Novel hydrogen sulfide scavenger for drilling liquid and preparing method of hydrogen sulfide scavenger

A hydrogen sulfide scavenger, drilling fluid technology, applied in chemical instruments and methods, carboxylate preparation, organic chemistry, etc., can solve the problems of formation environmental pollution, drilling fluid flocculation, and rock-carrying ability of the drilling fluid system. High sulfur removal efficiency and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

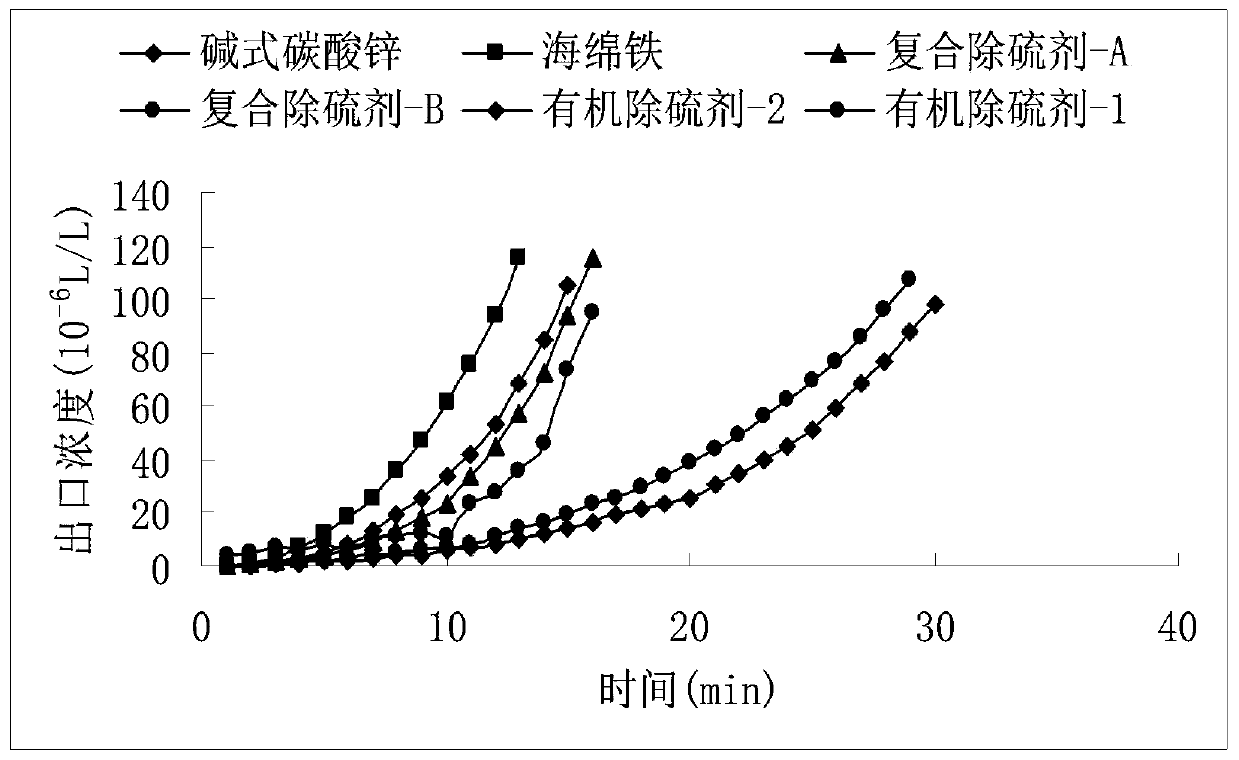

[0031] The invention can greatly reduce the harmful concentration of hydrogen sulfide gas invading the wellbore, reduce its corrosion to downhole drilling tools, and provide technical support and safety guarantee for the exploitation of high-sulfur oil and gas reservoirs in my country.

