Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Improve initial Coulombic efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

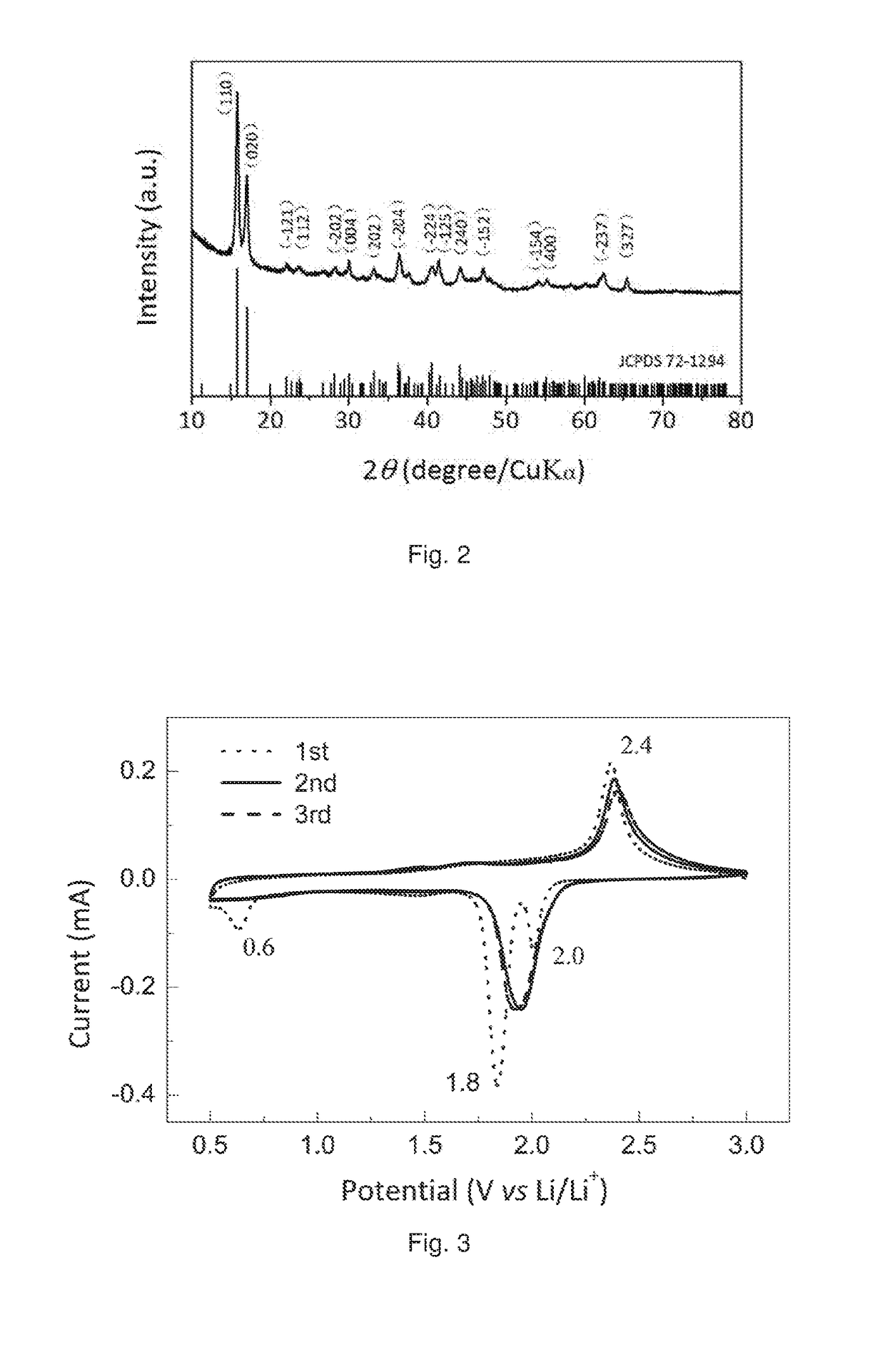

Positive electrode for lithium secondary battery and lithium secondary battery

InactiveUS20110223482A1Easy maintenanceImprove initial Coulombic efficiencyMaterial nanotechnologyLi-accumulatorsPhysical chemistryChemistry

An object of the present invention is to provide a positive electrode for a lithium secondary battery, which is capable of improving the initial coulomb efficiency of a lithium secondary battery, and the like. A positive electrode for a lithium secondary battery, which comprises lithium manganese iron phosphate and a lithium-nickel-manganese-cobalt composite oxide, is provided.

Owner:GS YUASA INT LTD

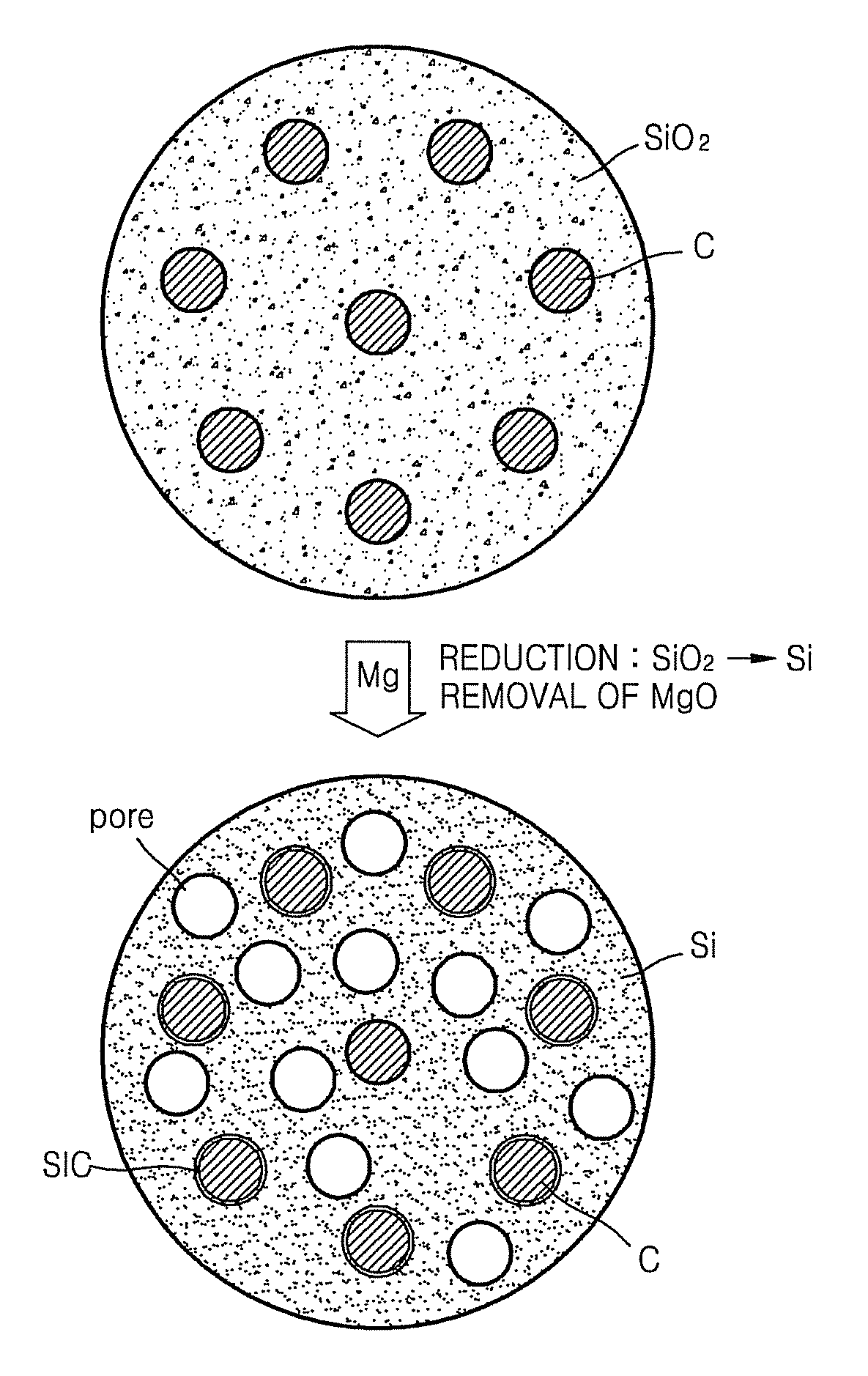

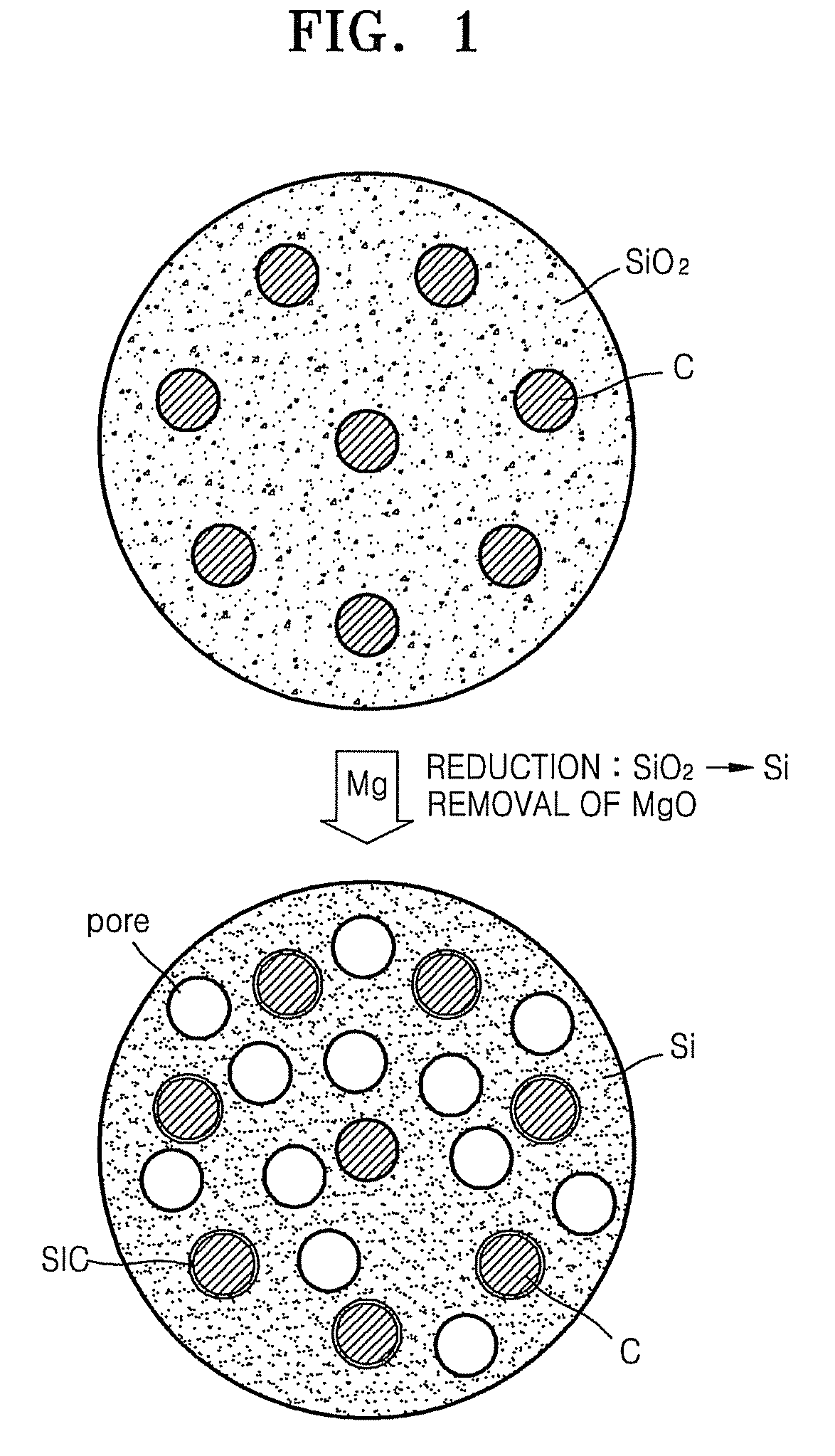

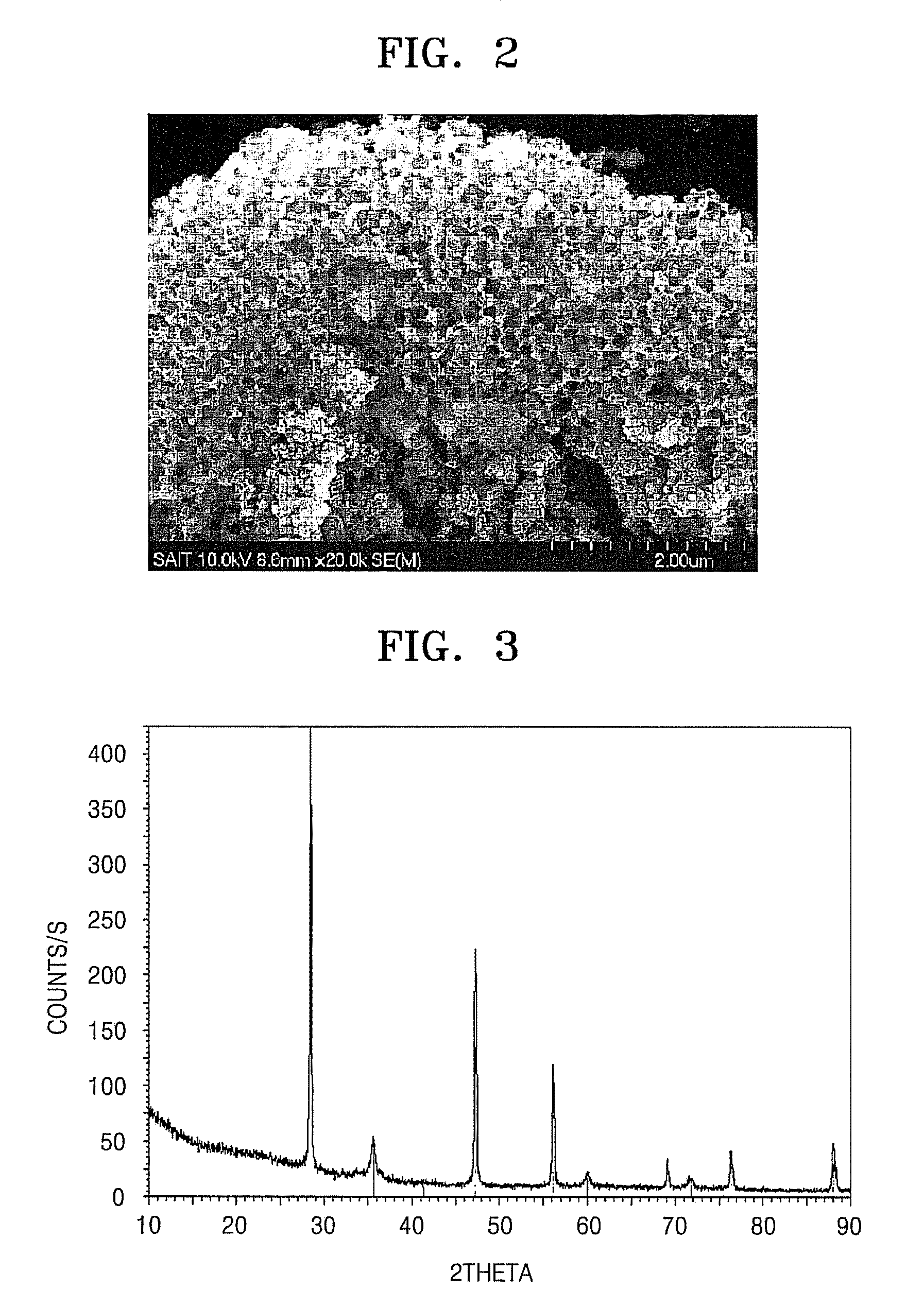

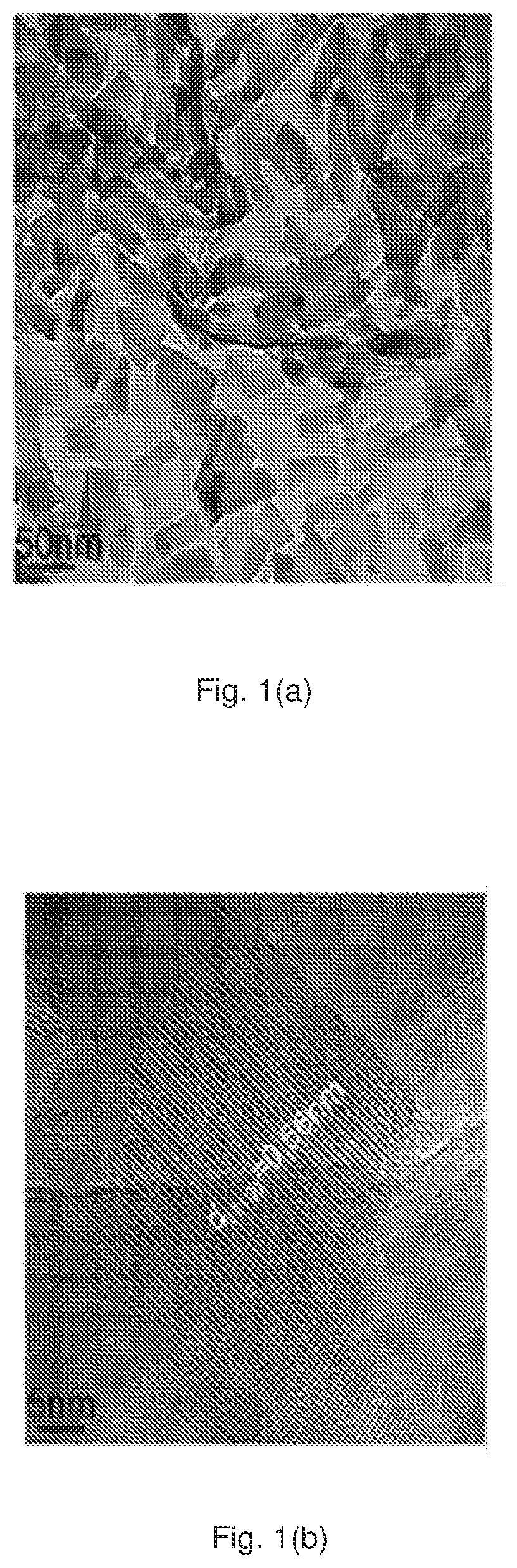

Si/C composite, anode active materials, and lithium battery including the same

ActiveUS8263265B2Improve initial Coulombic efficiencyGood capacity retentionLiquid surface applicatorsElectrode manufacturing processesLithium-ion batteryPorous silicon

An Si / C composite includes carbon (C) dispersed in porous silicon (Si) particles. The Si / C composite may be used to form an anode active material to provide a lithium battery having a high capacity and excellent capacity retention.

Owner:SAMSUNG SDI CO LTD

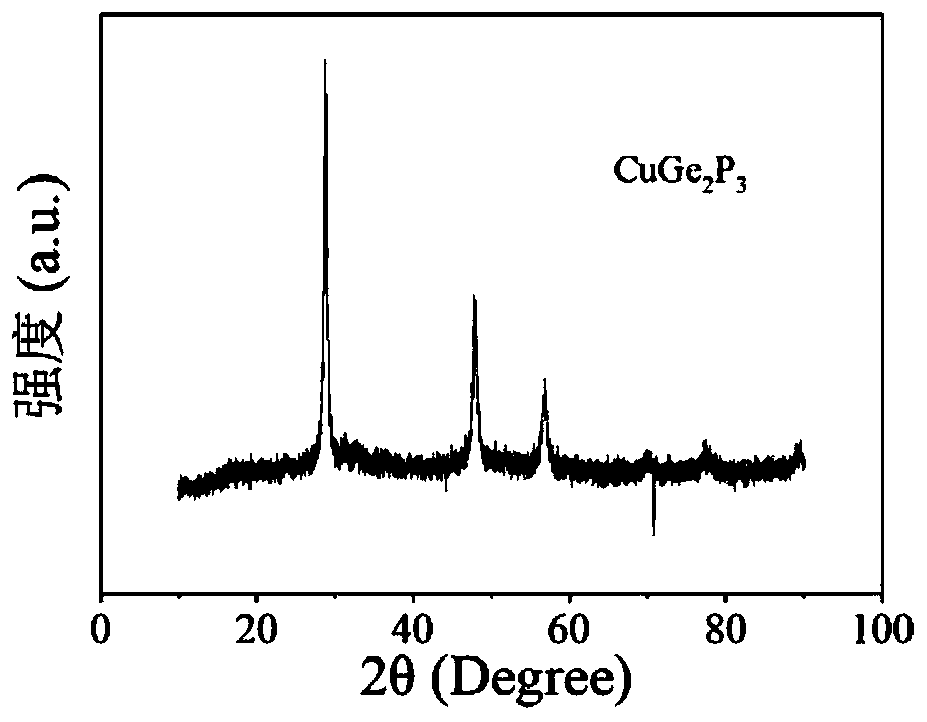

Lithium ion battery negative electrode active material, preparation method thereof and lithium ion battery

InactiveCN111276692AImprove conductivityRealize adjustableCell electrodesSecondary cellsPhysical chemistryLithium-ion battery

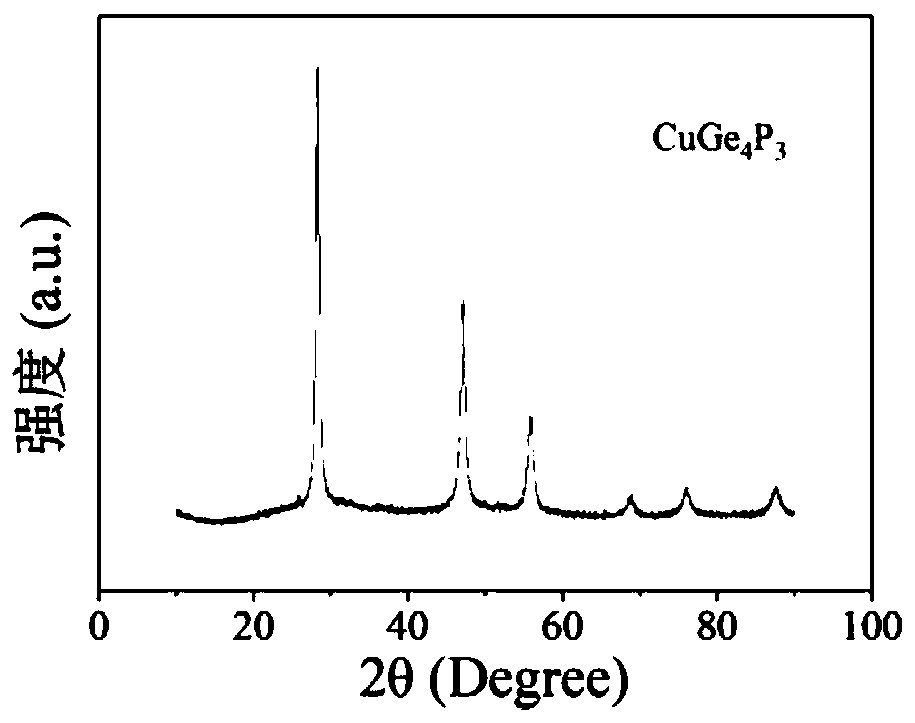

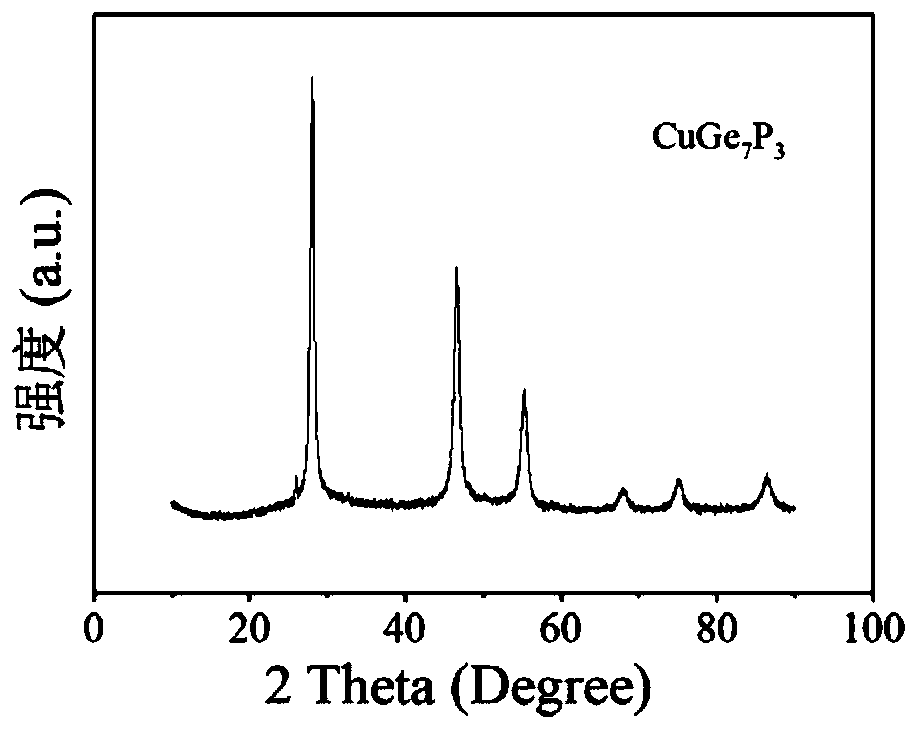

The invention provides a lithium ion battery negative electrode active material. The lithium ion battery negative electrode active material is a compound CuGe<2+x>P3 with a structure shown in a formula (I), wherein 0<=X<=10. According to the invention, a Cu element with high conductivity and Ge with lithium reaction activity are subjected to ball milling by using a high-energy ball milling method;the CuGe2P3 material is synthesized by simultaneously introducing a P element into a sphalerite structure of a component, and Ge solid solution is carried out on the material by using a high-energy ball milling method, so that CuGe2 + XP3 series materials are successfully prepared, and the charge-discharge platform of the material is adjustable. The obtained series of materials have the advantages of high initial coulombic efficiency, high specific capacity, proper working potential and small charging and discharging platform difference.

Owner:GUANGDONG UNIV OF TECH

Lithium supplementing method of lithium ion battery negative electrode active material

ActiveCN112234160AImprove efficiencyImprove electrochemical performanceElectrode manufacturing processesNegative electrodesElectrical batteryAnalytical chemistry

The invention discloses a lithium supplementing method of a lithium ion battery negative electrode active material, which belongs to the field of lithium ion batteries. The lithium supplementing method is characterized in that a negative electrode active substance is added into an organic lithium solution in two stages to obtain a second-stage lithium supplementing active substance, and then the second-stage lithium supplementing active substance is added into an organic compound solution to be calcined and cleaned to obtain a lithium supplementing active substance product. According to the invention, a two-stage method is adopted to supplement lithium, so that a compact SEI film is formed on the surface of the active substance, the lithium supplementing degree of the active substance is higher, and higher initial coulombic efficiency is achieved; the initial coulombic efficiency and the electrochemical performance of the battery are obviously and effectively improved by supplementinglithium to the negative active material of the lithium ion battery. The method adopts an organic solution redox method to supplement lithium to the negative electrode active substance, is mild in process, controllable in lithium supplement amount and high in accuracy, is suitable for existing equipment, and is beneficial to industrial application.

