Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve sulfur removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of organic composite efficient sulfur removal agent

ActiveCN106479468AEfficient removalReduce contentGaseous fuelsDrilling compositionDecompositionGlycerol

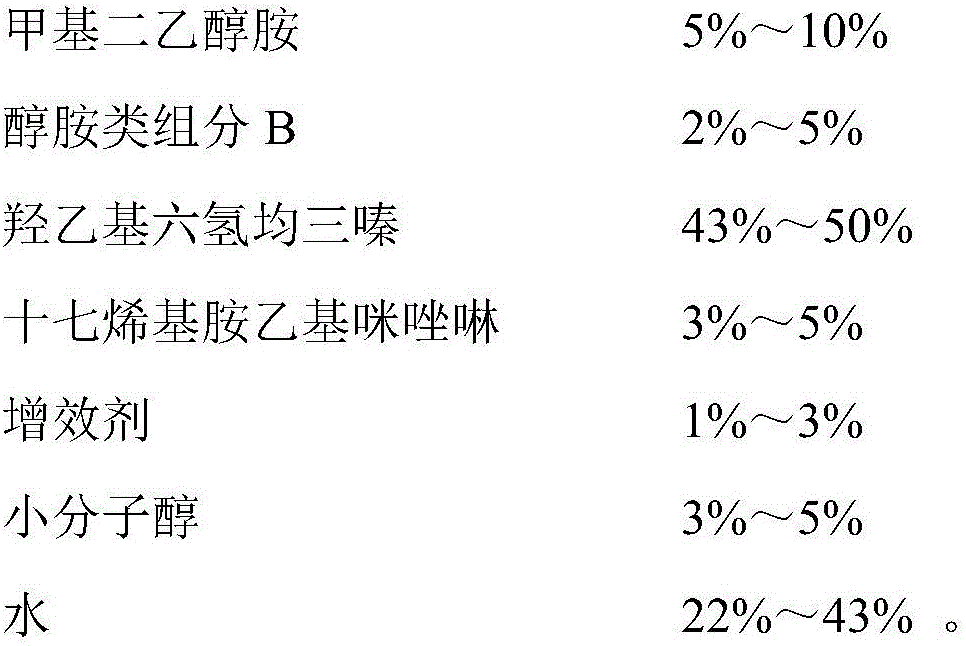

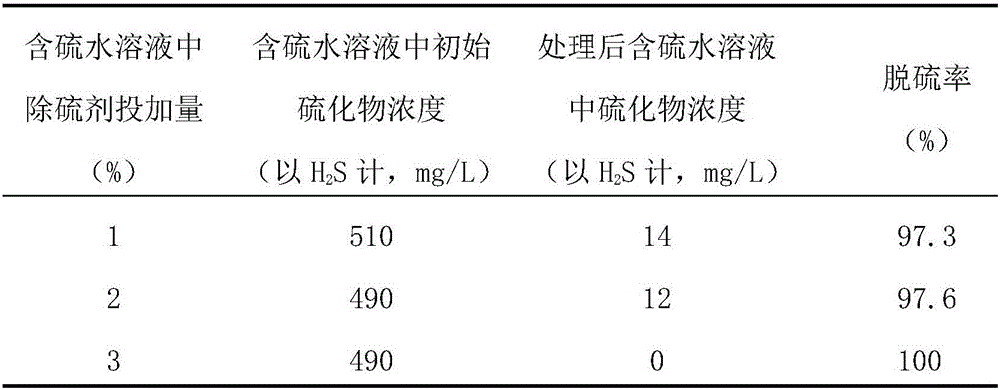

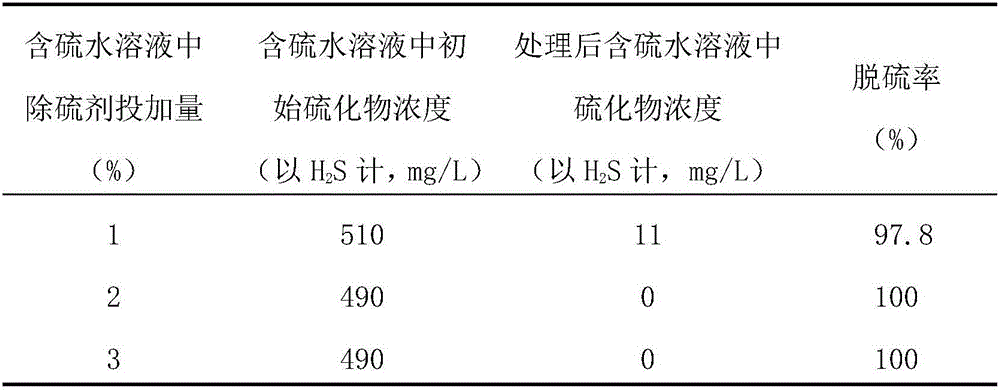

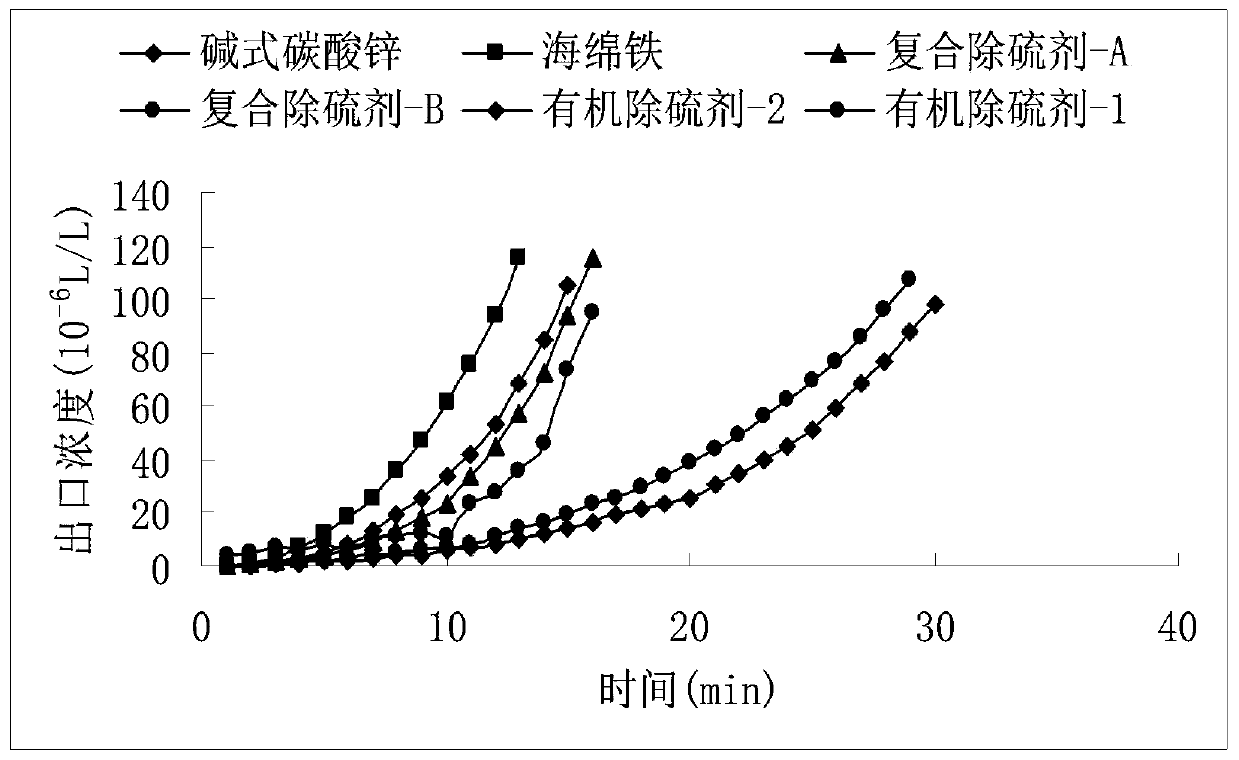

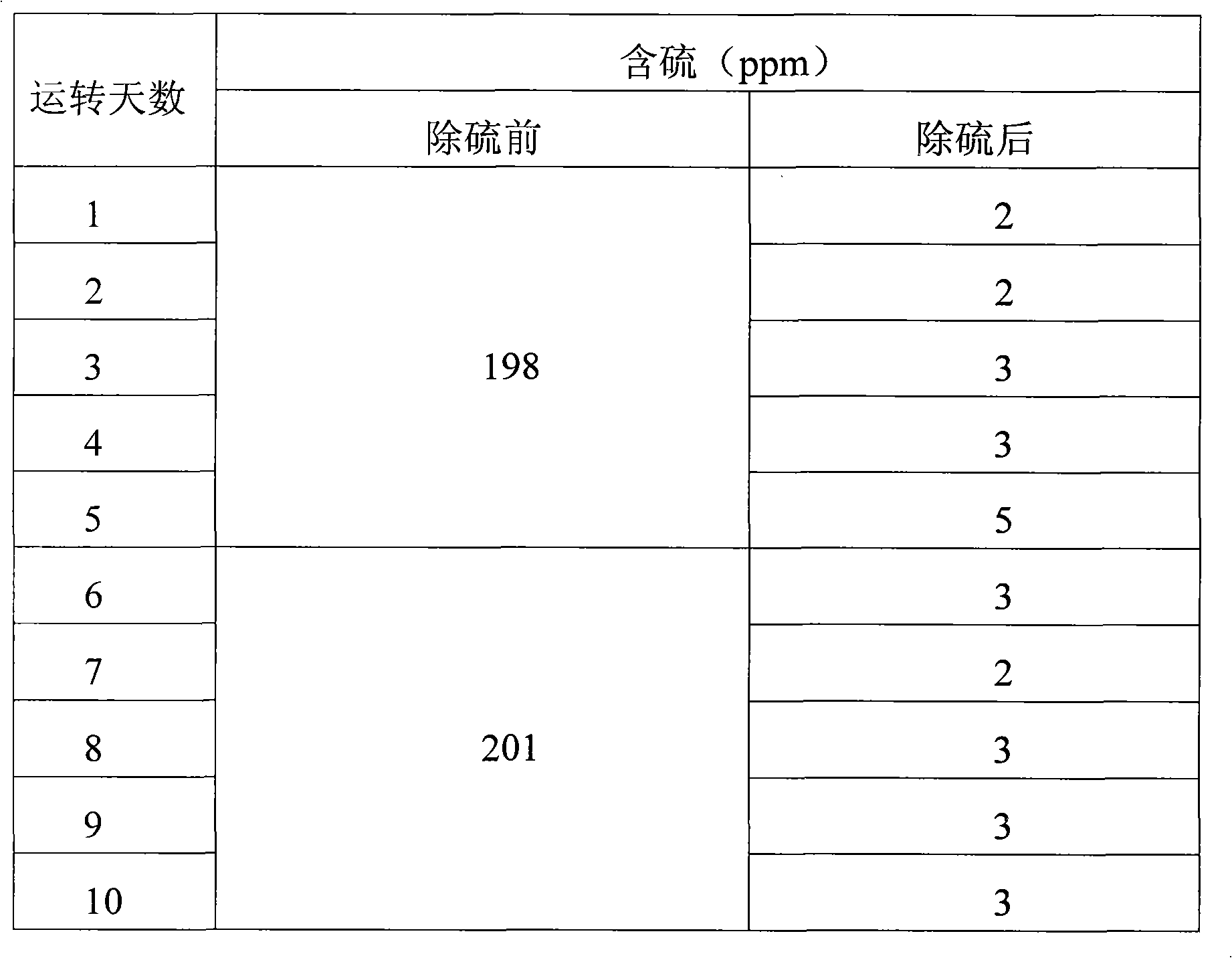

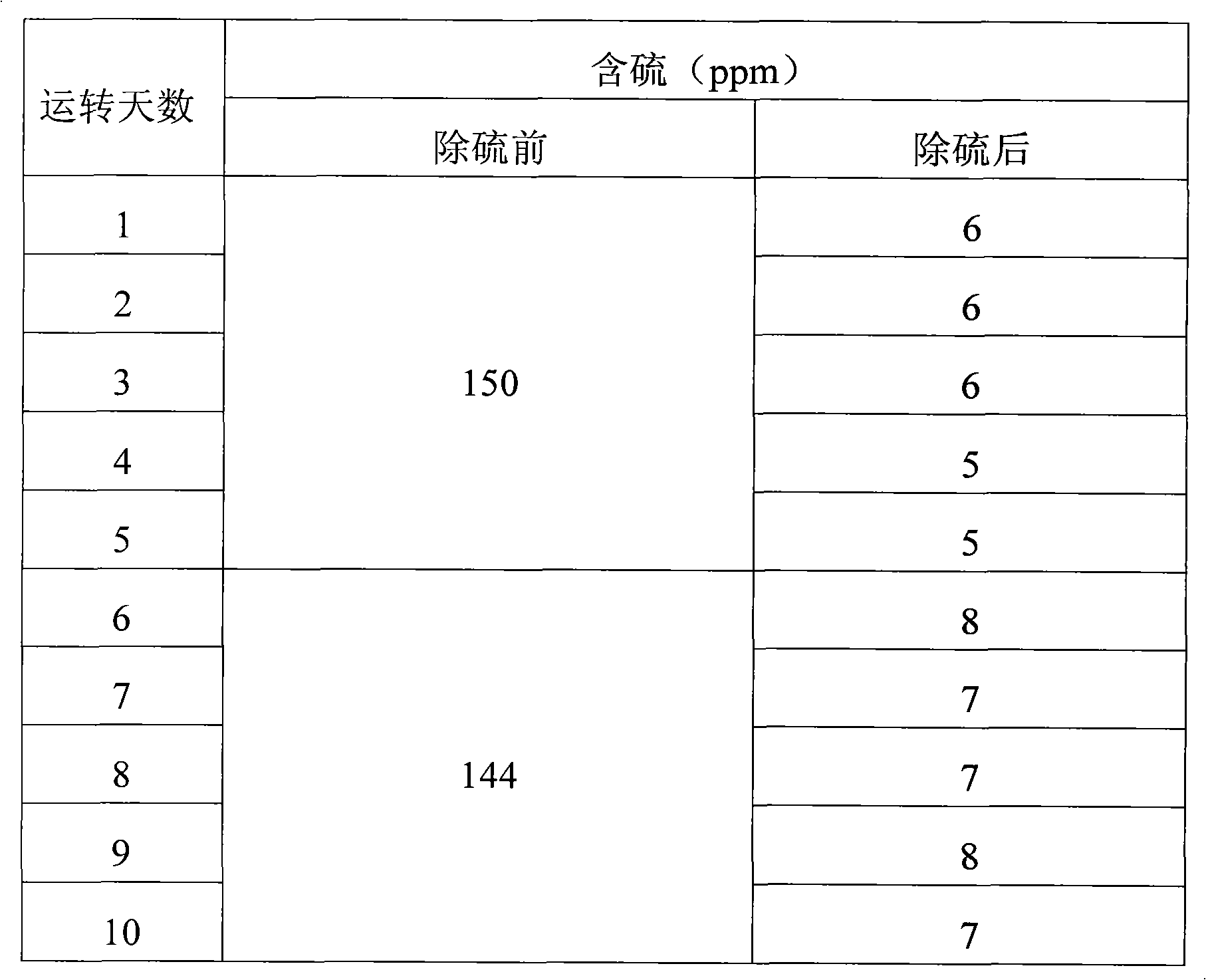

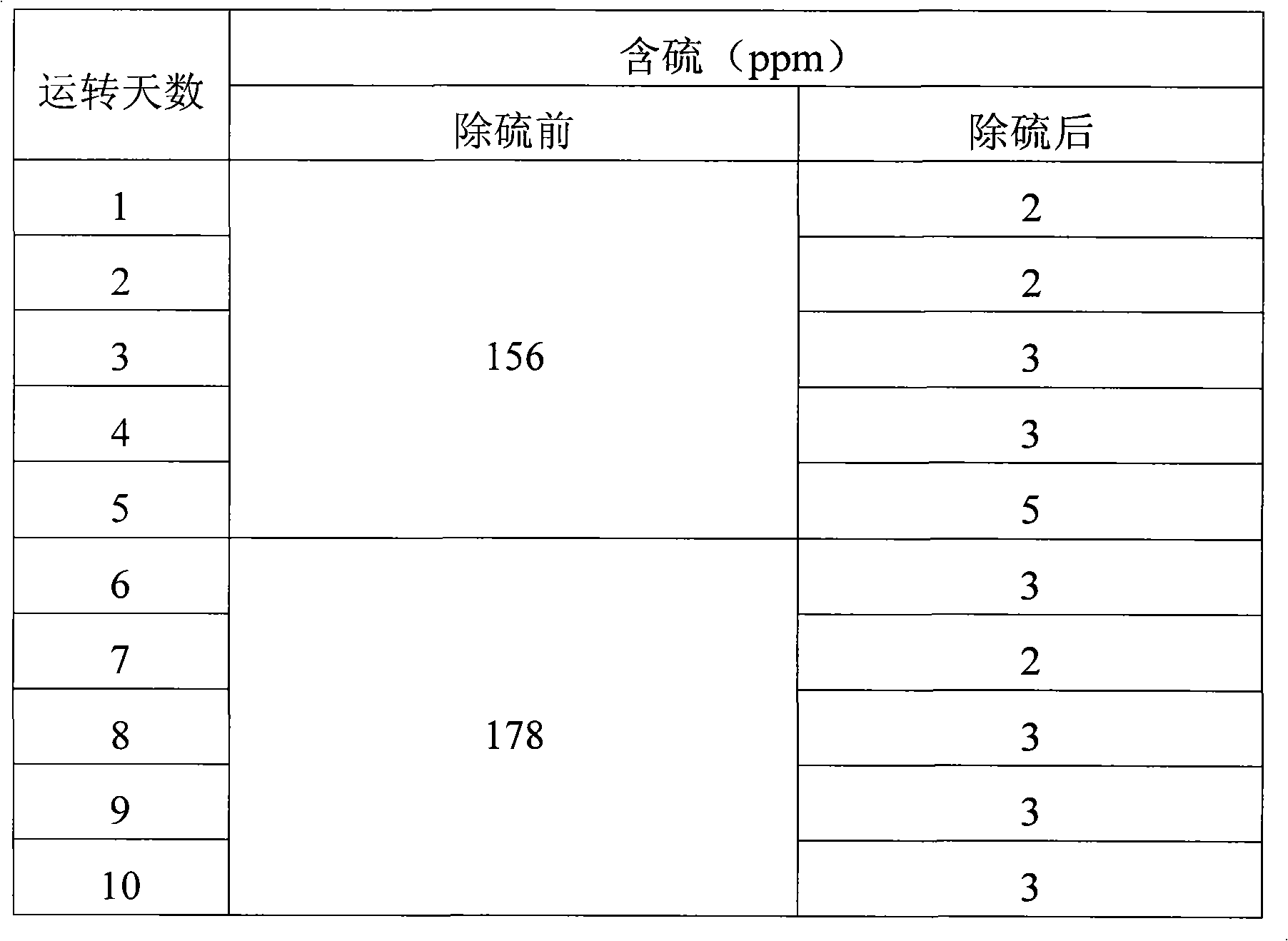

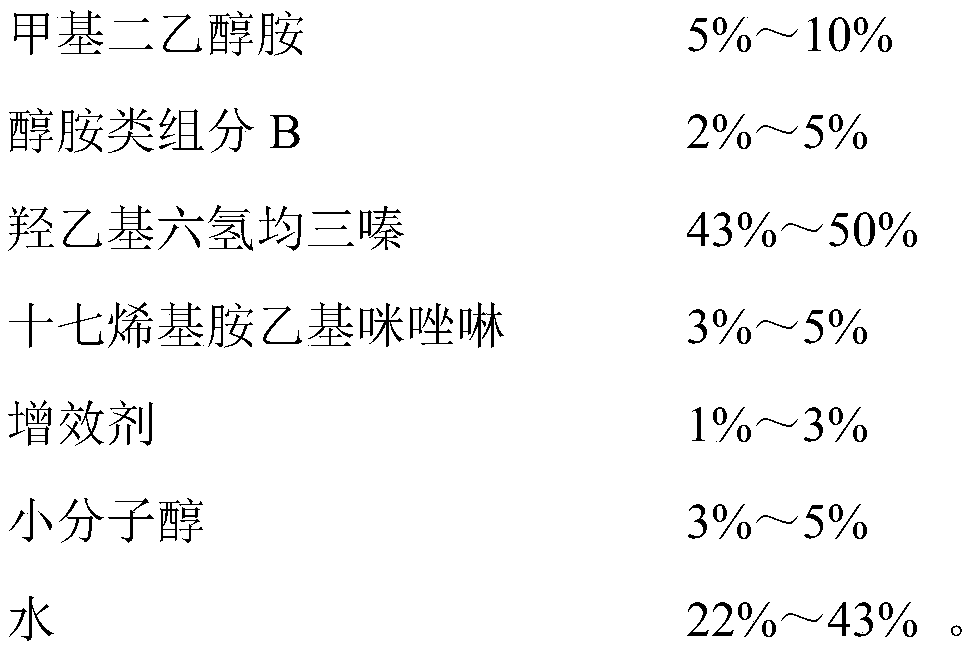

The invention discloses an organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of the organic composite efficient sulfur removal agent. The sulfur removal agent is characterized in that water serves a solvent and comprises an alcohol amine component A, an alcohol amine component B, a triazine derivative, inhibiter, synergist and low-molecular mass alcohols; the alcohol amine component A refers to methyldiethanolamine, the alcohol amine component B refers to one of triethanolamine and diethanolamine or a mixture of triethanolamine and diethanolamine; triazine derivative refers to hexahydro-1,3,5-tris-s-triazine; the inhibiter refers to seventeen alkenyl amide ethyl imidazoline; the synergist refers to sulfolane; the low-molecular mass alcohols refer to one of ethylene glycol and glycerol or a mixture of ethylene glycol and glycerol. The sulfur removal agent has the advantages of good selectivity on sulfuretted hydrogen, small dosage, quick effect, high sulfur removal efficiency, no corrosion of steel, stable product performance, difficulty in heating decomposition, capability of being biodegradable and the like; sulfide like sulfuretted hydrogen existing in extraction of an oil-gas well can be effectively removed or reduced to safety threshold value range in content, corrosion of sulfide on pipelines and equipment is inhibited, and safety on the equipment and operation personnel is guaranteed.

Owner:陕西森瑞石油技术开发有限公司

Clean green fuel and its prepn process

InactiveCN101067100AClean and efficient useLarge specific surface areaSolid fuelsLiquid carbonaceous fuelsCombustionGranularity

