Polypropylene composite material and preparation method and application thereof

A composite material, polypropylene technology, applied in the field of polypropylene composite material and its preparation, achieves the effects of good flame retardancy, good compatibility and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

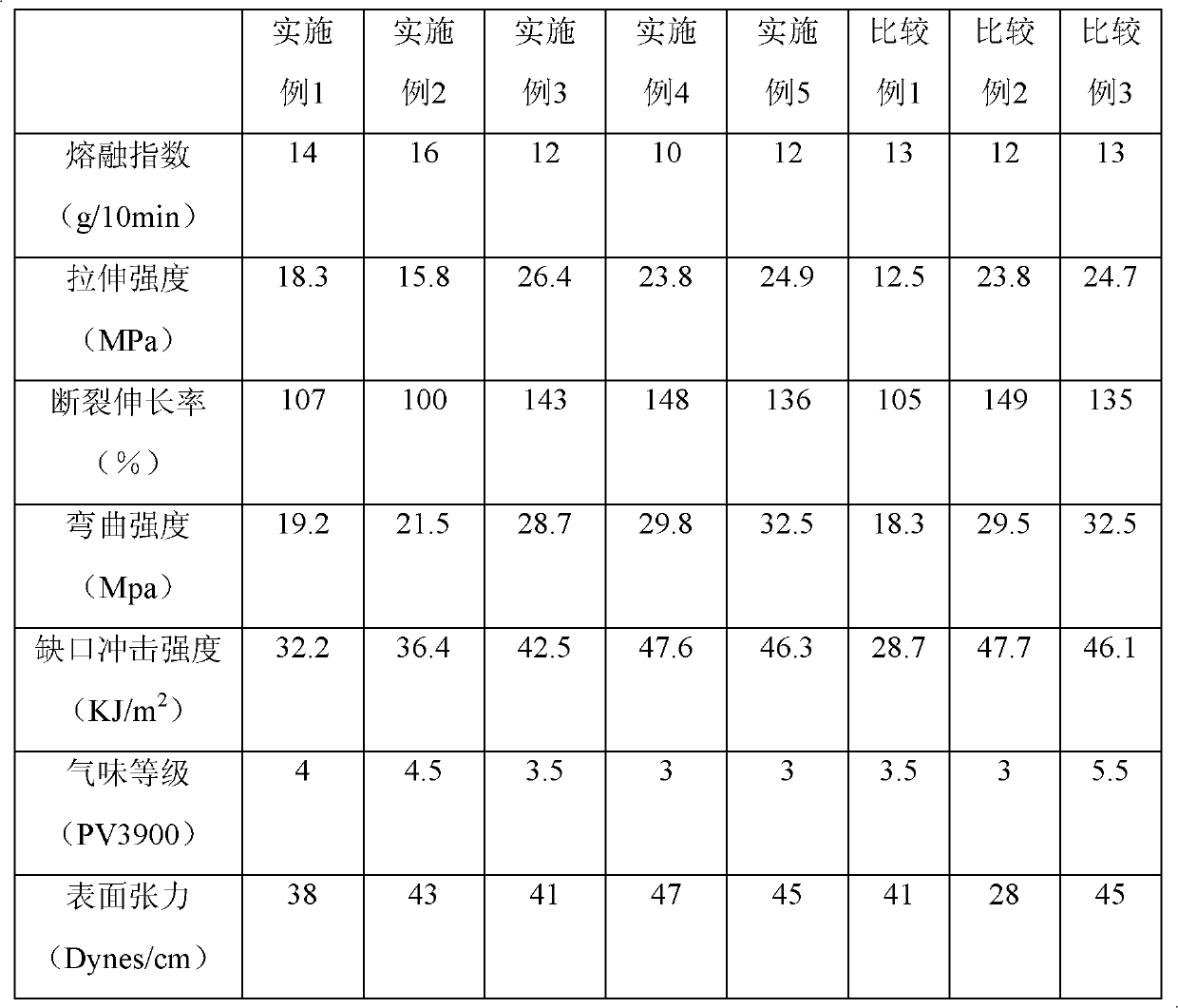

Examples

Embodiment 1

[0040] (1) Preparation of odor inhibitor: 100 parts of silica, 80 parts of zeolite, and 45 parts of magnesium oxide were placed in a muffle furnace for activation treatment at 600° C. for 2 hours in proportion, and then taken out and placed in an odorless oven at 100° C. to cool for later use;

[0041] (2) Weigh 67 parts of copolymerized polypropylene, 33 parts of homopolypropylene, 15 parts of ethylene acrylate, 10 parts of ethylene-octene copolymer, N, N'-di(β-naphthyl) p-phenylene 2.5 parts of diamine, 1.2 parts of maleic anhydride grafted polypropylene, 10 parts of inorganic composite flame retardant (the mass ratio of aluminum hydroxide to zinc borate is 2.2:1), 2.4 parts of odor inhibitor, and 0.4 parts of polyethylene wax. Pre-mix in the mixer for 3 minutes, then add 35 parts of glass fiber and mix for 5 minutes to obtain the mixed material. The speed of the mixer is 1080r / min;

[0042] (3) Put the mixed material into a twin-screw extruder to melt and extrude, granulate...

Embodiment 2

[0045] (1) Preparation of odor inhibitor: 100 parts of silica, 60 parts of zeolite and 100 parts of zinc oxide were placed in a muffle furnace for activation treatment at 550° C. for 2.5 hours in proportion, and then taken out and placed in an odorless oven at 90° C. to cool for later use;

[0046](2) Weigh 75 parts of copolymerized polypropylene, 25 parts of homopolypropylene, 12 parts of epoxy resin, 15 parts of ethylene-butene copolymer, N, N'-di(β-naphthyl) p-phenylene 1.5 parts of diamine, 2.4 parts of acrylic acid grafted polypropylene, 8 parts of inorganic composite flame retardant (mass ratio of aluminum hydroxide to zinc borate is 2.2:1), 1.5 parts of odor inhibitor, 0.3 parts of zinc stearate placed in Pre-mix in the mixer for 4 minutes, then add 20 parts of asbestos fiber and mix for 8 minutes to obtain the mixed material. The speed of the mixer is 960r / min;

[0047] (3) Put the mixed material into a twin-screw extruder to melt and extrude, granulate and dry.

[00...

Embodiment 3

[0050] (1) Preparation of odor inhibitor: 100 parts of silica, 75 parts of zeolite, and 35 parts of magnesium oxide were placed in a muffle furnace for activation treatment at 650° C. for 1.5 hours in proportion, and then taken out and placed in an odorless oven at 105° C. to cool for later use;

[0051] (2) Weigh 70 parts of copolymerized polypropylene, 30 parts of homopolypropylene, 8 parts of ethylene vinyl acetate, 10 parts of ethylene-octene copolymer and 15 parts of EPDM rubber according to the formula ratio, 1, 1, 3 -2.5 parts of three (2-methyl-4-hydroxyl-5-tert-butylphenyl) butane, 3.6 parts of maleic anhydride grafted polypropylene, 5 parts of inorganic composite flame retardant (the quality of aluminum hydroxide and zinc borate The ratio is 2.3:1), 3.6 parts of odor inhibitor, 0.8 parts of polyethylene wax are placed in the mixer for pre-mixing for 5 minutes, and then 60 parts of glass fibers are added and mixed for 8 minutes to obtain the mixed material. The speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com