A method and special device for removing sulfide in water

A sulfide and water removal technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Harshness, incomplete treatment, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

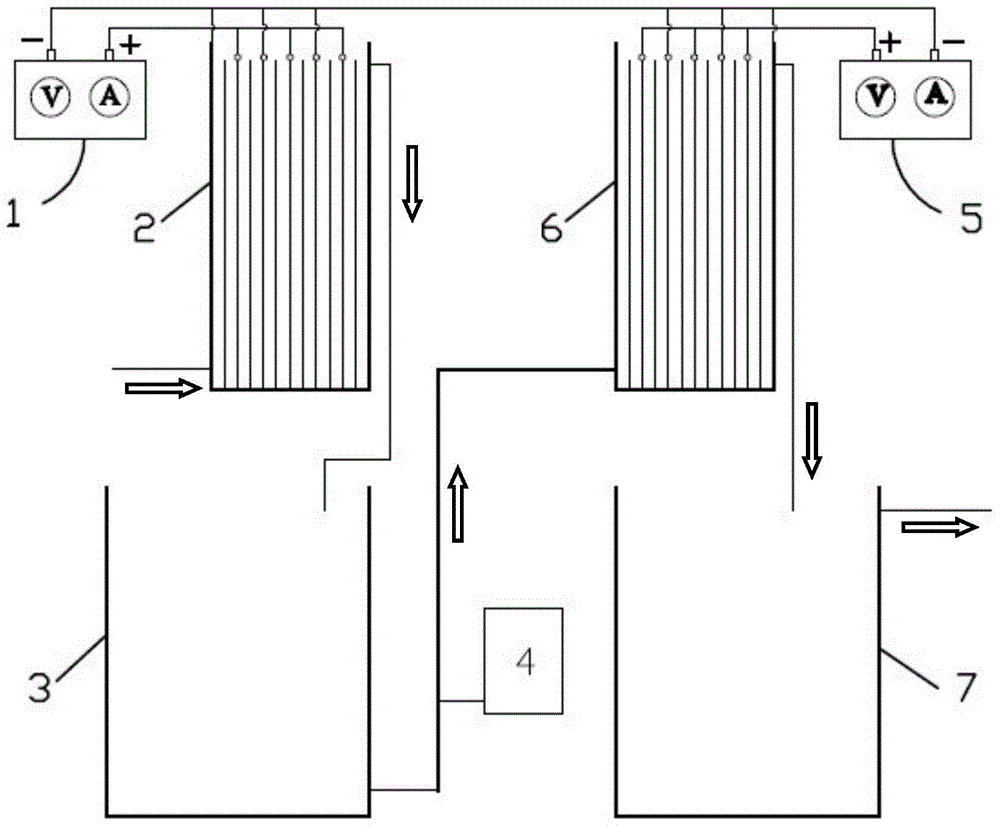

Embodiment 1

[0050] The concentration of sulfide in the raw water is 830mg / L, the conductivity is 3618μs / cm, and the pH value is about 7.2. It directly enters the first-level electrochemical device (the size is 45×45×250mm, the volume is 0.5L when no electrode is installed, and the anode plate is Low-carbon steel plate, the cathode plate is stainless steel plate, the distance between the adjacent anode plate and the cathode plate is 3mm), the water flow rate is 4L / hour, the working current is 2A, the working voltage is 5.3V, the plate current The density is 4mA / cm 2 , The electrolysis time is 240s. The water treated by primary electrochemical treatment entered the clarification tank, and after standing for 60 minutes, the sulfide content in the water was measured to be 3.6mg / L.

[0051] Add 0.1mL / L hydrogen peroxide to the water after the first-level electrochemical treatment, and then enter the second-level electrochemical device (the same size as the first-level electrochemical device) ...

Embodiment 2

[0054] After arsenic-containing waste acid water from a copper smelter in Guangxi was removed by sulfidation, the sulfide concentration in the water was 109mg / L, the conductivity was 13724μs / cm, and the pH value was about 3.7, and it directly entered the primary electrochemical device (size 45 ×45×250mm, the volume is 0.5L when no electrode is installed, the anode plate is low-carbon steel plate, the cathode plate is stainless steel plate, the distance between adjacent anode plates and cathode plates is 5mm), and the water flow rate is 4L / hour, the working current is set to 0.5A, the working voltage is 1.8V, and the plate current density is 1mA / cm 2 , The electrolysis time is 120s. The water treated by primary electrochemical treatment entered the clarification tank, and after standing for 60 minutes, the sulfide content in the water was measured to be 1.9mg / L.

[0055] Add 0.05mL / L hydrogen peroxide to the water after the first-level electrochemical treatment, and then ent...

Embodiment 3

[0058] The raw water contains 612μg / L sulfide, the conductivity is 427μs / cm, and the pH value is about 6.7. After adding 0.02mL / L hydrogen peroxide and mixing evenly, it directly enters the secondary electrochemical device (size 45×45×250mm, when no electrode is installed) The volume is 0.5L, the anode plate is low-carbon steel plate, the cathode plate is stainless steel plate, the distance between adjacent anode plates and cathode plates is 4mm), the water flow rate is 10L / hour, and the working current is set to 0.2A , the working voltage is 1.3V, the plate current density is 4mA / cm 2 , The electrolysis time is 360s. The treated water enters the clarification tank, and after standing for 60 minutes, the sulfide content in the water is measured to be 0.7 μg / L, reaching the drinking water standard.

[0059] According to the experimental parameters and results, it can be calculated that the power consumption per ton of water is 0.06kwh, and the consumption of iron is 62g.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com