Rebaudioside A and extraction method thereof

一种莱鲍迪甙、提取方法的技术,应用在莱鲍迪甙A及其提取领域,能够解决不能得到莱鲍迪甙A、不能分离开等问题,达到成本低、处理量大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

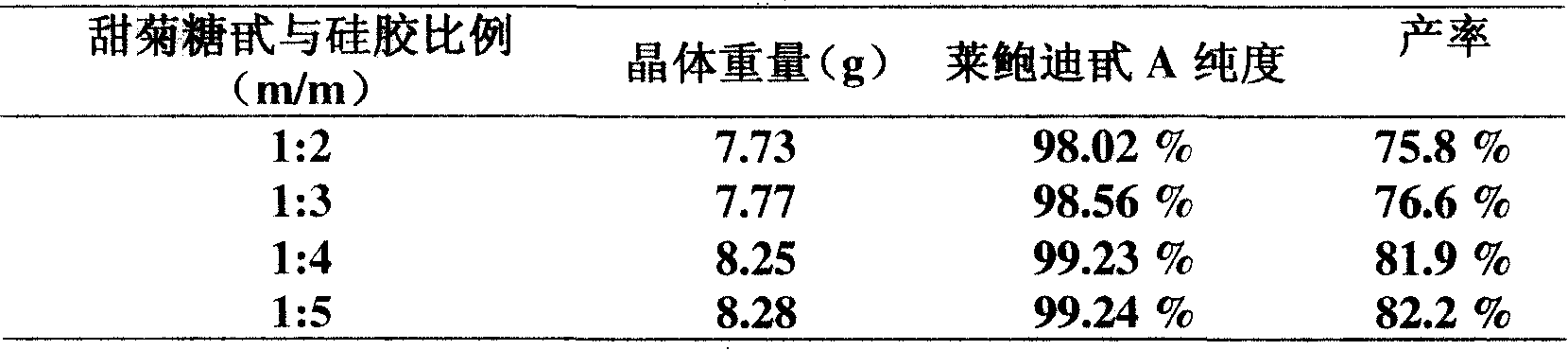

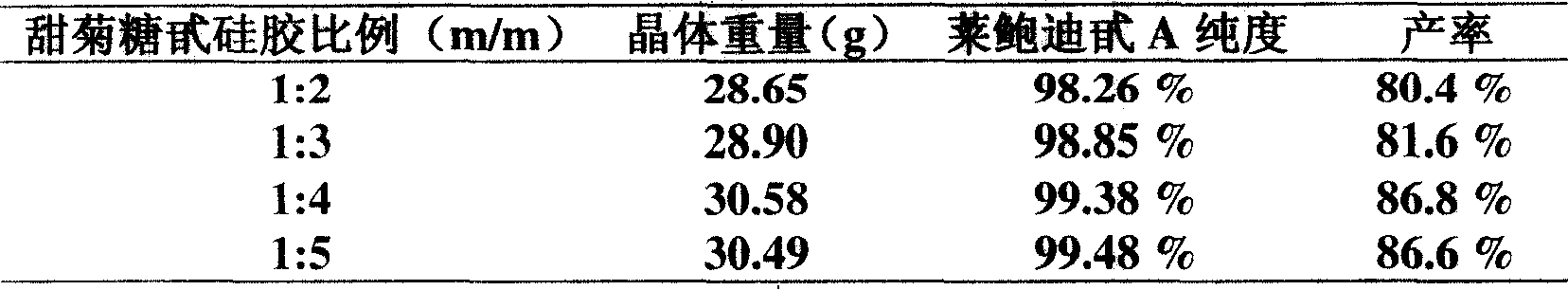

[0050] Embodiment 2 The impact of sample silica gel ratio on refining 70% rebaudioside A

[0051] According to the process of Example 1, the stevioside containing 70% rebaudioside A was refined, and the results are shown in Table 2.

