Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143 results about "Energy impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

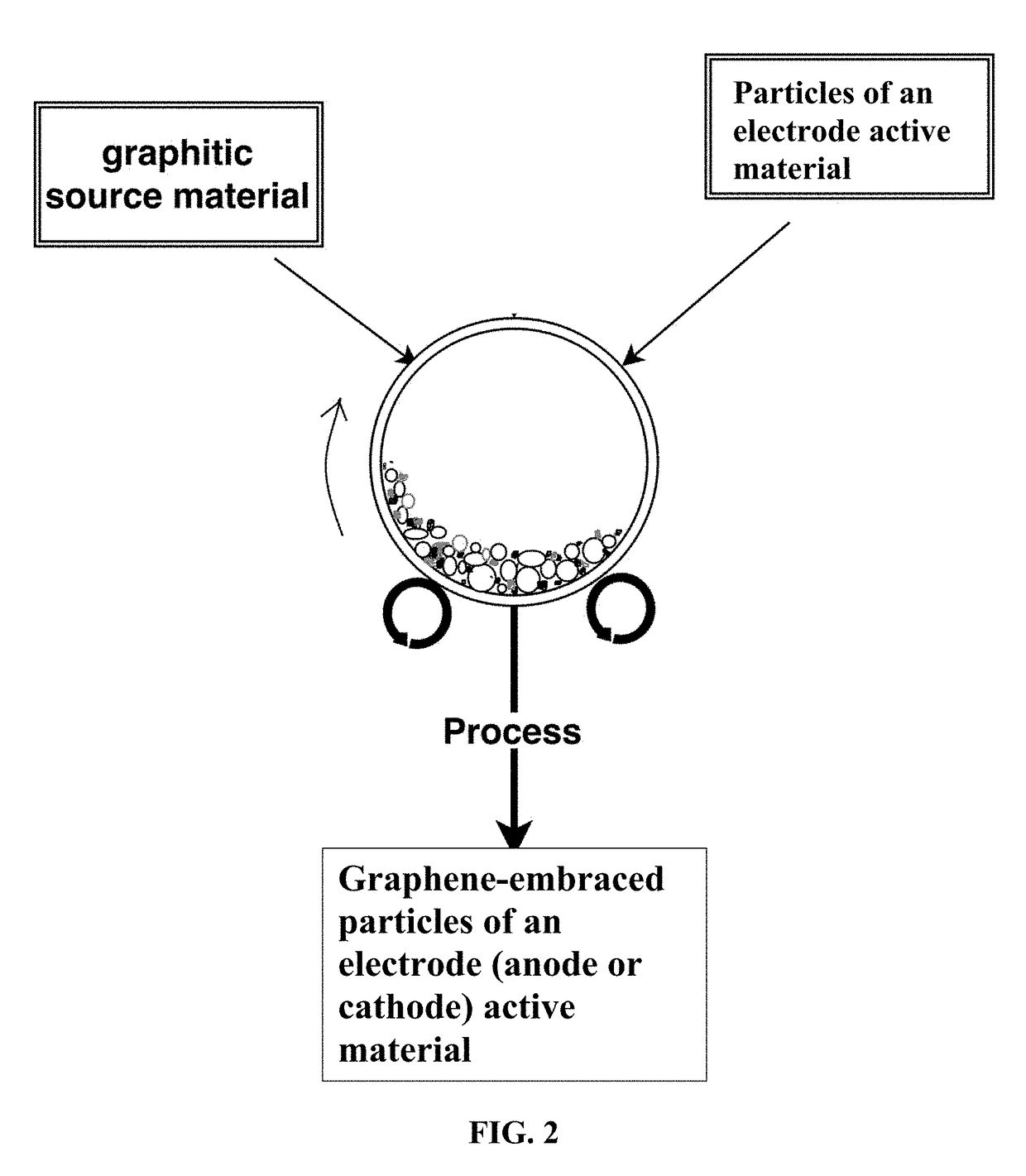

