Sludge resource utilization system and method

A recycling and sludge technology, applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve a large number of problems such as high cost of flue gas purification, high fuel cost, and large flue gas volume, so as to increase biogas production and power generation, low organic matter content, and high organic matter decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment.

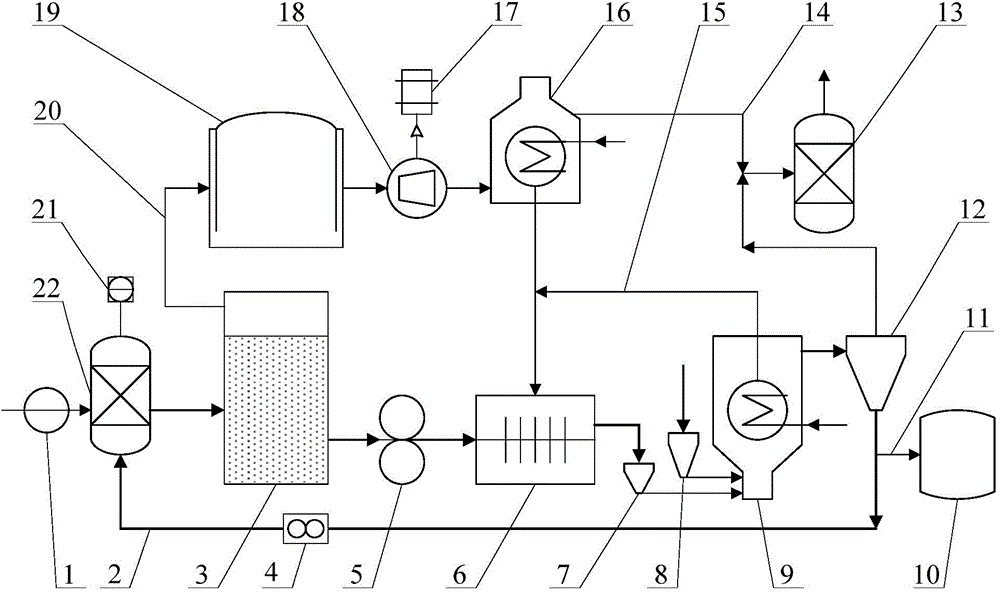

[0034] see figure 1 , a sludge resource utilization system, including a preprocessor 22 for decomposition of sludge organic matter, the preprocessor 22 is a sludge cell wall breaking device, and the specific method used is high temperature thermal hydrolysis, microwave thermal hydrolysis or Ultrasonic thermal hydrolysis, a sludge pump 1 is installed at the sludge inlet of the preprocessor 22, a pH meter 21 is arranged on the preprocessor 22, a metering device 4 is arranged at the fly ash inlet of the preprocessor 22, and the pretreatment The outlet of the device 22 is connected with the anaerobic fermentation tank 3, the biogas outlet of the anaerobic fermentation tank 3 is connected with the biogas tank 19, the sludge outlet of the anaerobic fermentation tank 3 is connected with the dehydrator 5 and the drier 6 in turn, and the sewage of the drier 6 The mud outlet is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com