UV curing coating and application method thereof

A technology for curing coatings and application methods, applied in the field of coatings, can solve problems such as heat loss, short curing time, and increased production costs, and achieve good wear resistance and adhesion performance, fast curing speed, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A UV curable coating, the raw materials used are: 79.2% polyester acrylate, 5.9% HDDA, 2.9% UV curable resin TMPTA, 10% titanium dioxide, 1% TPO, 1% ITX.

Embodiment 2

[0030] A UV curable paint, the raw materials used in the percentage by weight are: 79% polyester acrylate, 6% HDDA, 3% UV curable resin TMPTA, 10% titanium dioxide, 1% TPO, 1% ITX.

Embodiment 3

[0032] A UV curable coating, the raw materials used are: 80% polyester acrylate, 5% HDDA, 2% UV curable resin TMPTA, 10% titanium dioxide, 2% TPO, 1% ITX.

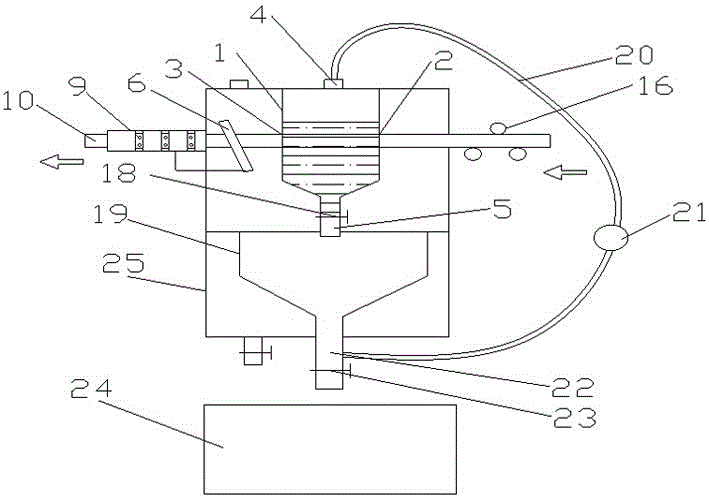

[0033] The immersion coating curing device includes a paint container 1 for containing paint, the side wall of the paint container 1 is provided with inlets and outlets 2 and 3 for strip materials to pass through, and the upper and lower parts of the paint container are respectively provided with paint Inlets and outlets 4, 5, a blower mechanism 6 is provided at the strip material outlet position of the paint container, and a positioning tube 13 with a built-in UV-LED lamp 7 is arranged on the side of the blower mechanism 6 .

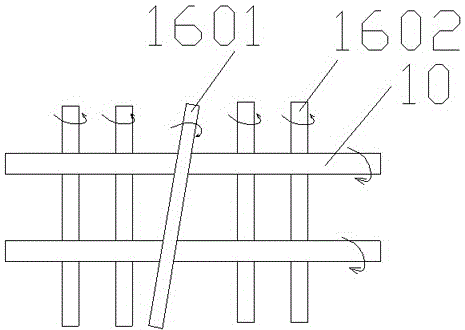

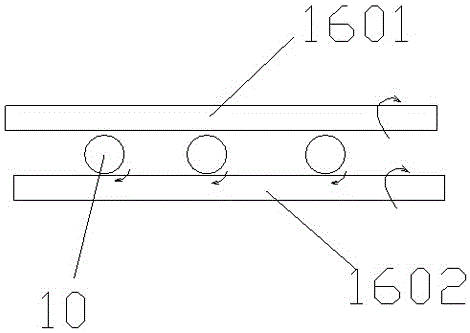

[0034] The positioning tube 13 has three transparent ring-shaped quartz tubes 9 and heat dissipation fins 12 nested between two sides of the transparent ring-shaped quartz tubes; the strip-shaped material 10 passes through the inner hole 11 of the ring-shaped quartz tubes. The transparent ring-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com