UV gloss oil and application thereof

A technology of varnish and light source, which is applied in the direction of coating, surface pretreatment, and devices for coating liquid on the surface, etc. It can solve the problems of easy discoloration of UV varnish coating, affecting the appearance of printed products, and unsatisfactory tolerance, and achieves Fast curing speed, low cost, and small heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

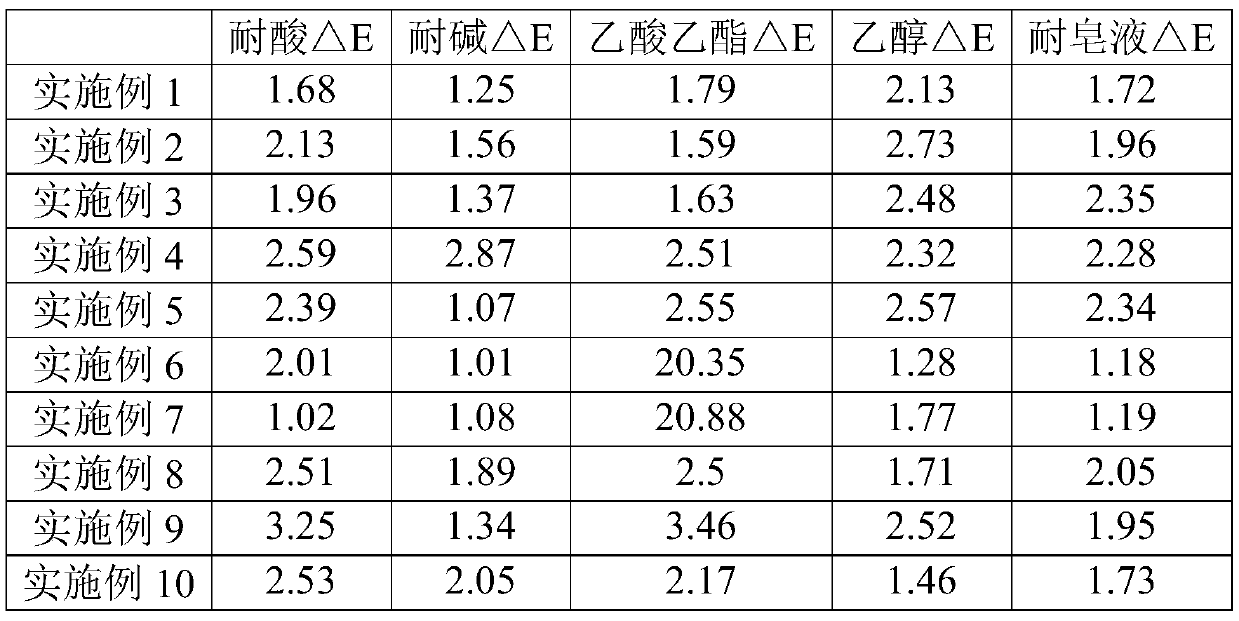

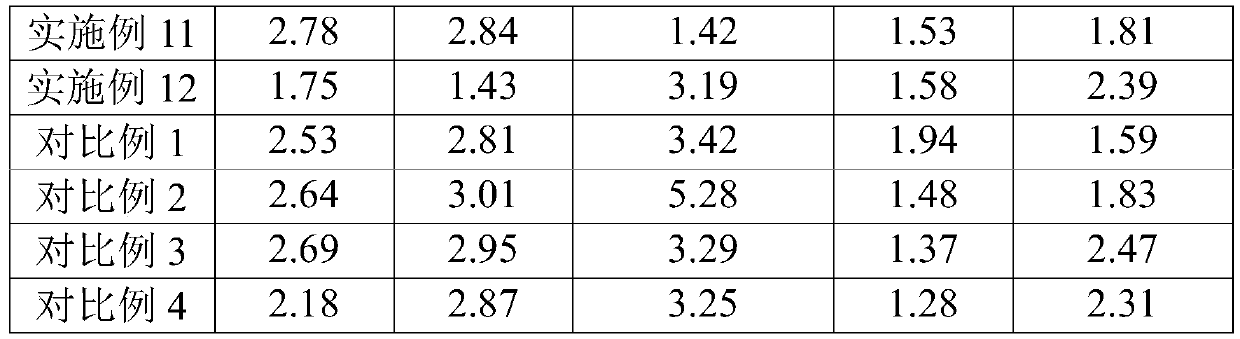

Examples

Embodiment 1

[0049] The present embodiment provides a UV varnish, comprising 59.98 parts of 4-acryloylmorpholine (ACMO), 25.71 parts of ethoxyethoxyethyl acrylate (EOEOEA), hyperbranched polyester acrylate (EB150) 4.97 parts, 0.74 parts of hyperbranched polyester acrylate (V100), 3.48 parts of photoinitiator 819, 2.52 parts of photoinitiator DETX, 2-phenylbenzyl-2-dimethylamine-1-(4 - Morpholine benzyl phenyl) butanone (EHA) and 1.6 parts and 1 part of leveling agent 432.

[0050] The preparation method is as follows: mix the above-mentioned raw materials according to the formula, place on a magnetic stirrer at room temperature and stir for 30 minutes until uniform, and then the UV varnish can be obtained.

Embodiment 2

[0052] The present embodiment provides a UV varnish, comprising 42.9 parts of hexanediol diacrylate (HDDA), 42.9 parts of pentaerythritol triacrylate (PETA), and 2.5 parts of hyperbranched polyester acrylate (EB150) in parts by mass , 2.5 parts of aliphatic polyurethane acrylate (EB270), 8 parts of photoinitiator 819 and 2-phenylbenzyl-2-dimethylamine-1-(4-morpholine benzylphenyl) butanone (EHA) 1.6 servings.

[0053] The preparation method is as follows: mix the above-mentioned raw materials according to the formula, place on a magnetic stirrer at room temperature and stir for 30 minutes until uniform, and then the UV varnish can be obtained.

Embodiment 3

[0055] This embodiment provides a UV varnish, which comprises 42.9 parts of hexanediol diacrylate (HDDA), 42.9 parts of 4-acryloylmorpholine (ACMO), 2.5 parts of aliphatic polyurethane acrylate (EB270) in terms of parts by mass. Parts, 0.74 parts of hyperbranched polyester acrylate (V100), 15098 parts of photoinitiator and 2-phenylbenzyl-2-dimethylamine-1-(4-morpholine benzylphenyl) butanone (EHA) 1.6 share.

[0056] Mix the above-mentioned raw materials according to the formula amount, place on a magnetic stirrer at room temperature and stir for 30 minutes until uniform, and then the UV varnish can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com