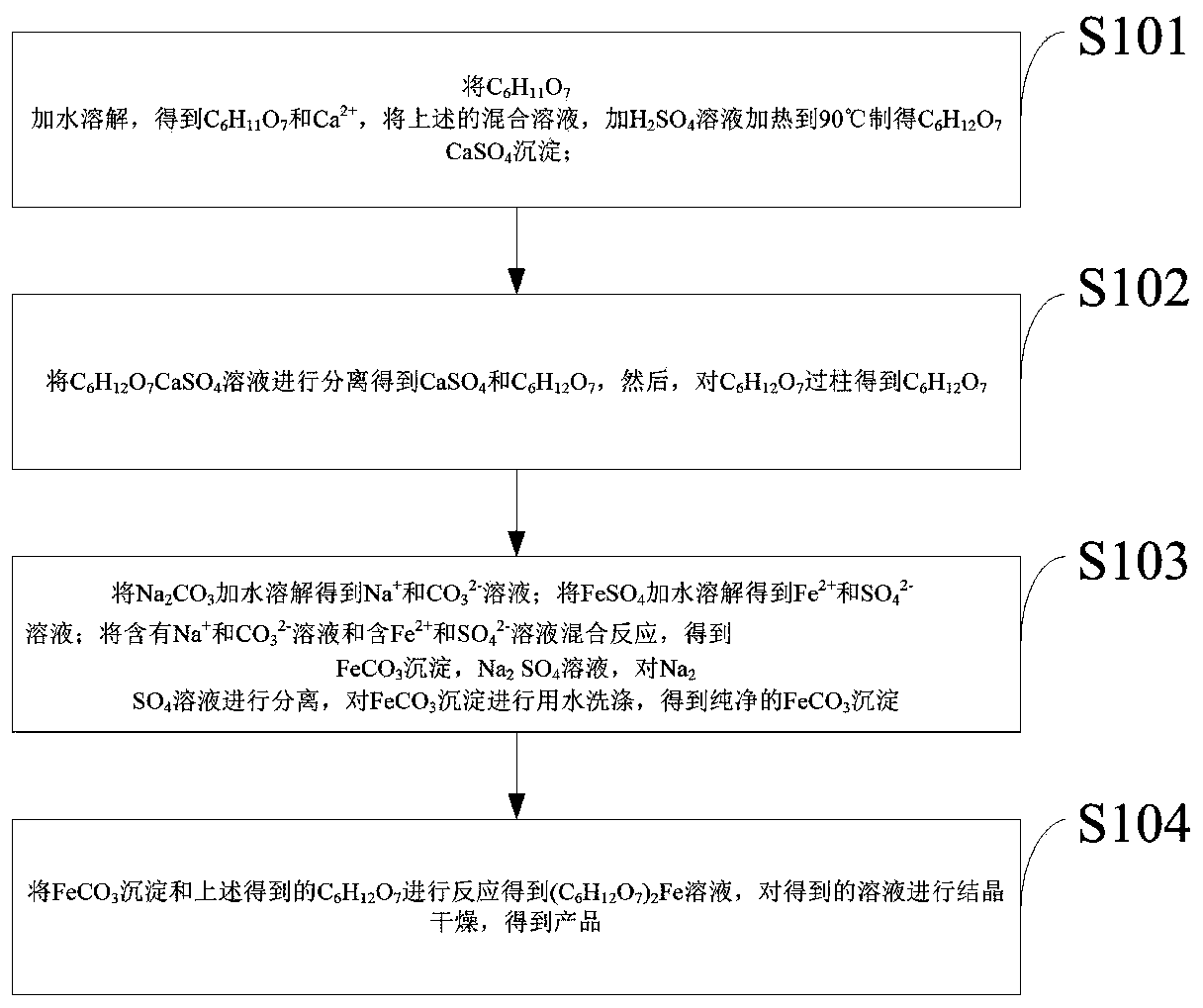

[0032] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] The novel hydrogen sulfide scavenger for drilling fluid provided by the embodiment of the present invention adopts ferrous gluconate.

[0034] The new type of hydrogen sulfide scavenger for dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com