Owner:SHAANXI COAL & CHEM TECH INST

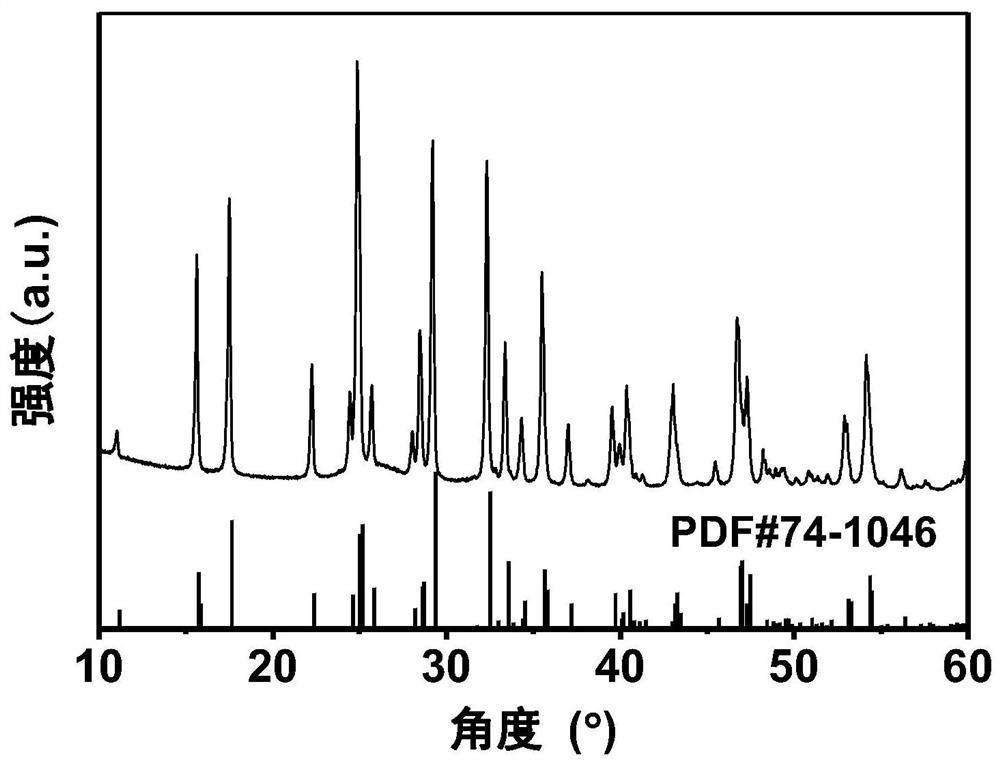

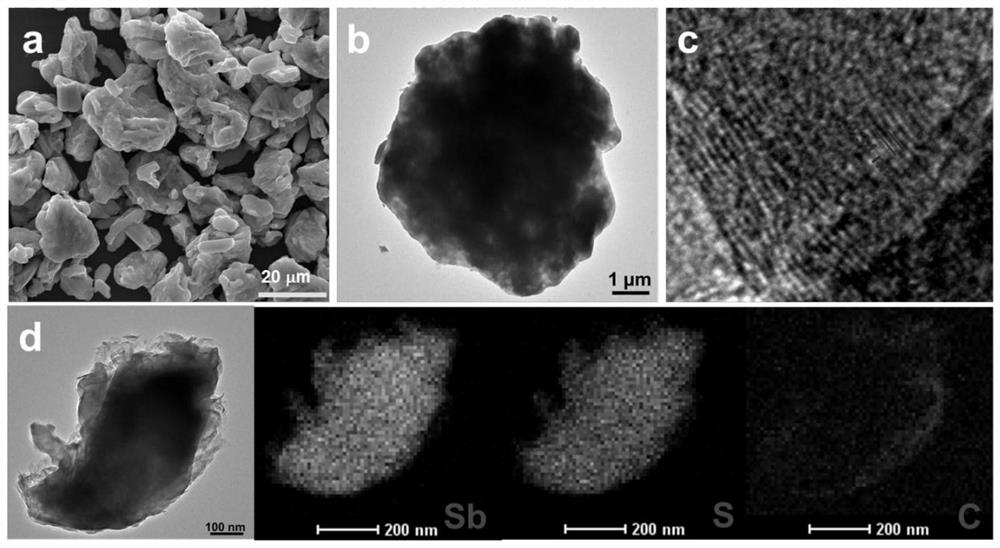

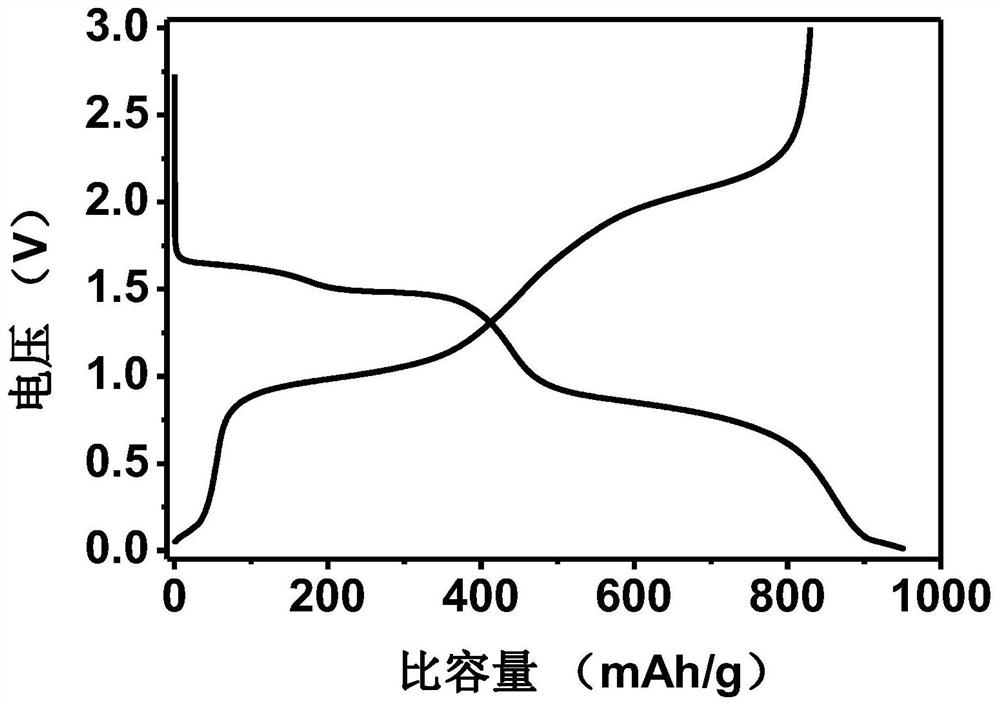

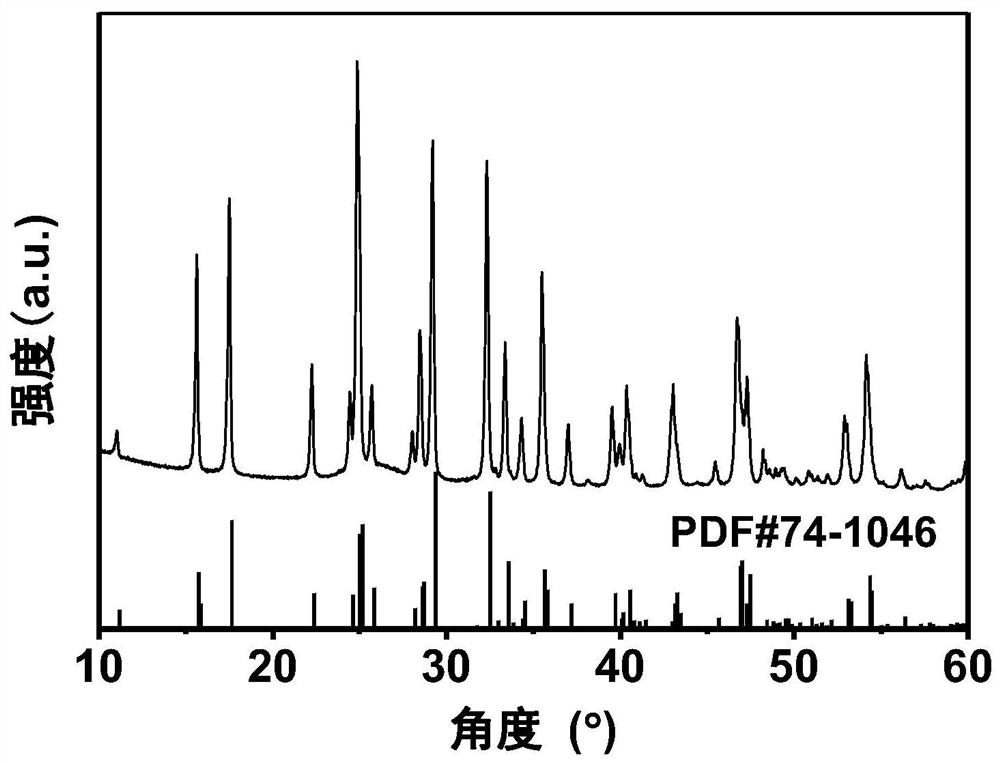

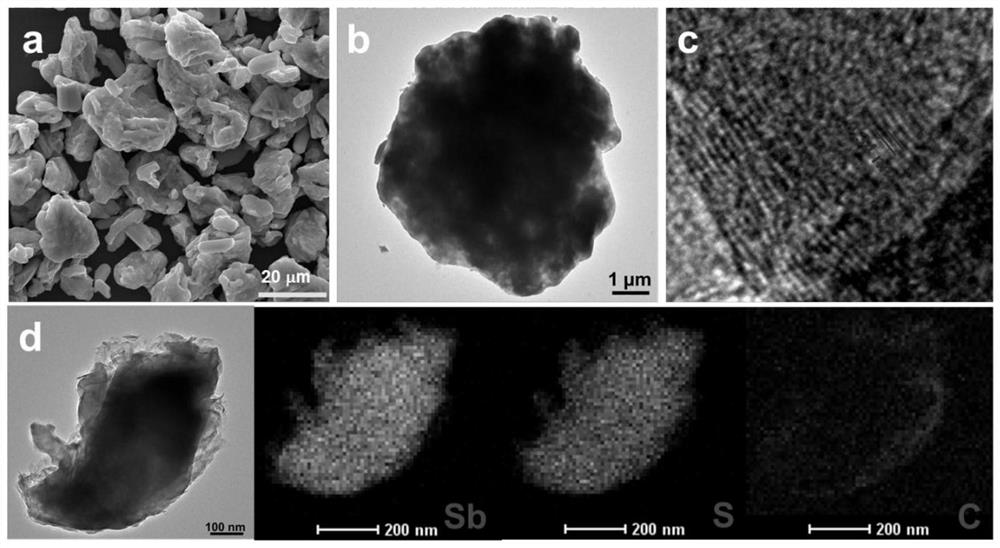

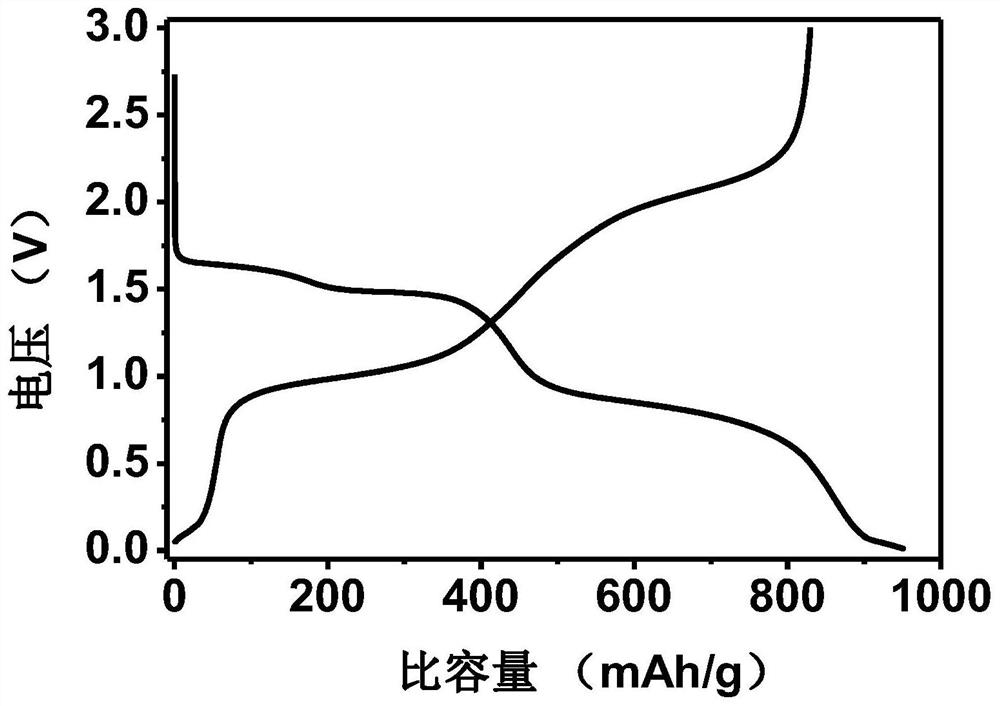

Antimony sulfide-based negative electrode material for lithium ion battery and preparation method of antimony sulfide-based negative electrode material

ActiveCN112133909AImprove electronic conductivityConducive to ease the reunionGraphiteCell electrodesCyclic stabilityLithium electrode

The invention provides an antimony sulfide-based negative electrode material for a lithium ion battery and a preparation method of the antimony sulfide-based negative electrode material, and relates to the field of lithium ion battery negative electrode materials. According to the method, antimony trioxide, expanded graphite and sulfur powder are mechanically mixed at a high speed for a long timeby adopting a mechanical ball milling method to form a composite material, and the composite material is annealed and vulcanized in argon to obtain the antimony sulfide-based composite material with the sulfur-doped graphite packaged antimony sulfide structure. According to the invention, the sulfur-doped graphite material and the graphene stripped from the expanded graphite are compounded so as to increase the electronic conductivity of the antimony sulfide, and the packaging structure formed by the existence of the sulfur powder during the ball milling can easily relieve agglomeration of theantimony sulfide caused by the volume expansion; and the initial Coulombic efficiency, the reversibility of the conversion reaction, the cycling stability and the rate capability are greatly improvedthrough the combined action of the components. The mechanical ball milling method disclosed by the invention is simple and easy to operate and convenient for large-scale production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

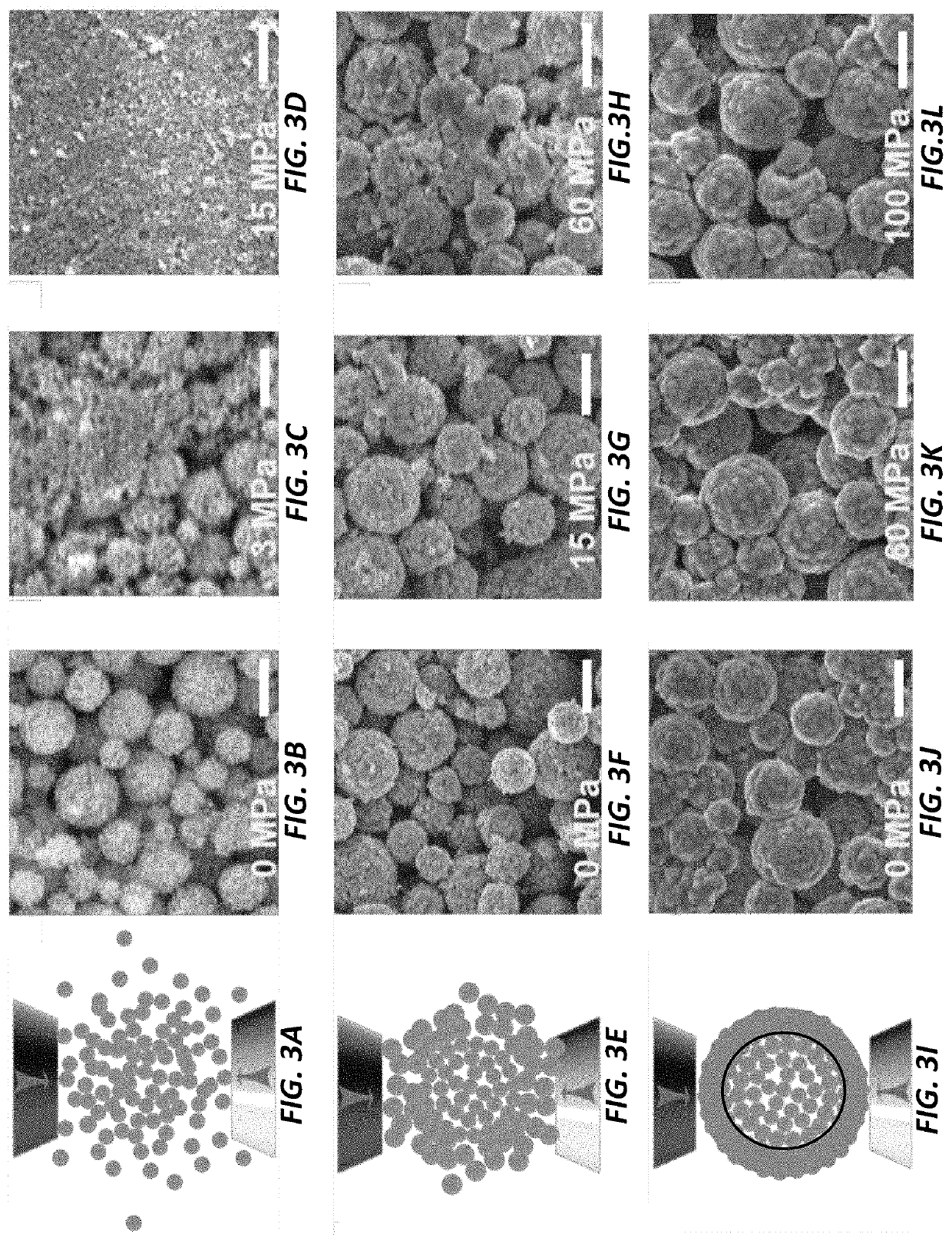

Multiple-Element Composite Material For Anodes, Preparation Method Therefor, And Lithium-Ion Battery Having Same

ActiveUS20170207457A1High electroconductivityHigh capacityElectrode thermal treatmentElectrode carriers/collectorsElectrically conductiveLithium electrode

A multiple-element composite material for negative electrodes, a preparation method therefor, and a lithium-ion battery using tile negative electrode material. The lithium-ion battery uses multiple-element composite material for negative electrodes has a core-shell structure containing multiple shell layers. The inner core consists of graphite and nano-active matter coating the surface of the graphite. The outer layers of the inner core are in order: the first shell layer is of an electrically conductive carbon material, the second shell layer is of a nano-active matter, and the third shell layer is an electrically conductive carbon material coating layer. The multiple-element composite material for negative electrodes of the present invention combines coating processing technology with surface composite modification and coating modification technology to successfully prepare a multiple-element composite material for negative electrodes having a core-shell structure containing multiple shell layers, and allows for high load and high dispersion for the nano-active matter, thereby substantially enhancing the material specific capacity, cycle performance, and initial efficiency. Additionally, the multiple-element composite material for negative electrodes of the present invention has high compacted density and good processing performance. The negative electrode material has simple preparation technique. and low raw material cost, is environmentally friendly, and causes no pollution.

Owner:BTR NEW MATERIAL GRP CO LTD

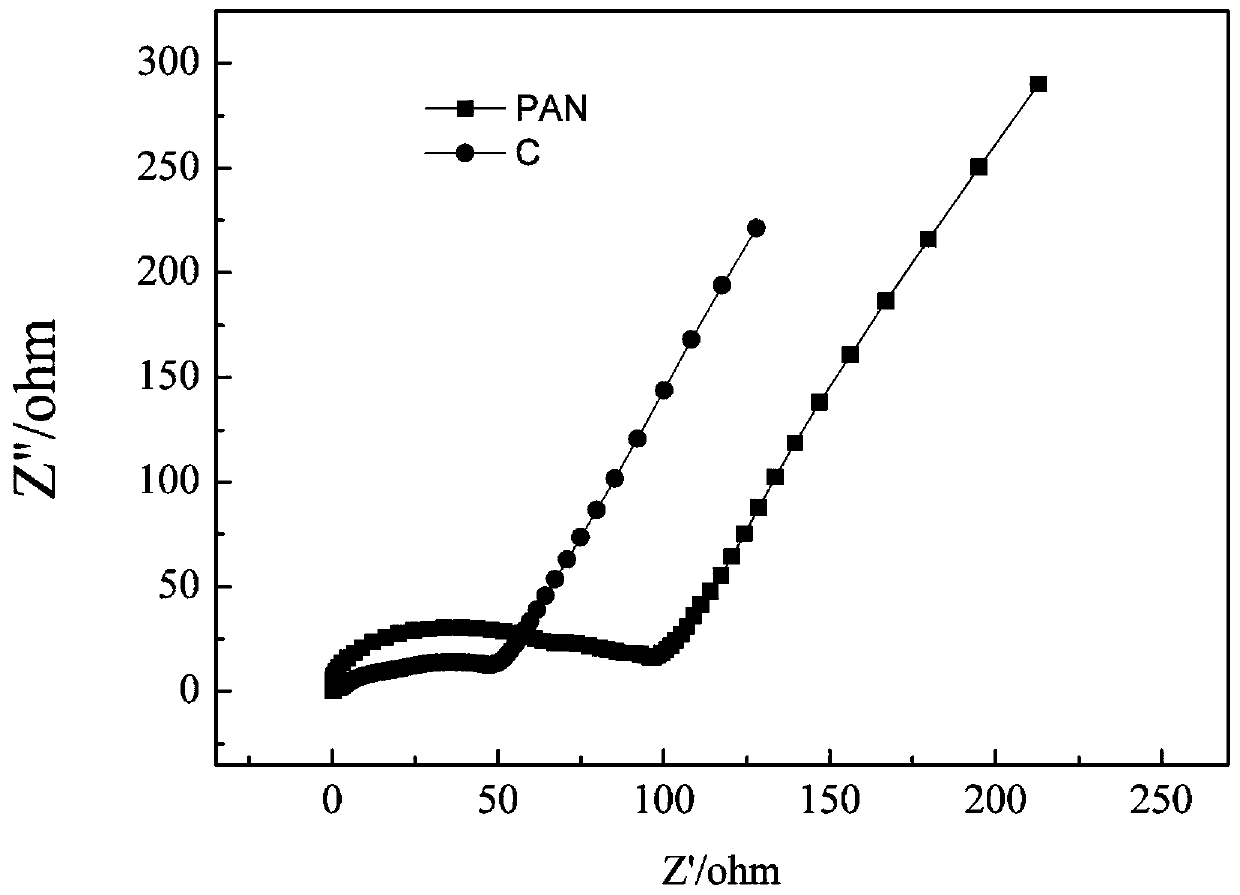

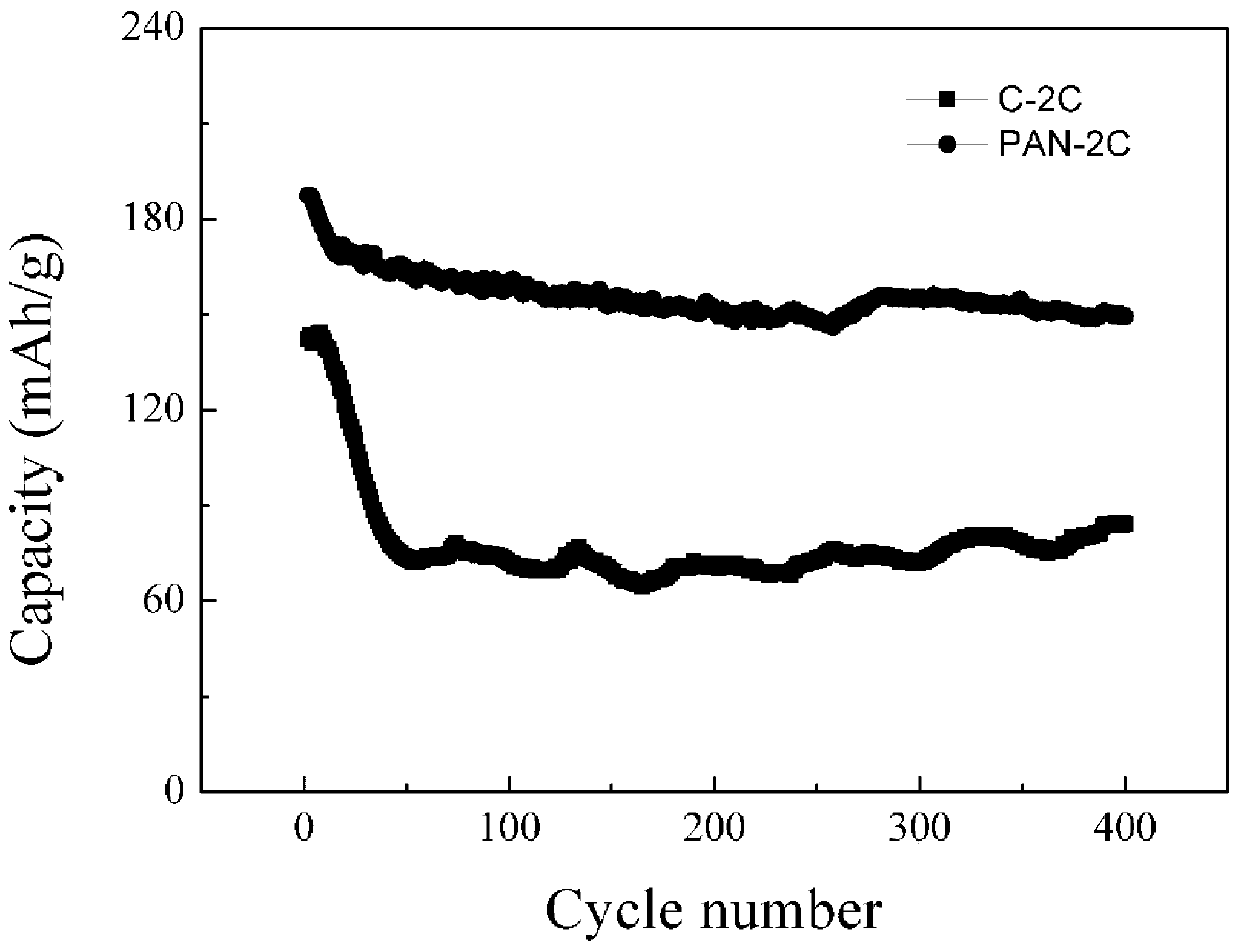

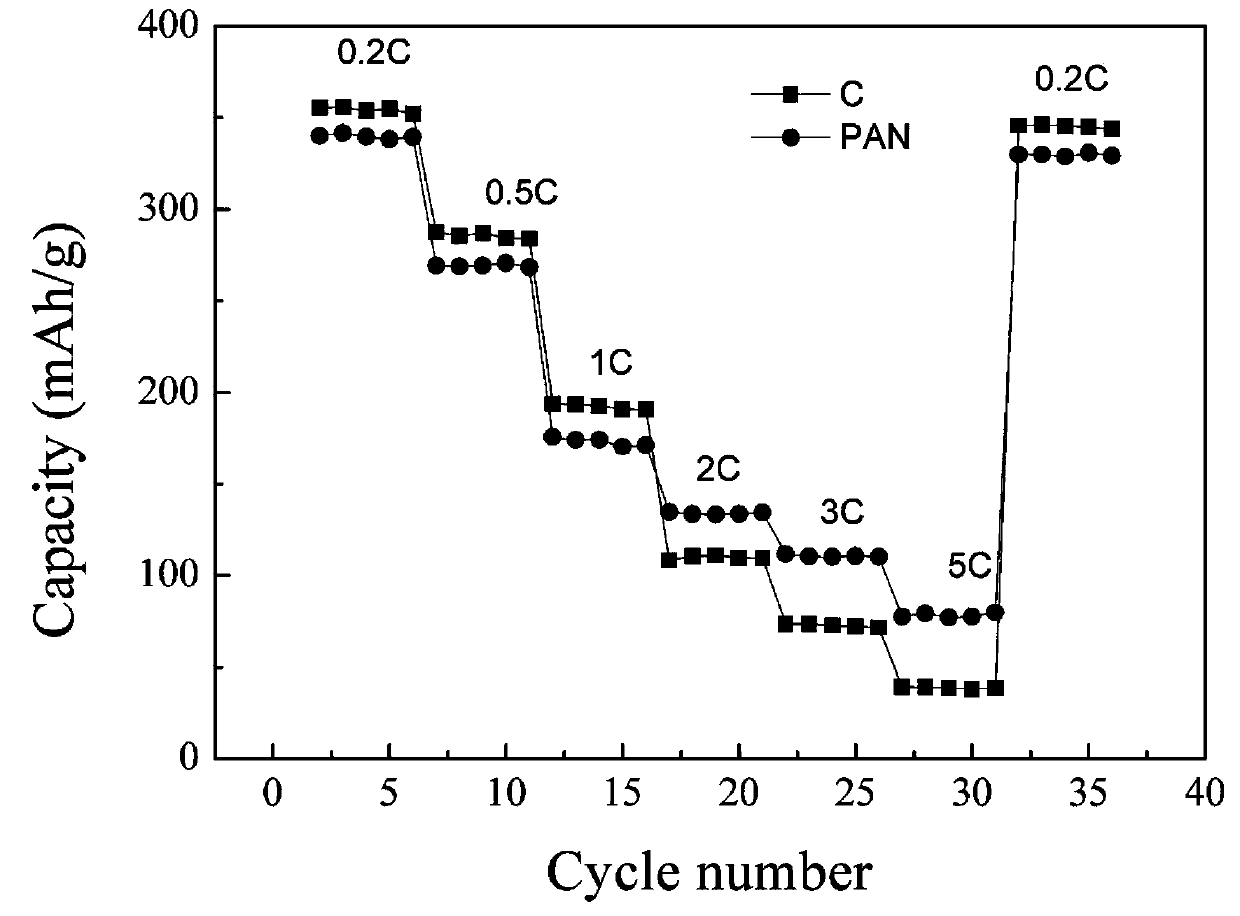

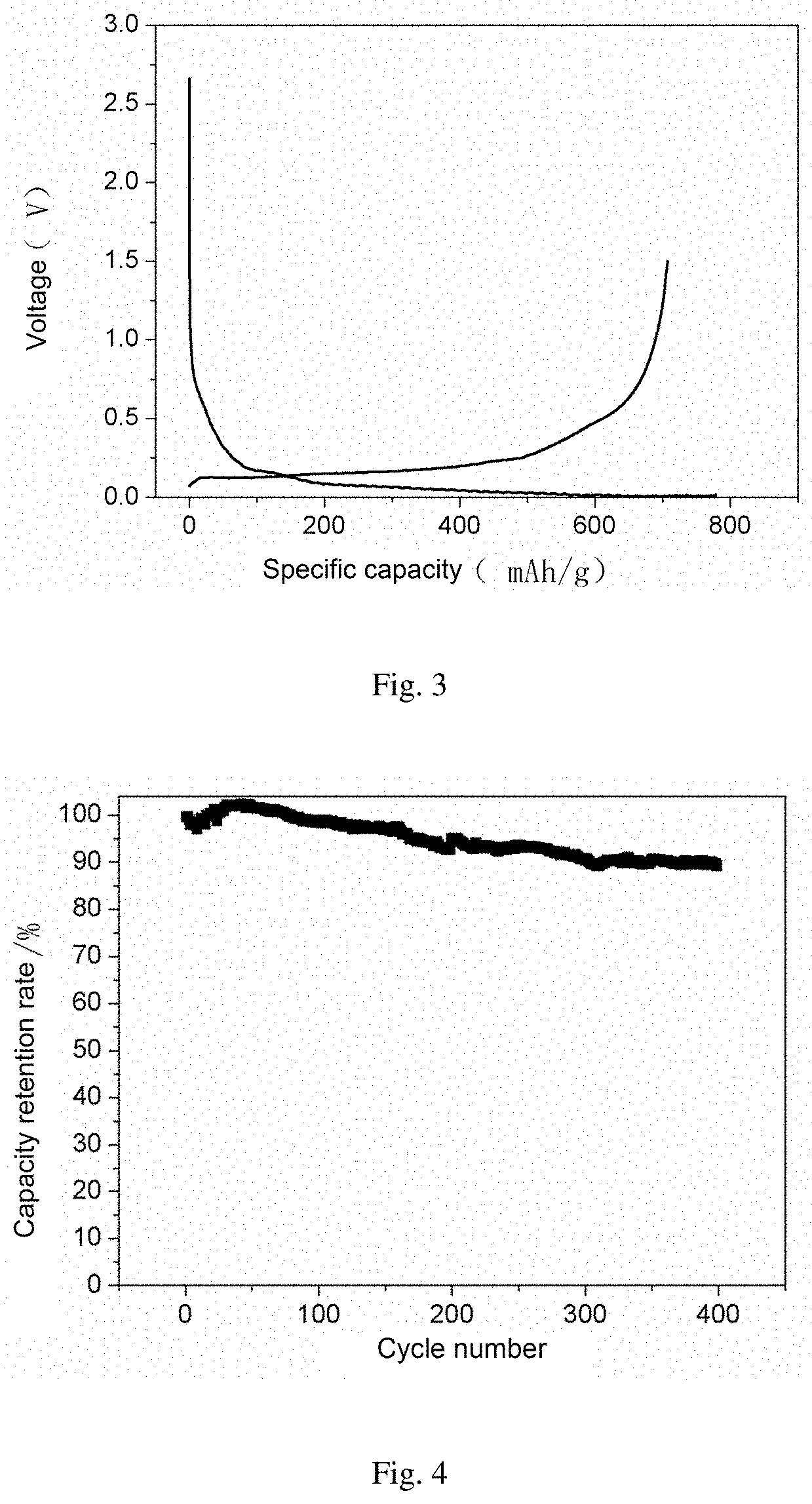

High-performance carbon positive electrode PAN hard carbon material and preparation method thereof

InactiveCN111017903ASimple ingredientsEasy to prepareCell electrodesSecondary cellsLithium-ion batteryBattery cell

The invention discloses a high-performance carbon positive electrode PAN hard carbon material and a preparation method thereof. The preparation method comprises a pre-oxidation process and a carbonization process, polyacrylonitrile powder is sintered at high temperature under inert gas to obtain polyacrylonitrile hard carbon microsphere blocks; a negative electrode material for a lithium ion battery has the advantages of simple preparation method, low cost, environmental protection, no toxicity and the like, the prepared high-performance carbon positive electrode material is uniform in size and controllable in diameter range, large-scale industrial production can be realized, the rate capability is good, the cycling stability is relatively good, and the rate capability of the lithium ion battery is greatly improved.