The present invention discloses one kind of clean green fuel and its preparation process. The preparation process includes the steps of: crushing coal to average size smaller than 2 mm, adding water to form slurry, superfine treating the slurry and adding desulfurizing agent. The present invention applies superfine treating technology and separating technology in treating coal to increase the specific surface area, raise combustion efficiency and raise desulfurizing rate, so as to realize the clean efficient combustion of coal at low cost.

Owner:武汉隆兴裕环保设备有限公司

Environment-friendly sulfur removal agent and removal technology thereof

ActiveCN107723042AReduce usageReduce fouling and cloggingGaseous fuelsHydrocarbon oils refiningWater solubleTriazine derivative

The invention relates to the technical field of organic sulfur removal, in particular to an environment-friendly sulfur removal agent and a removal technology thereof. The environment-friendly sulfurremoval agent is prepared from triazine derivatives, an anti-scaling agent and an activating agent in a certain ratio, wherein in percent by volume, the triazine derivatives accounts for 65-90%, the anti-scaling agent accounts for 1-30%, the activating agent accounts for 5-10%, the triazine derivatives react with organic sulfur, the anti-scaling agent is used for inhibiting scaling of high-hardness gas field water, the organic sulfur is insoluble in water, and the triazine derivatives are water soluble, so that the activating agent is used for quickening reaction between the triazine derivatives and the organic sulfur, and products after reaction are soluble in water. A filling technology adopts spray filling, the filling is carried out by adopting a spraying mode behind a sulfur removal tower in a gas field with high sulfur content, spray filling is directly carried out at the wellhead in a gas field with low sulfur content, and the average particle size during filling is less than 40microns. Compared with the traditional sulfur removal agent, the novel environment-friendly sulfur removal agent has the characteristics of high filling efficiency, no toxicity, no harm, no secondarypollution and applicability of products to industrial production.

Owner:CHINA PETROLEUM ENG & CONSTR +1

Novel hydrogen sulfide scavenger for drilling liquid and preparing method of hydrogen sulfide scavenger

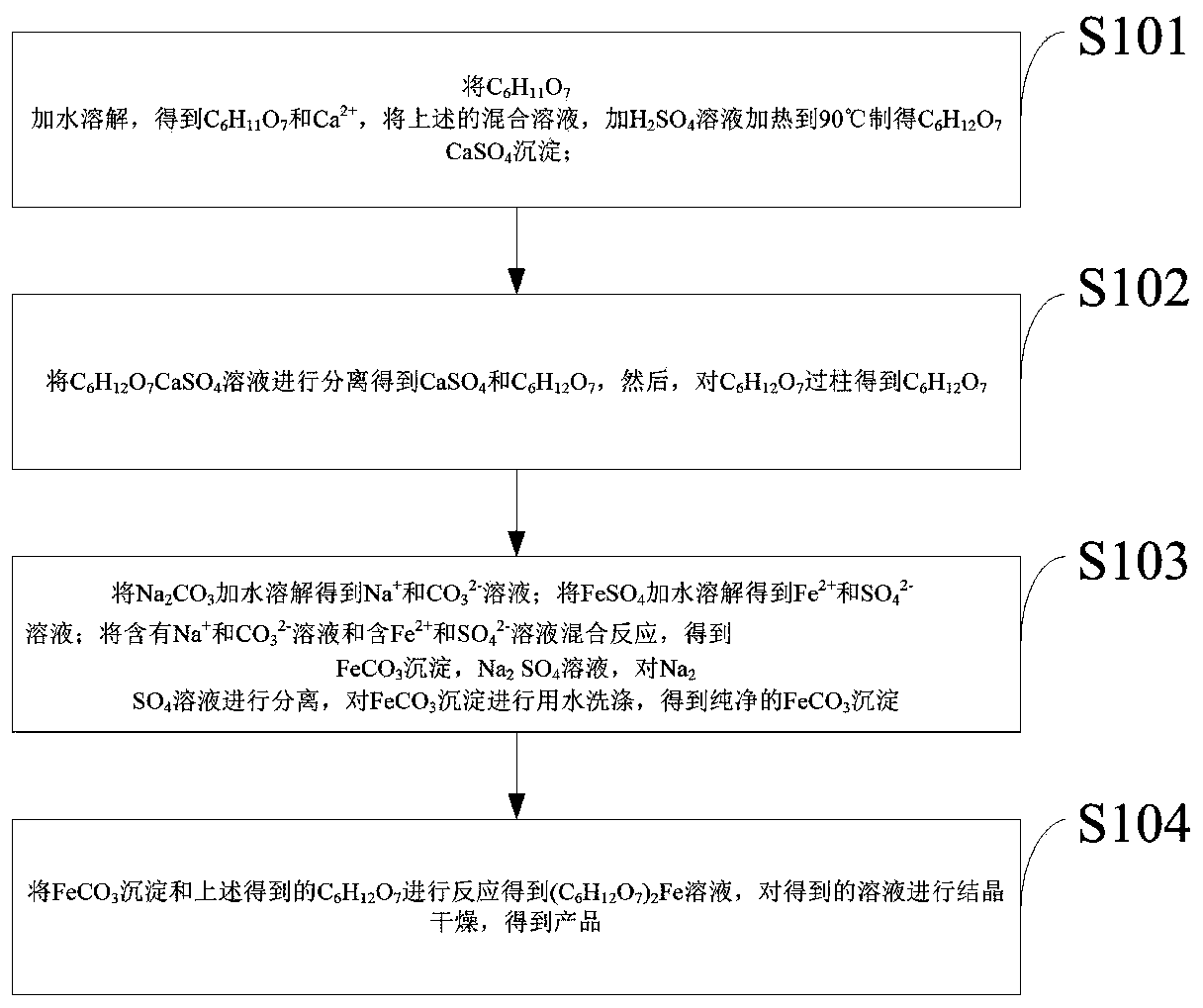

InactiveCN109777392AImprove solubilityCreate pollutionDrilling compositionCarboxylic acid salt preparationSolubilityScavenger