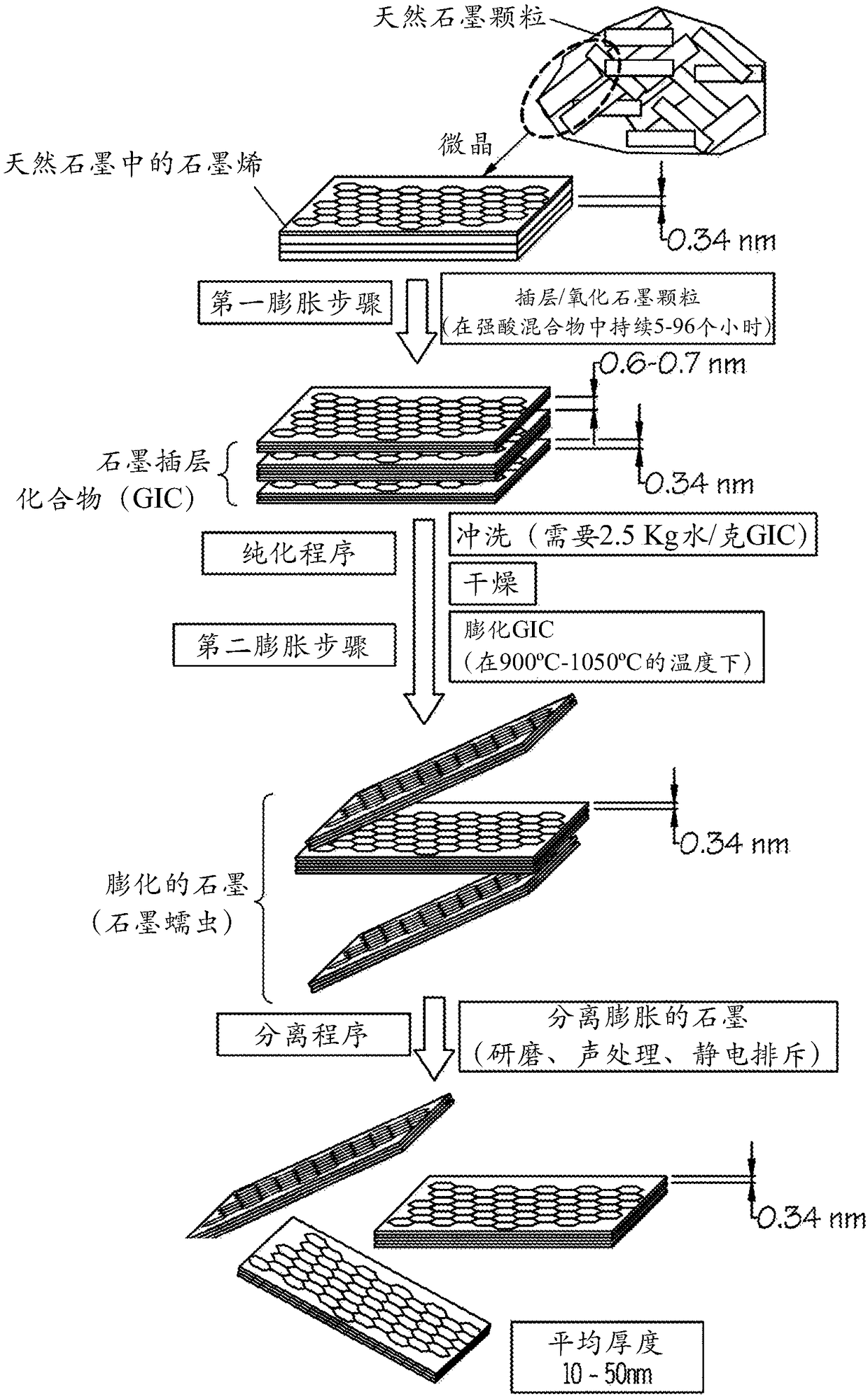

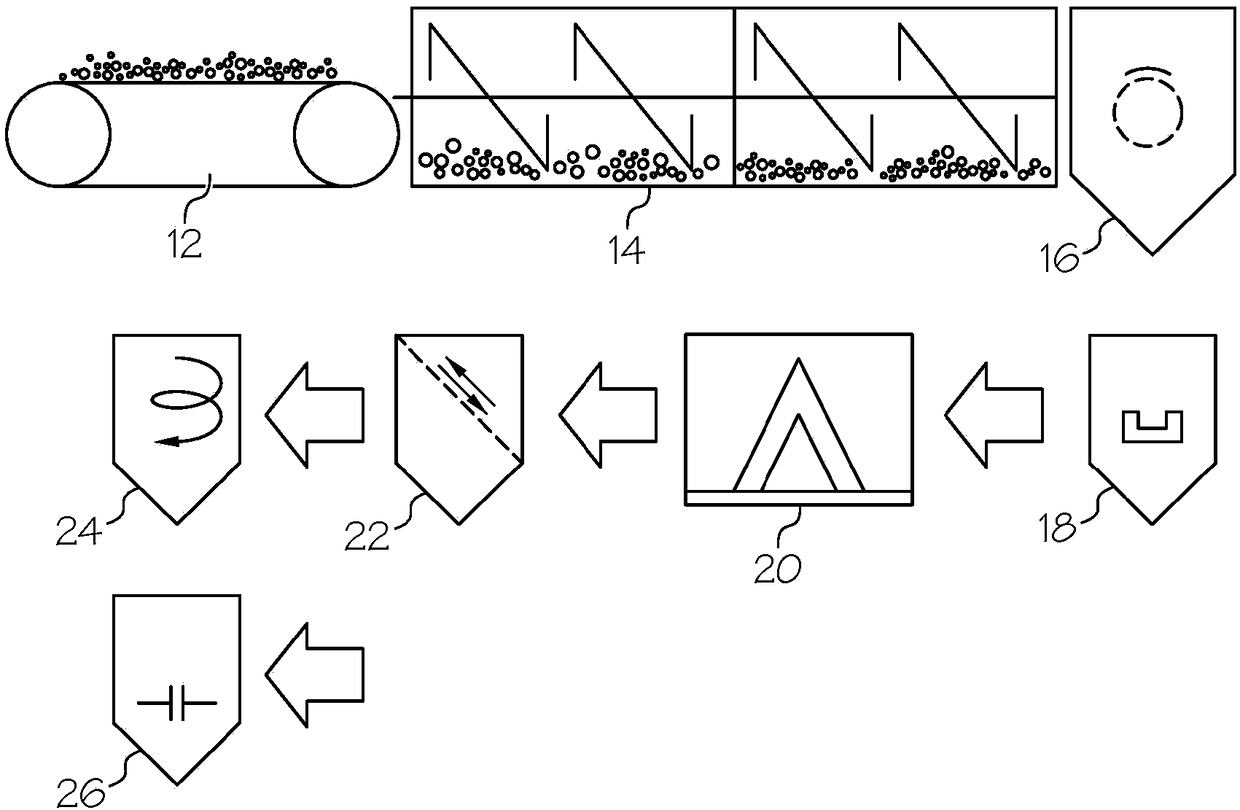

Chemical-Free Production of Graphene-Encapsulated Electrode Active Material Particles for Battery Applications

