Multiple dispersion strengthening copper-base composite material prepared in situ and preparation method thereof

A technology of dispersion-strengthening copper and in-situ generation, which is applied in the field of metal matrix composite materials and its preparation, can solve the problems of single type of disperse phase and coarse particles, and achieve excellent mechanical properties and conductivity, fine structure and stable production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

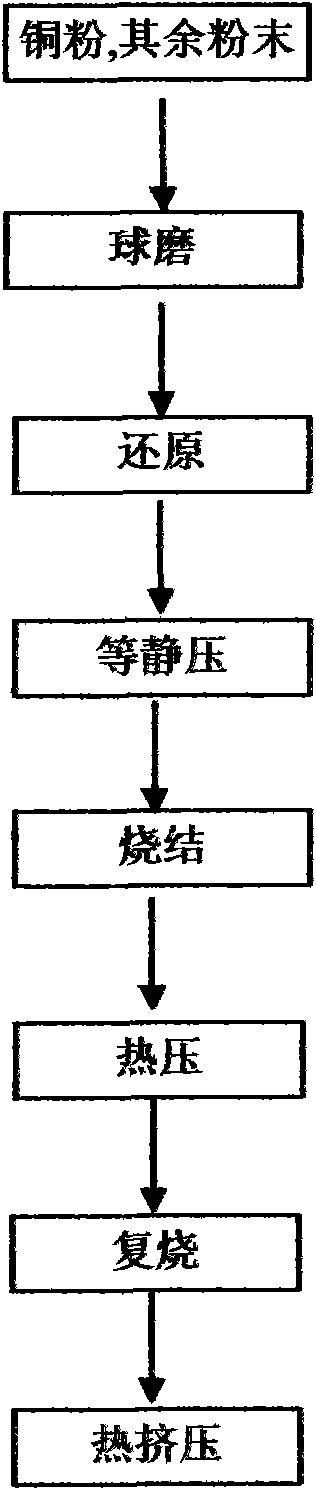

Method used

Image

Examples

Embodiment 1

[0040] To prepare Cu-0.3TiC-0.3TiB 2 -0.3ZrC multi-component copper matrix composite material as an example

[0041] 1. First, 99.2wt% Cu powder, 0.2wt% Ti powder, 0.2wt% Zr, 0.1wt% B and 0.3wt% C were mixed and ball milled for 50 hours, the ball-to-material ratio was 30:1, and the milling speed was 500 rpm. The ball milling atmosphere is argon;

[0042] 2. Then the ball-milled powder is annealed in hydrogen at 400°C for 3 hours;

[0043] 3. Then press the annealed powder into a green body under an isostatic pressure of 200 MPa;

[0044] 4. Sinter the compact at 900°C for 5 hours in a hydrogen atmosphere;

[0045] 5. Then hot-press the sintered body, the hot-pressing temperature is 800°C, the hot-pressing pressure is 400MPa, and the pressure is maintained for 10 minutes;

[0046] 6. Then refire the green body after hot pressing according to the original sintering process; the process parameters are the same as step 5;

[0047] 7. Then hot-extrude the reburned body into wire...

Embodiment 2

[0050] To prepare Cu-1Al 2 o 3 -0.5ZrC-0.3ZrO 2 Multi-component copper matrix composite material as an example

[0051] 1. First, 96.4wt% Cu powder, 0.8wt% Al powder, 0.1wt% Zr, 0.5wt% C, 1.3wt% Cu 2 O mixing ball milling for 100 hours, the ball-to-material ratio is 50:1, the ball milling speed is 600 rpm, and the ball milling atmosphere is argon;

[0052] 2. Then the ball-milled powder is annealed in hydrogen at 400°C for 3 hours;

[0053] 3. Then press the annealed powder into a green body under an isostatic pressure of 400MPa;

[0054] 4. Sinter the compact at 900°C for 5 hours in a hydrogen atmosphere;

[0055] 5. Then hot-press the sintered body, the hot-pressing temperature is 850°C, the hot-pressing pressure is 300MPa, and the pressure is maintained for 10 minutes;

[0056] 6. Then refire the green body after hot pressing according to the original sintering process; the process parameters are the same as step 5;

[0057] 7. Then hot-extrude the reburned green bod...

Embodiment 3

[0060] Taking the preparation of Cu-3TiC-1TiB-0.3ZrC multi-component copper matrix composite as an example

[0061] 1. First mix 95wt% Cu powder, 2.0wt% Ti powder, 1.5wt% Zr, 0.5wt% B and 1.0wt% C and ball mill for 75 hours, the ball-to-material ratio is 80:1, the ball milling speed is 400 rpm, and the ball milling The atmosphere is argon;

[0062] 2. Then the ball-milled powder is annealed in hydrogen at 400°C for 3 hours;

[0063] 3. Then press the annealed powder into a green body under an isostatic pressure of 400 MPa;

[0064] 4. Sinter the compact at 900°C for 8 hours in a hydrogen atmosphere;

[0065] 5. Then hot-press the sintered body, the hot-pressing temperature is 850°C, the hot-pressing pressure is 600MPa, and the pressure is maintained for 10 minutes;

[0066] 6. Then refire the green body after hot pressing according to the original sintering process; the process parameters are the same as step 5;

[0067] 7. Then hot-extrude the reburned body into rods or p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Recrystallization temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com