The invention belongs to the technical field of removal of hydrogen sulfide gas of drilling shafts, and discloses a novel hydrogen sulfide scavenger for drilling liquid and a preparing method of of the hydrogen sulfide scavenger. Ferrous gluconate organic matter is adopted for the first time as a sulphur removal reagent for the drilling liquid, ferrous gluconate is a carbohydrate, the solubility is large, and dissolved ferrous ions quickly react with sulphur ions to generate a precipitate; the ferrous gluconate serves as the carbohydrate, and cannot pollute a drilling liquid system or oil andgas reservoirs; a chemical experiment evaluation is carried out between the ferrous gluconate and the hydrogen sulfide gas, the function law, the optimal function condition and the function mechanismof the ferrous gluconate and the hydrogen sulfide gas are determined, the harm concentration of the hydrogen sulfide gas intruding into a shaft can be greatly lowered, the corrosion of the hydrogen sulfide gas to a downhole drilling tool is reduced, and theoretical foundations and technical supports are provided for domestic exploitation of sulfur-containing oil and gas reservoirs.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of realizing clean combustion of petroleum coke

InactiveCN1931979AClean and efficient useLarge specific surface areaSolid fuelsCombustionReaction rate

The present invention is method of realizing clean combustion of petroleum coke. The method includes the following steps: crushing petroleum coke with high pressure roller, adding water to form slurry, adding desulfurizer, and superfine treating. The present invention has submicron superfine technology and separating technology applied in the treatment of petroleum coke, and the treated petroleum coke with greatly increased specific surface area can raise the combustion efficiency greatly and raise the desulfurizing reaction rate greatly to realize the clean combustion of petroleum coke.

Owner:汪景武

Method for removing sulphur from coking benzol

ActiveCN101602647AReduce consumptionLess "three wastes"Molecular sieve catalystsChemical modification purification/separationBenzeneMolecular sieve

The invention relates to a method for removing sulphur from coking benzol, belonging to the technical field of organic chemical engineering; and the invention in particular relates to continuous sulphur removal technology of coking benzol; the coking benzol, solvent, oxidant and titanium-silicon molecular sieve catalyst particles are added in a slurry bed reaction kettle and are reacted under the temperature of 10-90 DEG C, and the reacted products are divided into oil-phase slurry and water-phase slurry, alkaline washing and water-washing layering are carried out to the oil-phase slurry for obtaining sulphur-removal benzene, and the water-phase slurry is returned to the reaction kettle. After being treated, the coking benzol contained about 200ppm of sulphur contains 0-5ppm of sulphur; the method has simple flow, less three wastes and high yield coefficient and is easy to realize industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Energy-saving and environment-friendly limestone-gypsum wet flue gas desulfurizing tower

InactiveCN111617604AAvoid enteringEven and complete contactGas treatmentCalcium/strontium/barium sulfatesFlue gasSlurry

The invention relates to the field of flue gas desulfurizing, in particular to a limestone-gypsum wet flue gas desulfurizing tower. A first liquid extracting pump and a liquid extracting pipe are utilized; limestone slurry is conveyed into a flowing cavity through a liquid conveying pipe. Finally, an atomizing nozzle is used for spraying; the area of the desulfurizing tower at the lower part of apartition plate is filled with atomized limestone slurry; flue gas entering the desulfurizing tower through a flue gas pipe and an air blower can be in more uniform and complete contact with the slurry; the reaction degree of the slurry and the flue gas is improved; the sulfur removal efficiency is improved; by continuously reacting the flue gas with the slurry, generated new liquid beads are gathered at the conical cylinder part of the desulfurizing tower, and enter an oxidation treatment box through a conveying pipe, oxygen is supplied through an oxygen supply fan, substances entering the oxidation treatment box are subjected to oxidation treatment in the oxidation treatment box to generate gypsum, redundant liquid can be conveyed into a limestone slurry cylinder through a second liquidsuction pump to be recycled, energy is saved, and the environment is protected.

Owner:CRYSTAL WATER & BLUE SKY ENVIRONMENTAL ENG

Method for removing sulphur and iron of sodium aluminate solution

ActiveCN102976381BImprove sulfur removal efficiencyTightly boundAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagSulfur

Owner:CENT SOUTH UNIV

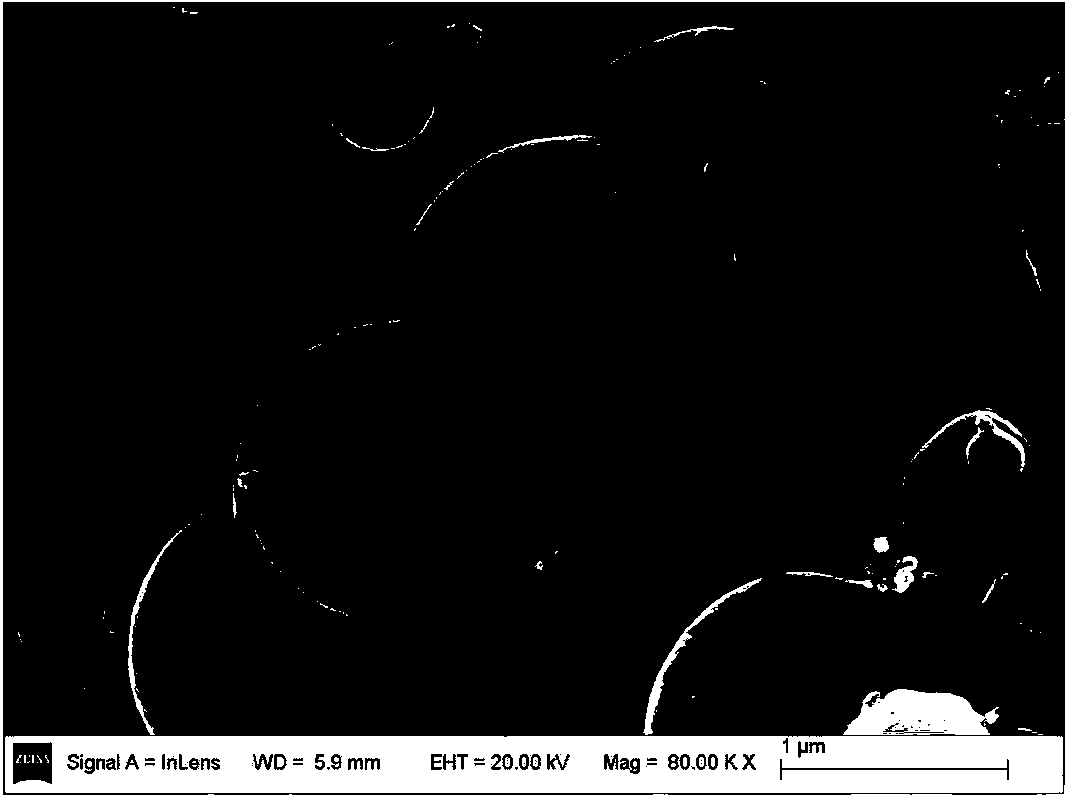

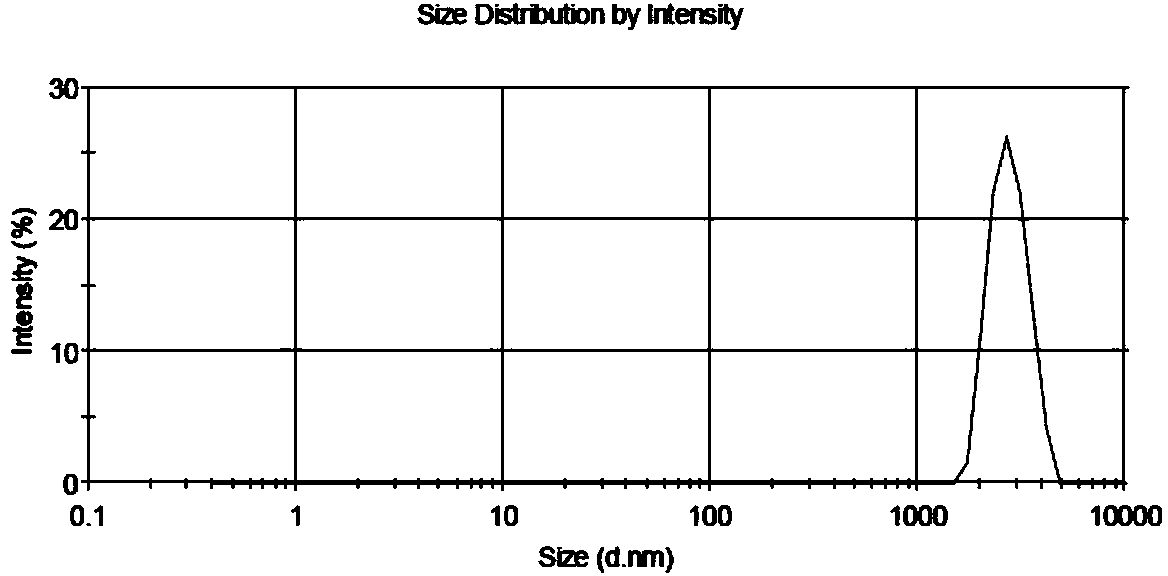

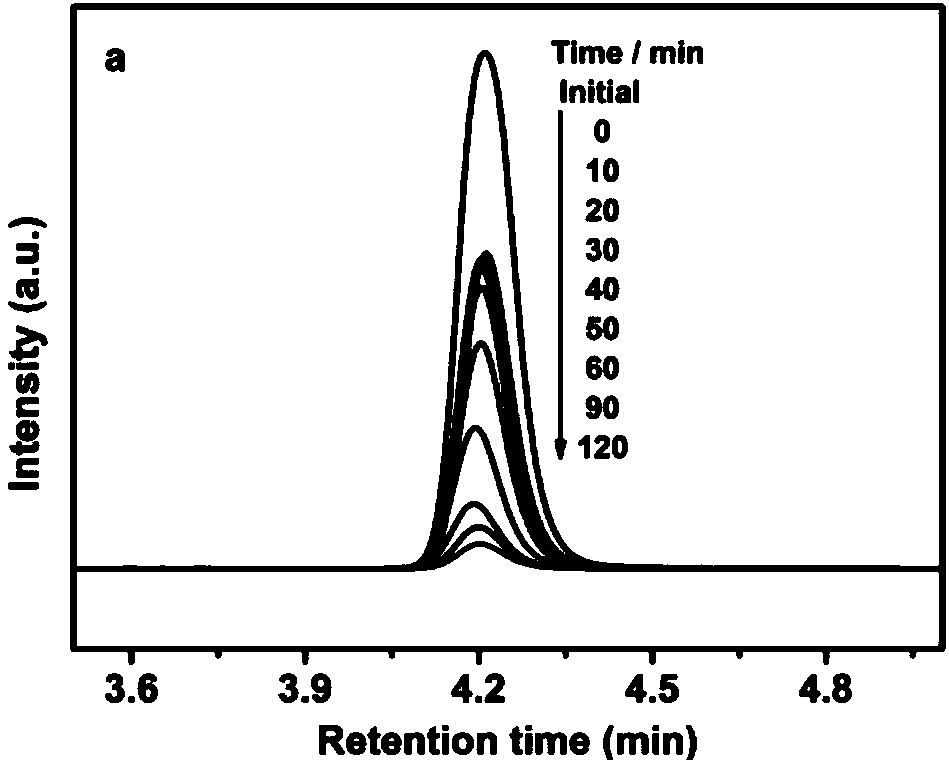

Method for synthesizing phosphotungstic acid-titanium dioxide composite spherical nanometer material by one-step sol-gel method

InactiveCN103962185AEasy to prepareAvoid consumptionMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystHigh energy

The invention discloses a method for synthesizing a phosphotungstic acid-titanium dioxide composite spherical nanometer material by a one-step sol-gel method and belongs to the technical field of preparation of functional nanometer materials. The method avoids complex experimental steps and high energy consumption of solvent-induced self-assembly and hydrothermal methods and greatly simplifies the experimental flow. The shape and size of the prepared phosphotungstic acid-titanium dioxide composite spherical nanometer material are controllable. The material with the spherical-like nanometer structure has high sulphur removal efficiency and is applied to a sulphur removal reaction by extraction combined with catalytic oxidation. DBT simulated oil with sulphur content being 350ppm can be degraded to reach the sulphur content of 4.8ppm by 70mg of catalyst within 2h. The novel preparation method of the nanometer catalyst is simple, has the characteristics of good thermal stability, less energy consumption of equipment and environmental friendliness, and is expected to be actually developed in and applied to the sulphur removal industry production.

