Nanometer SiO2 modifying process of ultraviolet ray cured adhesive

An adhesive and ultraviolet light technology, applied in the directions of non-polymer adhesive additives, adhesive additives, dyed silicone compounds, etc. The effect of improving performance and promoting dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

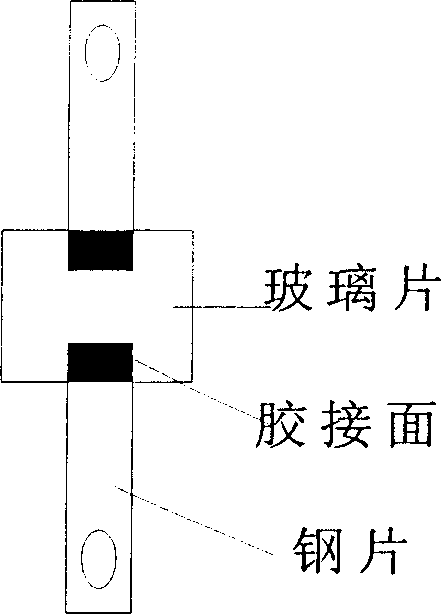

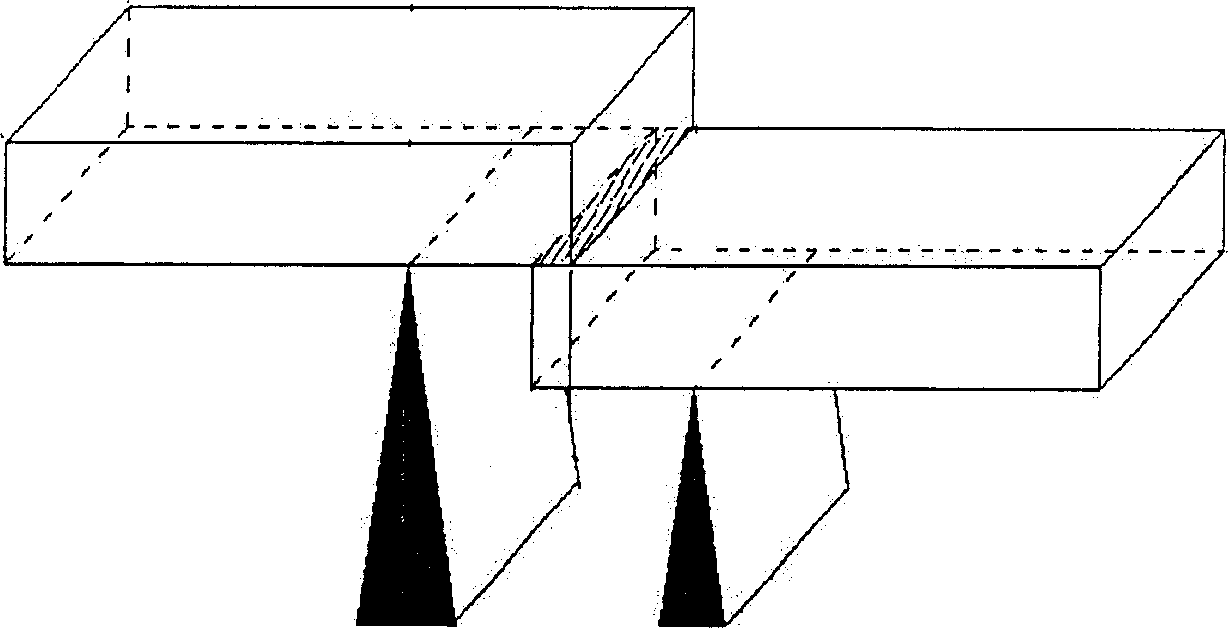

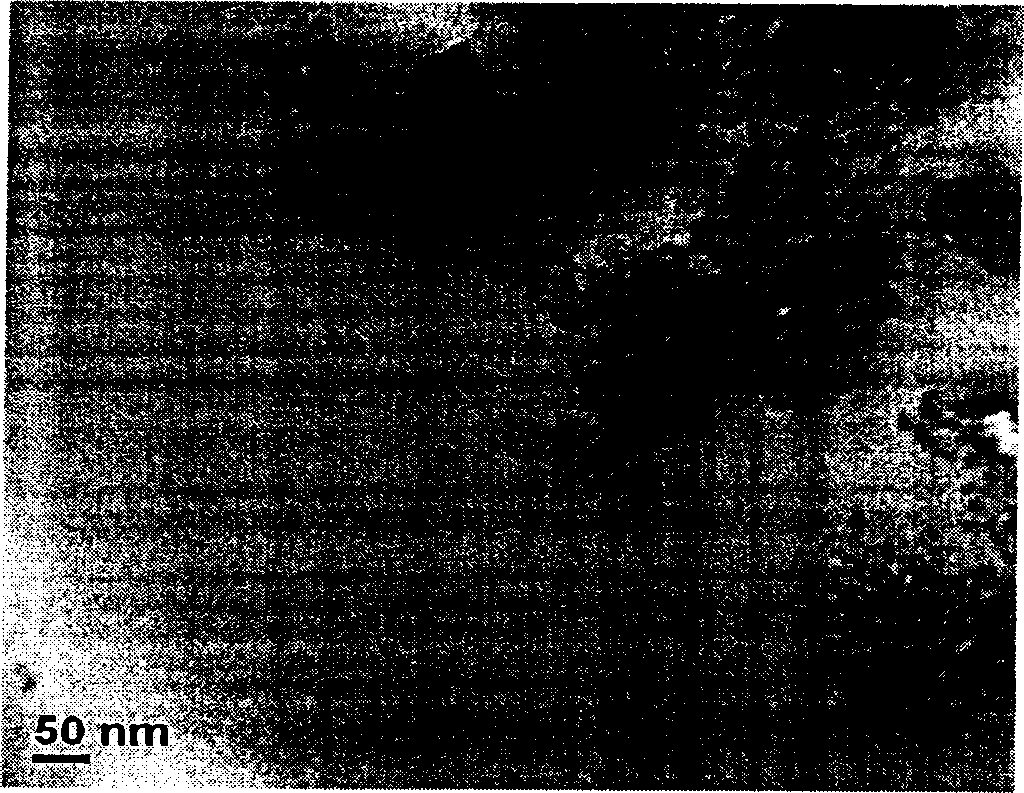

[0034] Add 2.5% Si-1, 15% urethane acrylate, and 87.5% acetone to the glass container respectively. After blending, ultrasonically disperse for 15 minutes, stir and heat at 60°C for 6 hours to promote SiO 2 Dispersion of particles in urethane acrylate, and then distill off the acetone and isopropanol solvents under reduced pressure; then the obtained SiO 2 / Urethane acrylate composite prepolymer by 60%, hydroxypropyl methacrylate 20%, trimethylolpropane (3 ethoxylated) triacrylate 5%, acid functional group acrylate 10%, 1173 photoinitiated 2%, KH570 1%, triethanolamine 1.5%, maleic acid 0.5% mass ratio mixed together, the sample obtained by stirring evenly is colorless and transparent; the sample is placed under a 300W ultraviolet lamp at 8cm within 5 seconds Can be fully cured; SiO in the sample after curing 2 The schematic diagram of particle dispersion is shown in Figure 5 , and other performance test results are shown in Table 1.

Embodiment 2