Owner:JIANGXI UNIV OF SCI & TECH

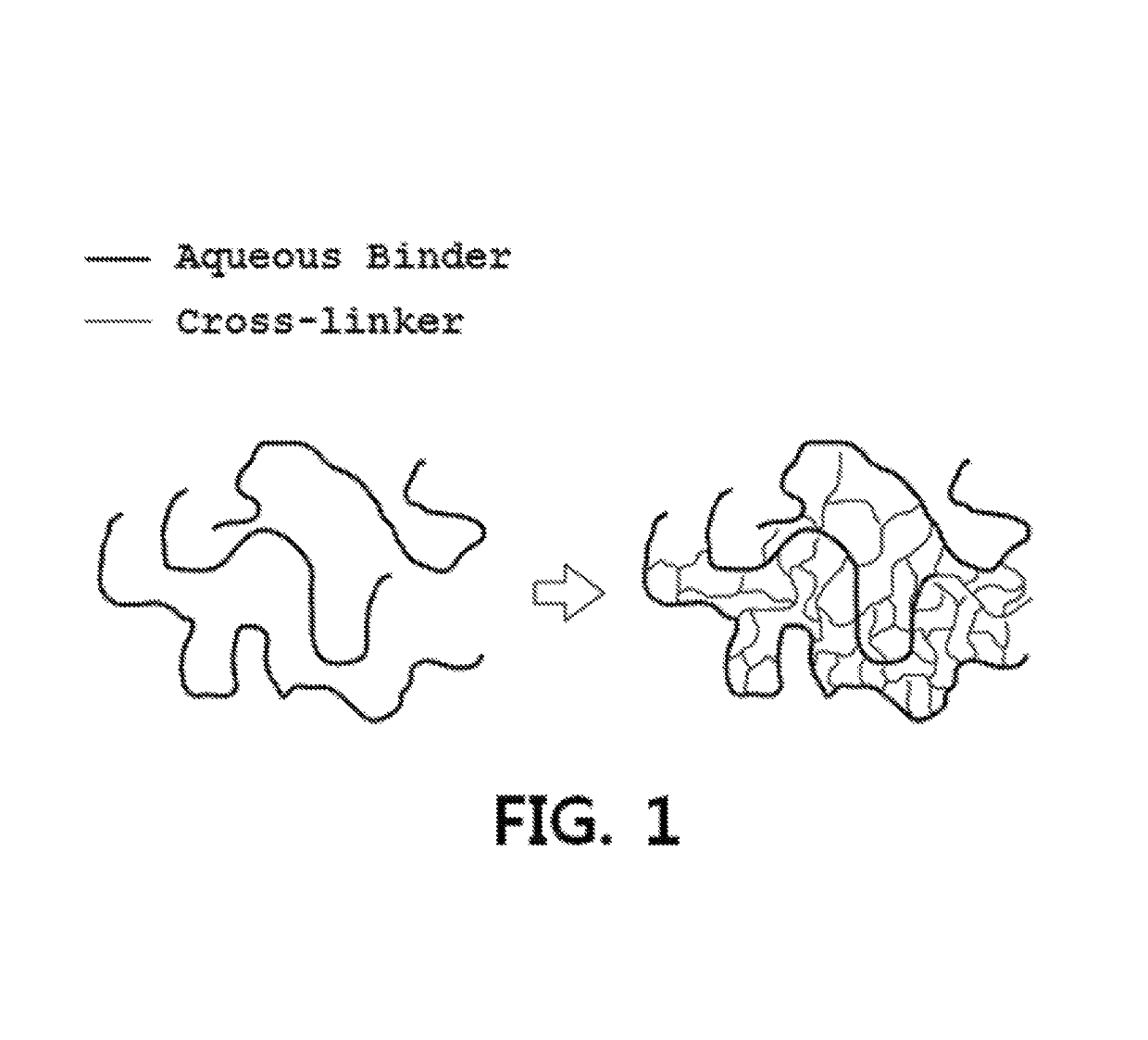

Electrode for lithium secondary battery, method for preparing same, electrode assembly for lithium secondary battery comprising same, and lithium secondary battery comprising same

ActiveUS10418633B2Improve initial Coulombic efficiencyGood physical propertiesFuel and primary cellsFinal product manufactureDischarge efficiencyCross-link

The present invention relates to an electrode for a lithium secondary battery, a method for preparing the same, an electrode assembly for a lithium secondary battery comprising the same, and a lithium secondary battery comprising the same, wherein the electrode comprises an electrode active material, an aqueous binder, a compound represented by Formula 1, and a compound represented by Formula 2. Formula 1 and Formula 2 are the same as set forth in the specification. The electrode for a lithium secondary battery improves the physical properties of the aqueous binder in a manner whereby a cross-linking reaction material is combined with the aqueous binder, so that the electrode can improve initial charge / discharge efficiency and the life span of a lithium secondary battery, preferably a lithium sulfur battery, and improve the area capacity of the electrode.

