Preparation method of suspension desulfurizer for water-based oil testing and completion fluid system

A well fluid system and suspension technology, applied in chemical instruments and methods, earthmoving, wellbore/well components, etc., can solve the problems of uneven dispersion, high surface energy, agglomeration, etc., and achieve high sulfur removal efficiency, Good stability and good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] As the best embodiment of the present invention, its components and proportioning are as follows:

[0028] (1) Formula composition: 60g of isopropyl titanate triisostearate, 10g of alkylphenol polyoxyethylene ether, 20g of sodium polyacrylate, 200g of nano-zinc oxide, 100g of isopropanol, and 610g of pure water.

[0029] (2) Preparation method: Add the surface modifier into isopropanol in container A, heat to 60-80°C, and stir to form a uniform solution. Add the dispersant, emulsifier, and nanopowder into the aqueous solution with a pH value of 9-10 in the B container, heat to 60-80°C, and stir to form a uniform solution. Under rapid stirring, add the uniform solution formed in container A into container B, stir for 2 hours to form a uniformly dispersed slurry, and cool to room temperature.

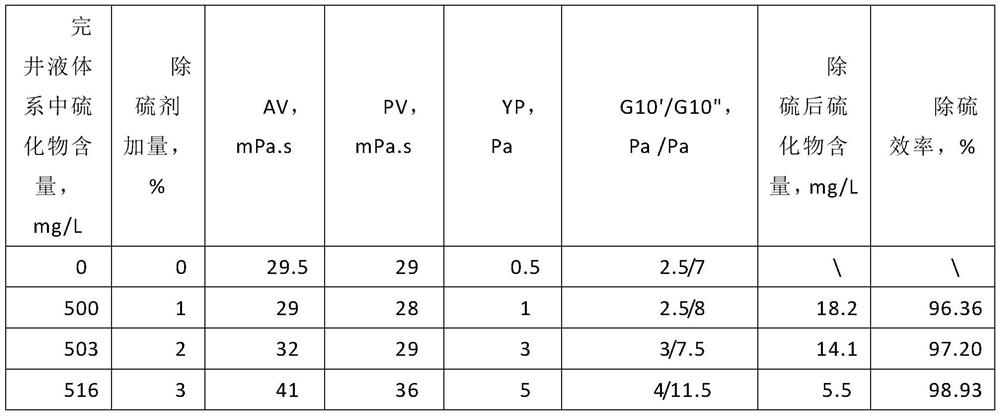

[0030] (3) The sulfur removal efficiency of sulfur removal agent 1# and the effect of high temperature on the rheology of the completion fluid system are shown in the table below,...

Embodiment 2

[0033] As the best embodiment of the present invention, its components and proportioning are as follows:

[0034] (1) Formula composition: 60g of isopropyl tris(dioctyl phosphate acyloxy) titanate, 10g of natural phenol polyoxyethylene ether, 20g of polycarboxylate sodium salt, 200g of nano zinc oxide powder, 100g of isopropanol , 610g of pure water.

[0035] (2) Preparation method: Add the surface modifier into isopropanol in container A, heat to 60-80°C, and stir to form a uniform solution. Add the dispersant, emulsifier, and nanopowder into the aqueous solution with a pH value of 9-10 in the B container, heat to 60-80°C, and stir to form a uniform solution. Under rapid stirring, add the uniform solution formed in container A into container B, stir for 2 hours to form a uniformly dispersed slurry, and cool to room temperature.

[0036] (3) The sulfur removal efficiency of sulfur removal agent 2# and the effect of high temperature on the rheology of the completion fluid sys...

Embodiment 3

[0039] As the best embodiment of the present invention, its components and proportioning are as follows:

[0040] (1) Formula composition: γ-methacryloxypropyltrimethoxysilane 60g, alkylphenol polyoxyethylene ether 5g, OP-10 5g, polyvinylpyrrolidone 30g, nano-zinc oxide powder 300g, isopropyl Alcohol 100g, pure water 500g.

[0041] (2) Preparation method: Add the surface modifier into isopropanol in container A, heat to 60-80°C, and stir to form a uniform solution. Add the dispersant, emulsifier, and nanopowder into the aqueous solution with a pH value of 9-10 in the B container, heat to 60-80°C, and stir to form a uniform solution. Under rapid stirring, add the uniform solution formed in container A into container B, stir for 2 hours to form a uniformly dispersed slurry, and cool to room temperature.

[0042] (3) The sulfur removal efficiency of sulfur removal agent 3# and the effect of high temperature on the rheology of the completion fluid system are shown in the table b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com