Carrier having a special feature, catalyzer and producing method thereof

A special shape, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high porosity, poor crush resistance and wear resistance, and low porosity, etc. Achieving the effect of high porosity, high pressure crushing strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] According to the preparation method of the present invention, the raw material oxide hydrate is well known to those skilled in the art, and refers to the precursor of the oxide containing water. For example, alumina, silica, titania, magnesia, alumina-magnesia, silica-magnesia, silica-zirconia, silica-thoria, silica-beryllia, silica-titania , silica-zirconia, titania-zirconia, silica-alumina-thoria, silica-alumina-titania, silica-alumina-magnesia, silica-alumina-zirconia, clay hydrates and their mixtures. Alumina hydrate is preferred, and pseudo-boehmite is more preferred.

[0020] The material should be formable so it should be in the form of a paste, stick or dough. The method of preparing the moldable raw material from the oxide hydrate-containing raw material is a common method in the art, for example, by kneading, extruding and other methods. When adopting the customary method to prepare the raw materials, it is allowed to introduce auxiliary agents into the oxi...

example 1

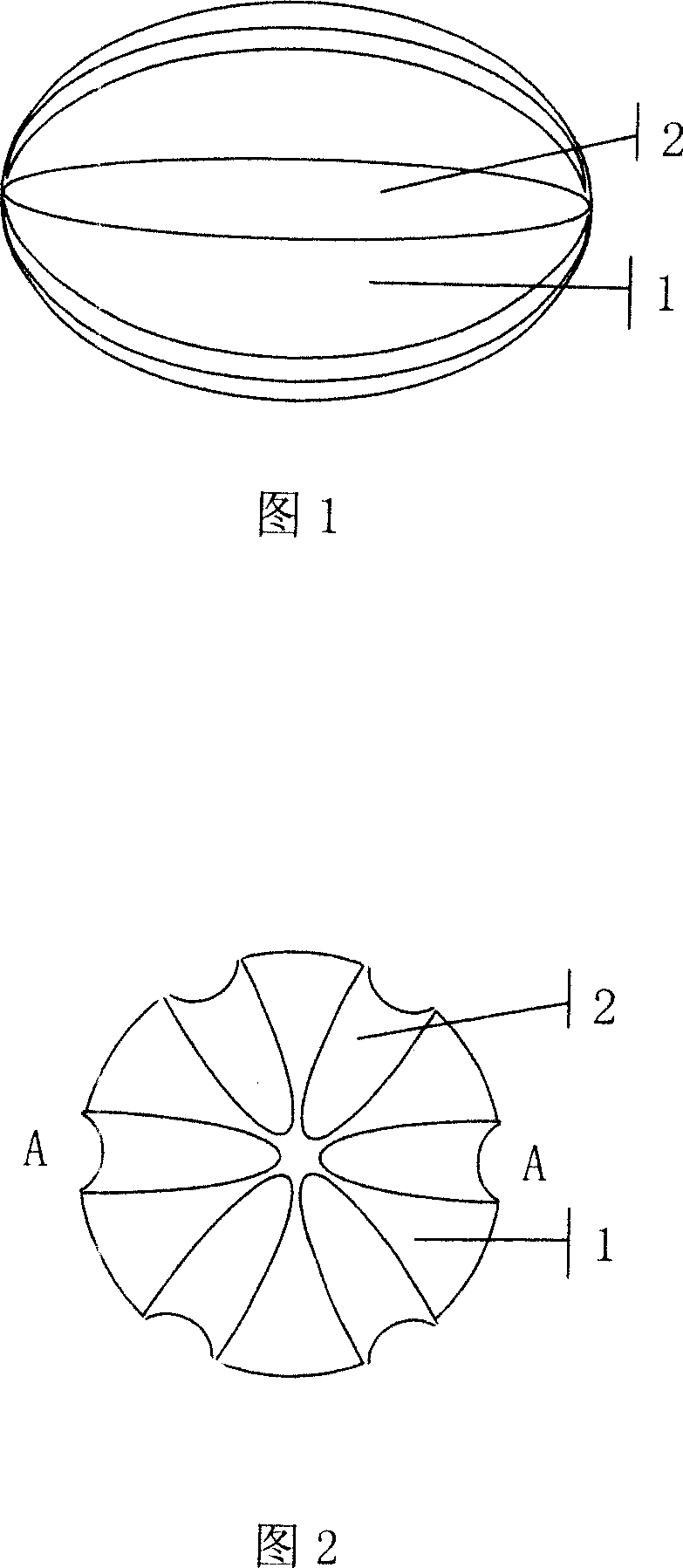

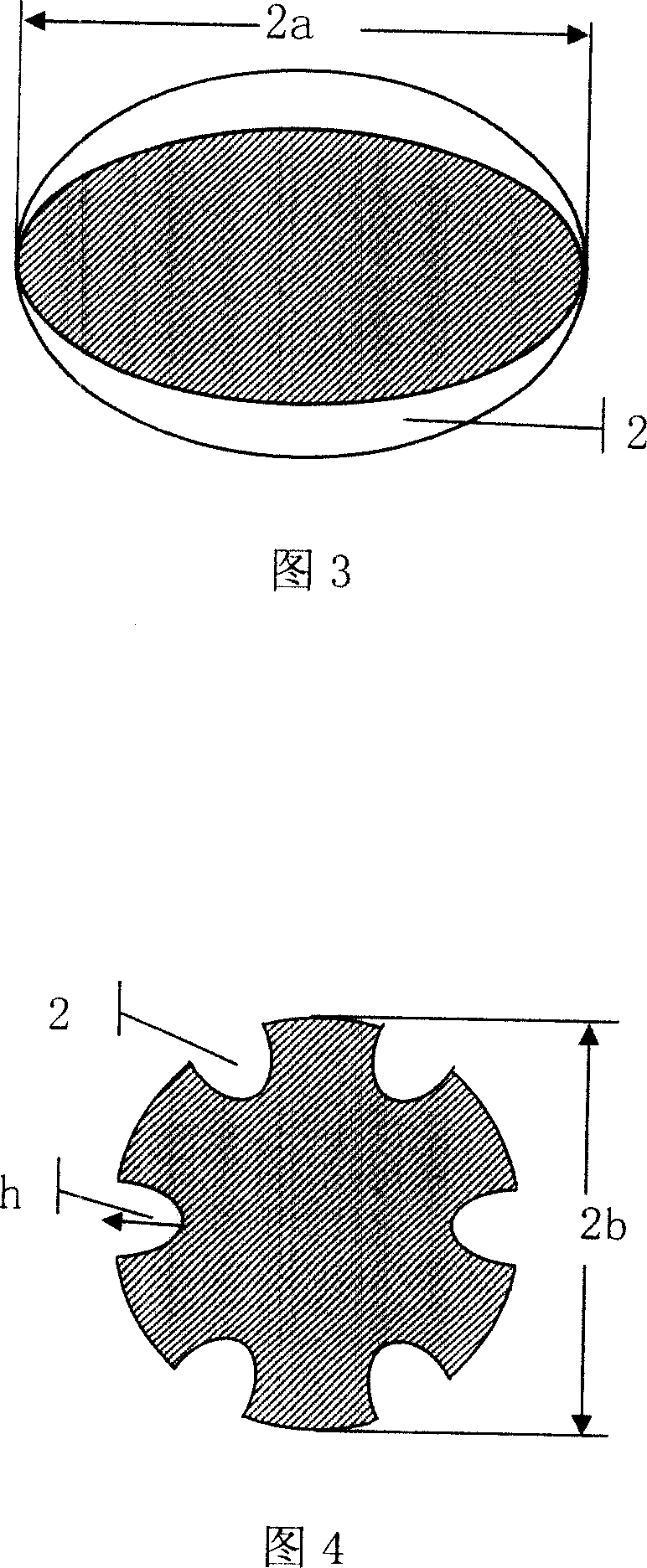

[0031] Take by weighing 300 grams of dried rubber powder (produced by Sinopec Catalyst Changling Branch Company, 73% on a dry basis), add 15 grams of fennel powder (product of Henan Lankao tianjing rubber factory), and mix evenly with 380 milliliters of dilute nitric acid aqueous solution , after kneading into a plastic body, extruded into strips on a twin-screw extruder, and pressed into a mold to obtain a Z1 catalyst carrier, the carrier dimensions (unit: mm) are shown in Table 1, and the physical and chemical properties of the carrier are shown in Table 2 shown.

example 2~ example 5

[0033] The raw materials are the same as in Example 1, and Z2, Z3, and Z4 are prepared by using different orifice plates and molds. The external dimensions of the carriers are shown in Table 1, and the physical and chemical properties of the carriers are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com