[0052] Table 2 Effect of the ratio of stevioside silica gel on refining 70% rebaudioside A

[0053]

[0054] The above experimental results show that rebaudioside A with a purity ≥ 99% can be purified from stevioside through the refining process of the present invention. And when the weight ratio of stevioside to silica gel is 1:4-1:5, the purification effect is the best.

[0055] The present invention is not limited to the specific content of rebaudioside A and the specific ratio of stevioside and silica gel in the examples.

Embodiment 3

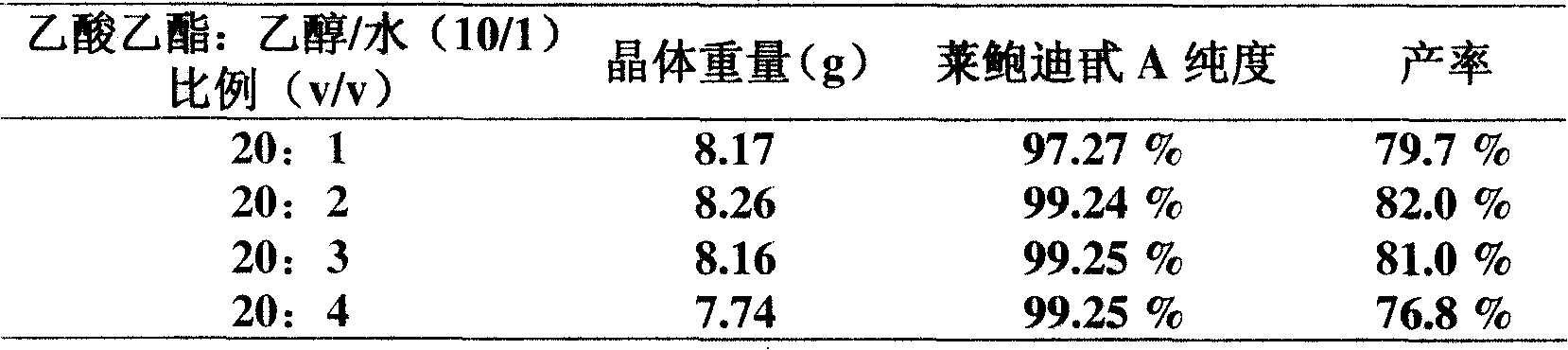

[0056] Example 3 The influence of the proportion of chromatographic eluent on refining 20% rebaudioside A

[0057] Carry out silica gel column chromatography to 4 parts of each 50.0g stevioside (containing 20% rebaudioside A) according to the sample silica gel ratio of 1: 4 (m / m), and with ethyl acetate: ethanol / water (10 / 1, v / v)=20:1~20:4 (v / v) mixed solvent for elution, and each fraction was collected separately. The rebaudioside A fractions were determined by thin-layer chromatography and then combined and concentrated to obtain rebaudioside A as a solid. Put the solid in a 250ml Erlenmeyer flask, add 5% (v / v) mixed solvent of water and ethanol at a ratio of 1:4 (m / v), heat and stir at 60°C for 4 hours, freeze and stir at -20°C for crystallization After 24 hours, the crystals were collected by filtration. The crystals were dried at 80°C to constant weight, weighed, and samples were taken for purity identification by HPLC. The experimental results are shown in Table 3...

Embodiment 4

[0062] Embodiment 4 The influence of chromatographic eluent ratio on refining 70% rebaudioside A

[0063] According to the process of Example 1, the stevioside containing 70% rebaudioside A was refined, and the results are shown in Table 4.

[0064] The impact of table 4 chromatographic eluent ratio on refining 70% rebaudioside A

[0065]

[0066] The above experimental results show that rebaudioside A with a purity ≥ 99% can be purified from stevioside through the refining process of the present invention. And the best purification effect is obtained when the volume ratio of ethyl acetate:ethanol / water (10 / 1, v / v) is 20:2-20:3.

[0067] The present invention is not limited to the specific content of rebaudioside A and the specific ratio of the chromatographic eluent in the examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com