Preparation method of ultraviolet cured silicon-containing acrylate conductive printed adhesive

A technology of silicon acrylate and ultraviolet light, which is applied in the direction of conductive adhesives, adhesives, non-polymer organic compound adhesives, etc., can solve the problem of degrading the releasability of embossing adhesives, adhesion and contact between embossing adhesives and templates Area increase and other problems, to achieve the effect of reducing surface energy, reducing viscosity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

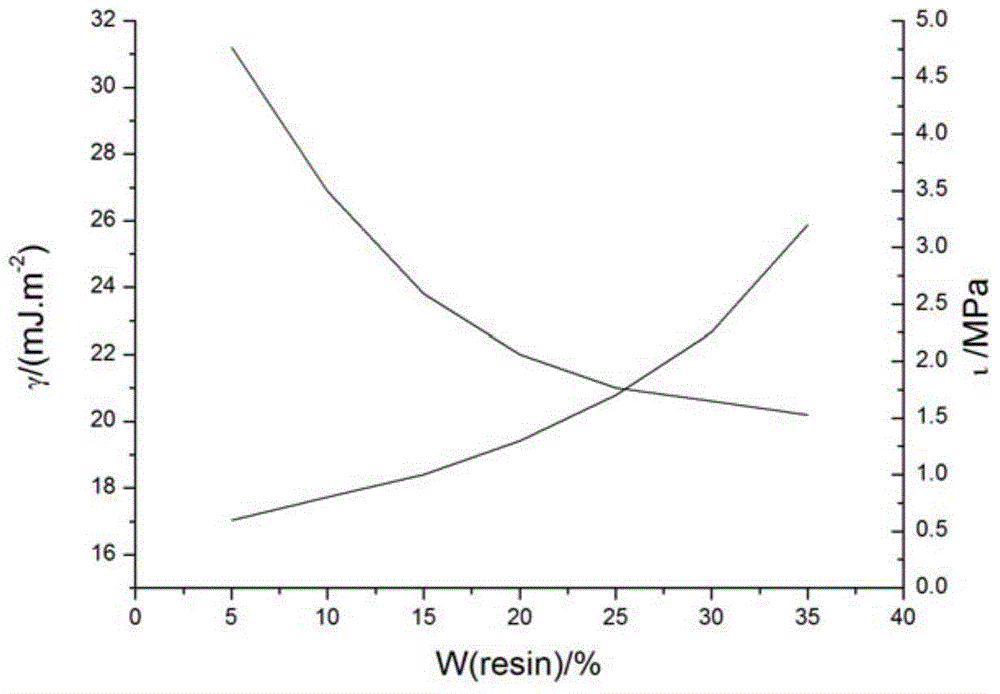

Image

Examples

Embodiment 1

[0050] Use wet ball milling to process copper powder, add absolute ethanol to the copper powder as a medium, and use a planetary ball mill for ball milling under nitrogen protection, and grind for 20 hours to obtain flake copper powder with pearlescent color and a particle size of 1-10 microns ;

[0051] Wash the above flaky copper powder three times with a dilute sulfuric acid solution with a concentration of 5%, and then wash it three times with absolute ethanol. After filtering, add a dispersant or a coupling agent to the filter residue, quickly put it in a vacuum drying oven, and dry it for later use. ;

[0052] According to the number of parts by mass, mix 163 parts of trimethylchlorosilane and 62 parts of KH-550, and evenly drop a mixed solution of 40.8 parts of deionized water and 48 parts of methanol within 30 minutes, and stir until uniform; the reaction temperature is controlled Below 50°C;

[0053] After continuing to stir at room temperature for 12 hours, the org...

Embodiment 2

[0059] Use wet ball milling to process copper powder, add absolute ethanol to the copper powder as a medium, and use a planetary ball mill for ball milling under nitrogen protection, and grind for 20 hours to obtain flake copper powder with pearlescent color and a particle size of 1-10 microns ;

[0060] Wash the above flaky copper powder three times with a dilute sulfuric acid solution with a concentration of 5%, and then wash it three times with absolute ethanol. After filtering, add a dispersant or a coupling agent to the filter residue, quickly put it in a vacuum drying oven, and dry it for later use. ;

[0061] According to the number of parts by mass, mix 163 parts of trimethylchlorosilane and 62 parts of KH-550, and evenly drop a mixed solution of 40.8 parts of deionized water and 48 parts of methanol within 30 minutes, and stir until uniform; the reaction temperature is controlled Below 50°C;

[0062] After continuing to stir at room temperature for 12 hours, the org...

Embodiment 3

[0068] Use wet ball milling to process copper powder, add absolute ethanol to the copper powder as a medium, and use a planetary ball mill for ball milling under nitrogen protection, and grind for 20 hours to obtain flake copper powder with pearlescent color and a particle size of 1-10 microns ;

[0069] Wash the above flaky copper powder three times with a dilute sulfuric acid solution with a concentration of 5%, and then wash it three times with absolute ethanol. After filtering, add a dispersant or a coupling agent to the filter residue, quickly put it in a vacuum drying oven, and dry it for later use. ;

[0070] According to the number of parts by mass, mix 163 parts of trimethylchlorosilane and 62 parts of KH-550, and evenly drop a mixed solution of 40.8 parts of deionized water and 48 parts of methanol within 30 minutes, and stir until uniform; the reaction temperature is controlled Below 50°C;

[0071] After continuing to stir at room temperature for 12 hours, the org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com