Owner:BEIJING UNIV OF CHEM TECH

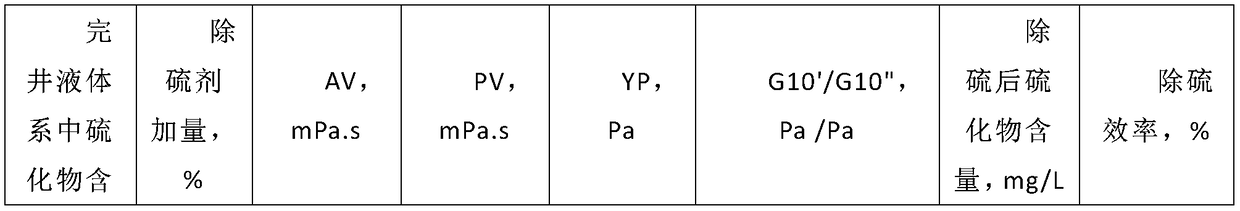

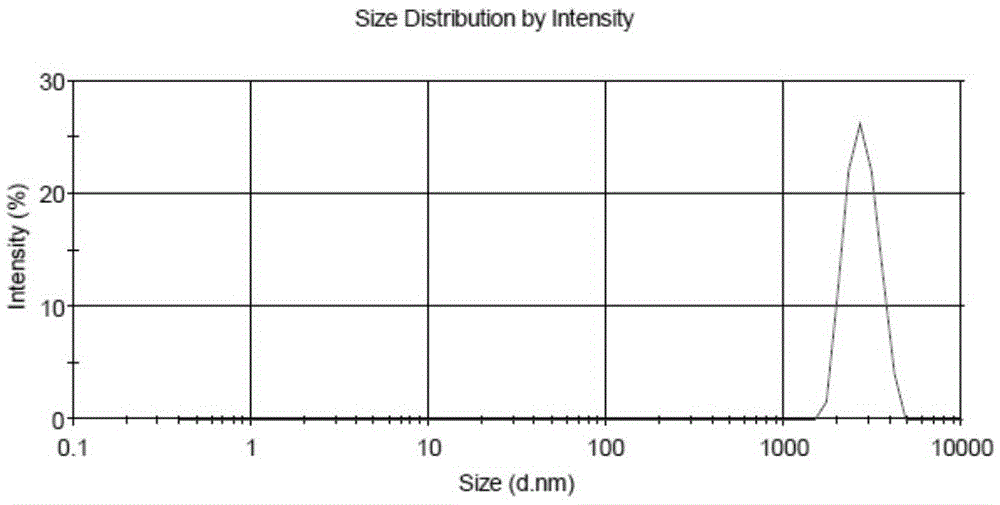

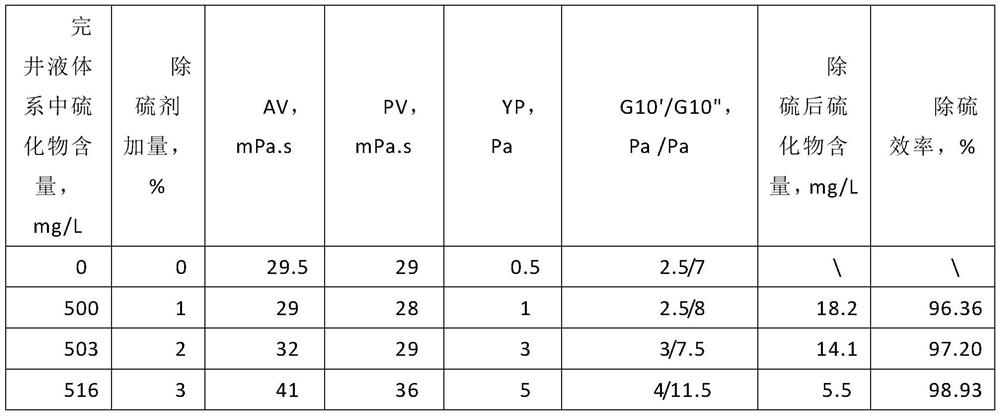

Preparation method of suspension liquid desulfurization agent for water-based oil testing well completion fluid system

ActiveCN108865094ALow viscosityLow sulfur removal efficiencyDrilling compositionBorehole/well accessoriesWater basedHydrogen

The invention discloses a preparation method of a suspension liquid desulfurization agent for a water-based oil testing well completion fluid system. The suspension liquid desulfurization agent is prepared from the following raw materials in parts by weight: 5 to 8 parts of a surface modifying agent, 0.8 to 1 part of an emulsifier, 1 to 3 percent of a dispersant and 10 to 30 parts of nano-powder;the preparation method comprises the following steps: adding the surface modifying agent into isopropyl alcohol in a container A; heating to 60 to 80 DEG C and stirring to form a uniform solution; adding the dispersant, the emulsifier and the nano-powder into a water solution with the pH (Potential of Hydrogen) of 9 to 10 in a container B; heating to 60 to 80 DEG C and stirring to form a uniform solution; under the action of rapid stirring, adding the uniform solution formed in the container A into the container B and stirring for 2h to form slurry which is uniformly dispersed; cooling to roomtemperature. According to the preparation method disclosed by the invention, the desulfurization agent and a well completion fluid system treatment agent are not gathered and consolidated under a high-temperature condition of 180 DEG C; the desulfurization agent does not influence the rheological property and sedimentation stability of the well completion fluid system under the high-temperature condition, and the aim of high desulfurization efficiency is realized.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Emulsification, combustion and desulphurization process of industrial heavy fuel

InactiveCN101805645ALess investmentImprove sulfur removal efficiencyMixing methodsLiquid carbonaceous fuelsCombustionEngineering

The invention relates to an emulsification, combustion and desulphurization process of an industrial heavy fuel, comprising the following steps of: preparing a sulfur-removing assistant, preparing emulsified oil, and removing sulfur. The invention has the advantages of low equipment investment, high sulfur-removing efficiency, low running cost, rapid and thorough reactive transformation and high utilization rate of a desulfurizing agent; the addition amount of the desulfurizing agent can be adjusted along the sulfur content of the fuel so that the invention achieves balanced energy efficiency; reactive products are beneficial and innocuous for the qualities of sintering and fusing products, in particular for molten glass, and the dosages of a fusing assistant and a clarifying agent can be reduced.

Owner:HANGZHOU ZHONGYING TECH GRP

Sulfur removing agent capable of rapidly removing carbonyl sulfide from tail gas

ActiveCN108525483AHigh efficiency in removing organic sulfurImproved efficiency of organic sulfur removalGas treatmentDispersed particle separationAlkalinityOrganic solvent

The invention relates to the technical field of carbonyl sulfide removing, in particular to a novel sulfur removing agent capable of rapidly removing carbonyl sulfide from tail gas. The removing agentcomprises amine with extremely strong alkalinity, activating agent, cosolvent and volatile organic solvent, and the removing agent is a special sulfur removing agent capable of rapidly removing the carbonyl sulfide from the tail gas and is prepared by the above materials according to a certain proportioning . Compared with a traditional sulphur removing agent, the novel sulphur removing agent isspecially used for removing the carbonyl sulfide, the removing efficiency is high, the novel sulphur removing agent is free from toxin and harmless, industrial production can be achieved, by means ofthe novel sulphur removing agent, the removing rate of methanthiol and ethanethiol can reach 99.5% or above, the removing problem of carbonyl sulfide can be solved, the carbonyl sulfide removing efficiency is high, the removing speed is fast, the tail gas can be purified to an extent that the total sulphur residue rate is lower than 20 ppm, which is higher than the national discharging standard ofnot more than 35 ppm, the converting cost of existing gas field is greatly saved and the operating benefit is improved.

Owner:CHINA PETROLEUM ENG & CONSTR +1

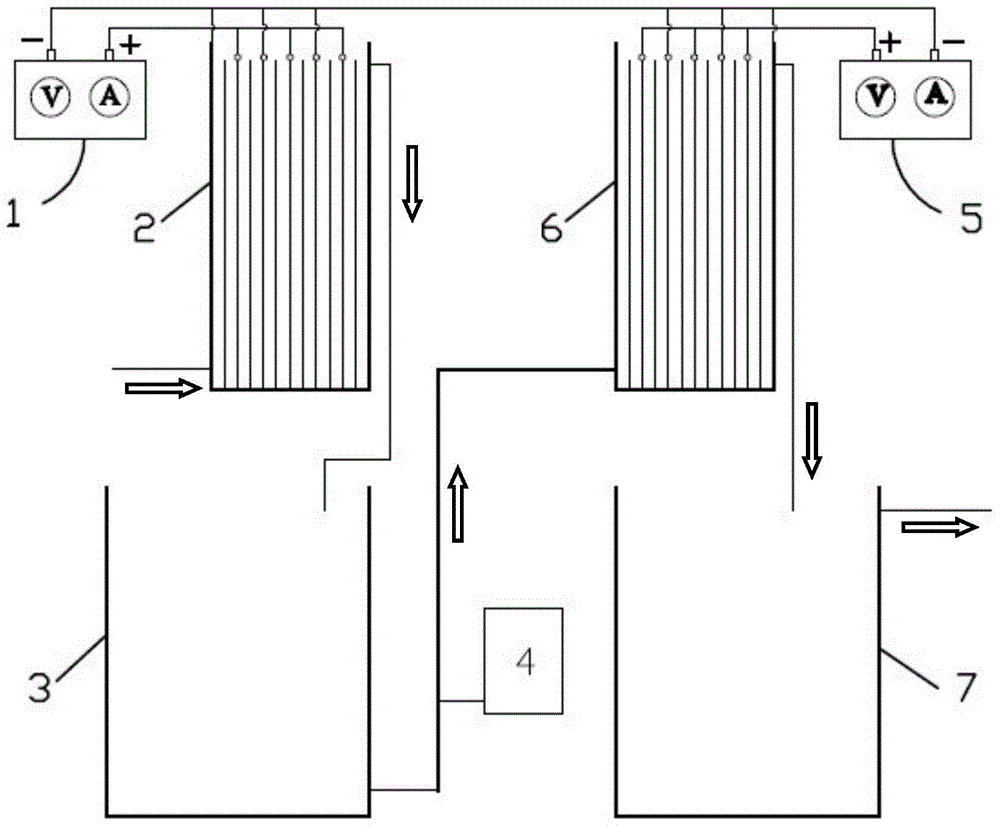

A method and special device for removing sulfide in water

ActiveCN104071929BImprove desulfurization effectAdaptableMultistage water/sewage treatmentHigh concentrationChemical treatment

The invention relates to the technical field of water purification and particularly relates to a method for efficiently removing sulfide in water and a special device for the method. Two-stage electrochemical treatment is carried out by using a two-stage chemical treatment device, and iron or iron alloy is used as an anode in the two-stage electrochemical treatment, wherein high-concentration sulfide in water is treated in the first-stage electrochemical treatment stage by means of the oxidation effect of the anode and the sedimentation effect of ferrous irons generated by dissolving iron anodes, and low-concentration sulfide in water is rapidly and thoroughly removed through adding a proper amount of hydrogen peroxide before second-stage electrochemical treatment by means of ferrous ions generated by uniformly dissolving the hydrogen peroxide and the anode, fenton reaction generated by electrochemical effects and an electrocatalytic effect. When the method is used for treating sulfide-contained wastewater or domestic drinking water, the removal rate of sulfide can be more than 99.9%. Generally speaking, after sulfide-contained wastewater and domestic drinking water are treated by using the method provided by the invention, the content of sulfide can be respectively up to the discharging standard and the drinking water standard.