Owner:LG ENERGY SOLUTION LTD

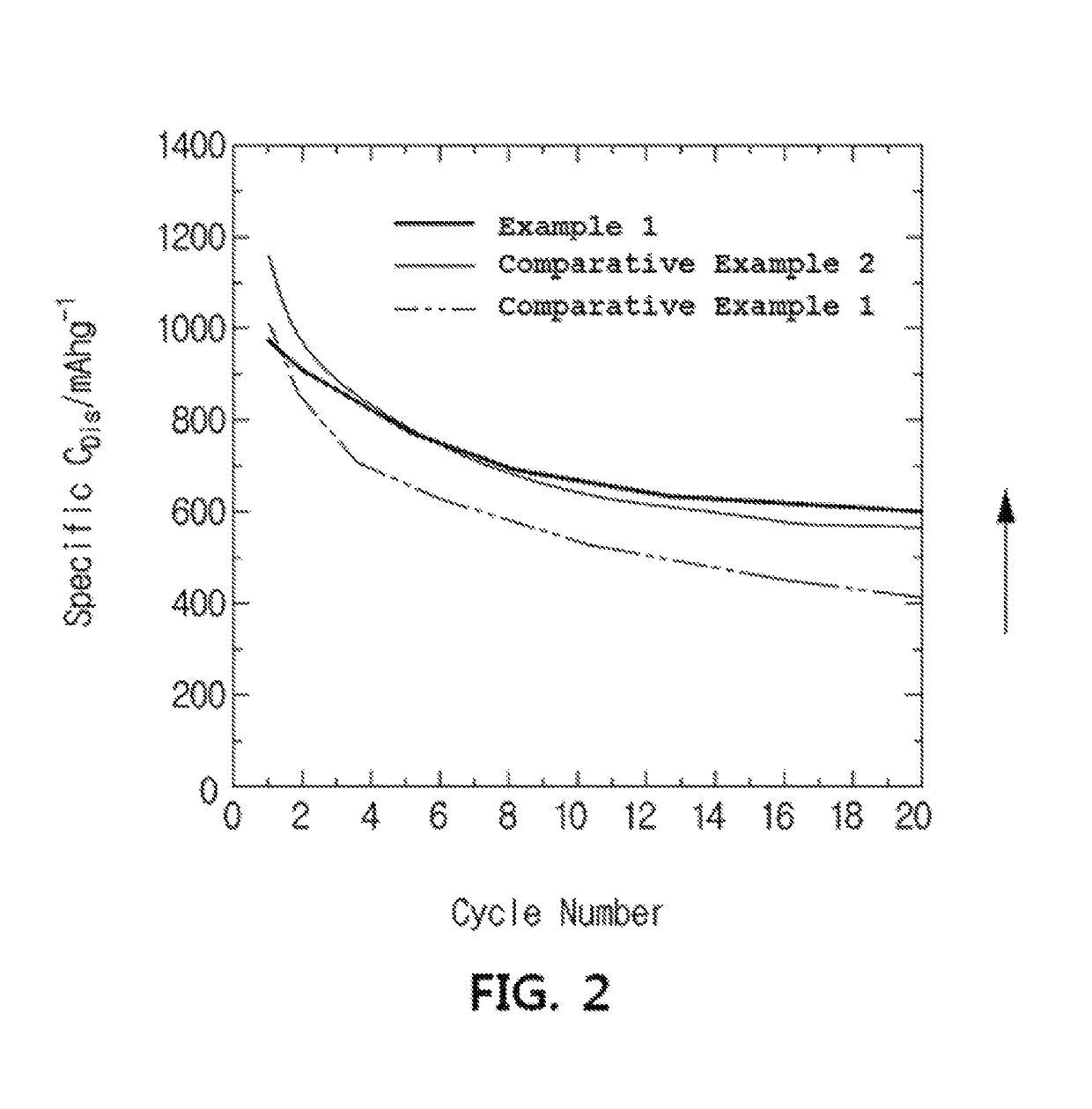

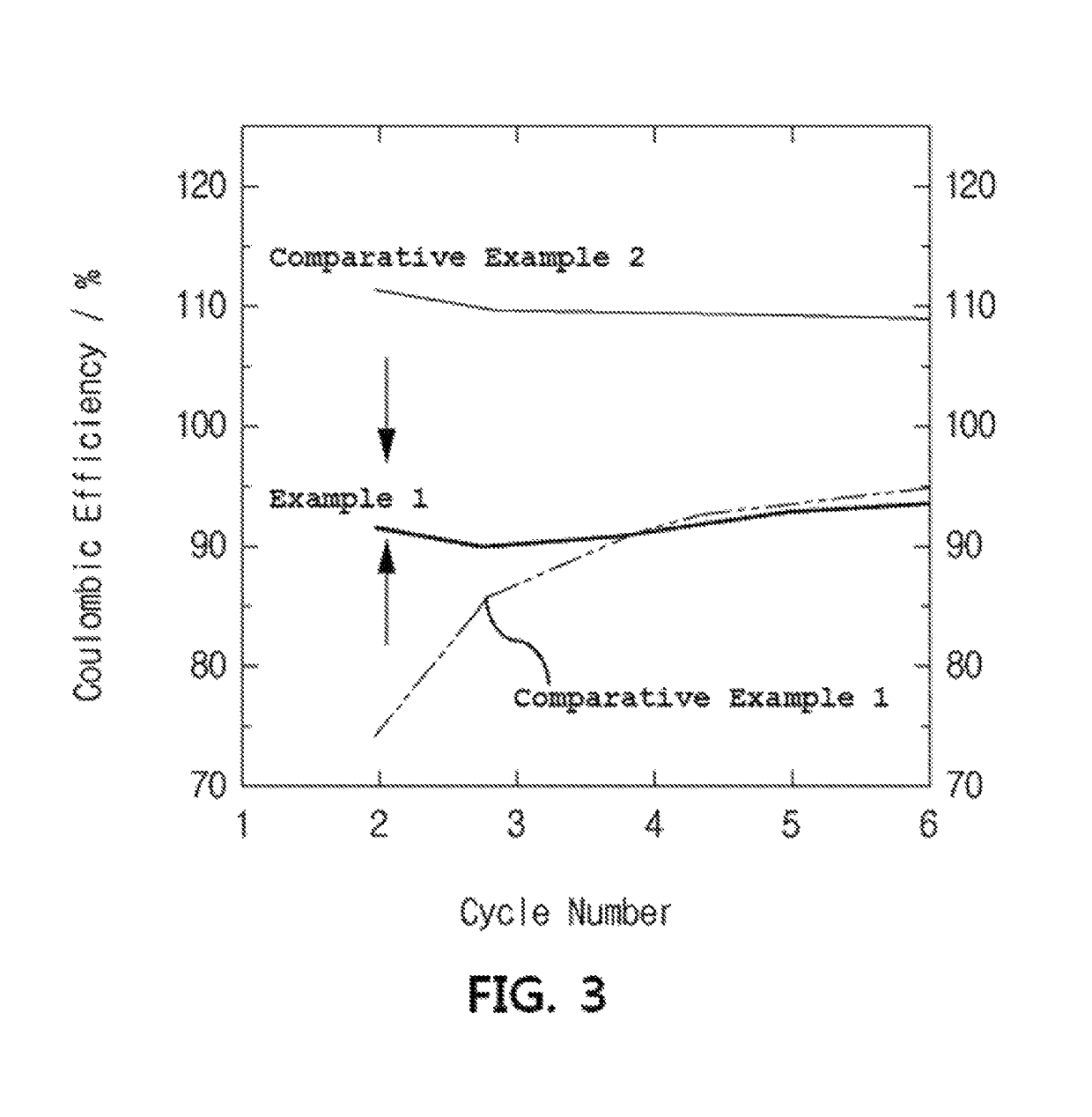

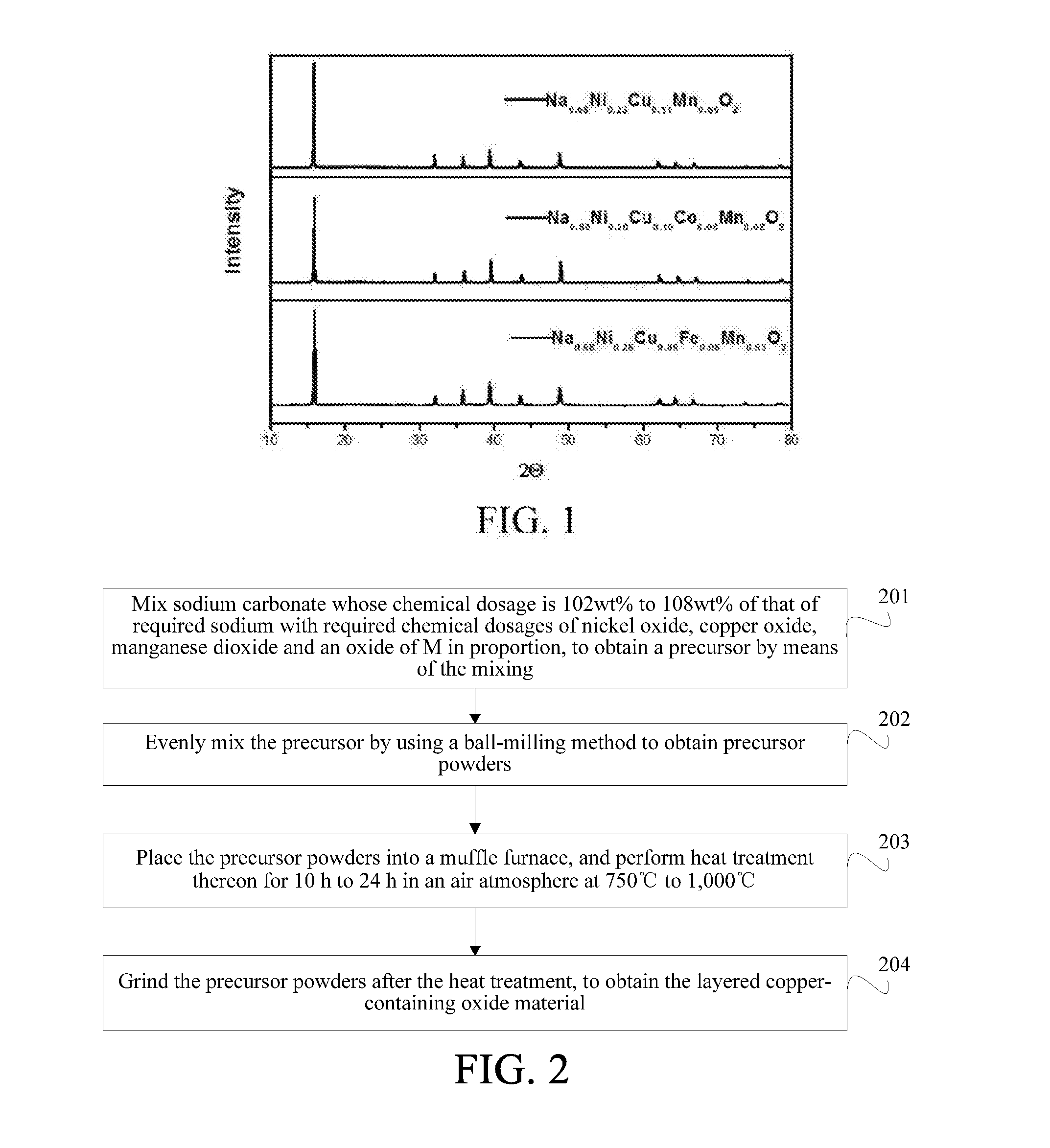

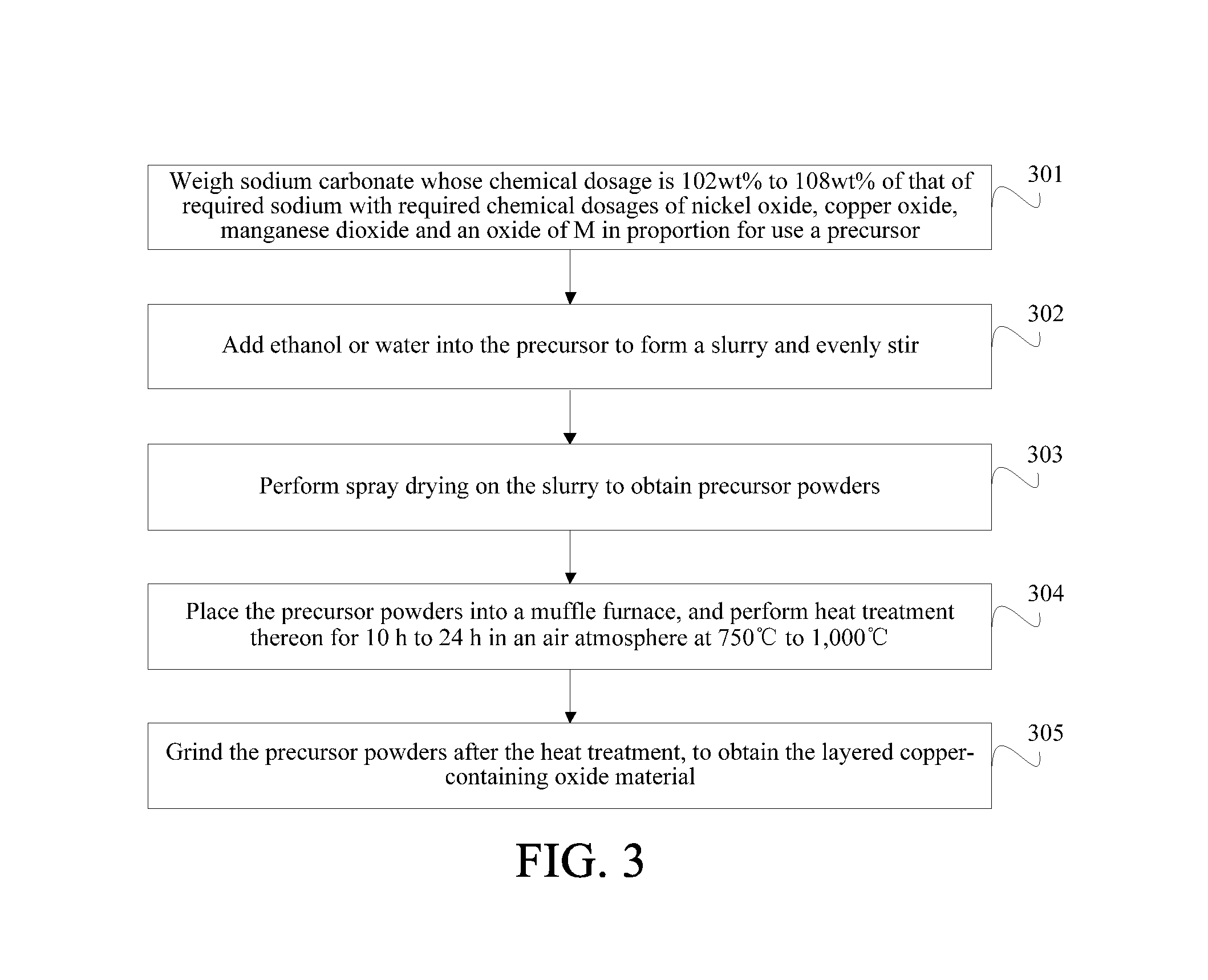

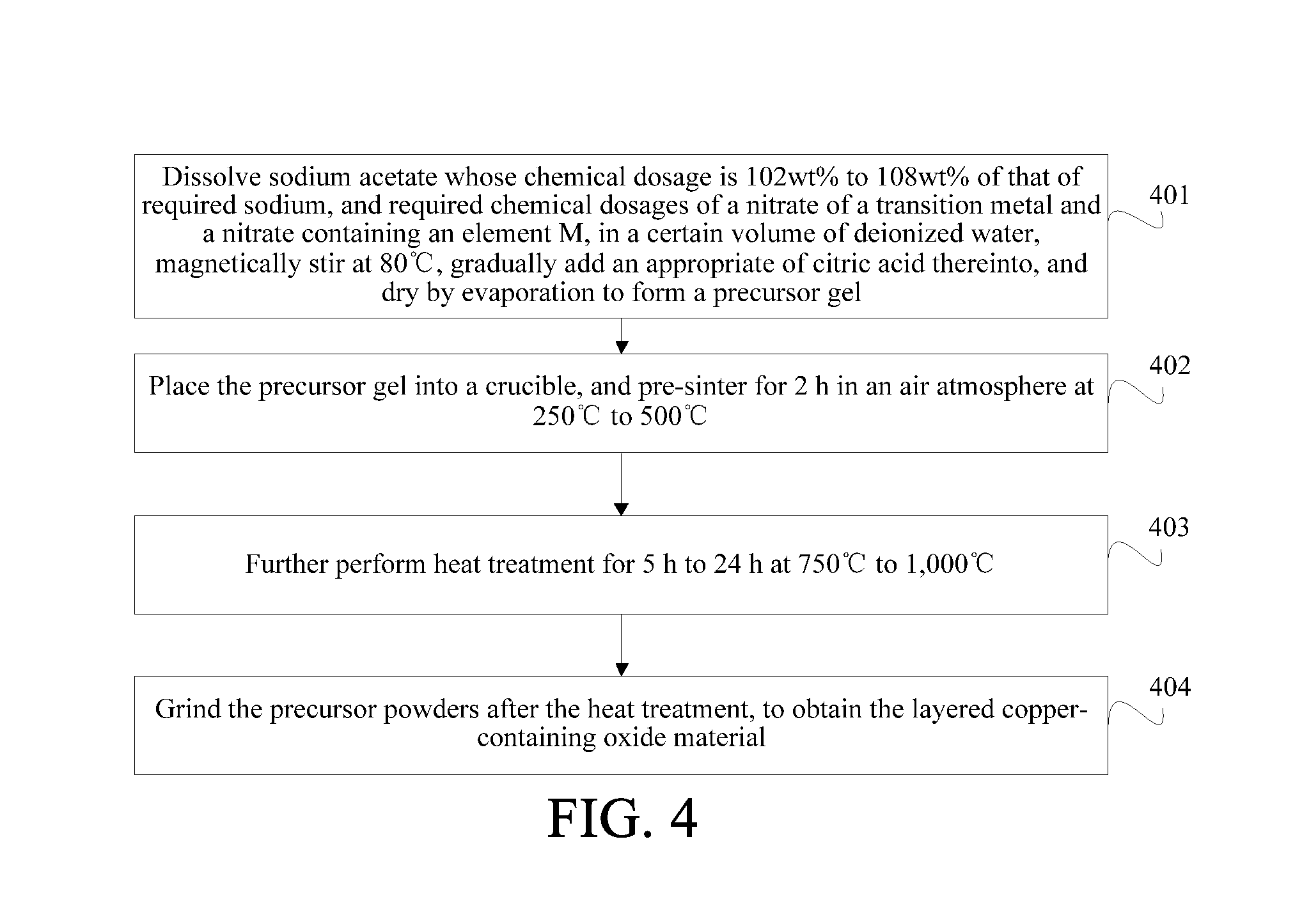

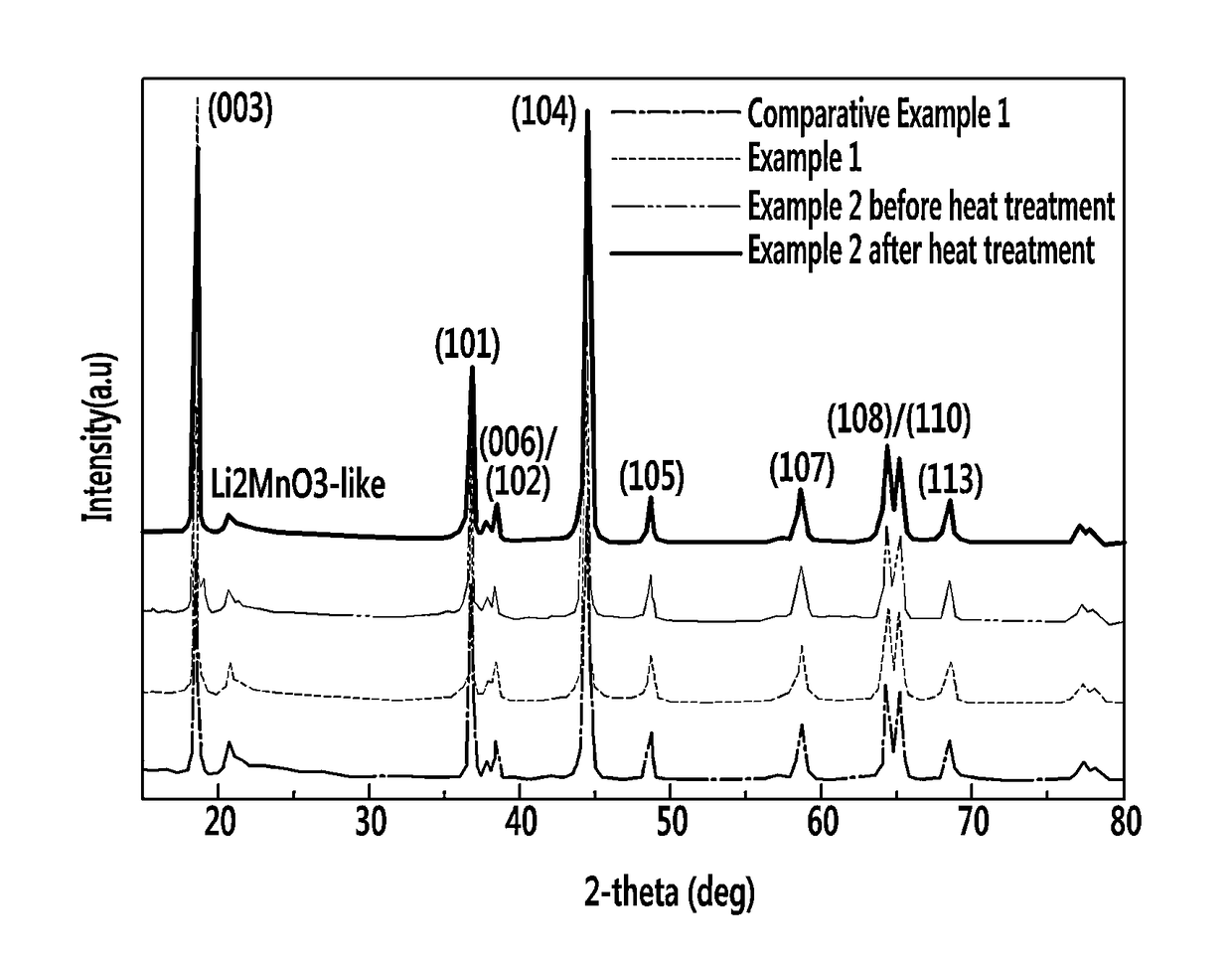

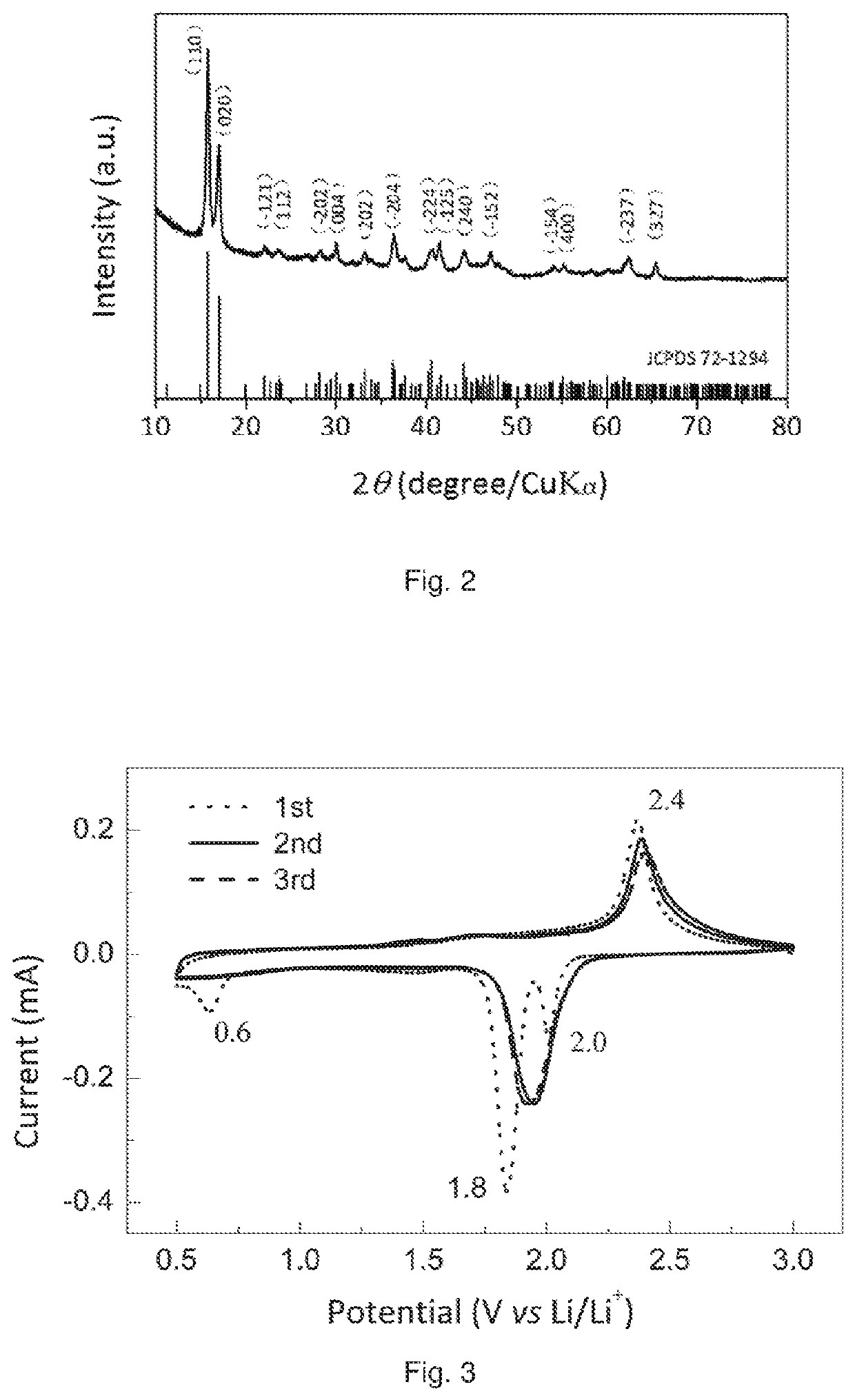

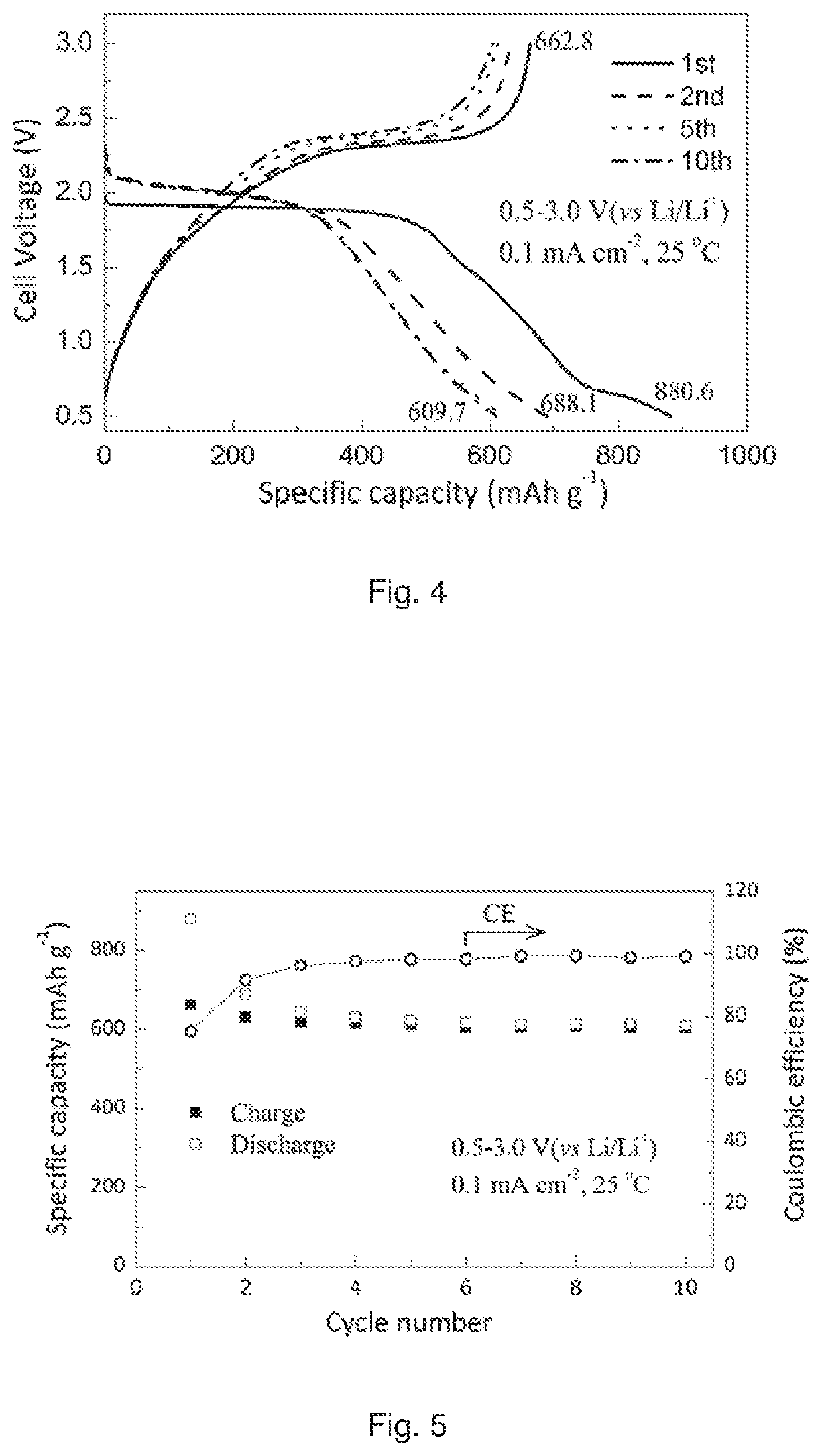

Layered copper-containing oxide material and preparation process and purpose thereof

InactiveUS20160211516A1Easy to makeAbundant raw material resourceEnergy inputSecondary cellsPhysical chemistryOxygen

The present invention discloses a layered copper-containing oxide material and a preparation process and purpose thereof The material has a general chemical formula of Na0.68+aNibCucMdMneO2+δ, where Ni, Cu, M, and Mn respectively form octahedral structures together with six oxygen atoms that are most adjacent therein, the octahedral structures have arrangements with common edges and constitute transition metal layers; alkali metal ions Na+ are located between every two of the transition metal layers; M is specifically one or more of Mg2+, Mn2+, Zn2+, Co2+, Al3+, B3+, Cr3+, Mn3+, Co3+, V3+, Zr4+, Ti4+, SiO4+, Mo4+, Ru4+, Nb4+, Sb5+, Nb5+, Mo6+, and Te6+; and a, b, c, d, e, δ, and m meet (0.68+a)+2(b+c)+md+4e=2(2+δ), and b+c+d+e=1.

Owner:INST OF PHYSICS

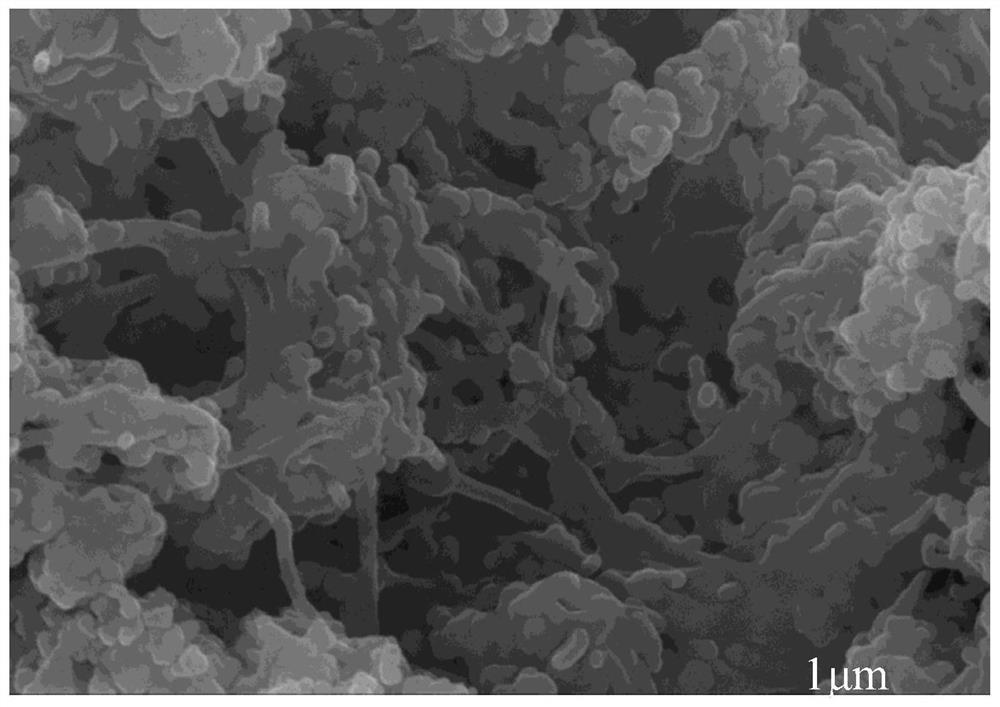

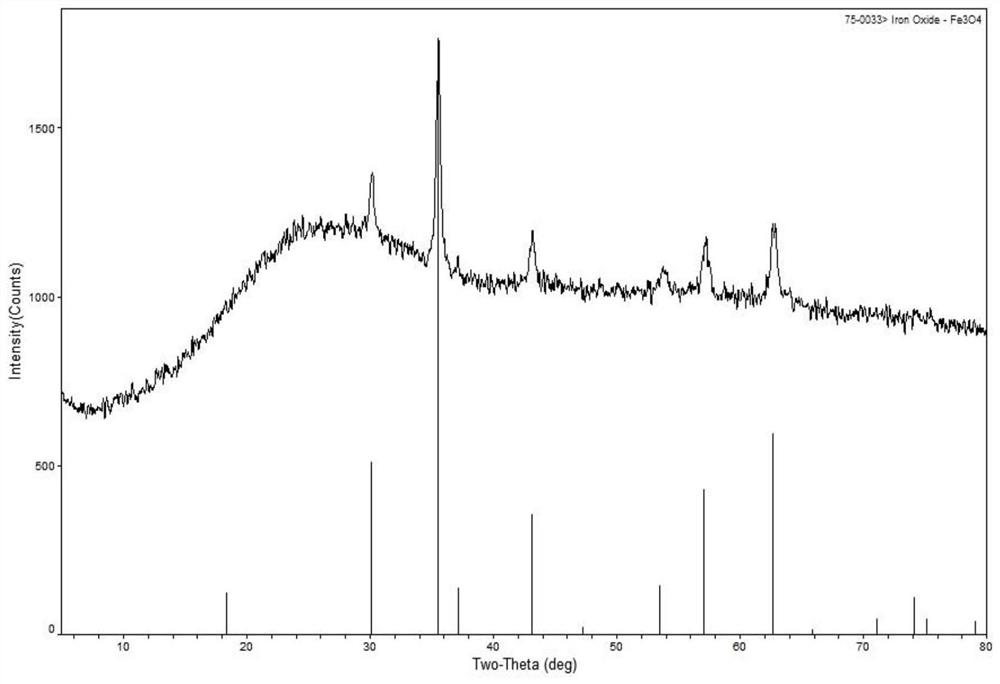

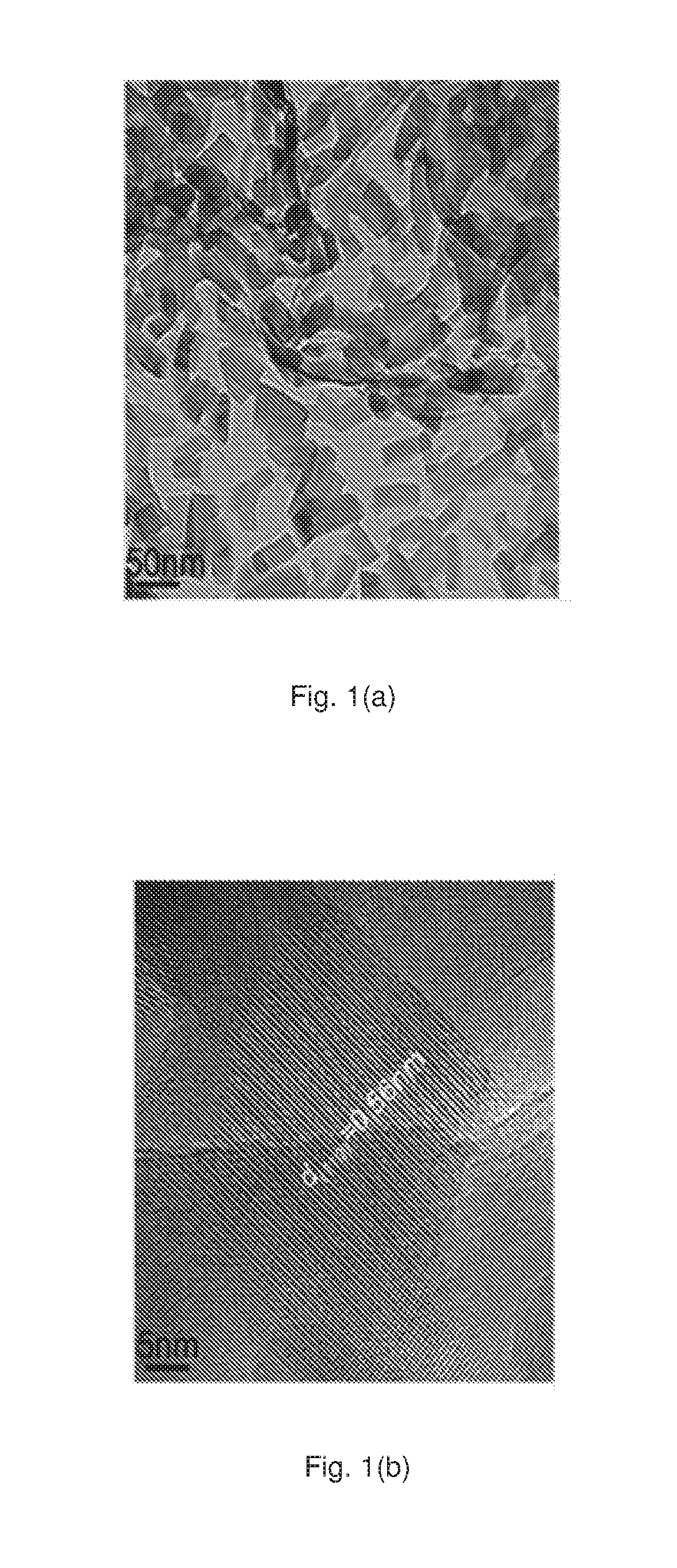

Biomass/carbon nanotube induced Fe3O4 nano composite material and application thereof as lithium ion battery negative electrode material

PendingCN112736235AImprove conductivityAbundant electrochemical active sitesMaterial nanotechnologySecondary cellsElectrochemical responsePorous carbon

The invention discloses a biomass / carbon nanotube induced Fe3O4 nano composite material and application thereof as a lithium ion battery negative electrode material. The biomass derived carbon / carbon nanotube / Fe3O4 composite material is prepared by a one-step hydrothermal method. A universal method for preparing the conductive metal oxide nanospheres by inducing the carbon material is developed. The biomass porous carbon material is fraxinus chinensis wing peel, is easy to obtain and is environment friendly, and contains a large amount of lignin, and the lignin is a good carbon source. Besides, the carbon nanotubes have good conductivity, and the conductivity of the composite material can be improved; meanwhile, the carbon nanotubes, the biomass-derived carbon and the Fe3O4 form a skeleton structure, the volume expansion of Fe3O4 is relieved, and the skeleton structure has important significance in promoting electron transfer in electrochemical reaction. Therefore, the biomass-derived carbon / carbon nanotube and Fe3O4 composite material has an important application prospect.

Owner:LIAONING UNIVERSITY

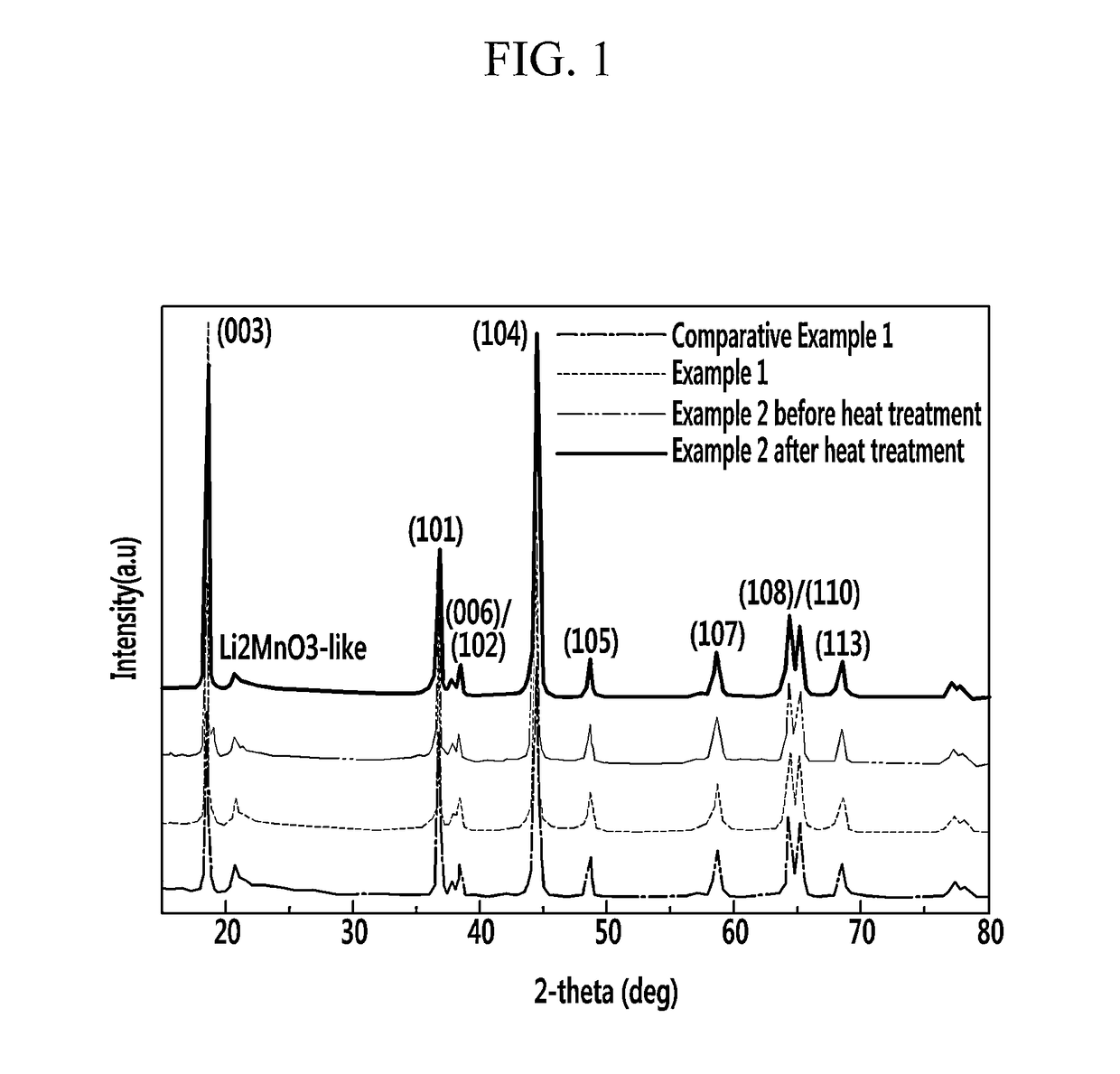

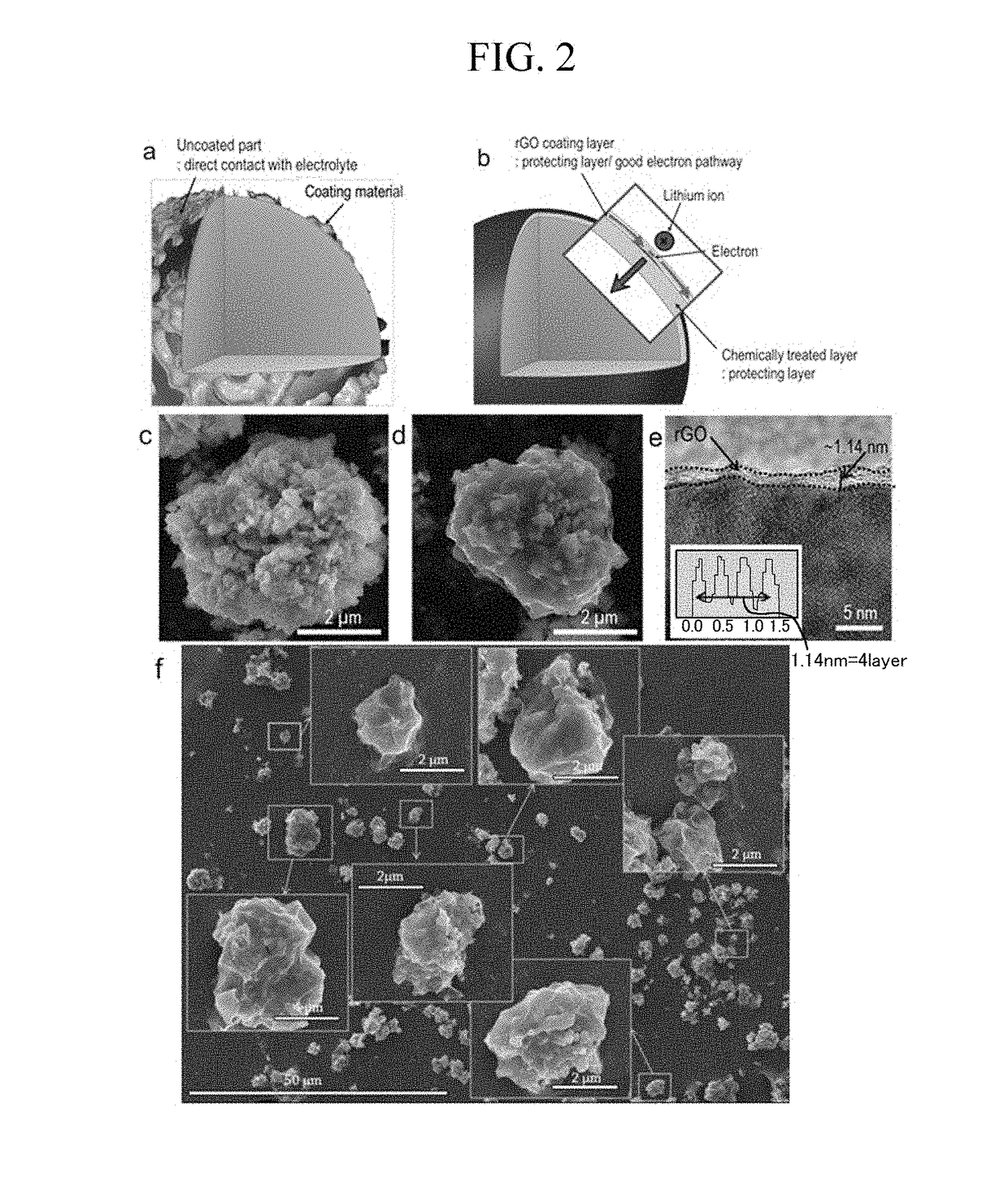

Cathode active material for lithium rechargeable battery, method of manufacturing the same, and lithium rechargeable battery including the same

ActiveUS9954221B2Improve featuresImprove initial Coulombic efficiencyElectrode thermal treatmentPositive electrodesLithiumCoating

