Catalyst for producing low carbon olefin from synthesis gas and use method of catalyst

A technology of low-carbon olefins and catalysts, applied in the field of catalysts, can solve the problems of low selectivity of low-carbon olefins and low conversion rate of CO, and achieve the effects of increasing conversion rate, reducing surface area carbon, and improving anti-carbon deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

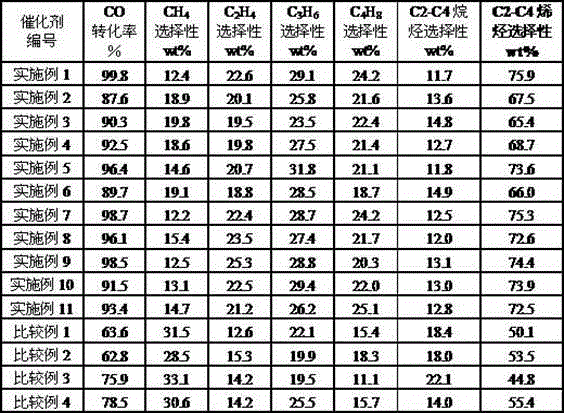

Examples

Embodiment 1

[0028] Weigh 45.0 g of α-alumina (Al 2 o 3 ) powder and 40.1 grams of ground calcium carbonate (CaCO 3 ) powder with 3.4 g of titanium dioxide (TiO 2 ) powders were mixed evenly, and mixed in a ball mill for 1 hour to make a mixture G for use; weigh 11.5 grams of potassium carbonate (K 2 CO 3 ), add 30 ml of deionized water, and after it is completely dissolved, add it to the above-mentioned mixed material G for kneading and extrusion molding; after drying, sinter at 1300°C for 2 hours to make a composite carrier, cool The composite oxide carrier H was prepared by crushing and screening into 60-80 meshes; 101.2 grams of ferric nitrate nonahydrate, 25.2 grams of 50% manganese nitrate solution, and 10.4 grams of bismuth nitrate pentahydrate were dissolved in 35.0 grams of deionized water to make a mixed Solution I; under the condition of vacuum degree of 80kPa, impregnating the above mixed solution I on 70.0 grams of prepared composite oxide carrier H to obtain catalyst prec...

Embodiment 2

[0031] Weigh 63.1 g of α-alumina (Al 2 o 3 ) powder and 8.0 g ground calcium carbonate (CaCO 3 ) powder with 9.0 g of titanium dioxide (TiO 2 ) powders were mixed evenly, and mixed in a ball mill for 1 hour to make a mixture G for use; weigh 19.8 grams of potassium carbonate (K 2 CO 3 ), add 30 ml of deionized water, and after it is completely dissolved, add it to the above-mentioned mixed material G for kneading and extrusion molding; after drying, sinter at 1300°C for 2 hours to make a composite carrier, cool The composite oxide carrier H was prepared by crushing and screening into 60-80 meshes; 253.0 grams of ferric nitrate nonahydrate, 100.9 grams of 50% manganese nitrate solution, and 10.4 grams of bismuth nitrate pentahydrate were dissolved in 35.0 grams of deionized water to make a mixed Solution I; under the condition of vacuum degree of 80kPa, impregnating the above mixed solution I on 25.0 grams of prepared composite oxide carrier H to obtain catalyst precursor J...

Embodiment 3

[0034] Weigh 18.6 g of α-alumina (Al 2 o 3 ) powder and 59.9 grams of ground calcium carbonate (CaCO 3 ) powder with 0.7 g of titanium dioxide (TiO 2 ) powders were mixed evenly, and mixed in a ball mill for 1 hour to make a mixture G for use; weigh 20.8 grams of potassium carbonate (K 2 CO 3 ), add 30 ml of deionized water, and after it is completely dissolved, add it to the above-mentioned mixed material G for kneading and extrusion molding; after drying, sinter at 1300°C for 2 hours to make a composite carrier, cool The composite oxide carrier H was prepared by crushing and screening into 60-80 meshes; 25.3 grams of ferric nitrate nonahydrate, 20.2 grams of 50% manganese nitrate solution, and 2.1 grams of bismuth nitrate pentahydrate were dissolved in 35.0 grams of deionized water to make a mixed Solution I; under the condition of vacuum degree of 80kPa, impregnating the above mixed solution I on 90.0 grams of prepared composite oxide carrier H to obtain catalyst precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com