Emulsification, combustion and desulphurization process of industrial heavy fuel

A heavy fuel and industrial technology, applied in the fuel, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of large investment and high operating cost for sulfur removal, and achieve high sulfur removal efficiency, low operating cost, and reduced consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

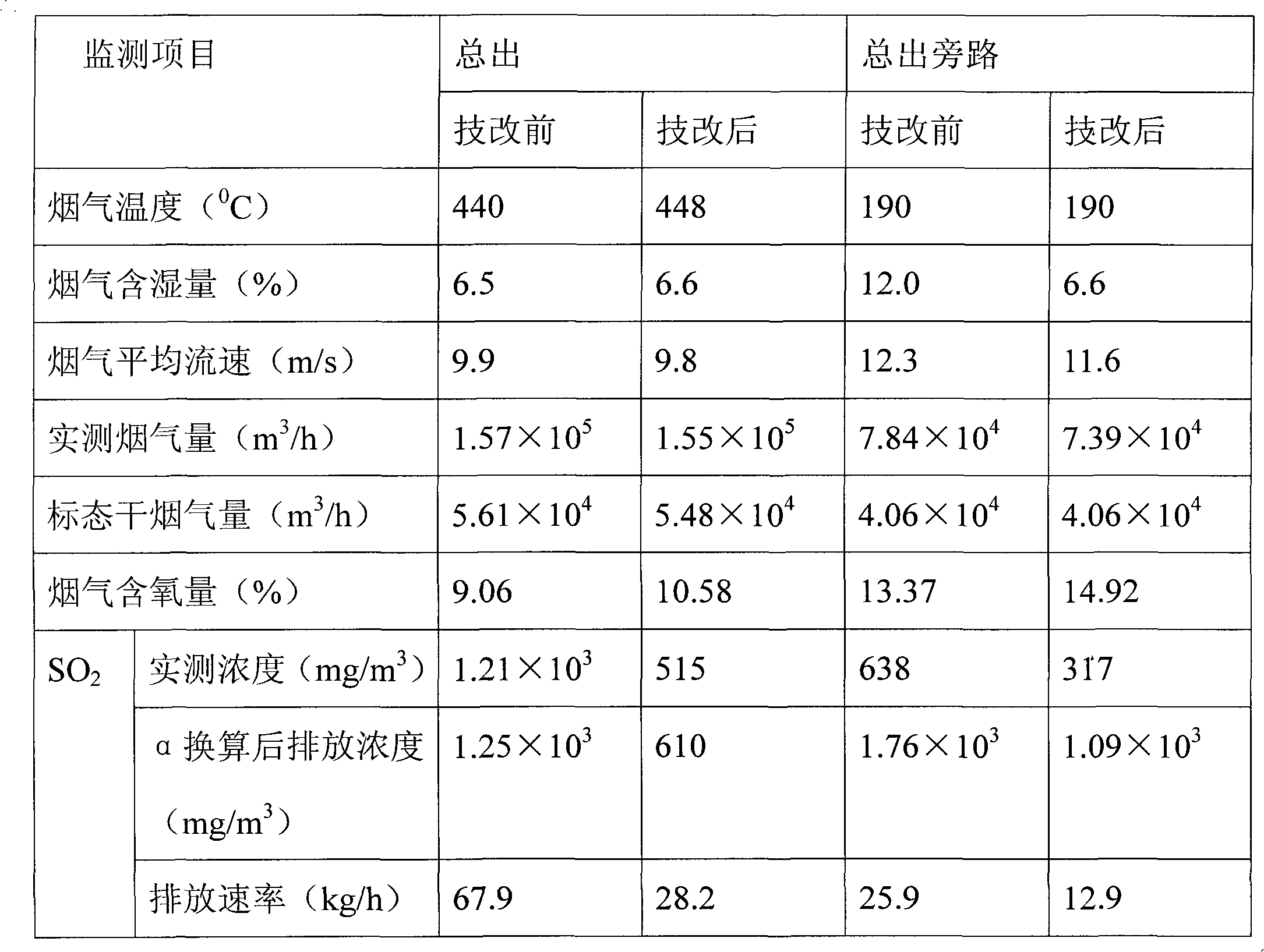

Image

Examples

Embodiment 1

[0030] Preparation of sulfur removal additives: under normal temperature conditions, the basic metal Ca(OH) 2 Dissolved in water as a desulfurization aid, in an acid and alkali resistant stirring tank with stirring equipment to Ca(OH) 2 all dissolved;

[0031] Preparation of emulsified oil: the above-mentioned desulfurization additive Ca(OH) 2 Put the emulsifying additive into the dynamic and static integrated homogeneous emulsifier, and the emulsifying additive is Na 2 CO 3 , NaOH, the composition of Span 20 and Tween 80, its weight and number ratio is Na 2 CO 3 : NaOH: Span 20: Tween 80 = 20: 40: 2: 8, carry out emulsification treatment at 80°C to form water-in-oil type (W / O) emulsified oil, the above sulfur removal additives and emulsification additives The ratio of parts by weight is 20:60;

[0032] Desulfurization: The above-mentioned emulsified oil is input into the combustion chamber, and the emulsified oil is directly combined with SO in the gas produced by heavy...

Embodiment 2

[0034] In the step of preparing the desulfurization aid, the basic metal is Na 2 O;

[0035] In the described step of preparing emulsified oil, the emulsifying additive is Na 2 CO 3 : NaOH: Span 20: Tween 80=5: 10: 1: 4; Carry out emulsification treatment under the condition of 90 ℃, the weight and number ratio of desulfurization auxiliary agent and emulsification additive is 5: 20, other steps are the same as embodiment 1 .

Embodiment 3

[0037] In the step of preparing the desulfurization aid, the basic metal is Na 2 CO 3 ;

[0038] In the described step of preparing emulsified oil, the emulsifying additive is Na 2 CO 3 : NaOH: Span 20: Tween 80=40: 55: 5: 20; Carry out emulsification treatment under the condition of 85 ℃, the weight and number ratio of sulfur removal auxiliary agent and emulsification additive is 40: 100, other steps are the same as embodiment 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com