Owner:江阴和悦鑫环保科技有限公司

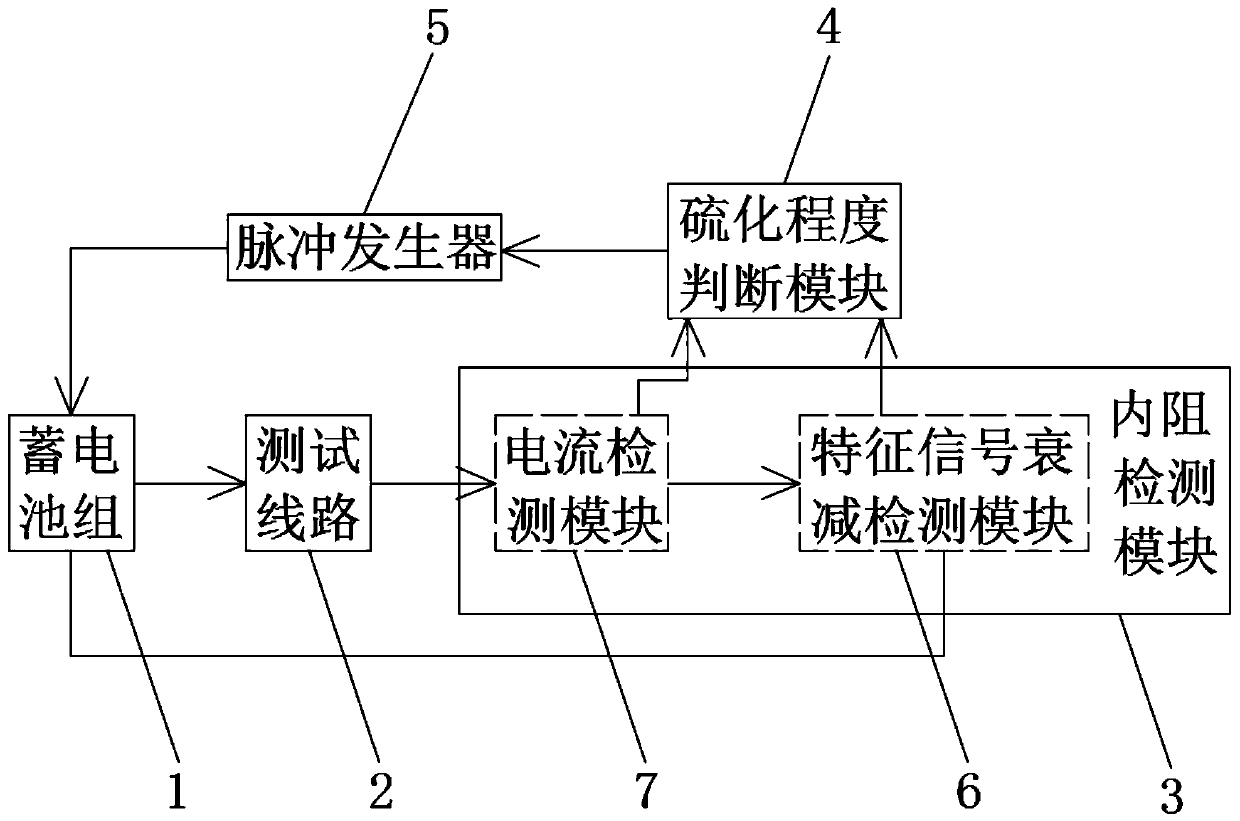

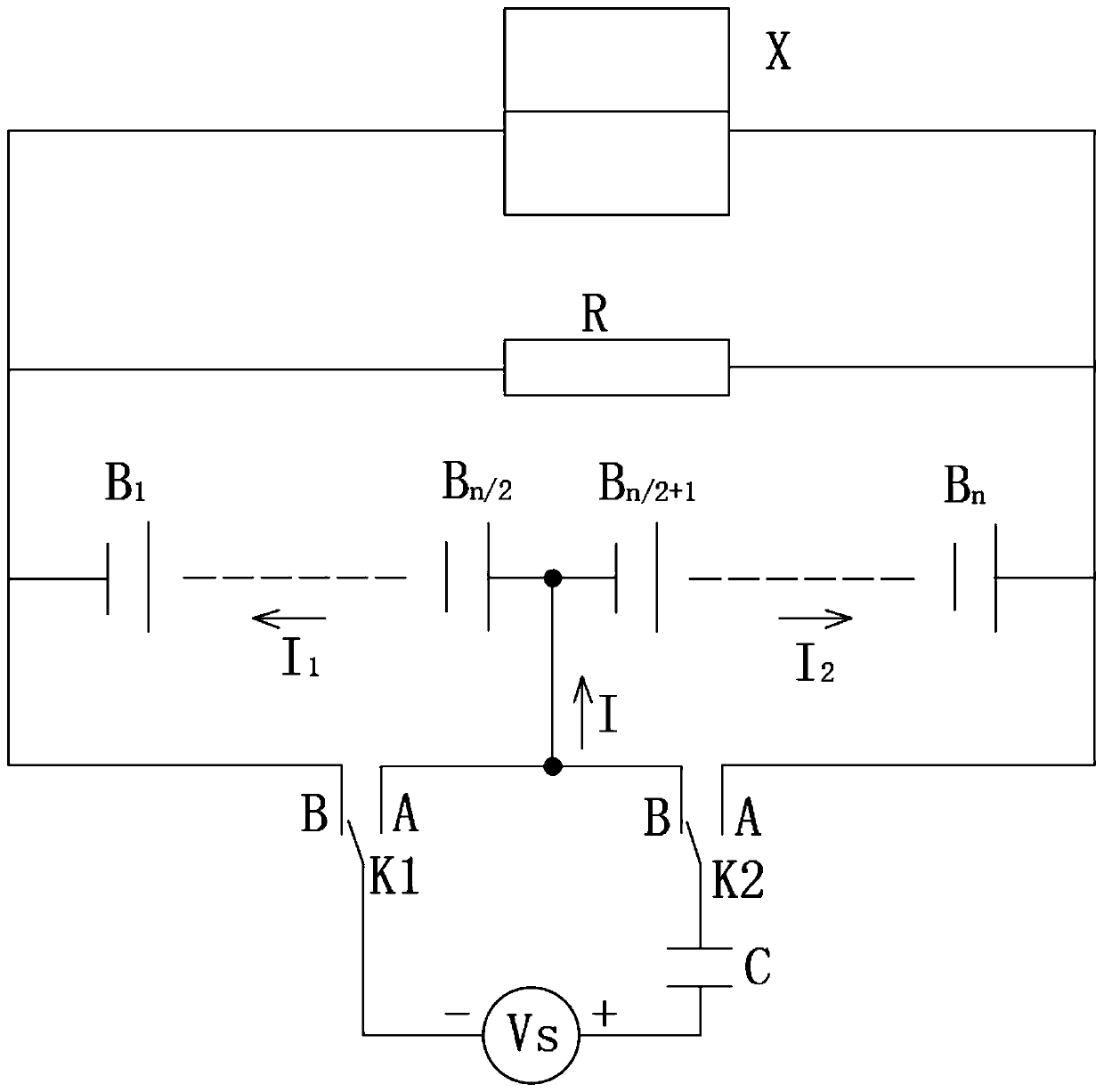

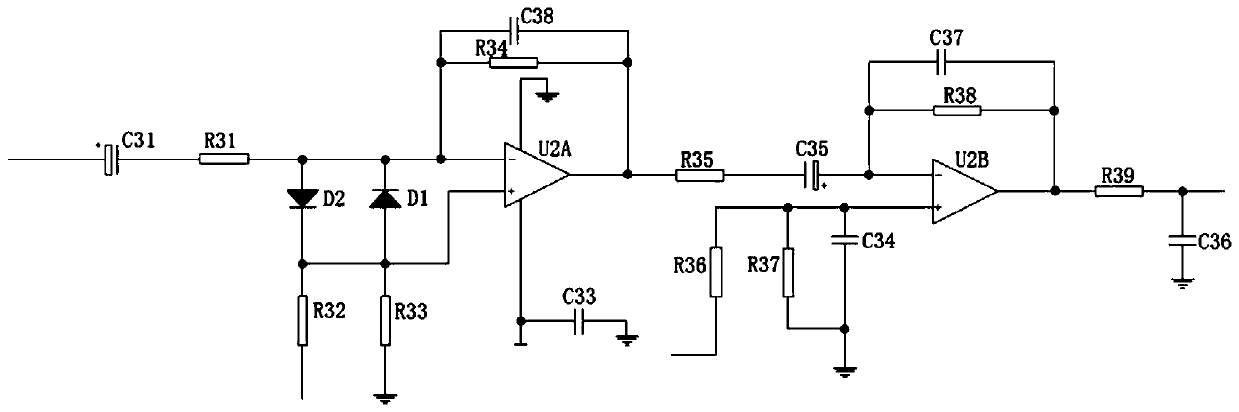

Online desulfurization system and method for storage batteries based on frequency conversion signals

ActiveCN110828917AImprove sulfur removal efficiencyGuaranteed measurement accuracyResistance/reactance/impedenceElectrolyte/reactants regenerationFrequency conversionInternal resistance

The invention provides an online desulfurization system and method for storage batteries based on frequency conversion signals. A test circuit is connected to a storage battery pack, the storage battery pack is divided into a front half pack and a rear half pack through two sets of single-pole double-throw switches, the internal resistance of the front half storage battery pack and the internal resistance of the rear half storage battery pack are measured, and the vulcanization degree of the storage batteries is judged according to a standard internal resistance information table of the storage batteries, so that pulse signals with the corresponding frequency can be selected according to the vulcanization degree, the desulfurization effect is guaranteed, and the conditions that desulfurization cannot be conducted due to the over-low pulse signal frequency and that the storage batteries are damaged due to the over-high pulse signal frequency can be prevented at the same time. On the other hand, the front half storage battery pack and the rear half storage battery pack can be exchanged by switching the single-pole double-throw switches to be closed towards the other movable end, so that the measurement precision of the internal resistance of the storage batteries is improved, the influence of errors of internal resistance measurement on the judgment of the vulcanization degree isprevented, the desulfurization effect is ensured, and meanwhile, the resource waste and the manpower use are reduced.

Owner:海南电力产业发展有限责任公司

Coal desulfurization and decoking process

InactiveCN106433854ABurn fullyReduce desulfurization costSolid fuelsCombustion chamberBoiler furnace

The invention belongs to the technical field of boiler fuel, and particularly relates to a coal desulfurization and decoking process. The process comprises the following steps: preparing a desulfurizer by modifying chlor-alkali salt sludge, and blending with coal before feeding into a boiler combustion chamber, wherein the addition amount of the desulfurizer accounts for 0.8-1.2% of the weight of the coal; and when the combustion temperature in the combustion chamber exceeds 800 DEG C, spraying the desulfurizer into the combustion chamber in a mist form through a boiler furnace spray gun, wherein the addition amount of the desulfurizer accounts for 0.4-0.6% of the weight of the coal. Compared with the prior art, the coal desulfurization and decoking process has the following advantages: the chlor-alkali salt sludge is effectively utilized, and desulfurization is performed twice before combustion and in the combustion process, so that the desulfurization efficiency is greatly improved, thereby ensuring that the coal can be sufficiently combusted at high combustion stability; coke residues in the combustion chamber are loose and easy to fall; and secondary pollution is decreased. Thus, the desulfurization cost of a large power plant can be lowered.

Owner:马鞍山科宇环保设备股份有限公司

Micro-foaming rubber runway and preparation method thereof

PendingCN111849080AImprove sulfur removal efficiencyIncrease elasticityGround pavingsPolyurethane adhesiveEthylene-propylene-diene-monomer

The invention provides a micro-foaming rubber runway. The micro-foaming rubber runway comprises micro-foaming rubber particles and a polyurethane adhesive, the polyurethane adhesive is used for adhering and curing the micro-foaming rubber particles to form the micro-foaming rubber runway, the micro-foaming rubber runway layers are stacked and are adhered and cured through a polyurethane adhesive to form the micro-foaming rubber runway layers, the micro-foaming rubber particles are prepared from the following raw materials in parts by weight: 100 parts of ethylene propylene diene monomer, 20-30parts of a reinforcing agent, 3-7 parts of a vulcanizing agent, 3-5 parts of a coupling agent, 5-10 parts of a foaming agent and 1-5 parts of an anti-aging agent, and the foaming agent comprises thefollowing components in parts by weight: 4-8 parts of an AC foaming agent and 1-2 parts of 2, 5-ditert-pentylhydroquinone. The invention provides the micro-foaming rubber runway with good elasticity,good tensile and tear resistance and excellent anti-aging performance and a preparation method of the micro-foaming rubber runway.

Owner:湖北晟弘新材料有限公司

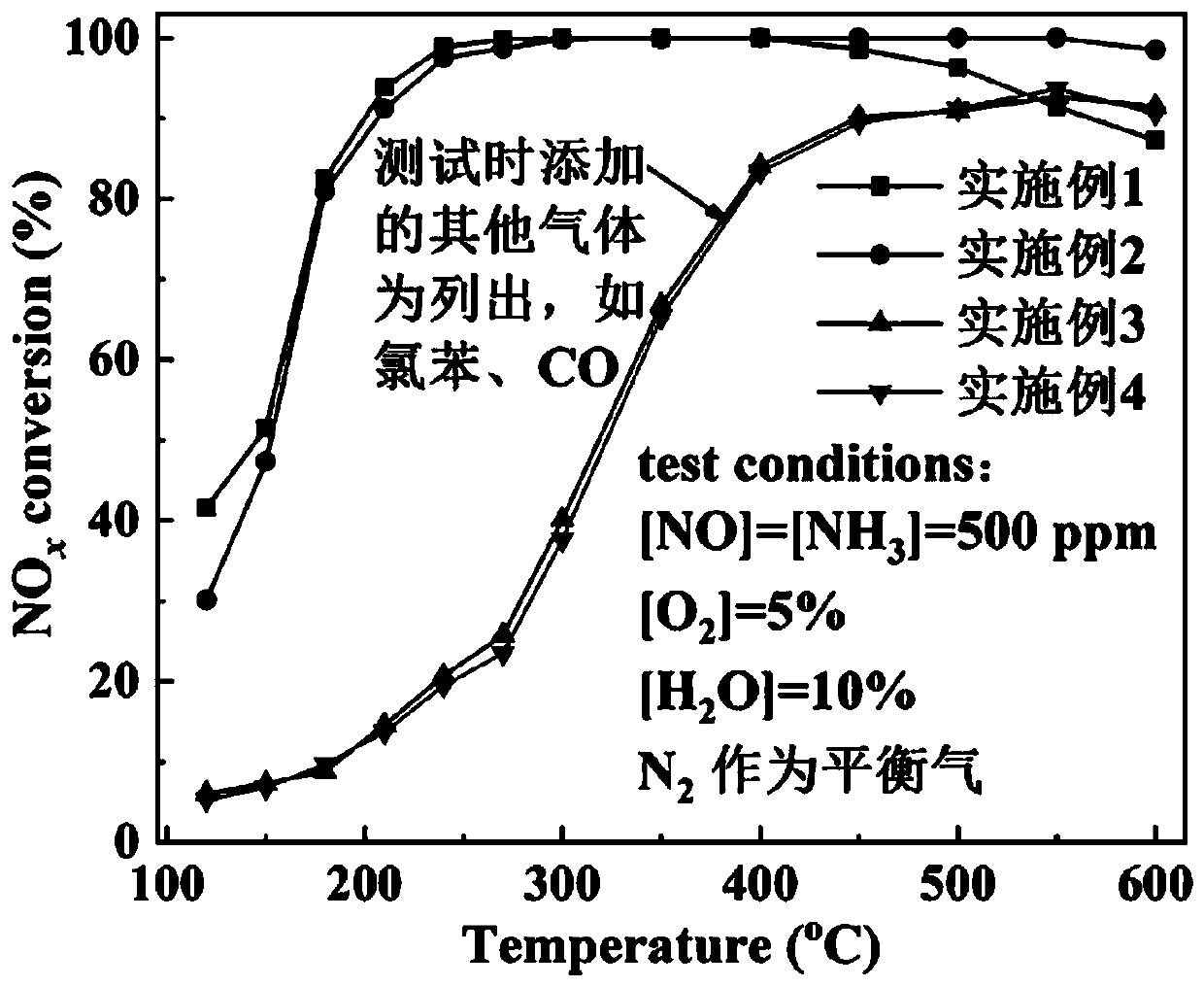

Preparation process and application of composite titaniferous solution for waste gas catalytic purification