Owner:SM LAB CO LTD

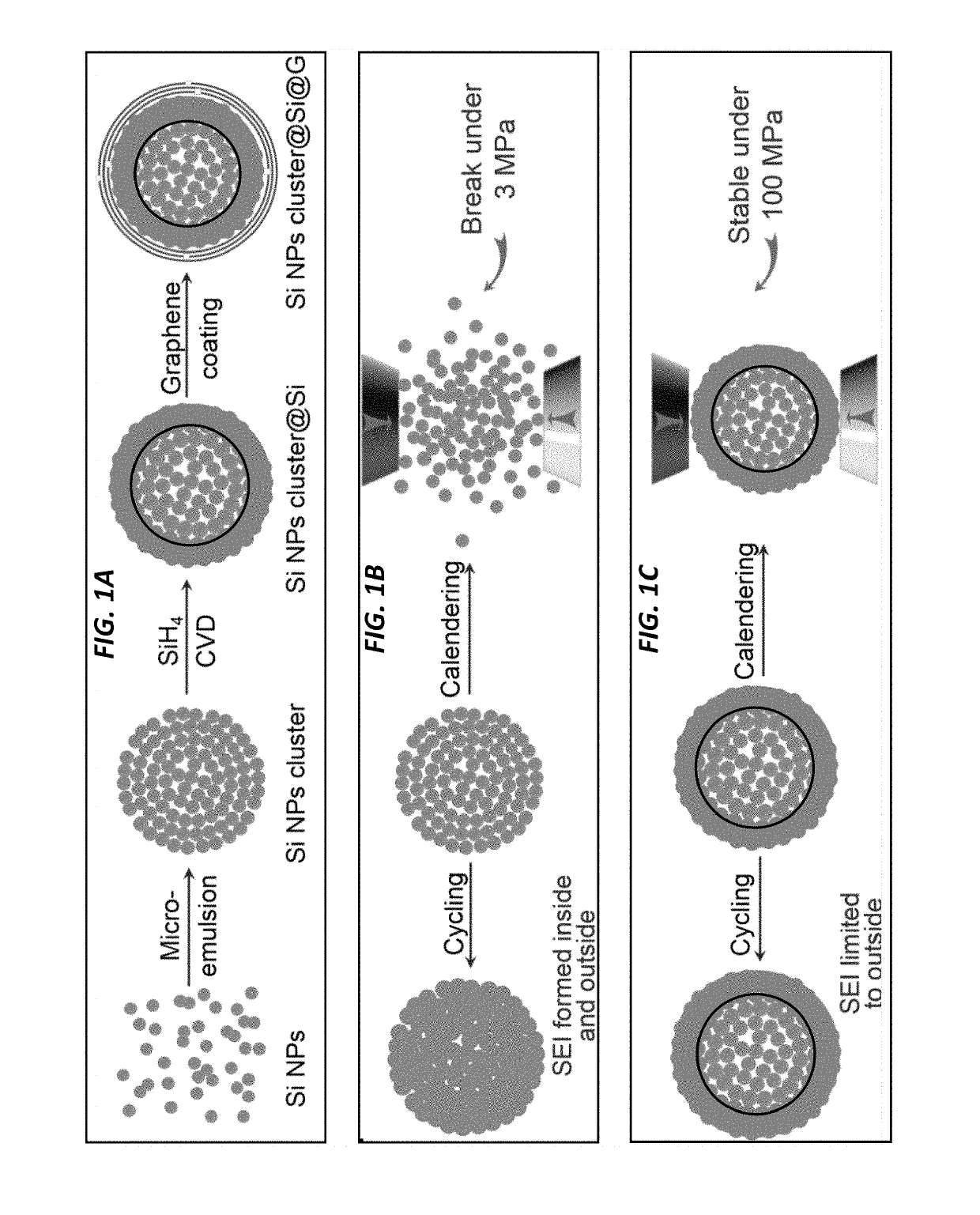

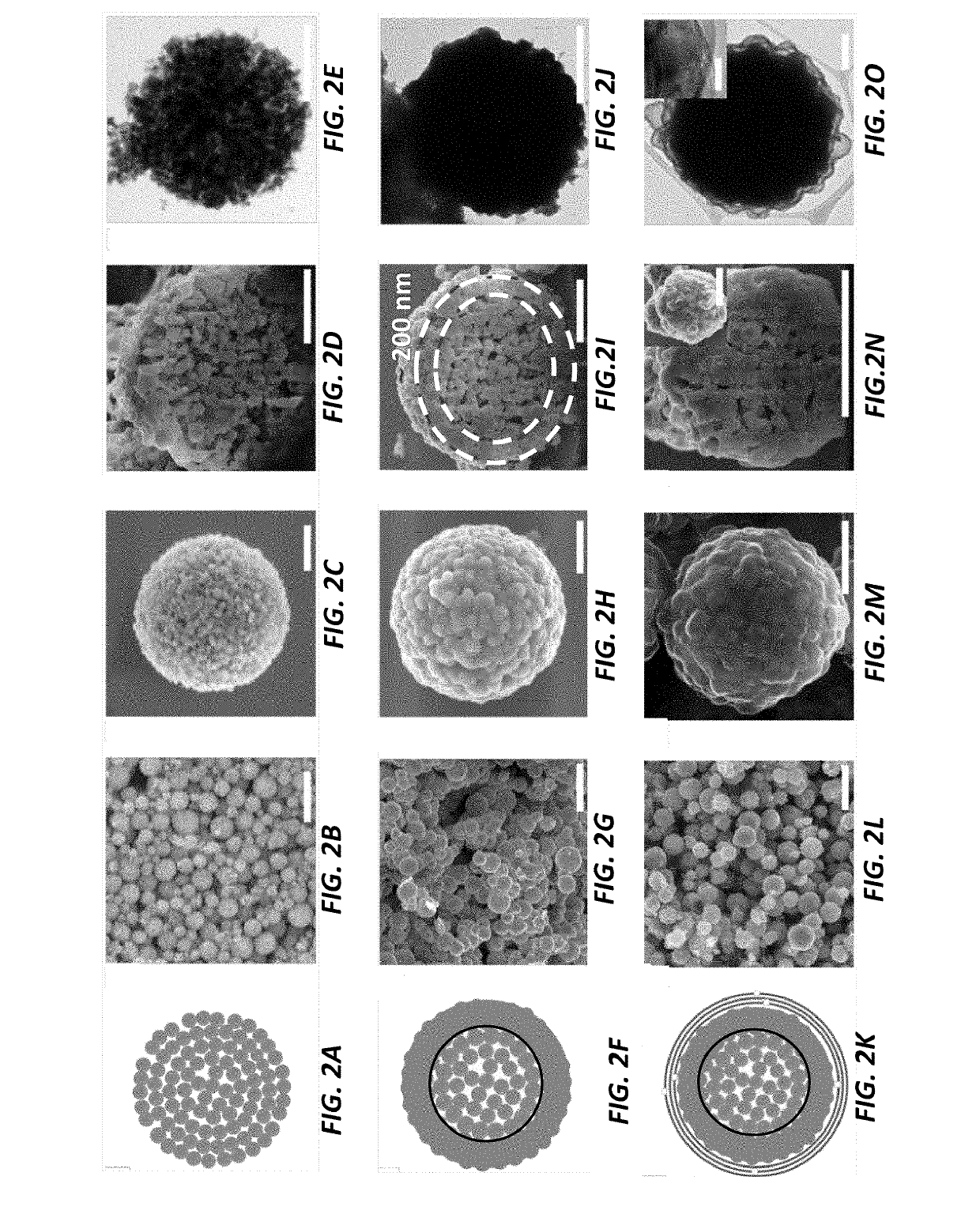

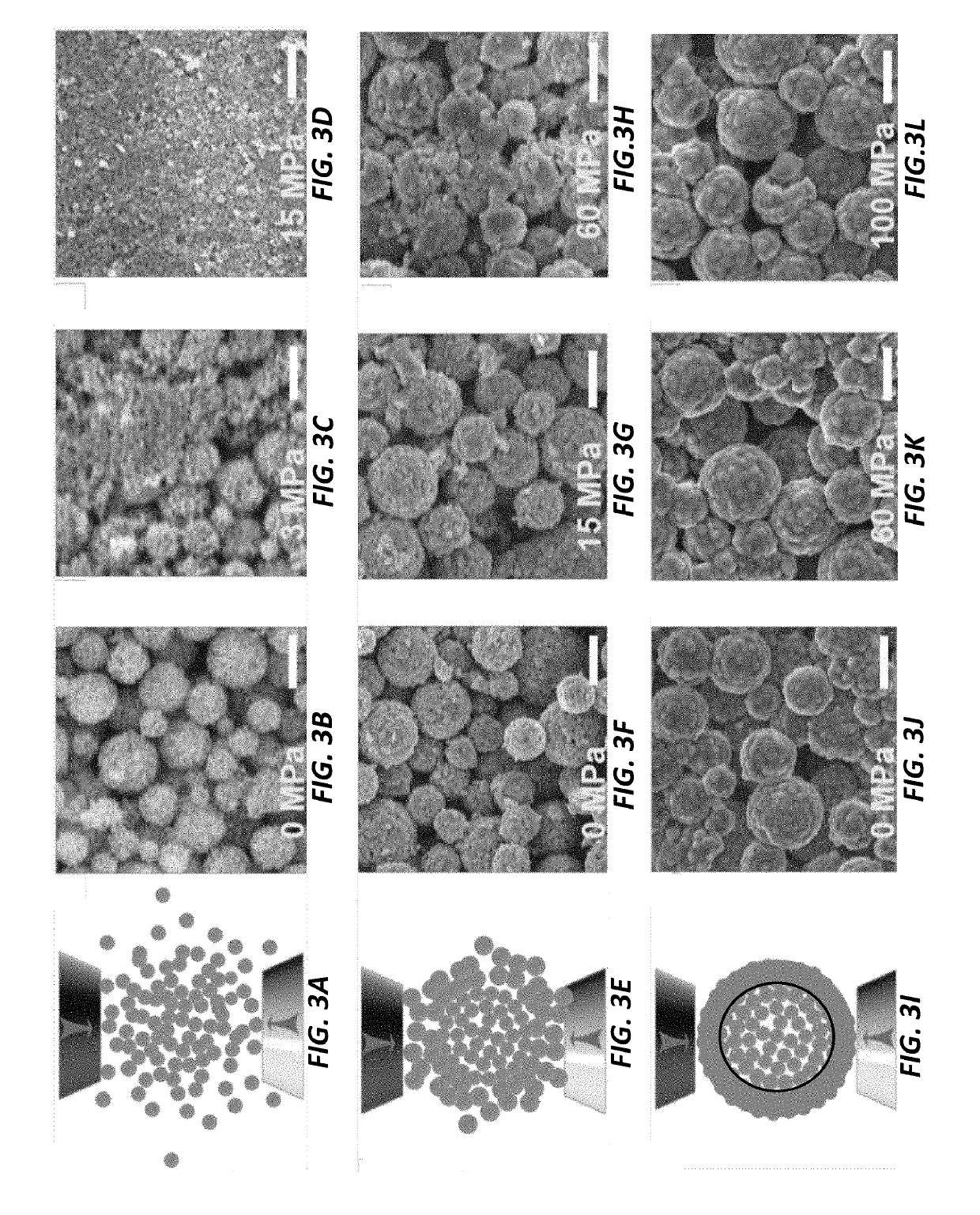

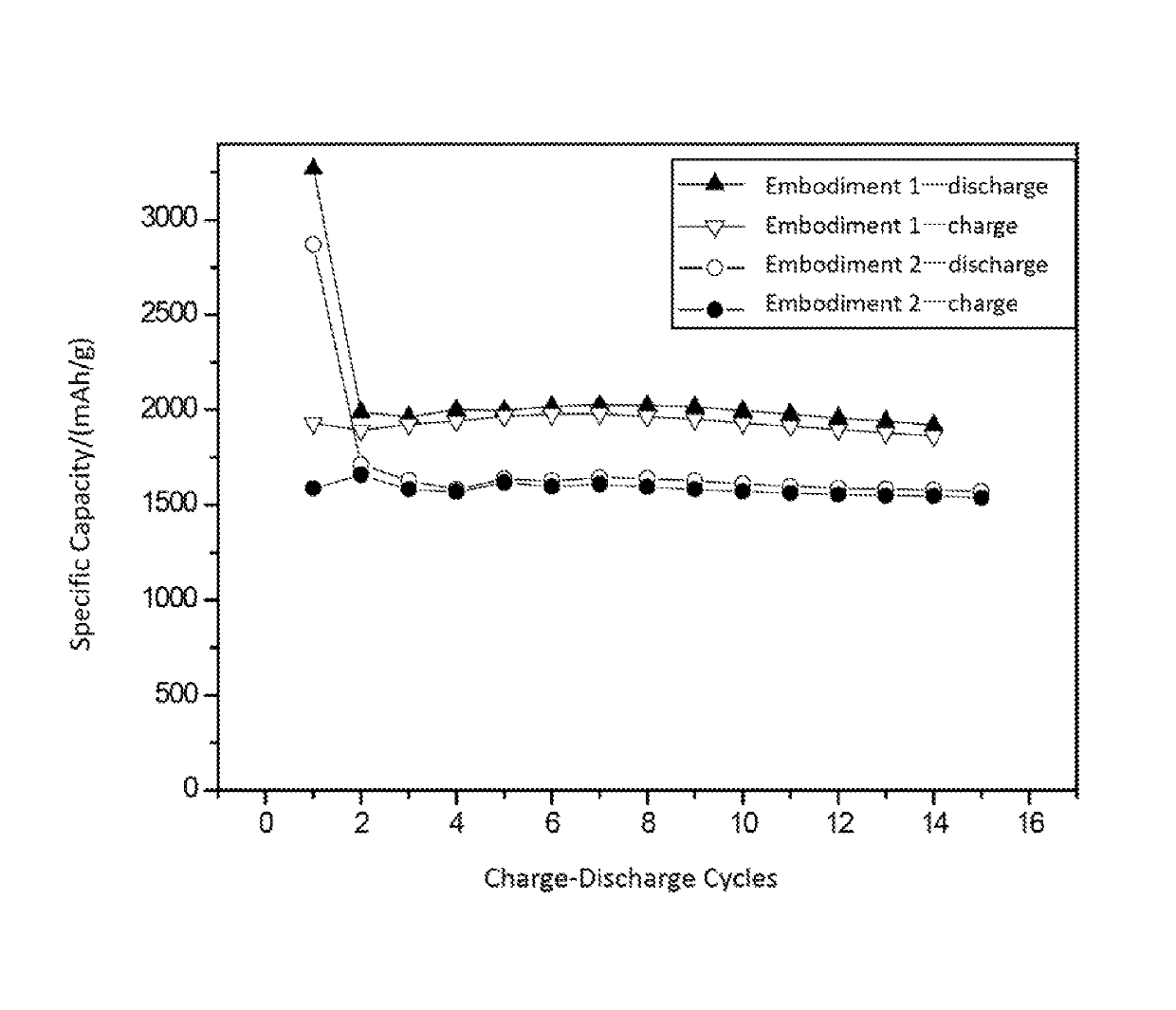

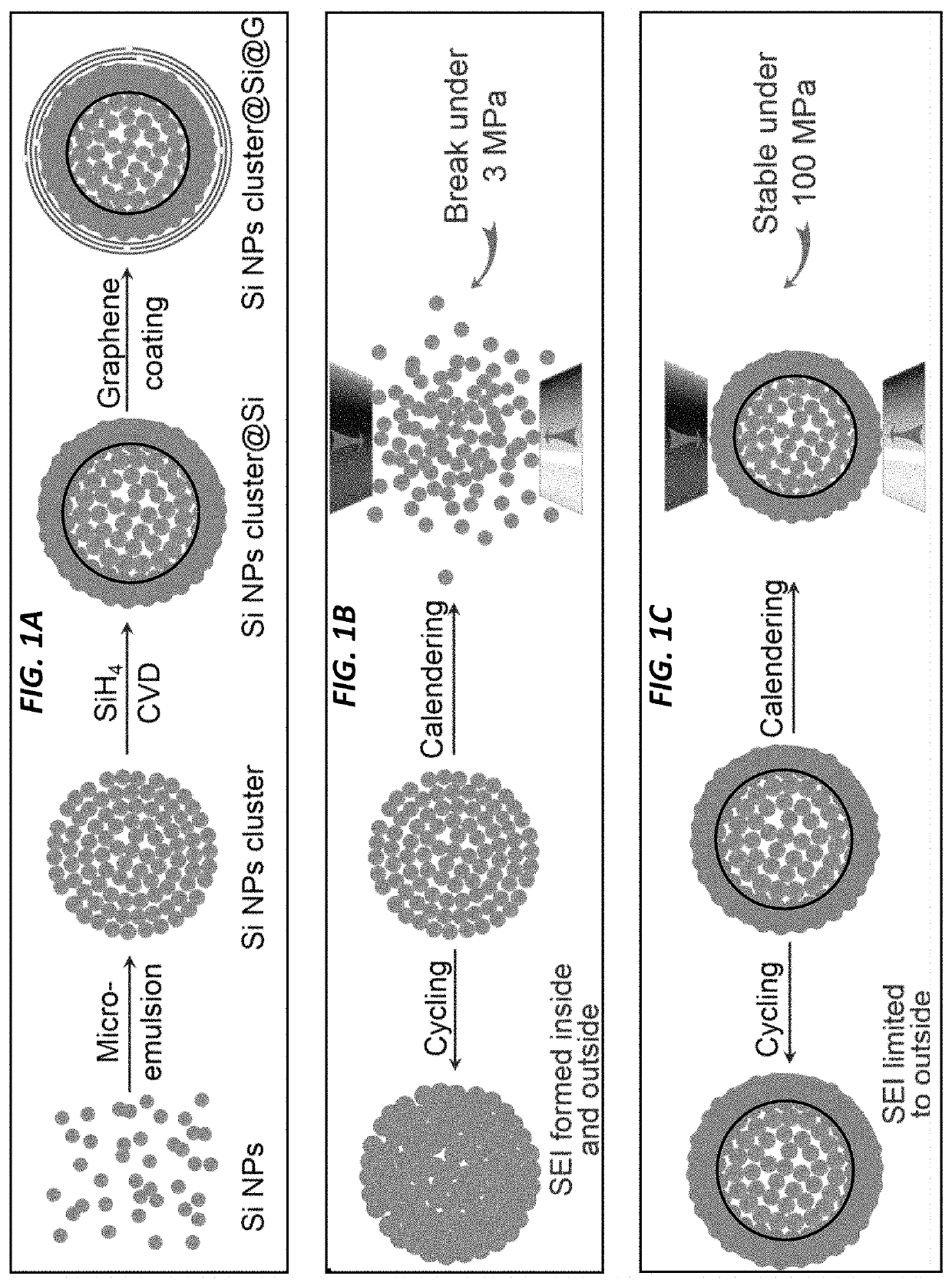

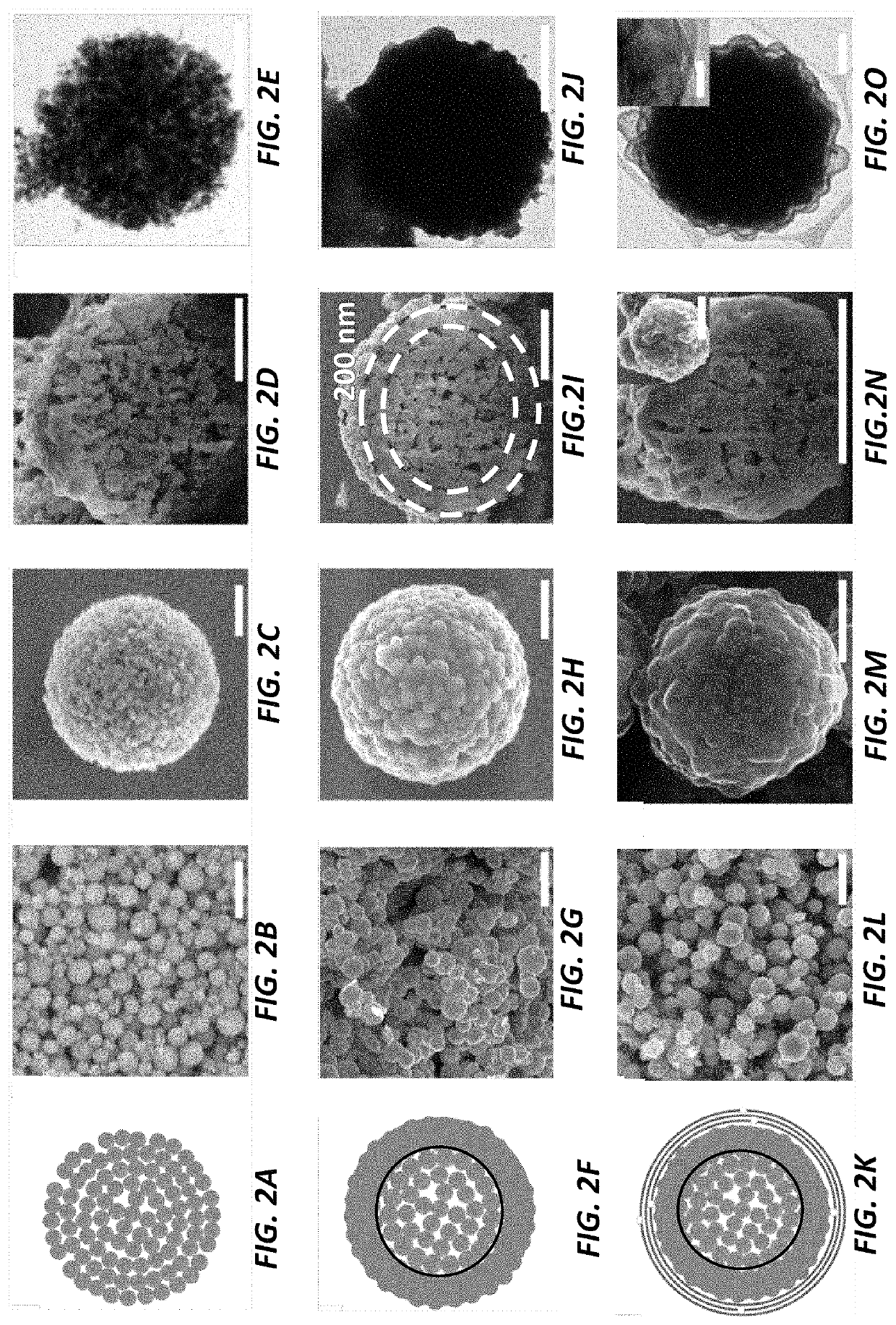

Silicon sealing for high performance battery anode materials

ActiveUS20190305295A1High densityInhibited DiffusionElectrode thermal treatmentNegative electrodesGraphene coatingSilicon microstructures

A battery electrode is provided that includes a porous silicon microstructure precursor, a silicon shell coating deposited on the silicon microstructure precursor, and a graphene coating deposited on the silicon shell coating, where the graphene coating encapsulates the silicon shell coating forming a graphene-encapsulated silicon-shell-protected porous silicon microstructure precursor battery electrode.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

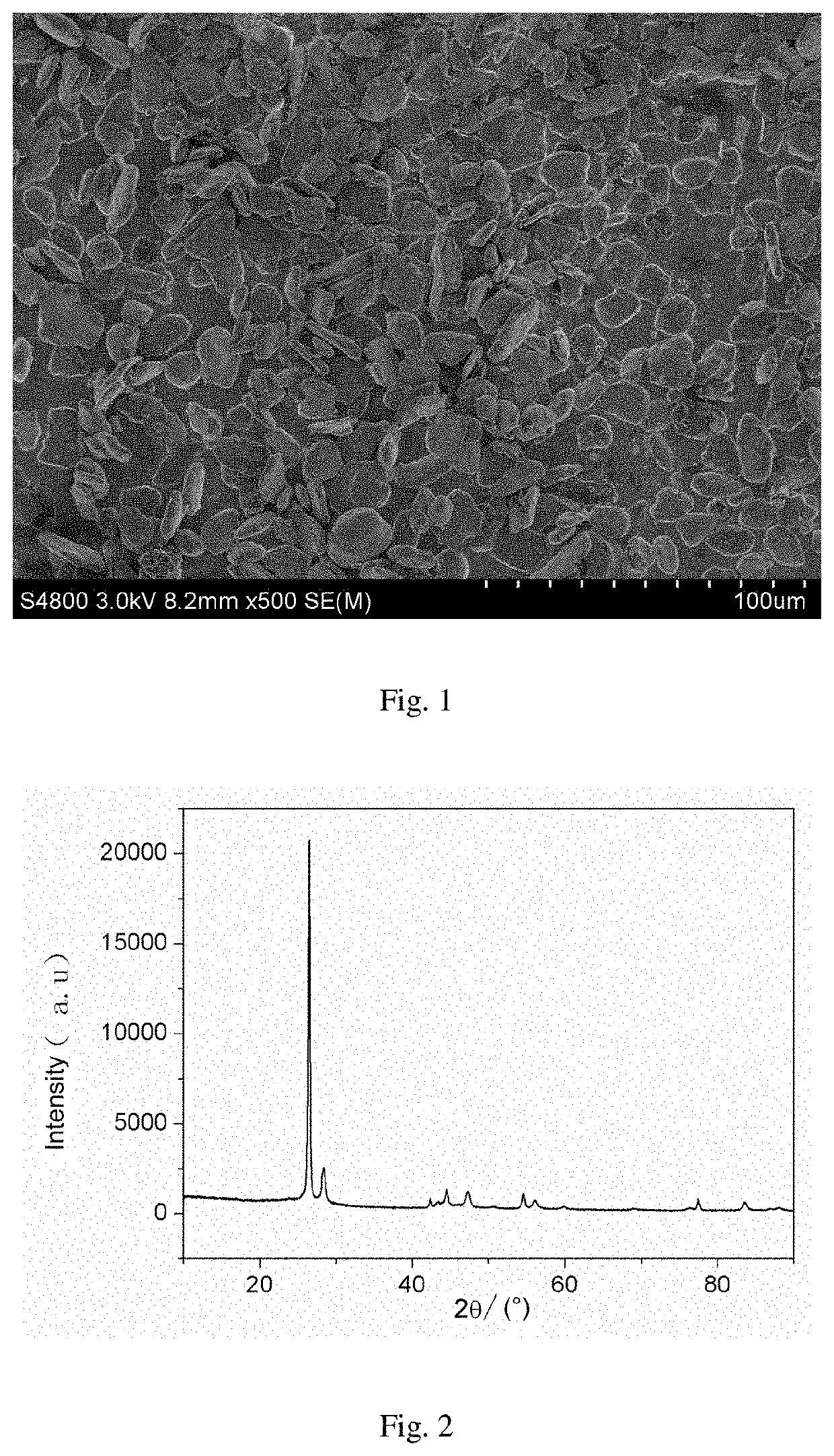

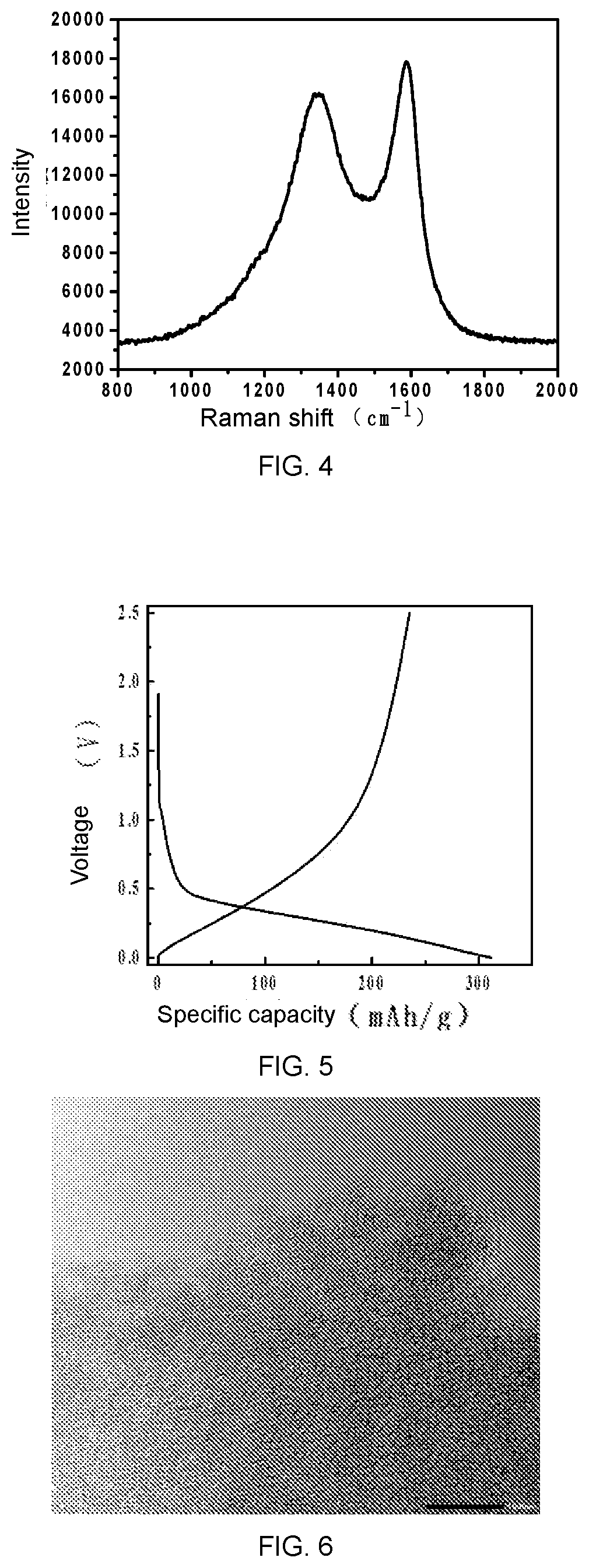

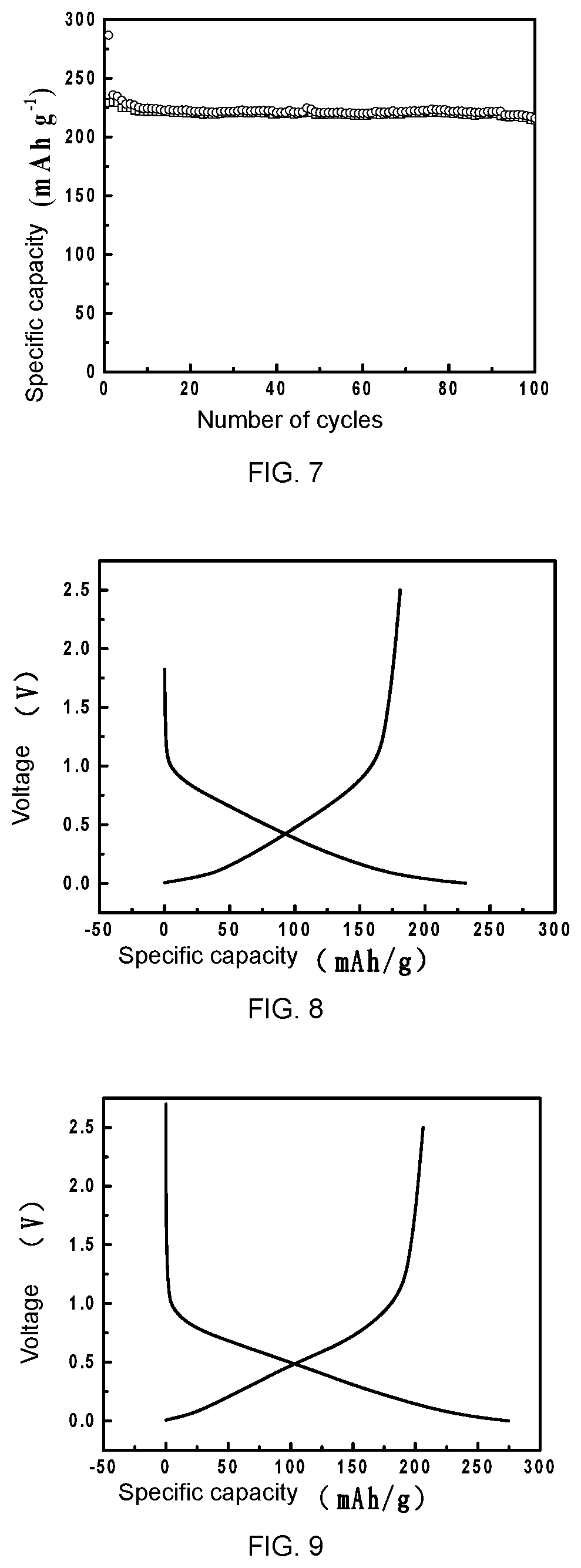

Lithium Ion Battery Anode Material, The Method Thereof And Lithium Ion Batteries

ActiveUS20180241074A1High capacityLow capacityElectrode manufacturing processesNegative electrodesSolid phasesFunctionalized graphene

A lithium ion battery anode material, a method thereof and a lithium ion battery. The lithium ion battery anode material includes graphite carbon materials and functionalized graphene. The method of the lithium ion battery anode material includes the following steps: compounding a graphite phase carbon material and functionalized graphene by liquid phase compounding method or solid phase compounding method, to obtain a lithium ion battery composite material. The lithium ion battery anode material provided by the present invention has the advantages of high capacity, high initial coulombic efficiency, excellent cycle performance and low production cost.

