Electrostatic spinning nanofiber membrane as well as preparation method thereof

A nanofiber membrane, electrospinning technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of high cost, complicated process, limited popularization and application, etc., and achieve the effect of high production efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

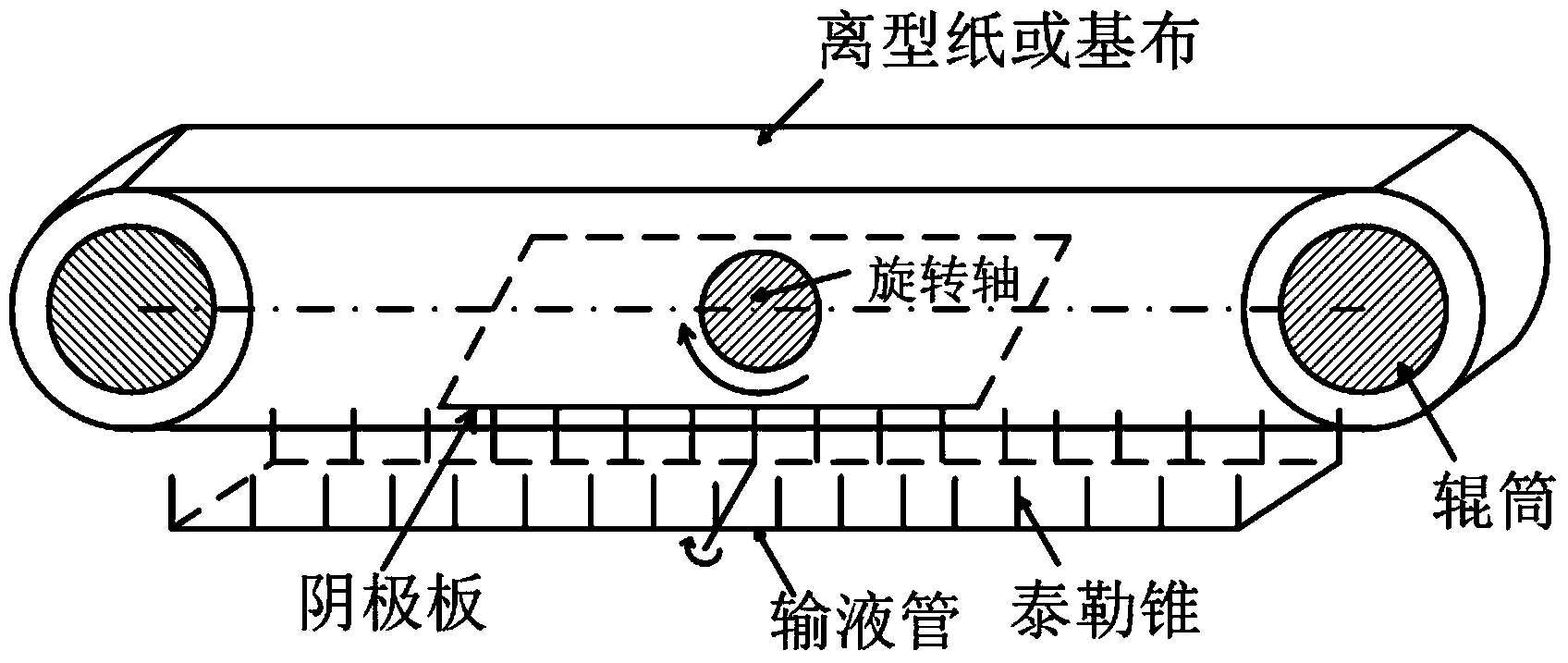

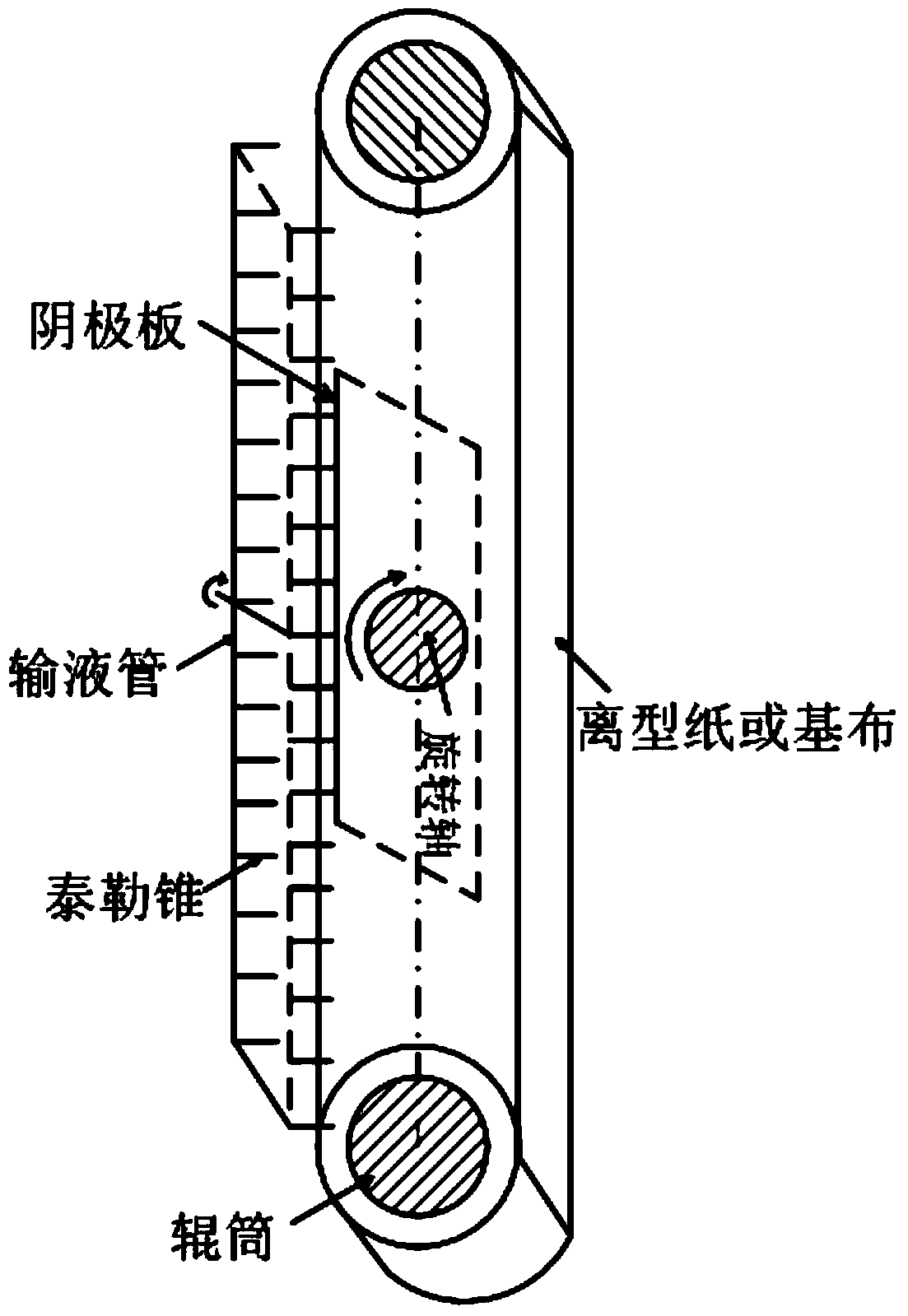

[0048] The invention provides a method for preparing an electrospun nanofiber membrane, comprising the following steps:

[0049] Dissolving the high melting point polymer in the first spinning solvent to obtain a high melting point polymer spinning solution;

[0050] dissolving the low-melting polymer in the second spinning solvent to obtain a low-melting polymer spinning solution, and the difference between the melting points of the high-melting polymer and the low-melting polymer is not less than 10°C;

[0051] performing first electrospinning on the high-melting-point polymer spinning solution to obtain a high-melting-point polymer fiber membrane;

[0052] performing second electrospinning on the low-melting-point polymer spinning solution to obtain a low-melting-point polymer fiber membrane;

[0053] The high-melting-point fiber membrane and the low-melting-point fiber membrane are combined and hot-pressed to obtain an electrospun nanofiber membrane. The temperature of th...

Embodiment 1

[0079]Dry the PET powder and PVDF powder in a vacuum oven at 110°C for 12 hours, then cool to room temperature, weigh 100g of the dried PET powder and dissolve it in a mixed solvent of 700g of trifluoroacetic acid and dichloromethane, and stir at room temperature for 12h. Obtain a transparent PET organic solution; add 1 g of nano-silica particles to the obtained PET organic solution, and ultrasonically disperse the obtained mixed solution for 6 hours to obtain a PET spinning solution for subsequent use;