ActiveCN111013567AIncrease contact areaImprove performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberPhysical chemistry

The invention discloses a preparation process and application of a composite titaniferous solution for catalytic purification of waste gas. The process comprises the following steps: pumping an alkaline gas into a metatitanic acid slurry which is continuously stirred by a bubbling method to realize desulfurization, adding a strong acid or a strong alkali solution and a dispersing agent into a titanium cake obtained by desulfurization, grinding to obtain ultrafine titaniferous solution, adding an active component, an auxiliary agent and a stabilizing agent which are soluble under strong acid orstrong alkali conditions, and stirring to form composite titaniferous solution; carrying out uniform loading of the obtained product into a wall flow type carrier (such as a ceramic fiber pipe, a filter bag, a basalt filter pipe, a DPF and the like) with rich pore structures in a pressurizing or negative pressure extraction form, wherein the coated carrier can be used for denitration of a fixed source and a movable source. The composite titaniferous solution disclosed by the invention has the excellent properties of ultrafine granularity, high dispersion degree, strong permeability and the like, the production period can be greatly shortened and the production cost can be reduced when the composite titaniferous solution is used for coating the wall flow type carrier, and the produced catalytic purification product can be used for efficiently and synergistically removing various atmospheric pollutants and preventing a catalytic material from poisoning.

Owner:SHAOXING UNIVERSITY

Desulfurization method for aluminium oxide production based on high-sulfur bauxite

InactiveCN107986309AImprove sulfur removal efficiencyEliminate serious security risksAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationActivated carbonCorrosion

The invention relates to a desulfurization method for aluminium oxide production based on high-sulfur bauxite and belongs to the technical field of environmental protection and metallurgy. A reducingagent is added to slurry in a process of aluminium oxide production based on high-sulfur bauxite for desulfurization, wherein the reducing agent is one or a mixture of activated carbon, aluminium, iron and zinc in any ratio. According to the method, variable-valence sulfur such as S<2->, S2O3<2->, SO3<2-> and SO4<2-> in various forms in a solution can be removed, and desulfurization efficiency ishigh; meanwhile, the defect of severe potential safety hazard possibly caused by corrosion of sulfur to a heater wall can be overcome.

Owner:KUNMING UNIV OF SCI & TECH

A kind of organic composite high-efficiency sulfur removal agent for oil and gas fields, its preparation method and application

ActiveCN106479468BImprove desulfurization effectSimple preparation processGaseous fuelsDrilling compositionDecompositionGlycerol

The invention discloses an organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of the organic composite efficient sulfur removal agent. The sulfur removal agent is characterized in that water serves a solvent and comprises an alcohol amine component A, an alcohol amine component B, a triazine derivative, inhibiter, synergist and low-molecular mass alcohols; the alcohol amine component A refers to methyldiethanolamine, the alcohol amine component B refers to one of triethanolamine and diethanolamine or a mixture of triethanolamine and diethanolamine; triazine derivative refers to hexahydro-1,3,5-tris-s-triazine; the inhibiter refers to seventeen alkenyl amide ethyl imidazoline; the synergist refers to sulfolane; the low-molecular mass alcohols refer to one of ethylene glycol and glycerol or a mixture of ethylene glycol and glycerol. The sulfur removal agent has the advantages of good selectivity on sulfuretted hydrogen, small dosage, quick effect, high sulfur removal efficiency, no corrosion of steel, stable product performance, difficulty in heating decomposition, capability of being biodegradable and the like; sulfide like sulfuretted hydrogen existing in extraction of an oil-gas well can be effectively removed or reduced to safety threshold value range in content, corrosion of sulfide on pipelines and equipment is inhibited, and safety on the equipment and operation personnel is guaranteed.