Owner:HUBEI HIGHLAND GRAPHENE TECH CO LTD

Multiple-element composite material for anodes, preparation method therefor, and lithium-ion battery having same

ActiveUS10522834B2Improve conductivityImprove cycle performanceElectrode thermal treatmentElectrode carriers/collectorsActive matterGraphite

Owner:BTR NEW MATERIAL GRP CO LTD

All-solid-state lithium rechargeable cells

ActiveUS20190067684A1Improve discharge capacityImprove initial Coulombic efficiencyCell electrodesFinal product manufactureAll solid stateRechargeable cell

Owner:ROBERT BOSCH GMBH

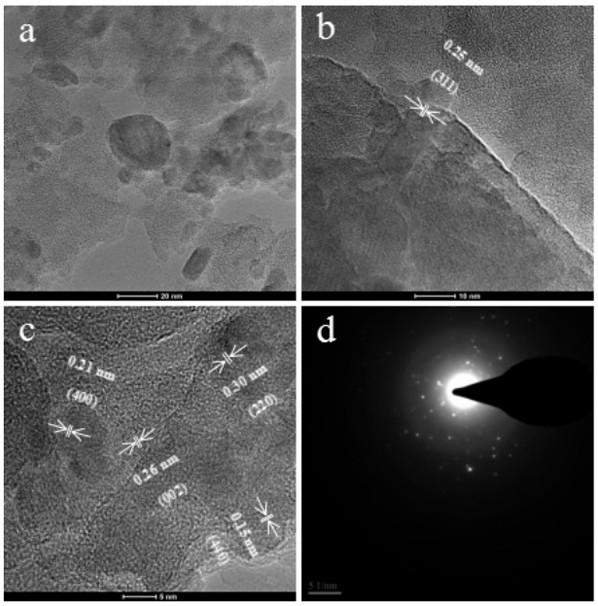

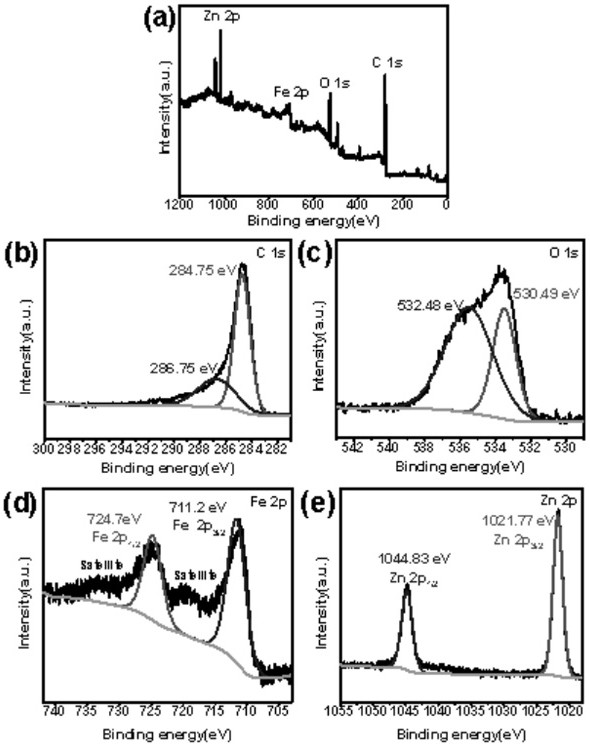

Polyphenol-modified zinc-iron-based heterojunction oxide carbon nano lithium ion battery negative electrode composite material and preparation method thereof

ActiveCN112751008AIncrease transfer rateEasy to operateMaterial nanotechnologyCell electrodesHeterojunctionElectrical battery

The invention belongs to the technical field of lithium ion battery materials, and particularly relates to a polyphenol-modified zinc-iron-based heterojunction oxide carbon nano lithium ion battery negative electrode composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing and stirring an iron source, a zinc source and a carbon source, centrifuging, drying, and carrying out heat treatment to obtain a ZnFe2O4 / ZnO / C negative electrode material. The negative electrode material provided by the invention solves the problems of poor cycle and rate performance, fast capacity fading, serious battery polarization, low charge and discharge coulombic efficiency and the like of the existing lithium ion battery negative electrode material. The ZnFe2O4 / ZnO / C has excellent electrochemical properties such as good cycling stability, excellent rate capability, small battery overpotential polarization voltage and high charge and discharge coulombic efficiency when being used as a lithium ion battery negative electrode material.

Owner:FUZHOU UNIV

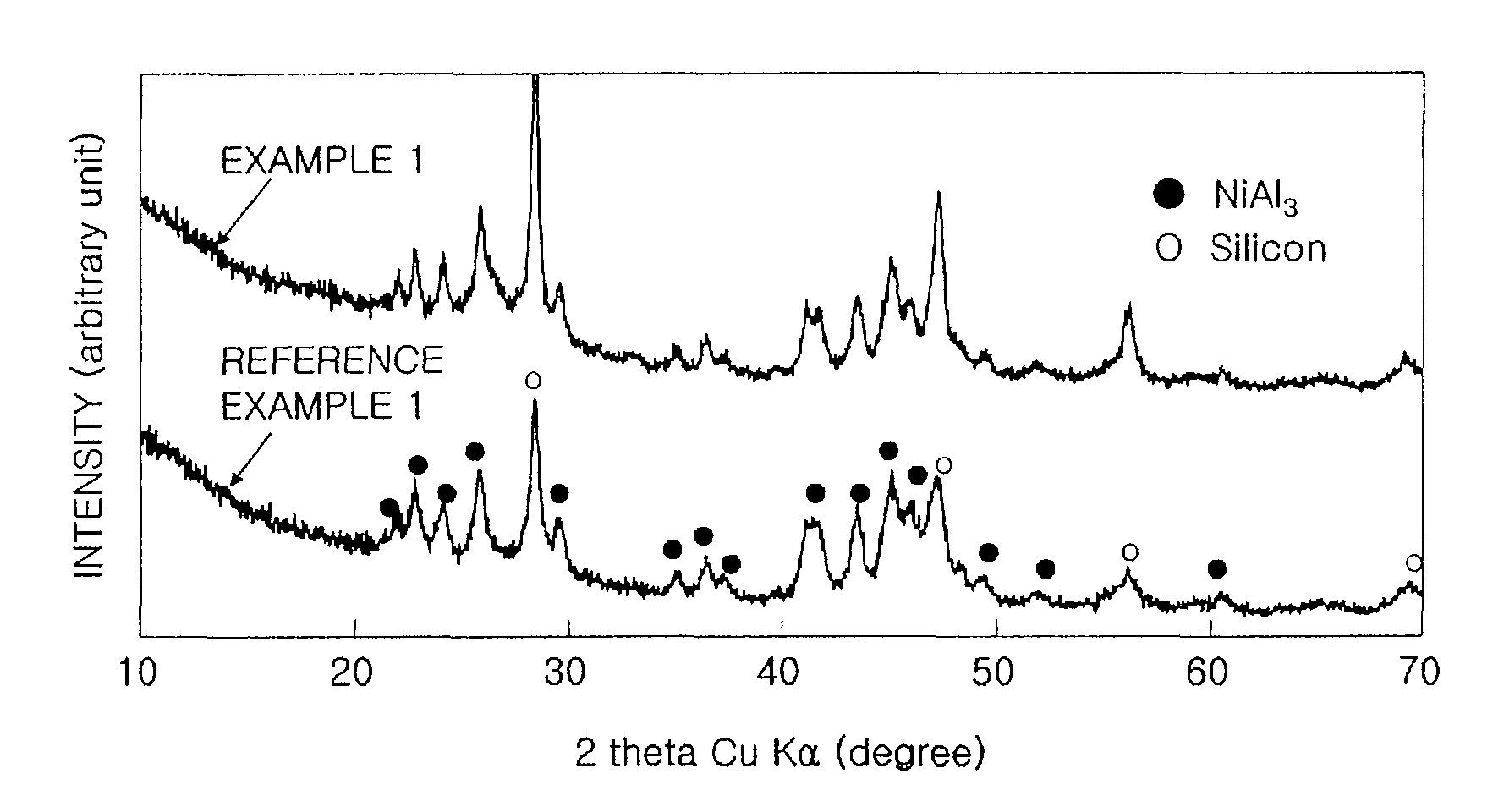

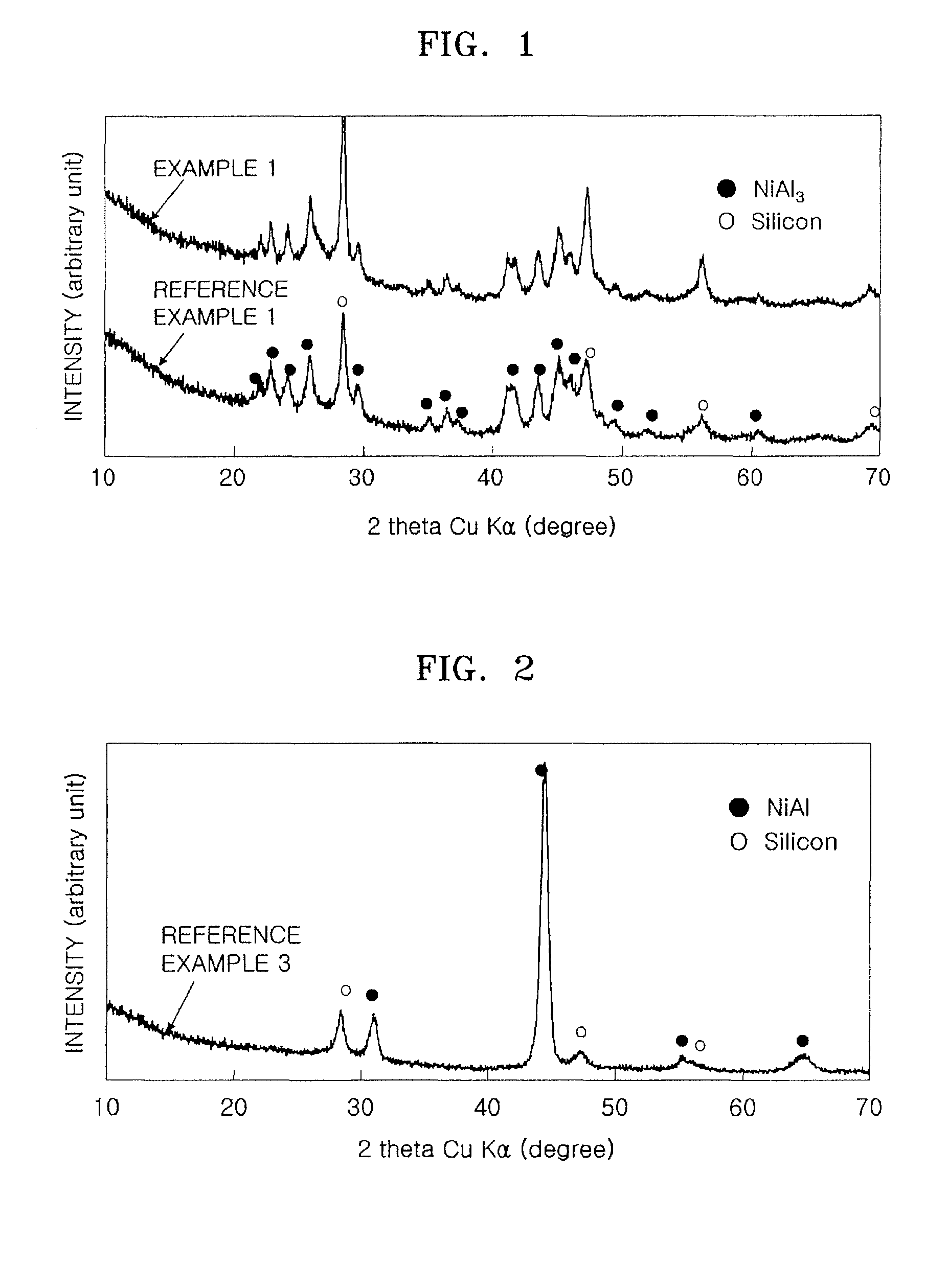

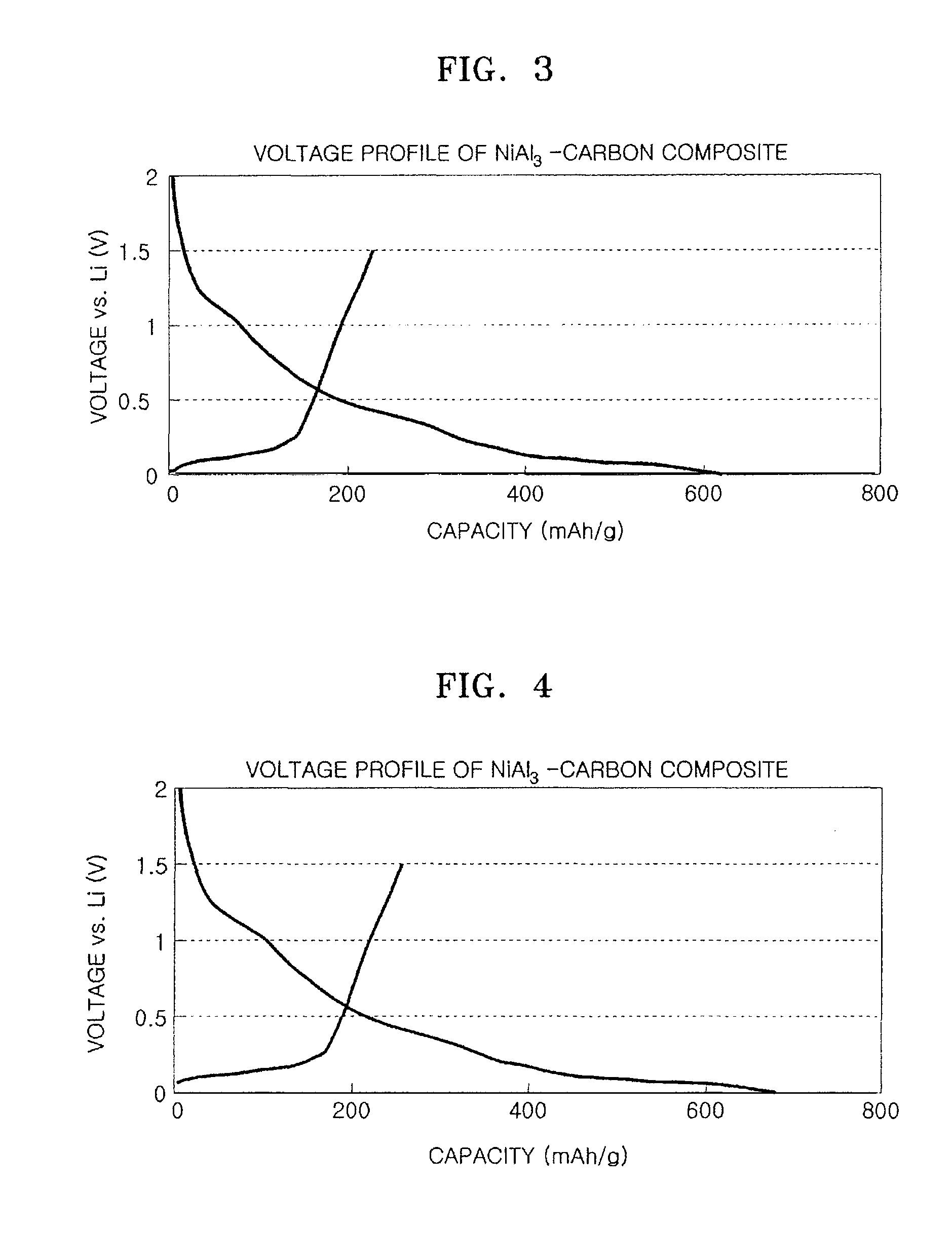

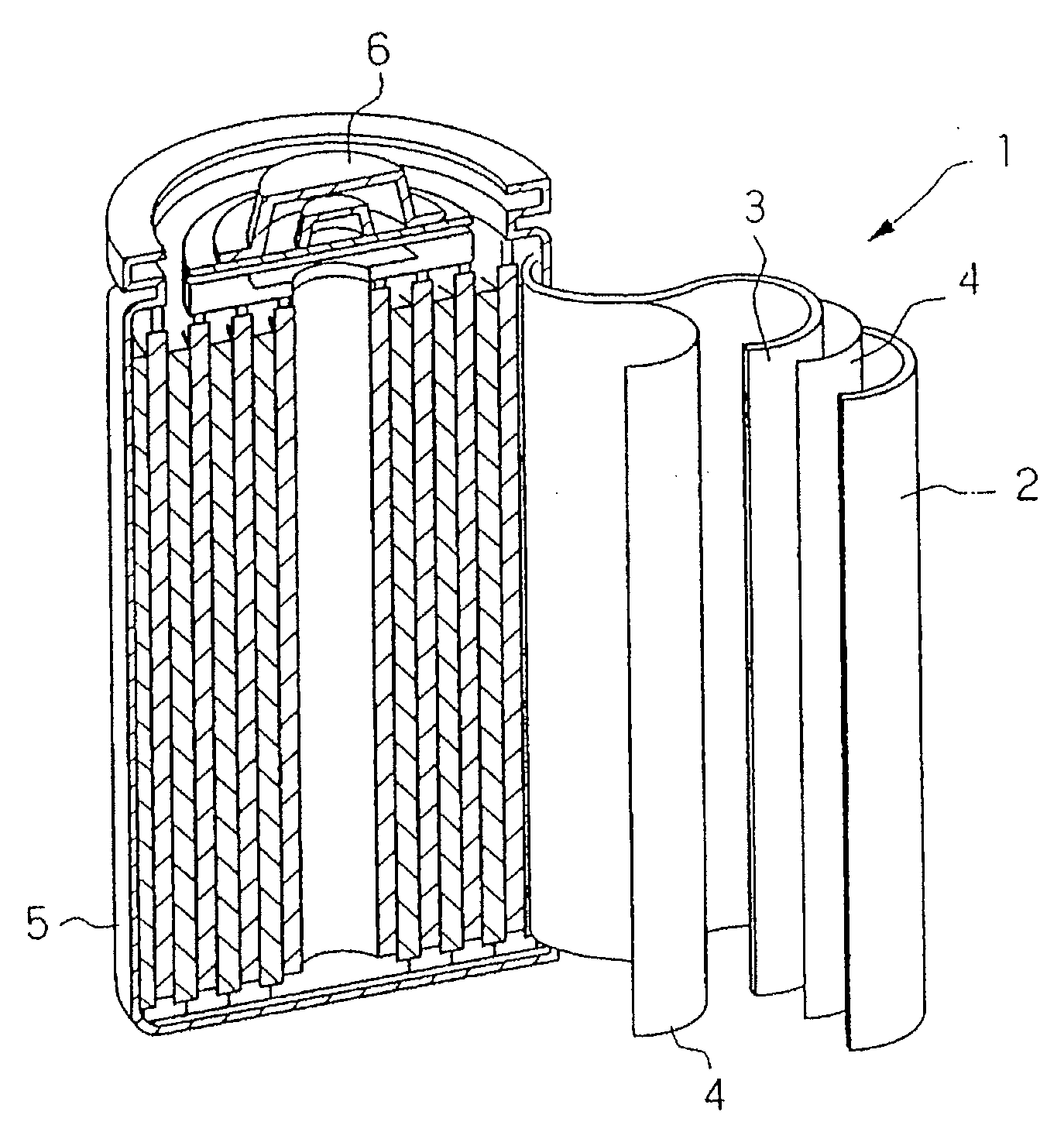

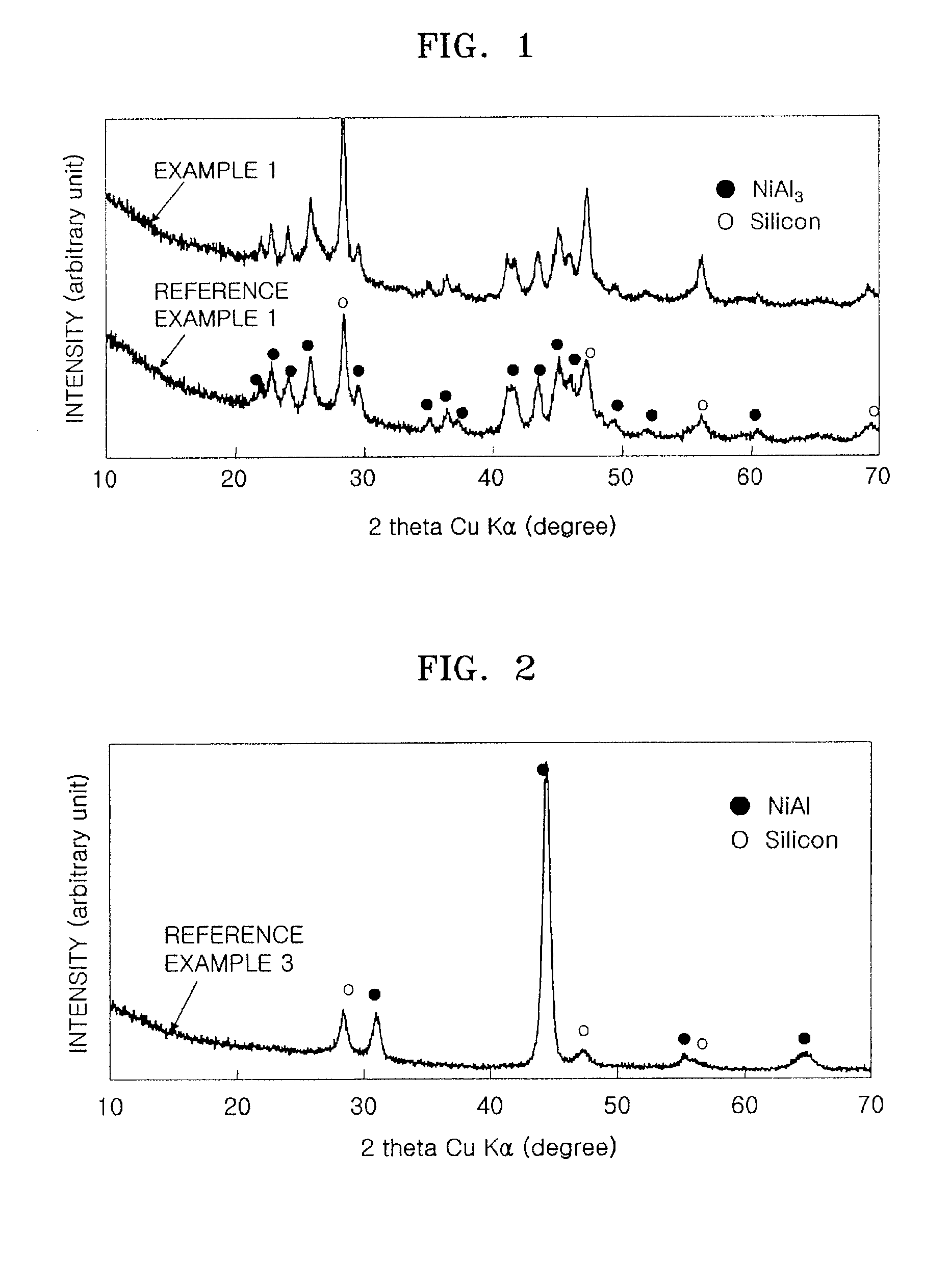

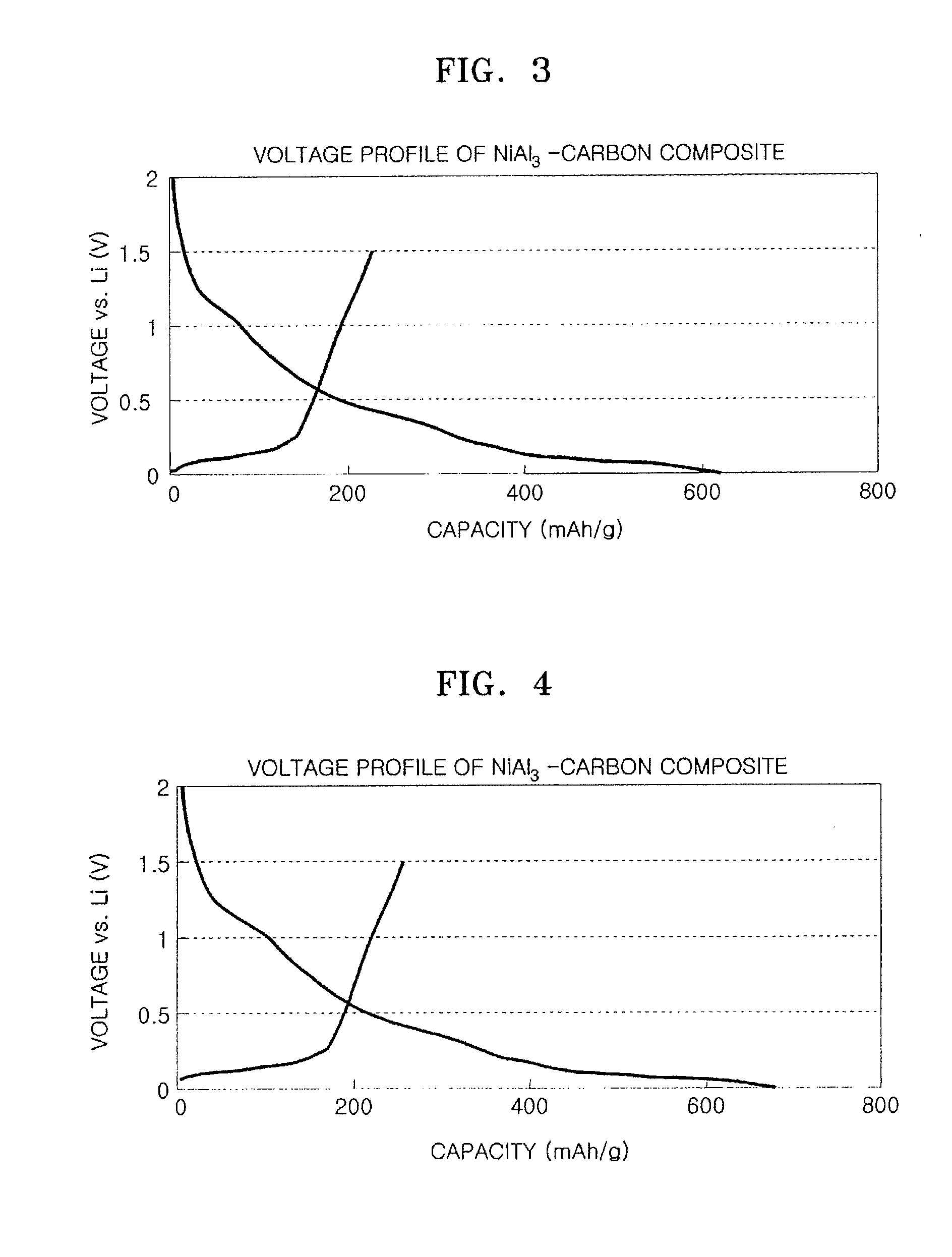

Composite anode active material, with intermetallic compound, method of preparing the same, and anode and lithium battery containing the material

A composite anode active material includes a metal that may be alloyed with lithium, an intermetallic compound incapable of alloying with lithium, and a carbonaceous material, wherein the intermetallic compound exists in a phase structurally separated from the metal capable of alloying with lithium. Since the composite active material contains an intermetallic compound that does not form any alloy phase with lithium nor the metal capable of alloying with lithium but rather exists in a structurally separated phase, the composite active material exhibits excellent coulombic efficiency. Further, anode electrodes and lithium batteries including the composite anode active material exhibit improved charge and discharge characteristics.

Owner:SAMSUNG SDI CO LTD

Composite anode active material, method of preparing the same, and anode and lithium battery containing the material

InactiveUS20080182173A1Improve initial Coulombic efficiencyImprove discharge characteristicsNegative electrodesNon-aqueous electrolyte accumulator electrodesCharge and dischargeAnode

A composite anode active material includes a metal that may be alloyed with lithium, an intermetallic compound incapable of alloying with lithium, and a carbonaceous material, wherein the intermetallic compound exists in a phase structurally separated from the metal capable of alloying with lithium. Since the composite active material contains an intermetallic compound that does not form any alloy phase with lithium nor the metal capable of alloying with lithium but rather exists in a structurally separated phase, the composite active material exhibits excellent coulombic efficiency. Further, anode electrodes and lithium batteries including the composite anode active material exhibit improved charge and discharge characteristics.