[0080] Weigh 100g of dry PVDF powder and dissolve in 400g of N,N-dimethylformamide and acetone mixed solvent, stir at room temperature for 12h to obtain PVDF spinning solution, set aside;

[0081] The viscosity of the obtained spinning solution was measured to be 5.1 Pa·s, and then the PET spinning solution and the PVDF spinning solution were spun through a high-voltage electrospinning machine at a room temperature of 25°C and a relative air humidity of about 30%. During the ...

Embodiment 2

[0087] Dissolve 80g of dried polyvinylidene fluoride (PVDF) in a mixed solvent of 126g N,N-dimethylformamide (DMF) and 294g of acetone, and stir the resulting solution at room temperature for 12 hours to obtain a transparent and uniform PVDF spinning silk solution, spare;

[0088] Dissolve 80g of vacuum-dried polyethersulfone (PES) in 420g of DMF solvent, and stir and dissolve the resulting mixture in an oil bath for 12 hours to obtain a transparent and uniform PES spinning solution;

[0089] After measuring the viscosity of the spinning solution, the obtained PVDF spinning solution and PES spinning solution were mixed and cross-spun through a high-voltage electrospinning machine at a room temperature of 25°C and a relative air humidity of about 35%. During the electrospinning process of PVDF spinning solution, each Taylor cone feeding (feeding) solution speed was 2.0mL / h, the spinning voltage was 45kV, and the receiving distance was 25cm. During the electrospinning process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com