Owner:陕西森瑞石油技术开发有限公司

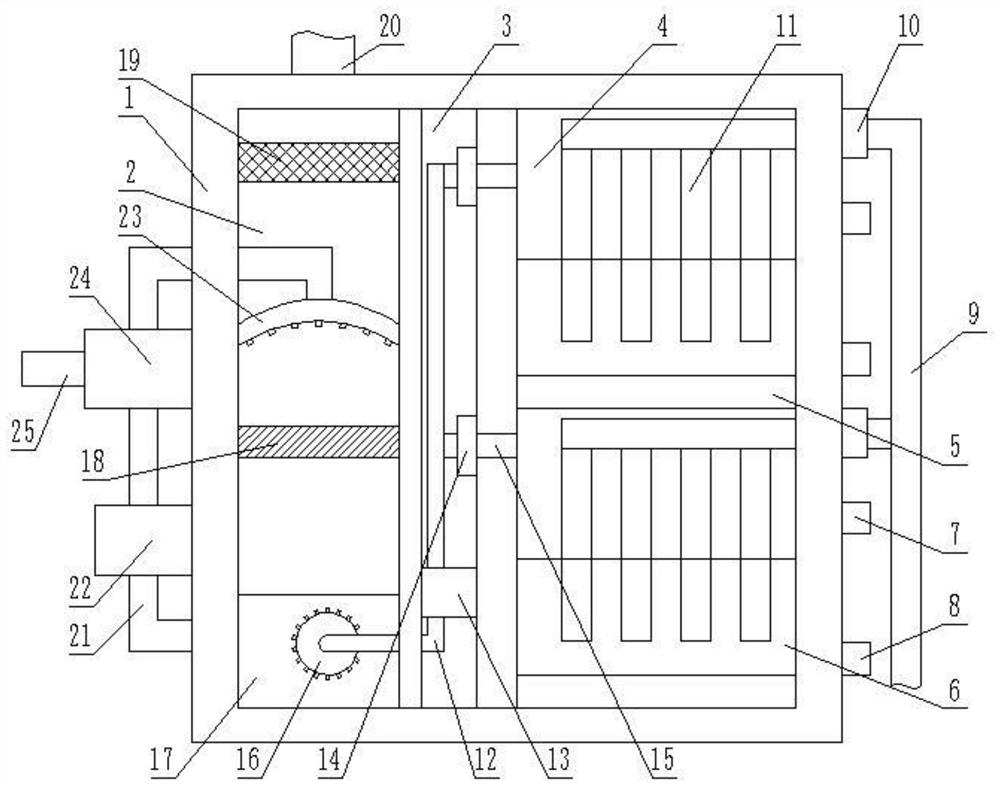

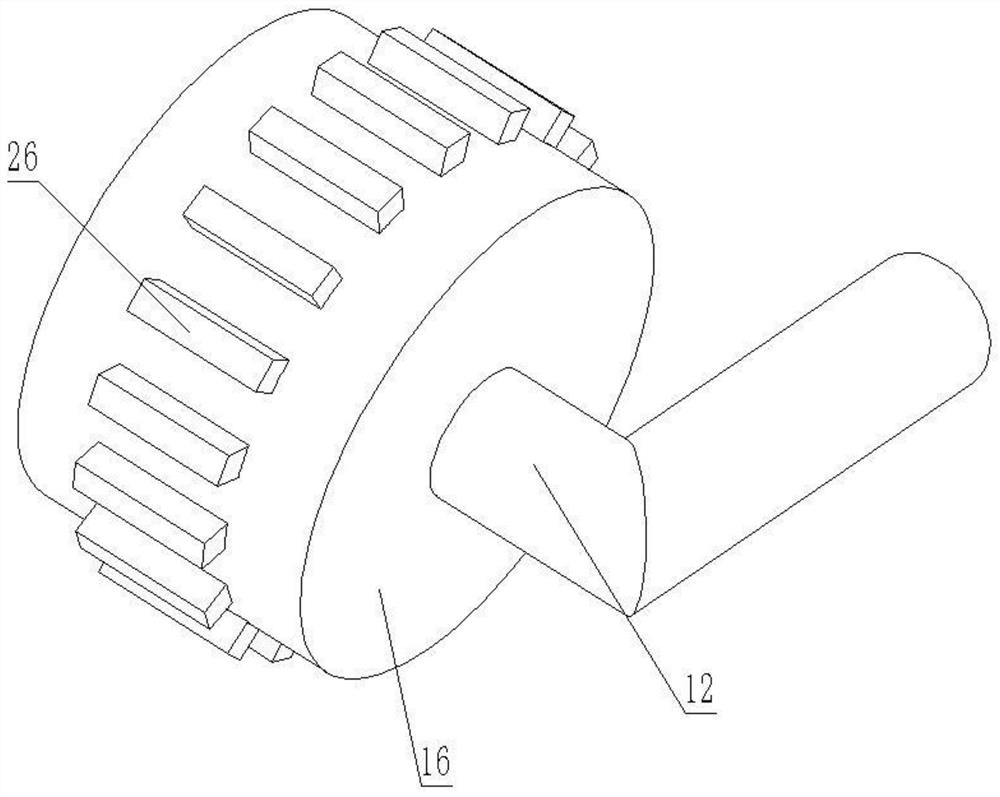

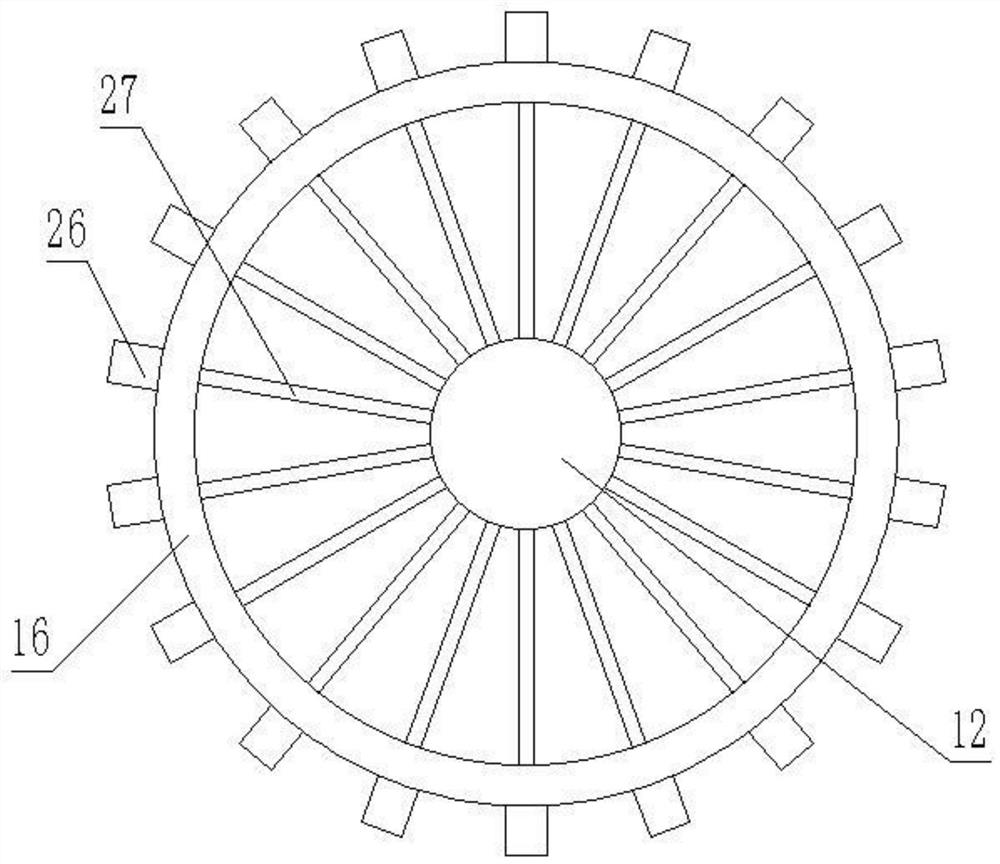

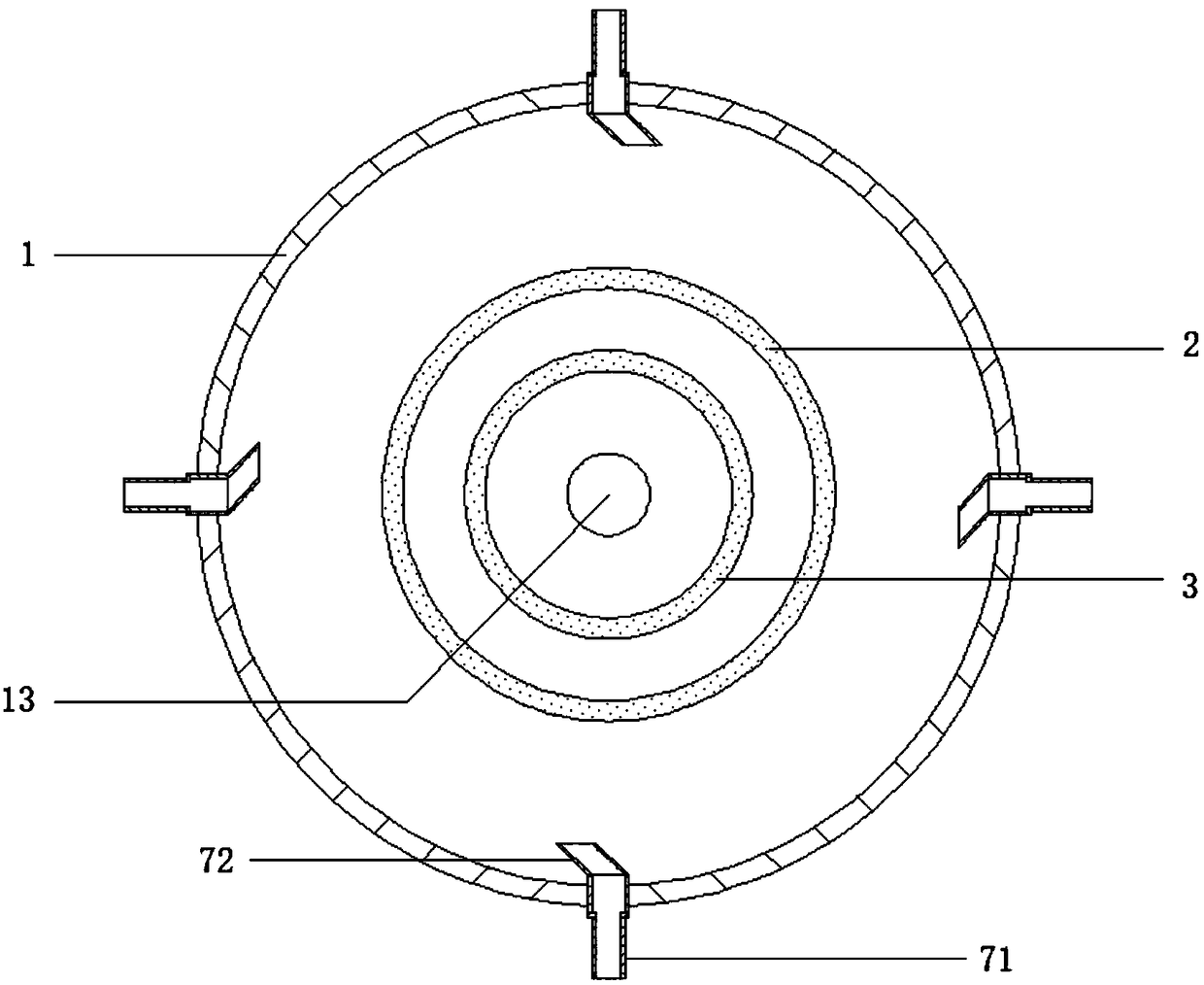

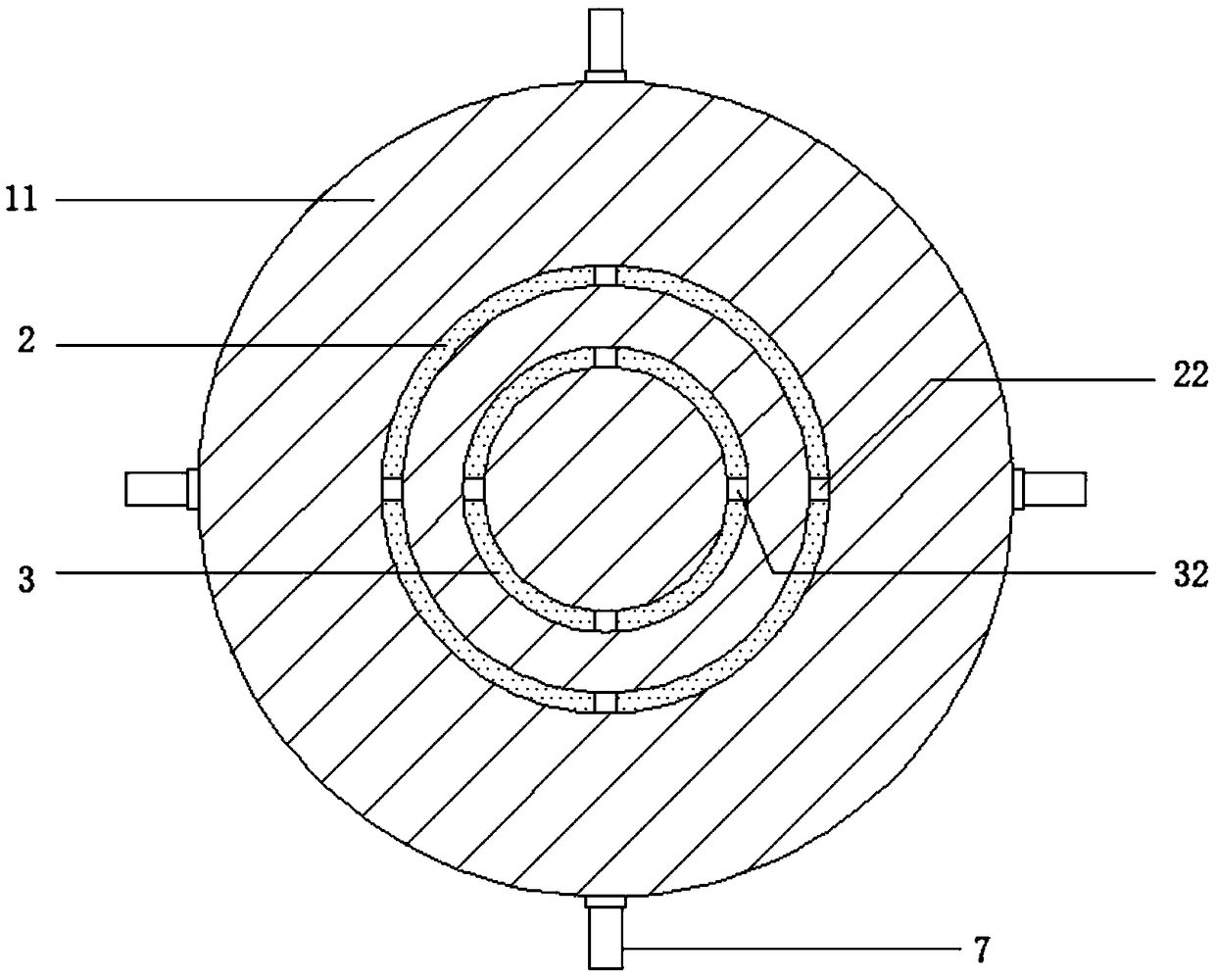

Ecological environment-friendly biogas utilization pool

InactiveCN111704944AImprove sulfur removal efficiencyGuaranteed desulfurization effectBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasEcological environment

The invention relates to the field of biogas utilization pool equipment, in particular to an ecological environment-friendly biogas utilization pool. The biogas utilization pool comprises a biogas digester body; an environment-friendly treatment device is fixedly mounted at the upper end of the biogas digester body; sulfur removal cavities are fixedly formed in the environment-friendly treatment device; a rotating column is movably mounted at the middle end in the environment-friendly treatment device; the outer side of the rotating column is movably sleeved with a dust scraping ring; the twosulfur removal cavities are formed in the two sides of the rotating column correspondingly. Biogas generated by the biogas digester body can be divided into two parts to enter the sulfur removal cavities, therefore, the sulfur removal efficiency is improved; filter screens are fixedly mounted on the two sides of the sulfur removal cavities, iron oxide particles are prevented from leaking, and dustin the biogas is blocked and the dust is prevented from continuously moving upwards; a pulling plate is movably mounted in the sulfur removal cavity, and driving plates are movably mounted on the front side and the rear side in the environment-friendly treatment device, so that biogas cannot linearly penetrate through the sulfur removal cavities through staggered arrangement of the pulling plates, and the sulfur removal effect is further guaranteed.

Owner:陈程

Desulfurization-sterilization-corrosion inhibition integrated treating agent and preparation method thereof

PendingCN109607668AImprove stabilityLow toxicityWaste water treatment from quariesSpecific water treatment objectivesAbsorption capacityNatural-gas processing

The invention belongs to the technical field of oil field environmental protection, and particularly relates to a desulfurization-sterilization-corrosion inhibition integrated treating agent and a preparation method thereof. The agent can achieve high sulfur removal efficiency and good corrosion inhibition and sterilization effects by combining a polyamine and polysulfide compound system with other auxiliary agents (cationic polyacrylamide and dimethyl formamide); the product after reaction has good stability, small product toxicity and no secondary pollution. The agent can also be used for natural gas treatment and has the advantages of wide purification range, high purification degree, large absorption capacity and the like when being used for natural gas treatment. According to the preparation method of the agent, specific preparation processes and steps are determined based on the properties of each component, and the components are uniformly and stably mixed, so that the sterilization, sulfur removal and corrosion inhibition effects of the agent are best exerted; and meanwhile, the agent is low in toxicity, and no obvious secondary pollution is caused to petroleum.

Owner:西安三维科技发展有限责任公司

Lime desulfurization method used in aluminium oxide production

InactiveCN107459051AReduce lossesHigh sulfur removal rateAlkali metal hydroxidesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateDissolution

A lime desulfurization method used in aluminium oxide production follows the principle that lime or lime milk is added into a sulfur-containing sodium aluminate solution to generate two calcium hydroaluminosulfate sediments, and sulfur impurities in the sodium aluminate solution are removed together with the sediments. The lime desulfurization method particularly comprises the following steps: diluting the sulfur-containing sodium aluminate solution with the molar ratio of 3:1 for 3-4 times with water, slowly adding lime milk of 15-20 g / L CaO into the sodium aluminate solution containing 20-30 g / L SO4<2-> ions under a stirring condition, performing purification to realize desulfurization, filtering the purified sodium aluminate solution, and recovering Al2O3 and NaOH. The lime desulfurization method has the following advantages: (1) the desulfurization efficiency is high, and loss of aluminium oxide is reduced; (2) the sulfur dissolution rate and the dissolution speed are high, and the alkali consumption is low; and (3) Al2O3 and NaOH are recycled, and the production cost is lowered. The lime desulfurization method is suitable for aluminium oxide manufacturers.

Owner:GUIZHOU UNIV

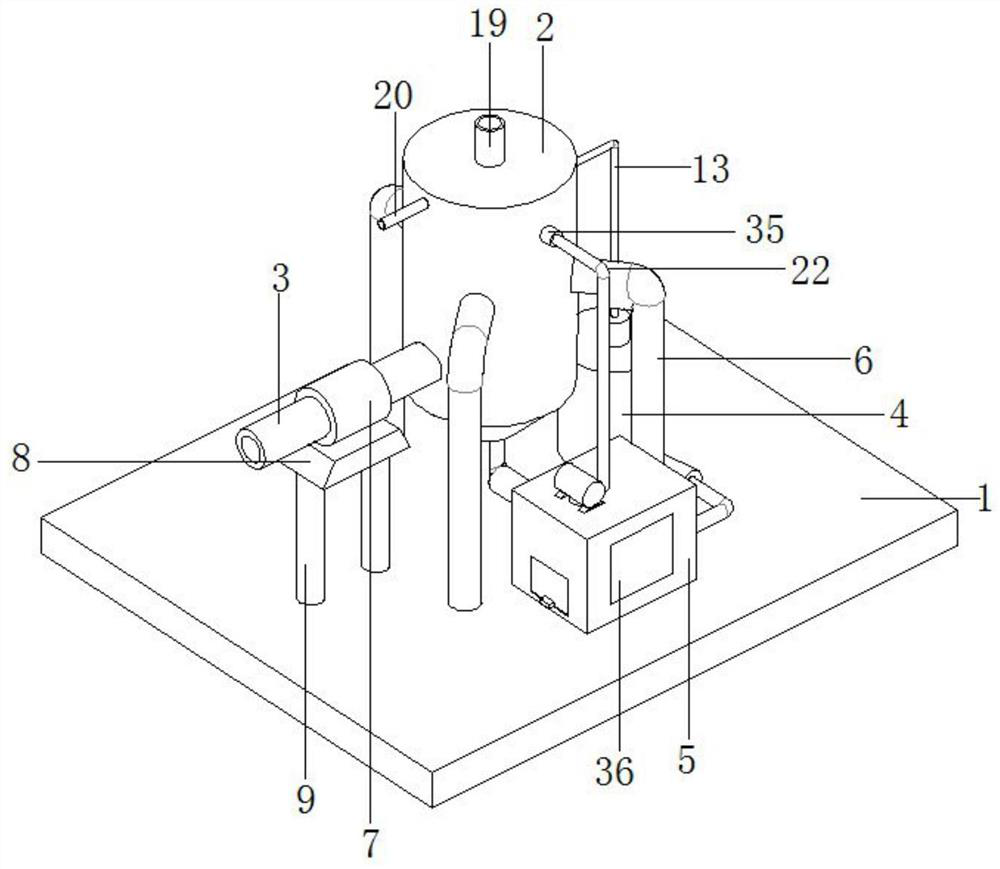

Carbon-molecule gasification combustion boiler engineering operation system

InactiveCN109282275AReduce consumptionReduce generationSolid fuel pretreatmentSolid fuel combustionSlagOxygen

The invention provides a carbon-molecule gasification combustion boiler engineering operation system. The carbon-molecule gasification combustion boiler engineering operation system achieves the purposes of source pollution prevention and control, element reduction and high-effectiveness utilization of coal resources. The carbon-molecule gasification combustion boiler engineering operation systemhas the advantages that anaerobic sulfur fixation (Ca / S approaches 1) is conducted at a gasification section, and sulfur-containing furnace slag serves as a cement raw material; hot coal gas and air are cross-mixed and are blown downwards to combust (alpha approaches 1 and the air is generally reduced by 10% or more compared with the domestic and overseas advanced direct coal combustion technology), and generation of noxious substances such as SOx and NOx related to oxygen is prevented, controlled and reduced; the combustion volume thermal intensity is 360 kw / m3 and above, the gauge pressure of a coal gas isolating valve is less than 0 pa, and coal gas does not lead in the combustion process; the exhaust gas temperature of a boiler is lower than 106 DEG C; and the whole system is high in energy cleaning and utilization efficiency and low in cost.