Owner:SAMSUNG SDI CO LTD

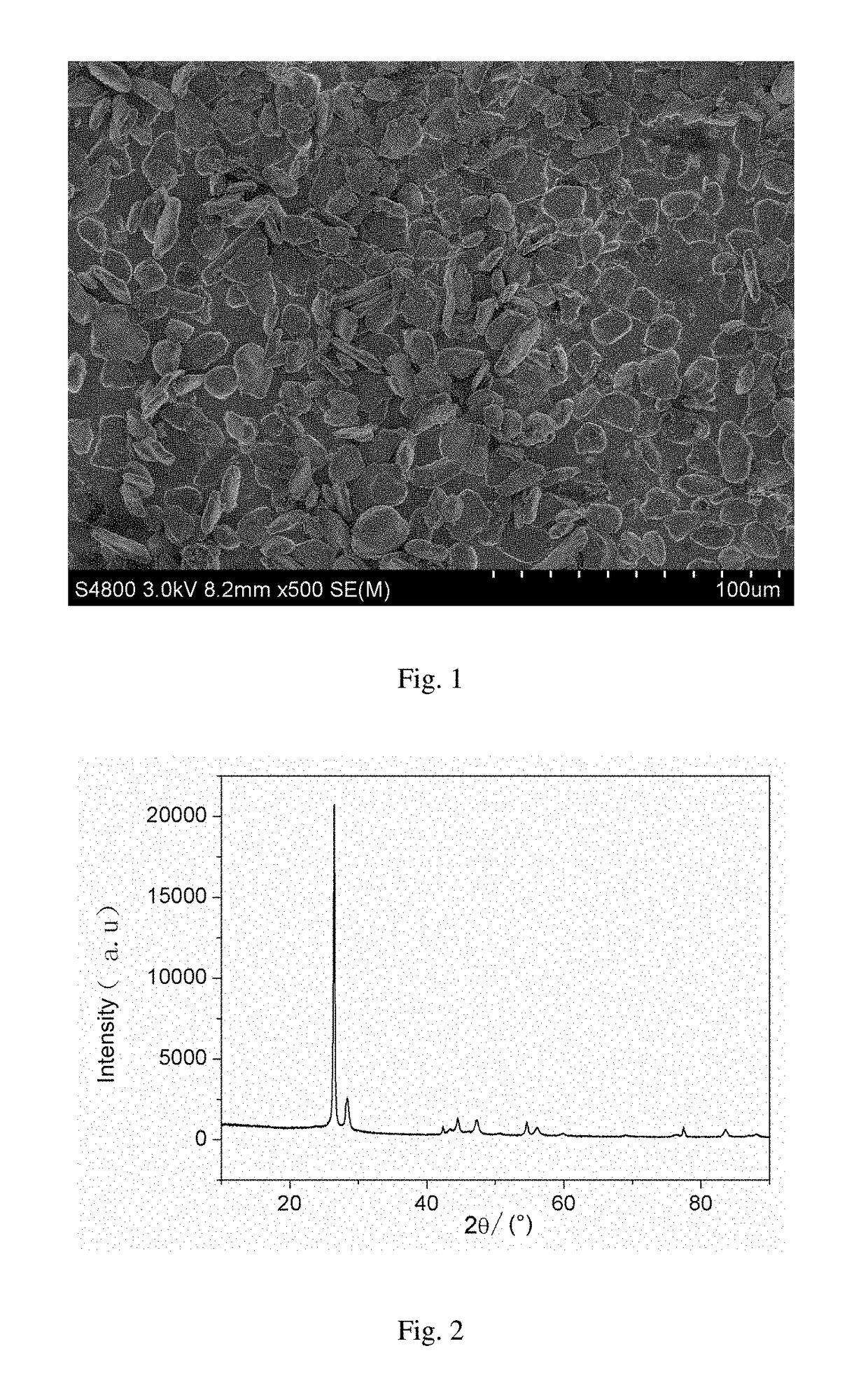

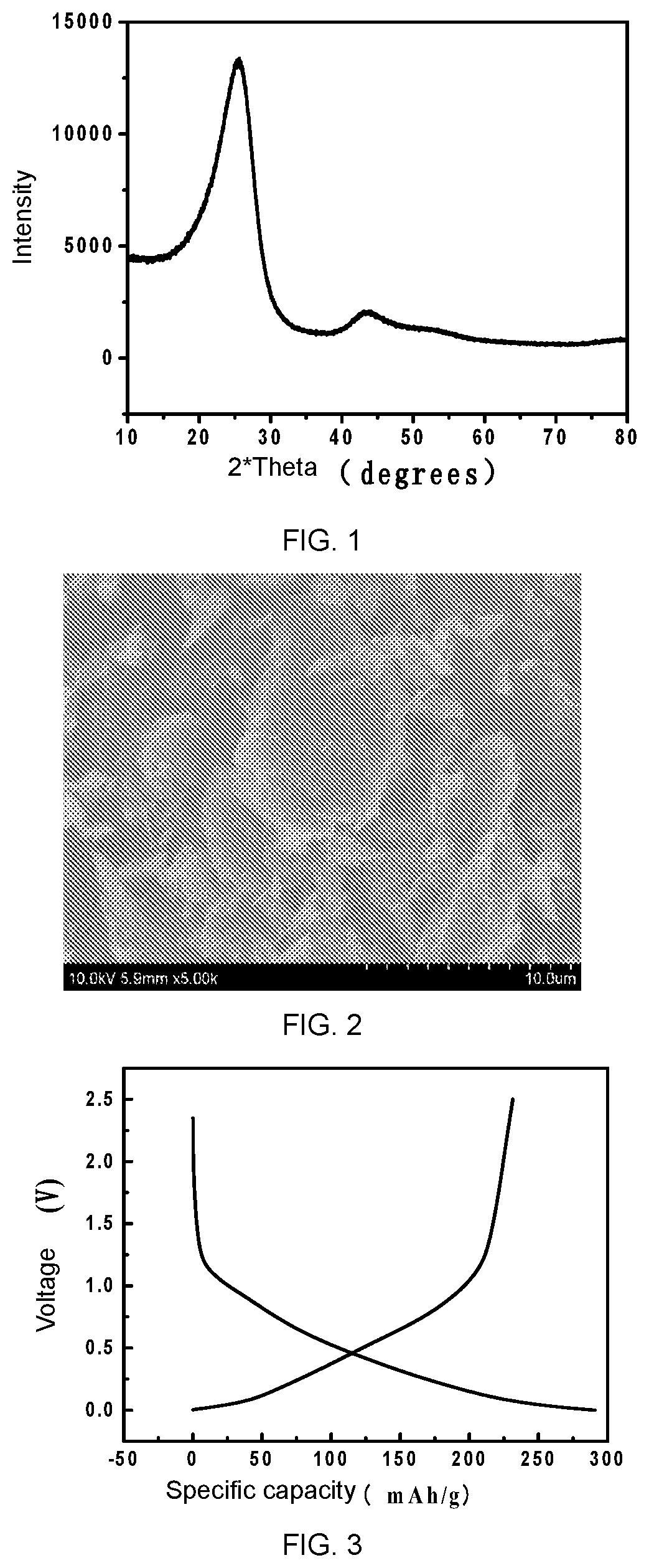

Carbon-based anode material with high slopecapacity and preparation method therefor and use thereof

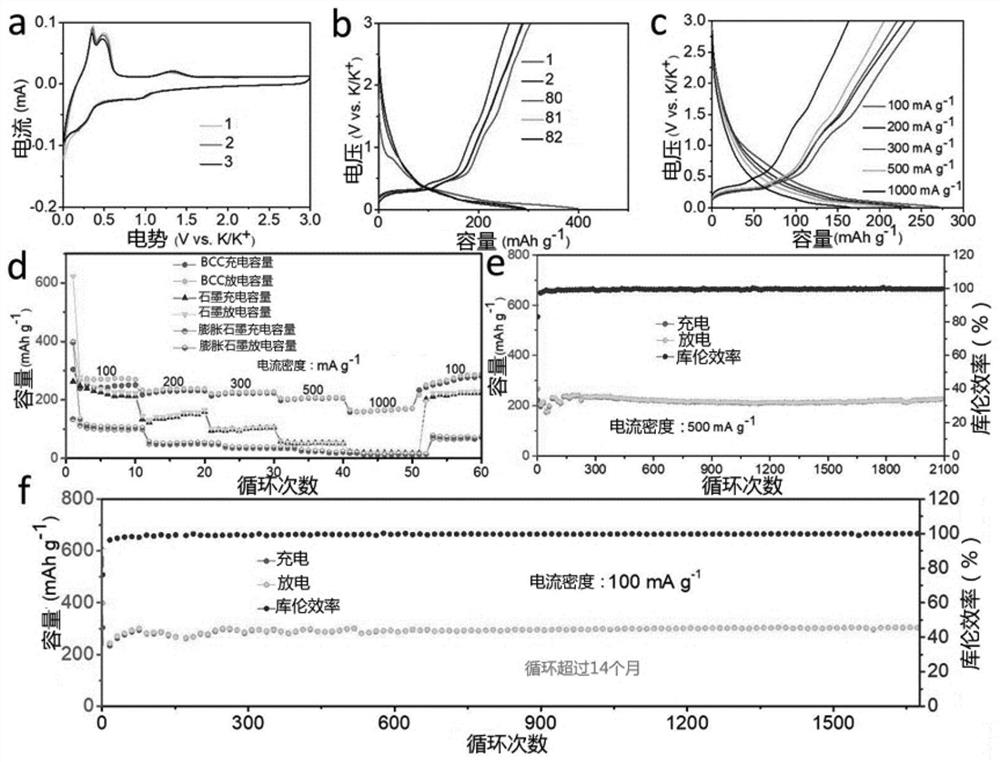

PendingUS20210253427A1High slope capacitySimple processNon-aqueous electrolyte accumulatorsCell electrodesCarbonizationSodium-ion battery

A carbon-based anode material with high ramp capacity, a preparation method therefore, and a use thereof. The method includes placing a carbon source precursor into a crucible and heating to 400° C-1000° C. at a heating rate of 0.2° C. / min-30° C. / min under an inert atmosphere, wherein the precursor includes any one or a combination of at least two of fossil fuel, biomass, resin, and organic chemicals; and carrying out heat treatment on the precursor at a temperature of 400° C. to 1000° C. for 0.5-48 hours to carbonize the precursor to obtain a carbon-based negative electrode material. The specific surface area of the anode material is less than 10 m2 / g. and assembling the obtained electrode material into a sodium ion battery and then carrying out charging and discharging between 0 and 2.5 V, to obtain a voltage curve. The ramp capacity being above 180 mAh / g and the first-cycle Coulombic efficiency is above 75%.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

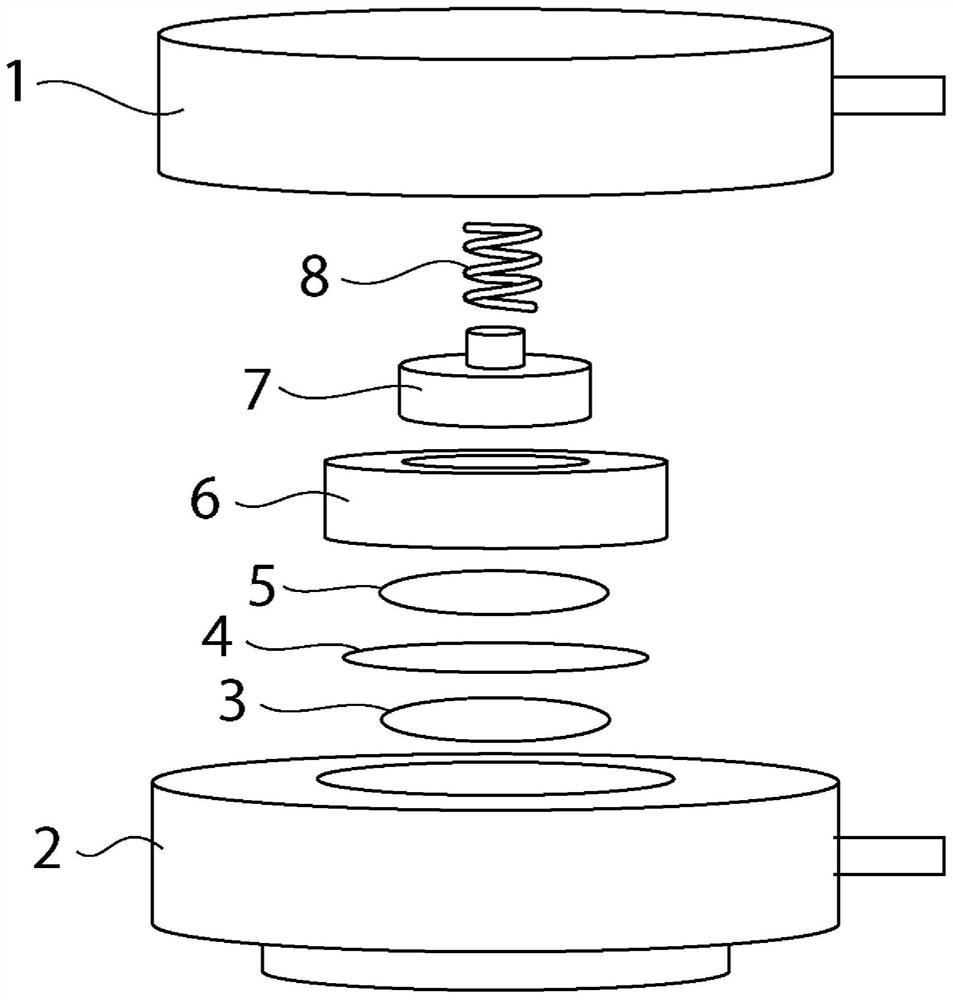

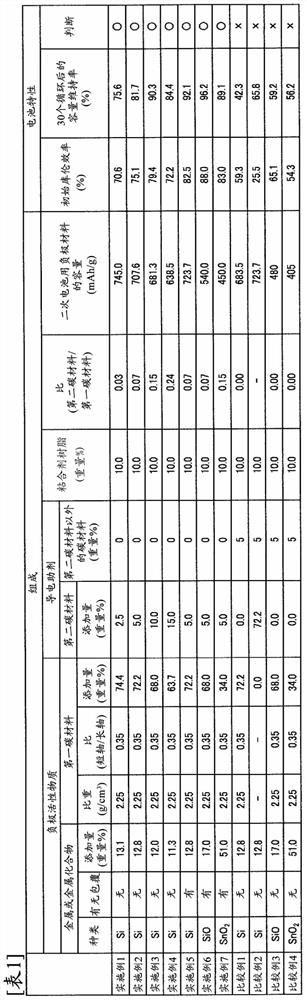

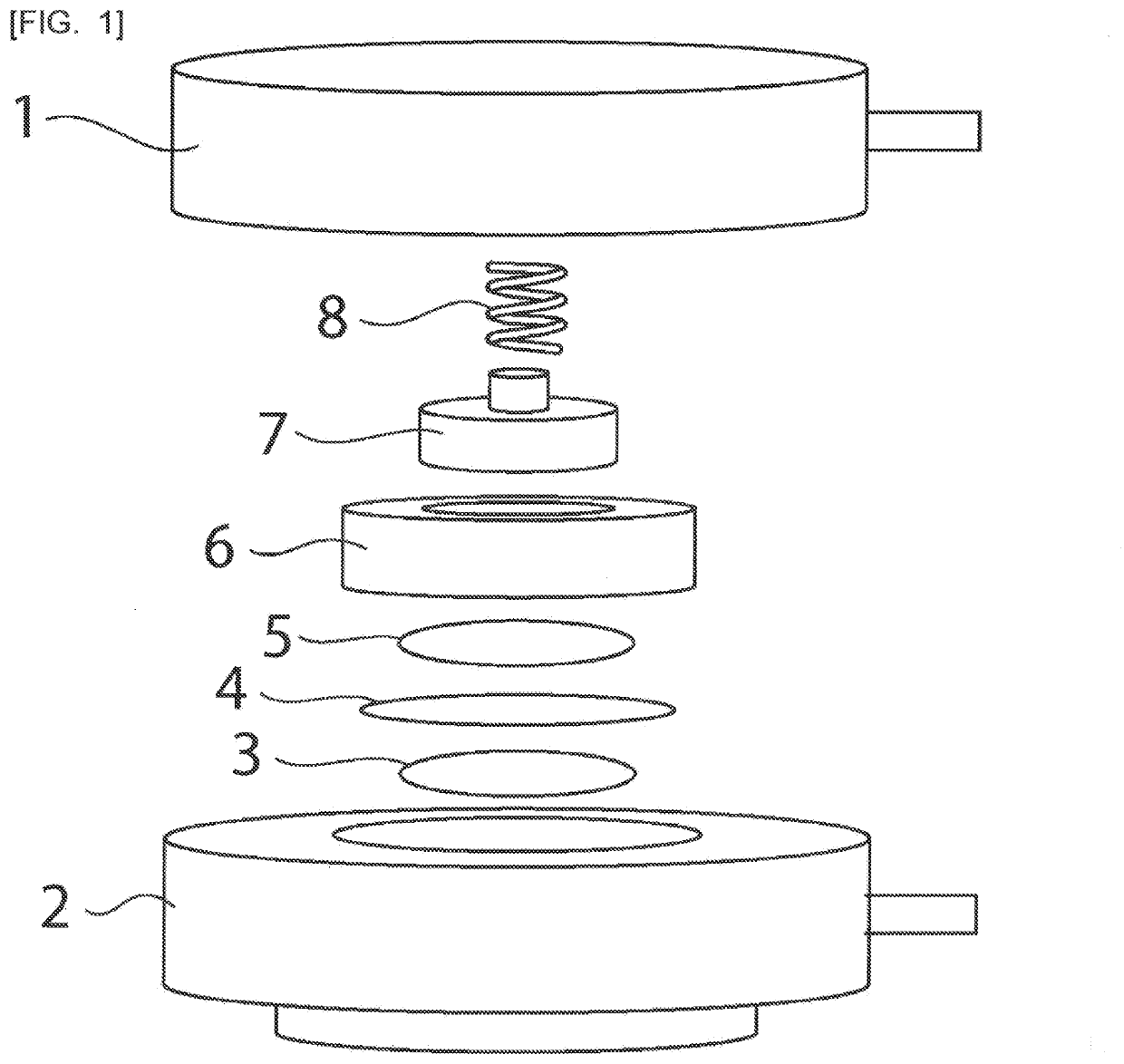

Negative electrode material for secondary battery, negative electrode for secondary battery, and secondary battery

PendingCN112534608AImprove initial Coulombic efficiencyLess prone to degradation of cycle characteristicsSiliconGraphiteCapacitanceAlkaline earth metal

Provided is a negative electrode material for a secondary battery that can inhibit deterioration of cycle characteristics during charging and discharging of a secondary battery and that can increase initial coulombic efficiency. This negative electrode material for a secondary battery has a capacitance of 400 mAh / g or more and comprises: a negative electrode active material that contains a metal or a metal compound that is capable of storing and discharging alkali metal ions or alkali earth metal ions, and a first carbon material; and a conductive auxiliary agent that contains a second carbonmaterial that is different from the first carbon material. The second carbon material is a partially-exfoliated graphite which has a graphite structure from which graphite has been partially exfoliated.

Owner:SEKISUI CHEM CO LTD

Negative electrode material for secondary battery, negative electrode for secondary battery, and secondary battery

InactiveUS20210367228A1Prevent characteristic deteriorationInhibit deteriorationGraphiteSecondary cellsElectrical batteryElectrically conductive

A negative electrode material for a secondary battery is provided that can prevent deterioration of the cycle characteristic during the charge and discharge of the secondary battery and can enhance the initial coulombic efficiency. A negative electrode material for a secondary battery, including: a negative electrode active material containing a metal or a metal compound that can absorb and release an alkali metal ion or an alkaline earth metal ion, and containing a first carbon material that can absorb and release the alkali metal ion or the alkaline earth metal ion; and a conductive auxiliary containing a second carbon material different from the first carbon material, the negative electrode material having a capacity of 400 mAh / g or more, and the second carbon material being partially exfoliated graphite having a graphite structure in which graphite is partially exfoliated.

Owner:SEKISUI CHEM CO LTD

All-solid-state lithium rechargeable cells

ActiveUS10749166B2Improve discharge capacityImprove initial Coulombic efficiencyCell electrodesFinal product manufactureAll solid stateHigh energy

Provided is an all-solid-state lithium rechargeable cell, comprising: a) a cathode, wherein the cathode comprises: a1) a composite of VS4 and graphene; and a2) a solid catholyte; and b) a lithium-based anode. In particular, the all-solid-state lithium rechargeable cell of the present disclosure may exhibit high initial discharge capacities, high initial Coulombic efficiencies, good reversible capacities, excellent cycling stabilities, high energy densities as well as outstanding safeties.

Owner:ROBERT BOSCH GMBH

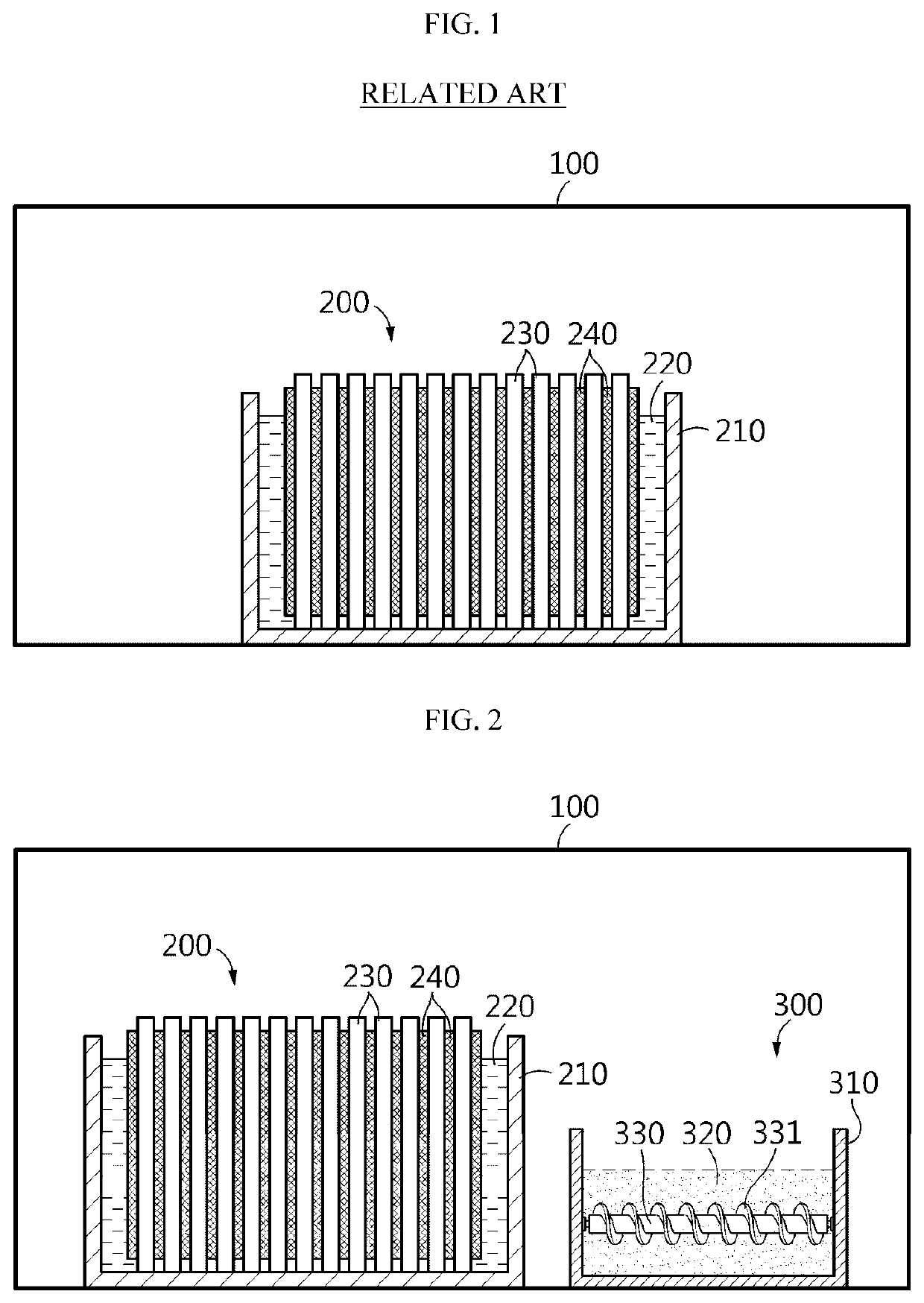

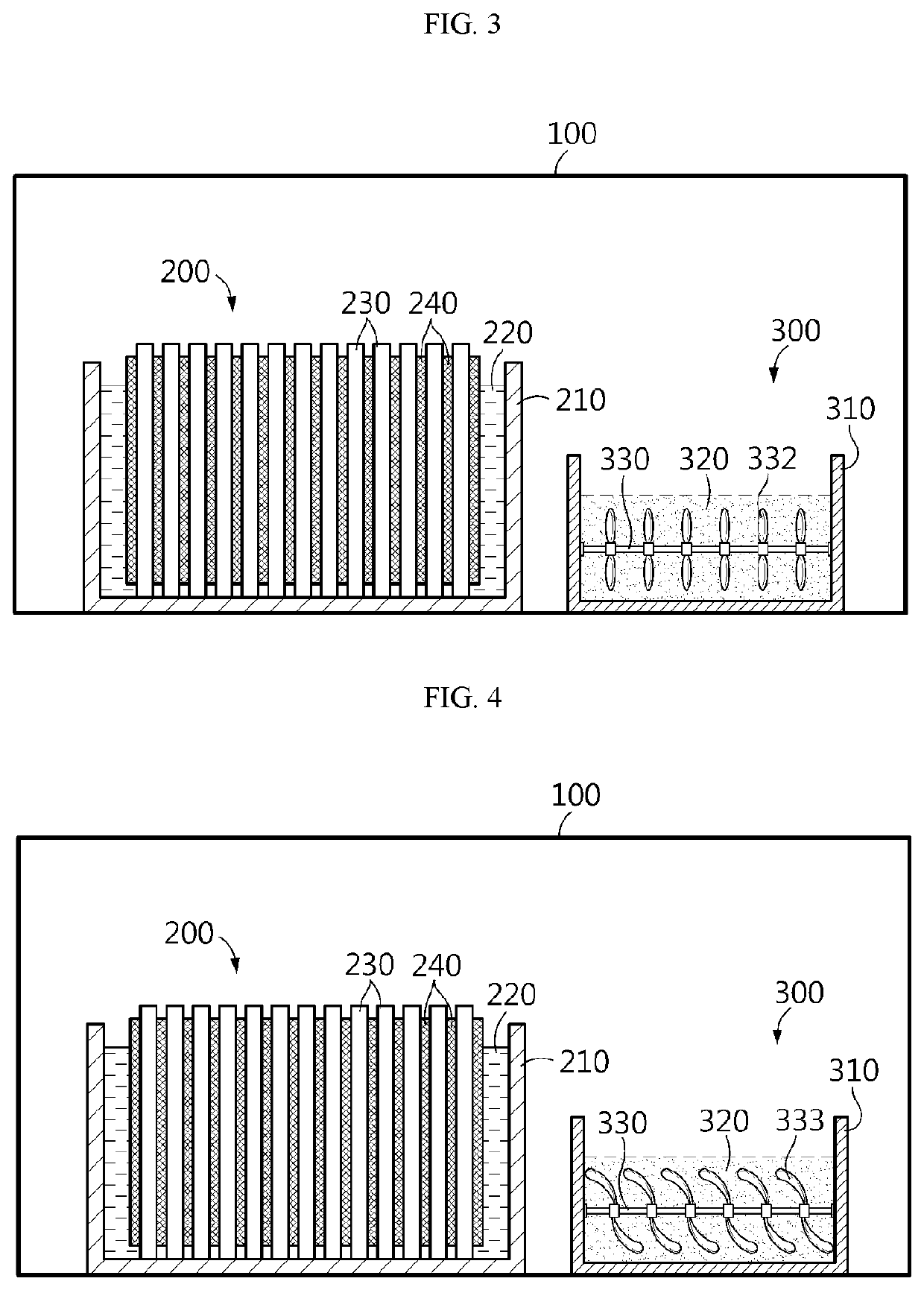

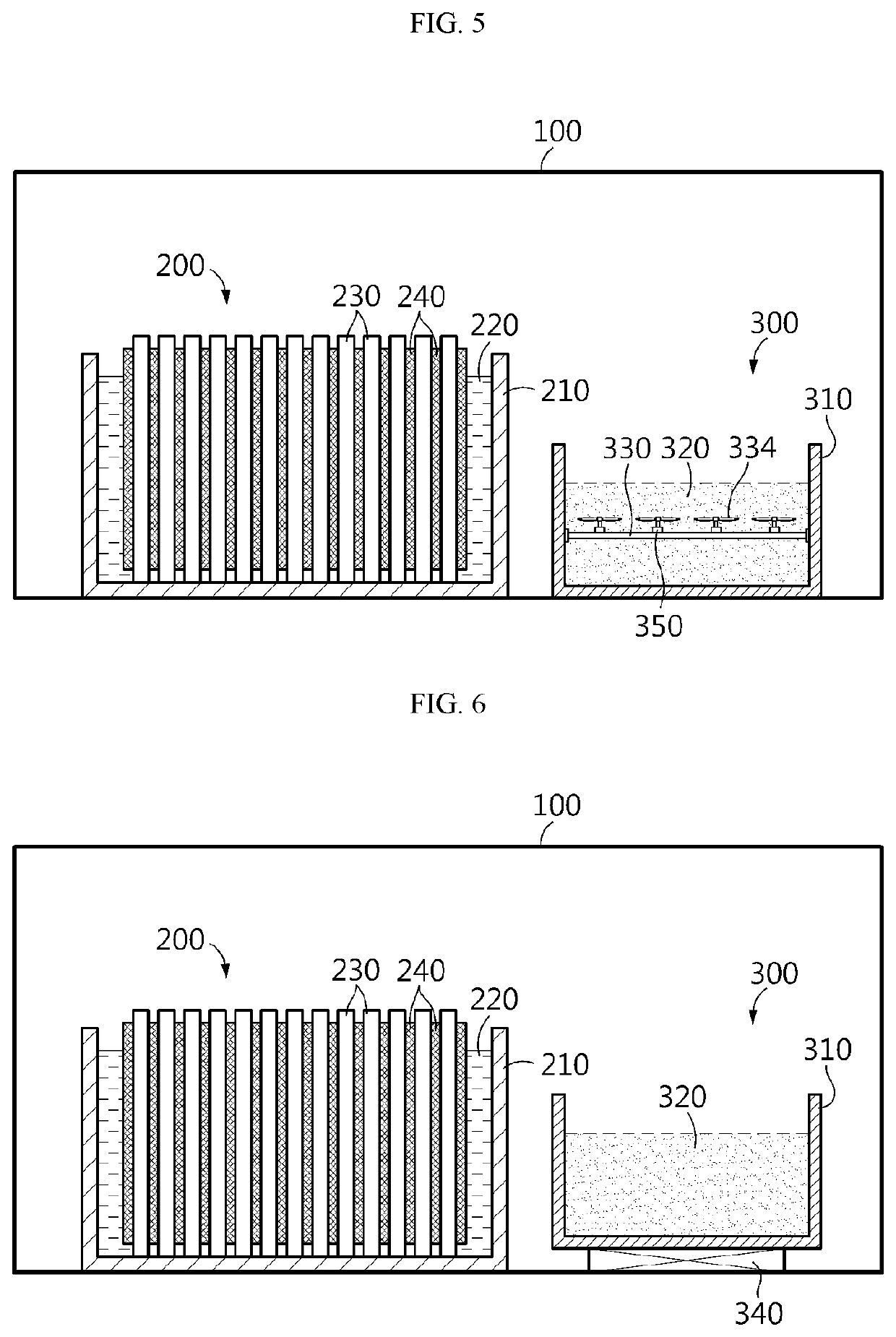

Pre-lithiation reaction chamber apparatus

PendingUS20220085349A1Avoid damageDesired levelElectrode manufacturing processesNegative electrodesBattery cellElectrolyte

A pre-lithiation reaction chamber apparatus including a pre-lithiation reaction vessel which can prevent harmful effects caused by water that may be generated during pre-lithiation is provided. The pre-lithiation reaction vessel includes an electrolyte including a lithium salt, a negative electrode for a lithium secondary battery and a lithium ion-supplying member. Each of the negative electrode for the lithium secondary battery and the lithium ion-supplying member is at least partially in contact with the electrolyte. The pre-lithiation reaction chamber apparatus further includes a water-capturing vessel. The water-capturing vessel includes water-capturing powder, a container configured to receive the water-capturing powder, and a position-changing member configured to change a position of the water-capturing powder in the container.