[0036] Add 2.5% Si-2, 15% urethane acrylate, and 87.5% acetone to the glass container respectively. After blending, ultrasonically disperse for 15 minutes, stir and heat at 60°C for 6 hours to promote SiO 2 Dispersion of particles in urethane acrylate, after the reaction, acetone and isopropanol solvents were evaporated under reduced pressure; then the obtained 40% SiO 2 / Urethane Acrylate Composite Prepolymer Press 40%, Epoxy Acrylate 20%, Hydroxypropyl Methacrylate 20%, Trimethylolpropane (3 Ethoxylated) Triacrylate 5%, Acid Functional Acrylic 10% of ester, 2.5% of 1173 photoinitiator, 1% of KH570, 1.0% of triethanolamine and 0.5% of maleic acid are mixed together, and the sample obtained by stirring evenly is colorless and transparent; the sample is placed in a 300W ultraviolet lamp It can be completely cured within 5 seconds at the lower 8cm; other performance test results are shown in Table 1.

Embodiment 3

[0038] Add 2.5% Si-3, 15% epoxy acrylate, and 87.5% acetone to the glass container respectively. After blending, ultrasonically disperse for 30 minutes, stir and heat at 60°C for 4 hours to promote SiO 2 After the dispersion of particles in epoxy acrylate, after the end, the acetone and isopropanol solvents were evaporated under reduced pressure; then the obtained SiO 2 / Epoxy acrylate composite prepolymer by 80%, 10% of hydroxypropyl methacrylate, 5% of trimethylolpropane (3 ethoxylated) triacrylate, 2.5% of 1173 photoinitiator, KH570 is 1 %, triethanolamine 1.0%, and maleic acid 0.5% by mass, and the sample obtained by stirring evenly is colorless and transparent; the sample can be completely cured within 5 seconds at 8cm under a 300W ultraviolet lamp; other performance tests The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com