Owner:陈涛

Method for synthesizing phosphotungstic acid-titanium dioxide composite spherical nanomaterials by one-step sol-gel method

InactiveCN103962185BEasy to prepareAvoid consumptionMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystHigh energy

The invention discloses a method for synthesizing a phosphotungstic acid-titanium dioxide composite spherical nanometer material by a one-step sol-gel method and belongs to the technical field of preparation of functional nanometer materials. The method avoids complex experimental steps and high energy consumption of solvent-induced self-assembly and hydrothermal methods and greatly simplifies the experimental flow. The shape and size of the prepared phosphotungstic acid-titanium dioxide composite spherical nanometer material are controllable. The material with the spherical-like nanometer structure has high sulphur removal efficiency and is applied to a sulphur removal reaction by extraction combined with catalytic oxidation. DBT simulated oil with sulphur content being 350ppm can be degraded to reach the sulphur content of 4.8ppm by 70mg of catalyst within 2h. The novel preparation method of the nanometer catalyst is simple, has the characteristics of good thermal stability, less energy consumption of equipment and environmental friendliness, and is expected to be actually developed in and applied to the sulphur removal industry production.

Owner:BEIJING UNIV OF CHEM TECH

A high-efficiency desulfurization tower

The invention discloses an efficient desulfurizing tower. The tower comprises a tower body, wherein the tower body is cuboid-shaped; a discharge tower and a transfer tower which are sequentially arranged in parallel are arranged in the tower body; a sealing plate is arranged between the discharge tower and the transfer tower; two input towers which are arranged in parallel in a vertical directionare arranged on the other side of the transfer tower; the two input towers are separated by a partition plate; a lime slurry pool is arranged at the bottom of each input tower, an opening is formed inthe top of each lime slurry pool, an input pipe is arranged on the side face of the tower body, the input pipe is provided with two branch pipes, the branch pipes are inserted into the input towers in a one-to-one correspondence mode, a plurality of diverting insertion pipes are arranged on the branch pipes, and the bottoms of the diverting insertion pipes are located in the lime slurry pools; and a transfer pipe is arranged in the transfer tower and is in butt joint with the input tower through a connecting inner pipe. When the efficient desulfurizing tower is used for desulfurizing gas, desulfurization efficiency is greatly improved through multi-stage absorption; and aeration absorption is carried out in an airflow dispersion mode through the arrangement of gas distribution pipes, so desulfurization effect is ensured.

Owner:深圳市格瑞斯达科技有限公司

Preparation method of suspension desulfurizer for water-based oil testing and completion fluid system

ActiveCN108865094BLow viscosityLow sulfur removal efficiencyDrilling compositionBorehole/well accessoriesProcess engineeringSlurry

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

A kind of environment-friendly sulfur removal agent and removal process

ActiveCN107723042BReduce usageReduce fouling and cloggingGaseous fuelsHydrocarbon oils refiningEnvironmental resistanceTriazine derivative

The invention relates to the technical field of organic sulfur removal, in particular to an environment-friendly sulfur removal agent and a removal technology thereof. The environment-friendly sulfurremoval agent is prepared from triazine derivatives, an anti-scaling agent and an activating agent in a certain ratio, wherein in percent by volume, the triazine derivatives accounts for 65-90%, the anti-scaling agent accounts for 1-30%, the activating agent accounts for 5-10%, the triazine derivatives react with organic sulfur, the anti-scaling agent is used for inhibiting scaling of high-hardness gas field water, the organic sulfur is insoluble in water, and the triazine derivatives are water soluble, so that the activating agent is used for quickening reaction between the triazine derivatives and the organic sulfur, and products after reaction are soluble in water. A filling technology adopts spray filling, the filling is carried out by adopting a spraying mode behind a sulfur removal tower in a gas field with high sulfur content, spray filling is directly carried out at the wellhead in a gas field with low sulfur content, and the average particle size during filling is less than 40microns. Compared with the traditional sulfur removal agent, the novel environment-friendly sulfur removal agent has the characteristics of high filling efficiency, no toxicity, no harm, no secondarypollution and applicability of products to industrial production.

Owner:CHINA PETROLEUM ENG & CONSTR +1

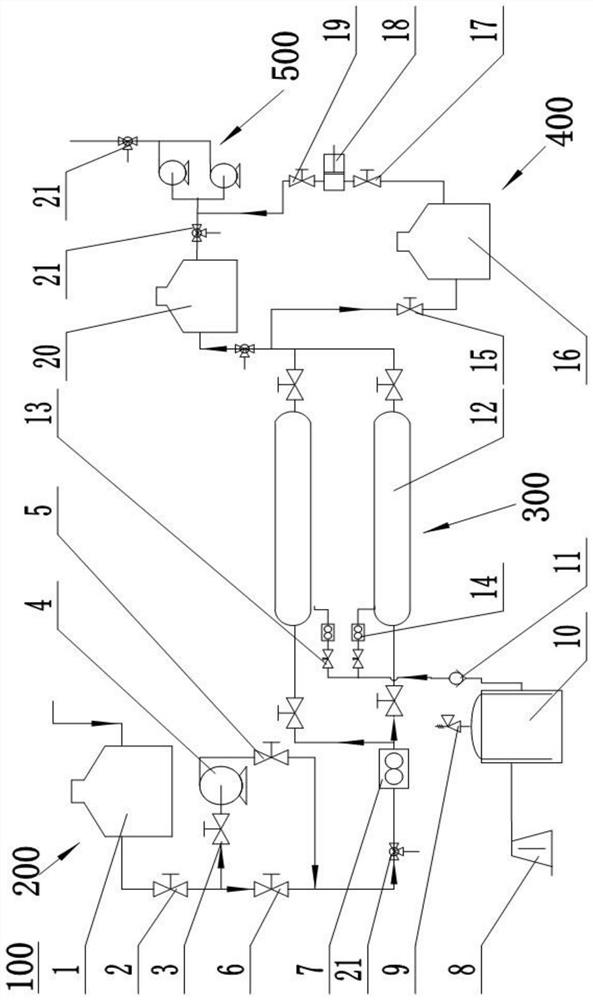

Sewage desulfurization system and desulfurization method

PendingCN114230064ASulfur removal achievedLarge amount of bubblesWaste water treatment from quariesWater contaminantsSewageSewage treatment

The invention discloses a sewage sulfur removal system and method, and relates to the technical field of sewage treatment.The sewage sulfur removal system comprises a pretreatment unit, a mixed reaction unit and a dosing unit, one end of the pretreatment unit is used for being communicated with a treatment station and used for conducting solid-liquid separation on sewage, and the other end of the pretreatment unit is used for conducting chemical dosing; the other end of the pretreatment unit is communicated with one end of the mixed reaction unit, sewage subjected to solid-liquid separation enters the mixed reaction unit and is subjected to mixed aeration in the mixed reaction unit, the other end of the mixed reaction unit is communicated with the chemical feeding unit, and the chemical feeding unit is used for performing chemical desulfurization on the sewage subjected to mixed aeration. According to the sewage desulfurization system and the desulfurization method, the desulfurization efficiency can be improved, and the cost is reduced.

Owner:KARAMAY SANDA NEW TECH

Desulfurizing agent for industrial processing and preparation method thereof

InactiveCN107261740AEffective desulfurization and desulfurizationAvoid destructionGas treatmentDispersed particle separationRare earthDolomite

The invention discloses a desulfurizing agent for industrial processing, and the desulfurizing agent comprises the following raw materials by weight: 5-25 parts of quick lime, 6-26 parts of iron oxide, 6-18 parts of molybdenum oxide, 7-21 parts of sodium chloride, 2-14 parts of dolomite, 3-13 parts of potassium permanganate, 2-16 parts of fluorite, 6-18 parts of calcium fluoride, 3-13 parts of rare earth, 6-18 parts of silicon dioxide, 6-16 parts of poly(butylene succinate), 2-18 parts of zirconia, 3-13 parts of calcium hydrogen carbonate, 5-25 parts of diatomite, 4-18 parts of vanadium pentoxide, 1-7 parts of a stabilizer, 2-8 parts of an inhibitor and 3-9 parts of a pore forming agent. The preparation method has the advantages of simple preparation method and high sulfur removing efficiency.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

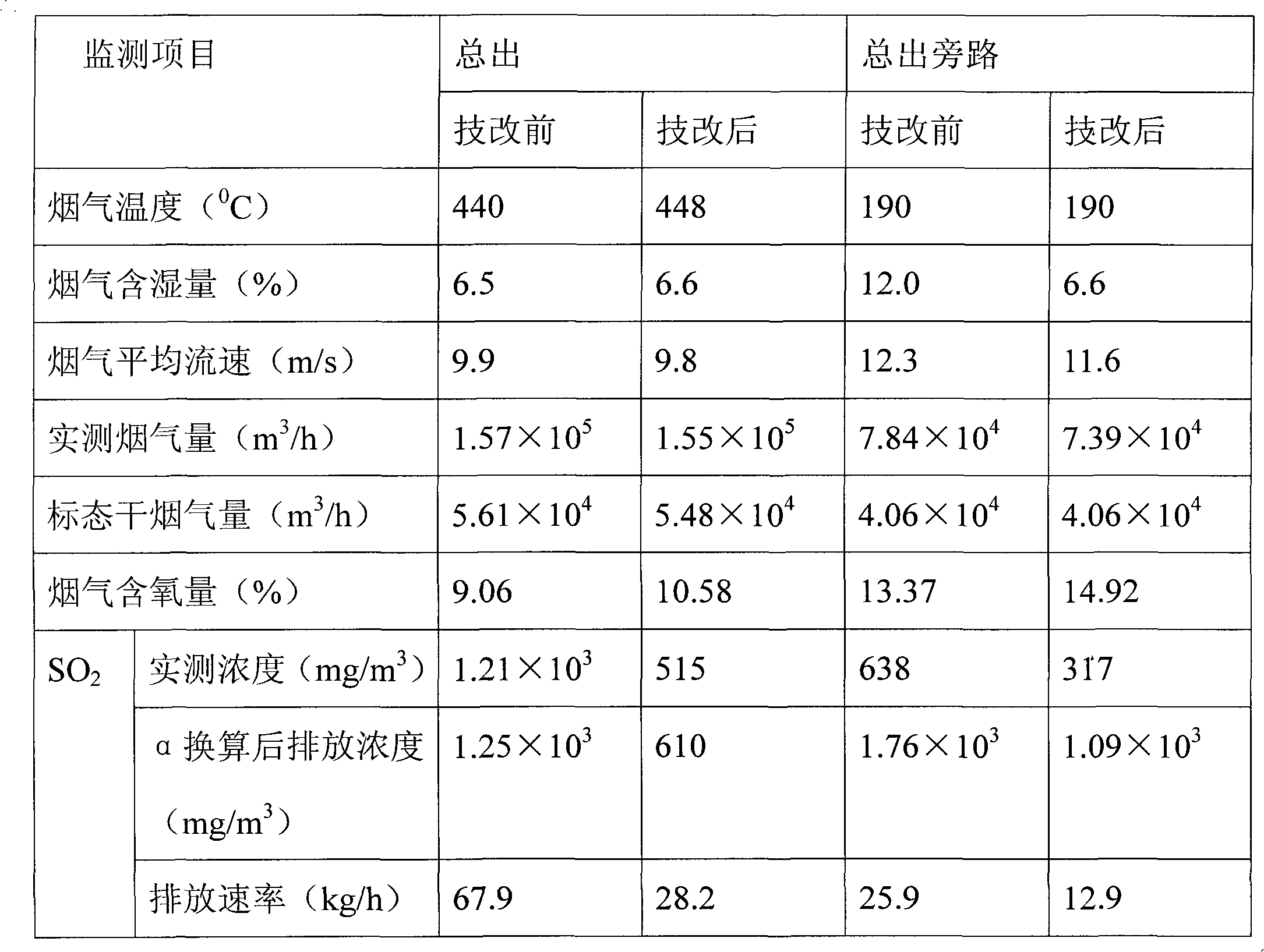

Gas desulfurization method and apparatus

InactiveCN109126378AAverage price distributionImprove sulfur removal efficiencyGas treatmentDispersed particle separationProduct gasEngineering

Owner:中技能源集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com