Owner:LG ENERGY SOLUTION LTD

Anode material including graphite phase carbon material and functionalized graphene, method thereof, and lithium ion battery

ActiveUS10665893B2High ability to capture lithium ionEasy compoundElectrode manufacturing processesSecondary cellsGraphite carbonBattery cell

A lithium ion battery anode material, a method thereof and a lithium ion battery. The lithium ion battery anode material includes graphite carbon materials and functionalized graphene. The method of the lithium ion battery anode material includes the following steps: compounding a graphite phase carbon material and functionalized graphene by liquid phase compounding method or solid phase compounding method, to obtain a lithium ion battery composite material. The lithium ion battery anode material provided by the present invention has the advantages of high capacity, high initial coulombic efficiency, excellent cycle performance and low production cost.

Owner:HUBEI HIGHLAND GRAPHENE TECH CO LTD

A kind of antimony sulfide-based negative electrode material for lithium ion battery and preparation method thereof

ActiveCN112133909BImprove electronic conductivityConducive to ease the reunionGraphiteCell electrodesAntimony trioxideLithium-ion battery

The invention provides an antimony sulfide-based negative electrode material for lithium ion batteries and a preparation method thereof, and relates to the field of lithium ion battery negative electrode materials. The method is to use mechanical ball milling method to mechanically mix antimony trioxide, expanded graphite and sulfur powder for a long time at high speed to form a composite material, and anneal and vulcanize in argon to obtain antimony sulfide with sulfur-doped graphite-encapsulated antimony sulfide structure base composite material. In the present invention, compounding with sulfur-doped graphite material and graphene exfoliated from expanded graphite can increase the electronic conductivity of antimony sulfide, and at the same time, the encapsulation structure formed by the presence of sulfur powder during ball milling is conducive to alleviating the vulcanization caused by volume expansion. Agglomeration of antimony; their joint action greatly improves the initial Coulombic efficiency, reversibility of conversion reaction, cycle stability and rate performance. The mechanical ball milling method of the invention is simple and easy to operate, and is convenient for large-scale production.

Owner:浙江霖润新能源科技有限公司

Lithium replenishment method for negative electrode active material of lithium ion battery

ActiveCN112234160BImprove efficiencyImprove electrochemical performanceElectrode manufacturing processesNegative electrodesBattery cellLithium electrode

The invention discloses a method for supplementing lithium with negative electrode active materials of lithium ion batteries, belonging to the field of lithium ion batteries. The key to the lithium supplementation method is to add the negative electrode active material into the organic lithium solution in two stages to obtain the second-stage lithium supplementary active material, and then add the second-stage lithium supplementary active material to the organic compound solution for calcination and cleaning , to obtain a lithium supplement active material product. The present invention adopts a two-stage method to supplement lithium, which not only helps to form a dense and good SEI film on the surface of the active material, but also makes the lithium supplementing degree of the active material higher and achieves a higher initial Coulombic efficiency; Lithium supplementation significantly and effectively improves the initial Coulombic efficiency and electrochemical performance of the battery. The invention adopts an organic solution oxidation-reduction method to supplement lithium to the negative electrode active material, the process is mild, the amount of lithium supplementation is controllable, and the accuracy is high, which is suitable for existing equipment and is beneficial to industrial application.

Owner:SHAANXI COAL & CHEM TECH INST

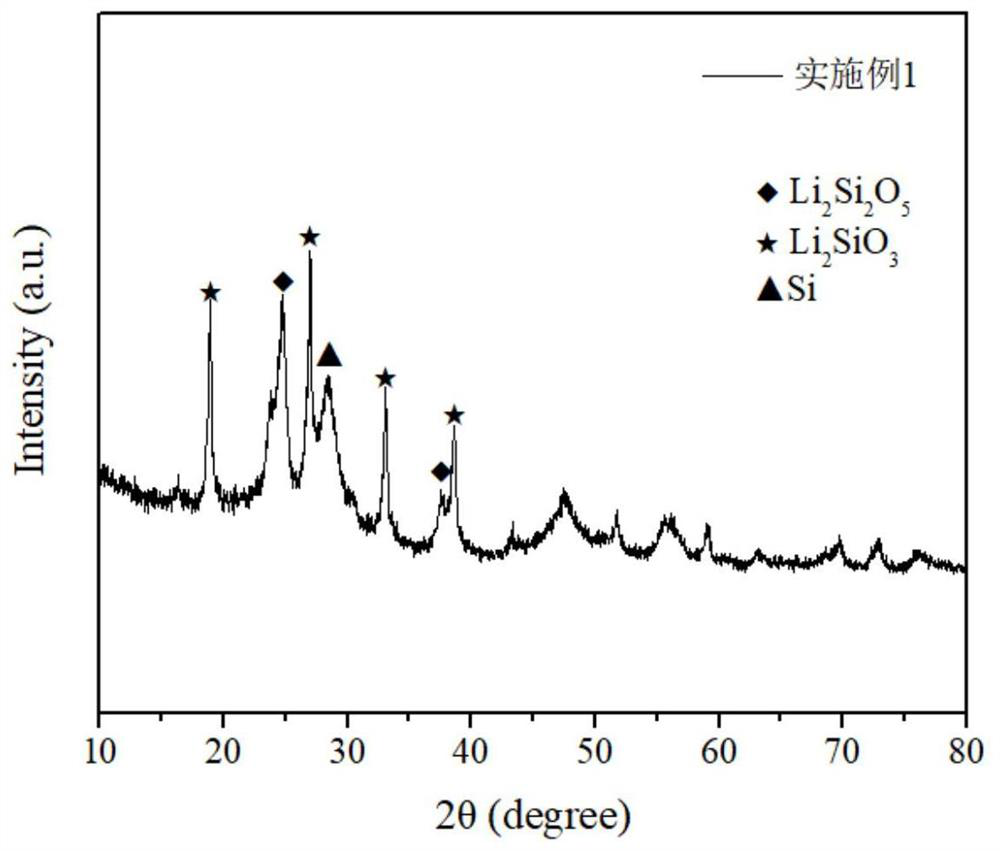

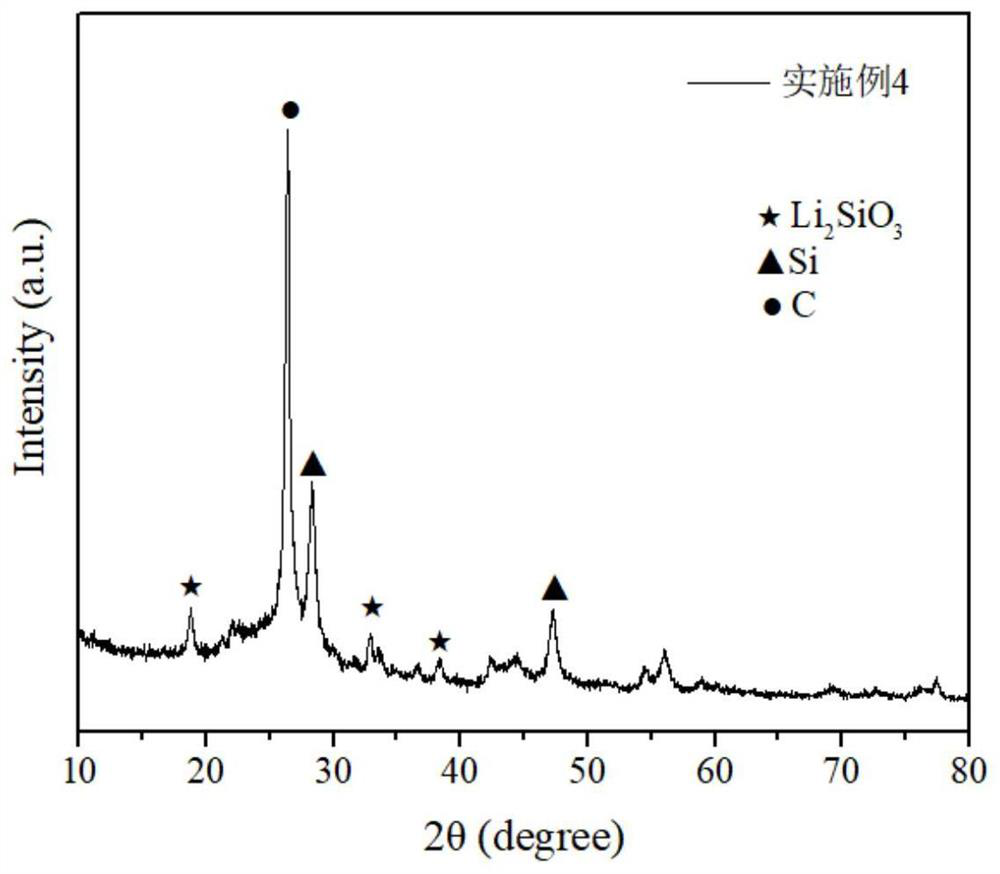

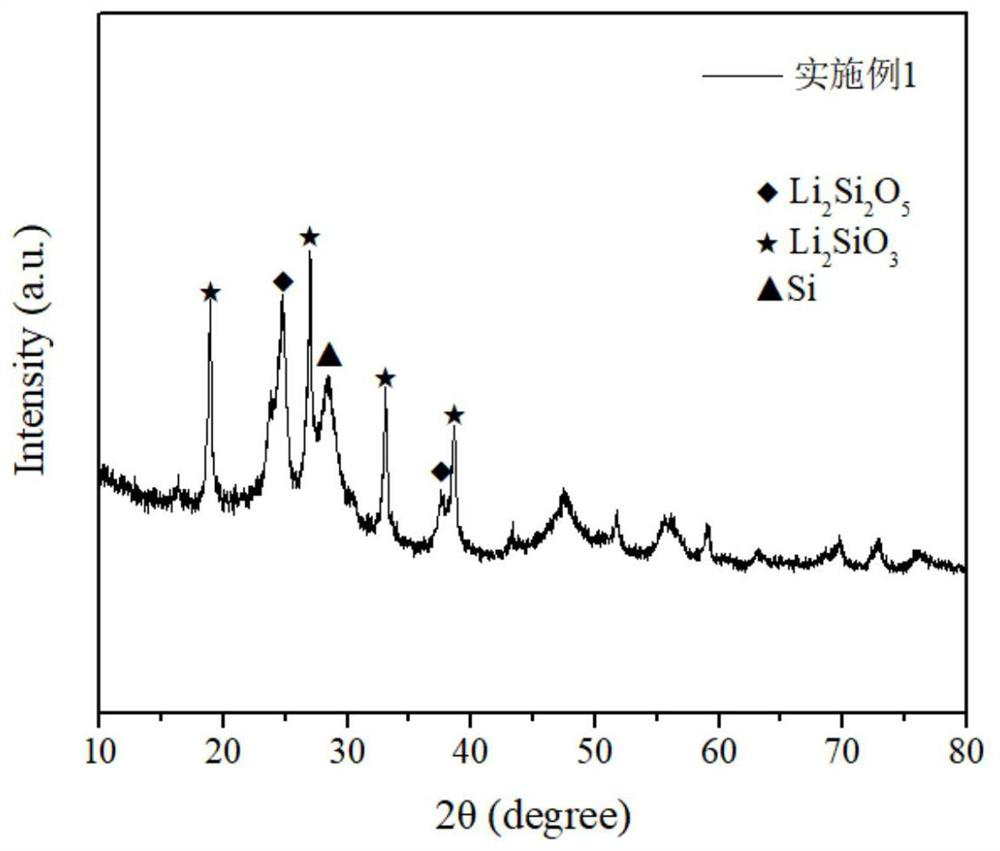

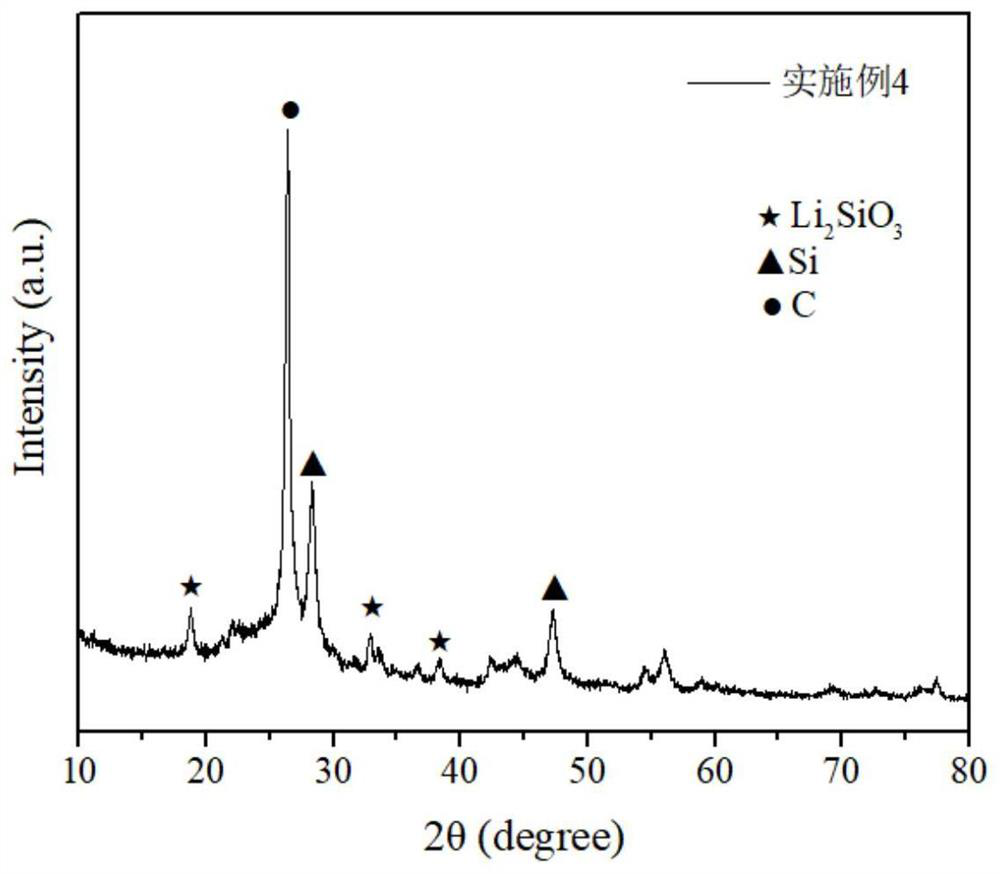

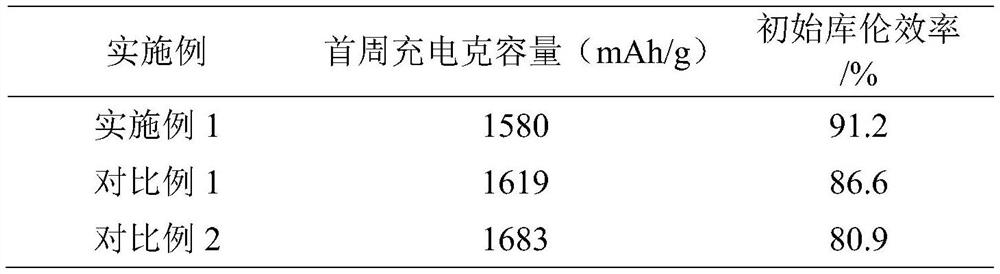

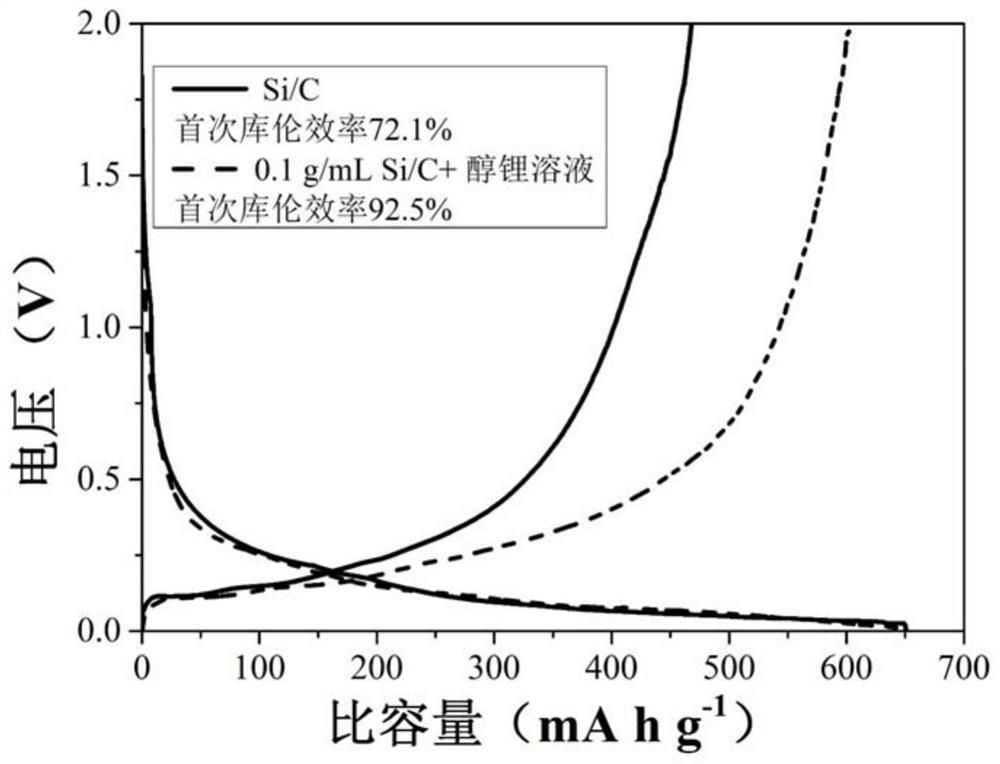

A modified silicon carbon negative electrode material and its preparation method and application

ActiveCN112652757BImprove initial Coulombic efficiencyLow costSiliconNegative electrodesMetallic lithiumPhysical chemistry

The invention provides a modified silicon-carbon negative electrode material and its preparation method and application. The preparation method includes the following steps: (1) mixing the silicon-carbon negative electrode material and lithium alkoxide solution, and performing solvothermal reaction; (2) alcohol washing Step (1) The solid powder obtained after the solvothermal reaction is dried to obtain a modified silicon-carbon negative electrode material; the lithium alkoxide solution is formed by mixing metal lithium and an alcohol solvent. The preparation method provided by the invention has a simple process, and the pre-lithiation of the surface of the silicon-carbon negative electrode material can be realized through a simple solvothermal reaction, which reduces the irreversible capacity in the first charge and discharge process, and improves the first Coulombic efficiency to more than 92%.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

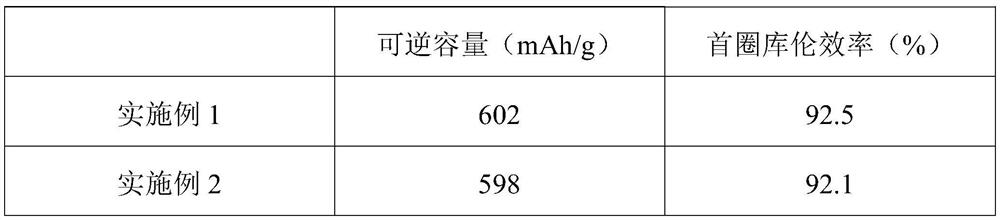

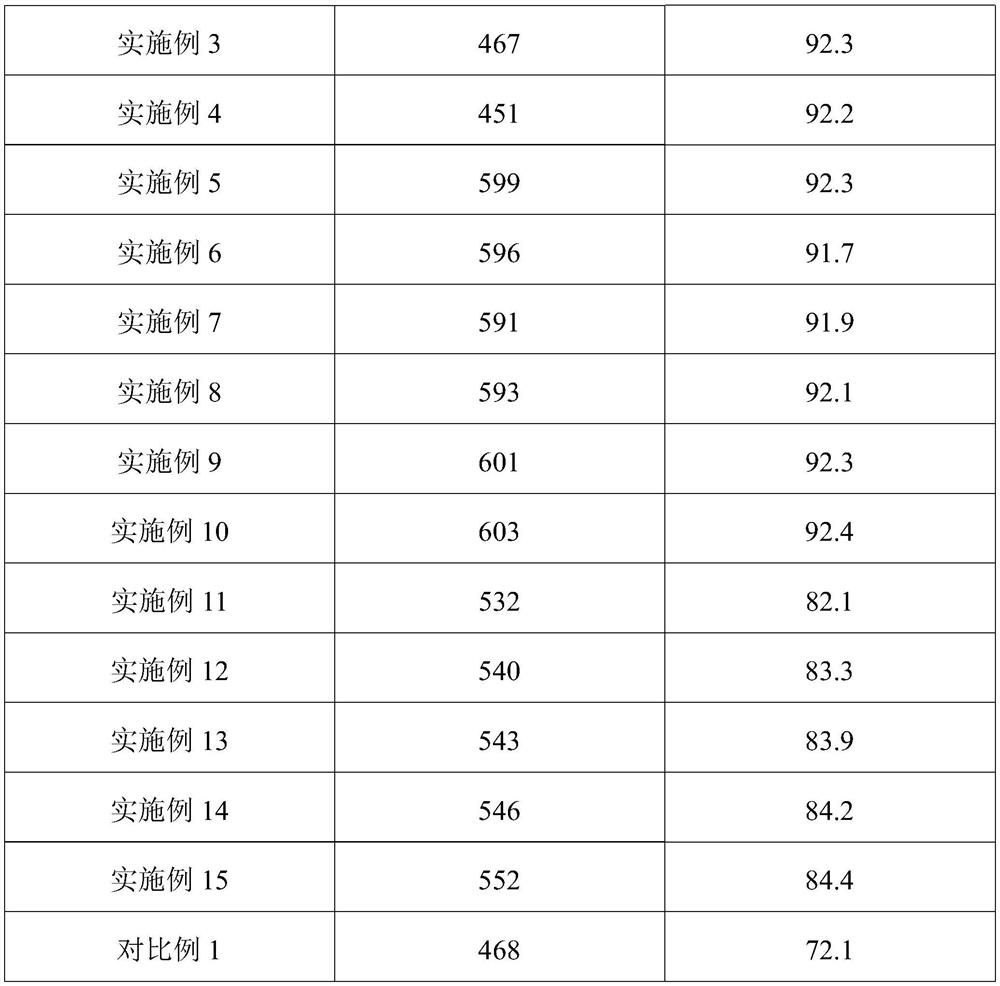

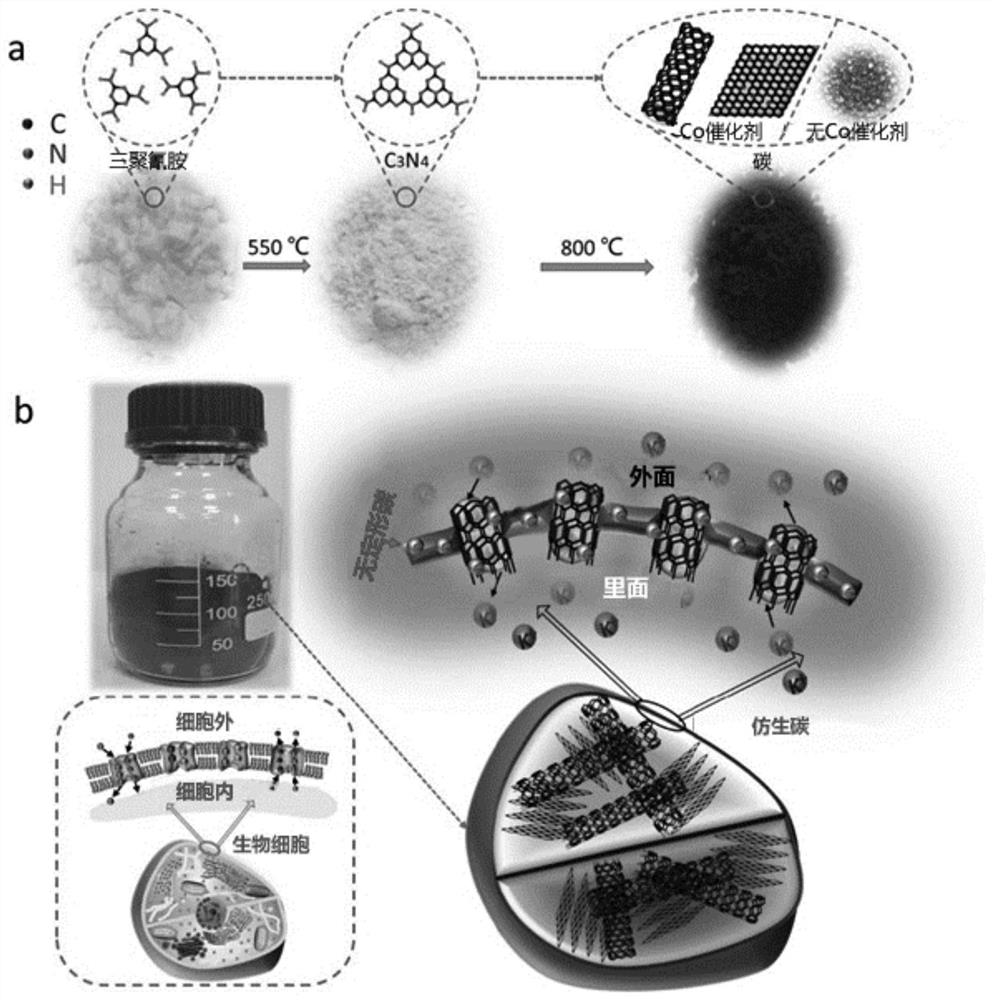

Preparation method of bionic carbon negative electrode material used as potassium ion battery negative electrode, and product

InactiveCN112436137AExcellent electrochemical performanceHigh reversible capacityMaterial nanotechnologyCell electrodesCarbonizationSulfonyl

The invention provides a preparation method of a bionic carbon negative electrode material used as a potassium ion battery negative electrode, and a product. The preparation method of the bionic carbon negative electrode material comprises the following steps: preparing a nitrogen-carbon compound (C3N4) intermediate; then catalyzing with a metal catalyst, and carbonizing at a high temperature of 700-900 DEG C; and finally, carrying out acid treatment to remove the metal catalyst, washing, and drying in a vacuum drying oven at 50-80 DEG C for 12-18 hours to obtain the biomimetic carbon negativeelectrode material similar to a biological cell structure. The negative electrode of the potassium ion battery is the biomimetic carbon negative electrode material prepared by the method, the potassium ion battery uses Prussian blue as a positive electrode, uses 4mol L<-1> of potassium bis(fluorosulfonyl) amide as an electrolyte, and uses 1, 2-dimethoxyethane as a solvent. The biomimetic carbon provided by the invention has excellent electrochemical properties such as high reversible capacity, excellent rate capability, excellent cycle performance and the like as a negative electrode materialof a potassium ion battery.

Owner:福建海峡石墨烯产业技术研究院有限公司

Anode slurry and method for preparing the same

ActiveUS10431819B2Improve performanceImprove initial Coulombic efficiencyElectrode manufacturing processesNegative electrodesSlurrySolvent

The present invention provides a method for preparing an anode slurry used in a lithium ion battery. The method includes the following steps: providing at least one anode active material, at least one conductive agent, at least one monomer or a prepolymer and at least one solvent. Mixing the anode active material, the conductive agent and the monomer or the prepolymer with the solvent; dispersing uniformly to form a mixture. Adding an initiator into the mixture; polymerizing the monomer or the prepolymer at a certain temperature; and yielding the anode slurry. Besides, the present invention also provides an anode slurry prepared by the above method, and an anode plate prepared by the anode slurry, and a lithium ion battery including the anode plate.

Owner:MICROVAST POWER SYST CO LTD +1

Silicon sealing for high performance battery anode materials

ActiveUS11081688B2Reduce areaReduce side effectsElectrode thermal treatmentNegative electrodesGraphene coatingGraphite

A battery electrode is provided that includes a porous silicon microstructure precursor, a silicon shell coating deposited on the silicon microstructure precursor, and a graphene coating deposited on the silicon shell coating, where the graphene coating encapsulates the silicon shell coating forming a graphene-encapsulated silicon-shell-protected porous silicon microstructure precursor battery electrode.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com