, which can solve problems such as large volume shrinkage, drop, cracking adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

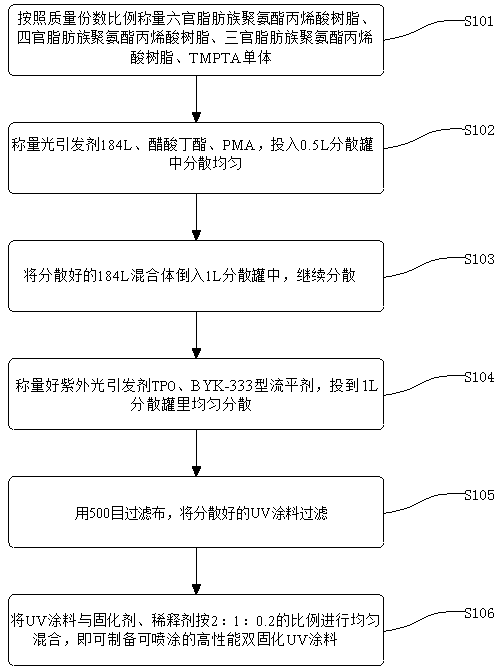

Image

Examples

Embodiment 1

[0030] A special high-performance dual-curing UV coating for automotive interior parts, comprising the following raw material formula in parts by mass:

[0031] 2 parts of hexafunctional aliphatic urethane acrylic resin, 50 parts of tetrafunctional aliphatic urethane acrylic resin, 20 parts of trifunctional aliphatic urethane acrylic resin, 10 parts of TMPTA monomer, 1 part of UV photoinitiator 184L, 1 part of UV photoinitiator TPO 0.5 parts of BYK-333 leveling agent, 8 parts of butyl acetate, and 7 parts of PMA (propylene glycol methyl ether acetate).

[0032] Hexafunctional aliphatic urethane acrylate resins are polyurethane acrylic oligomers, trifunctional aliphatic urethane acrylic resins and tetrafunctional aliphatic urethane acrylate resins are aliphatic urethane acrylate oligomers, and tetrafunctional hydroxy urethane acrylate resins are hydroxyl-containing Polyurethane acrylic oligomer, TMPTA monomer is trifunctional acrylic oligomer.

[0033] Based on the above-menti...

Embodiment 2

[0041] A special high-performance dual-curing UV coating for automotive interior parts, comprising the following raw material formula in parts by mass:

[0042] 3 parts of hexafunctional aliphatic polyurethane acrylic resin, 30 parts of tetrafunctional aliphatic polyurethane acrylic resin, 30 parts of trifunctional aliphatic polyurethane acrylic resin, 20 parts of TMPTA monomer, 5 parts of UV photoinitiator 184L, and UV photoinitiator TPO 0.5 1.5 parts of BYK-333 type leveling agent, 2 parts of butyl acetate, 8 parts of PMA (propylene glycol methyl ether acetate).

[0043] Based on the above-mentioned raw material formula, a preparation method of high-performance dual-curing UV coatings for automotive interior parts is now proposed. The process is as follows figure 1 , including the following steps:

[0044] S101: Weigh 30 g of hexafunctional aliphatic urethane acrylic resin, 300 g of tetrafunctional aliphatic urethane acrylic resin, 300 g of trifunctional aliphatic urethane ...

Embodiment 3

[0051] A special high-performance dual-curing UV coating for automotive interior parts, comprising the following raw material formula in parts by mass:

[0052] 5 parts of hexafunctional aliphatic polyurethane acrylic resin, 40 parts of tetrafunctional aliphatic polyurethane acrylic resin, 25 parts of trifunctional aliphatic polyurethane acrylic resin, 15 parts of TMPTA monomer, 3 parts of UV photoinitiator 184L, 1 part of UV photoinitiator TPO 1 part, BYK-333 type leveling agent 1 part, butyl acetate 5 parts, PMA (propylene glycol methyl ether acetate) 5 parts.

[0053] Based on the above-mentioned raw material formula, a preparation method of high-performance dual-curing UV coatings for automotive interior parts is now proposed. The process is as follows figure 1 , including the following steps:

[0054] S101: Weigh 50 g of hexafunctional aliphatic urethane acrylic resin, 400 g of tetrafunctional aliphatic urethane acrylic resin, 250 g of trifunctional aliphatic urethane ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com