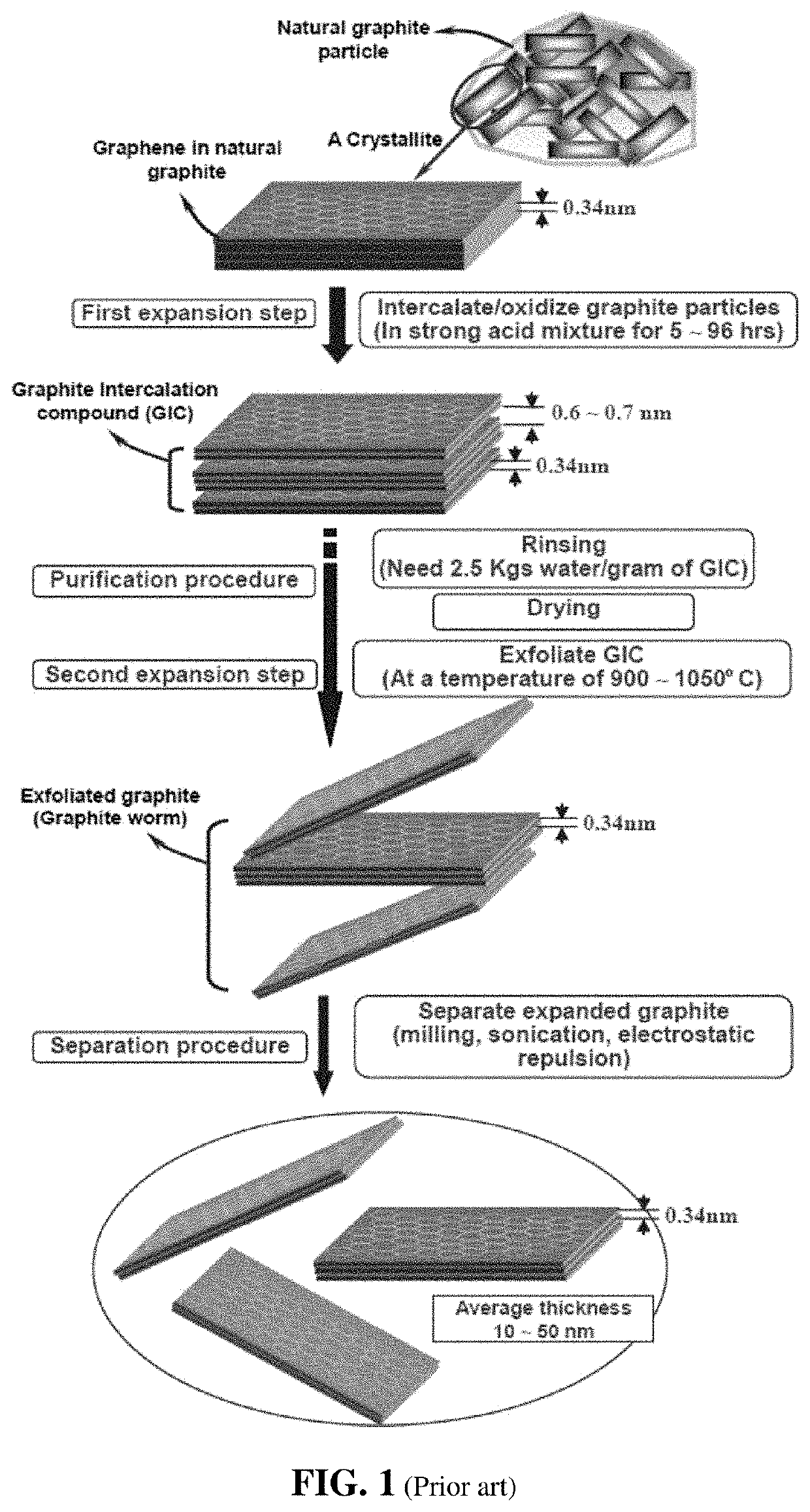

ActiveUS20170338472A1Improve mechanical propertiesImprove thermal conductivityGrapheneNegative electrodesEnergy impactGraphite

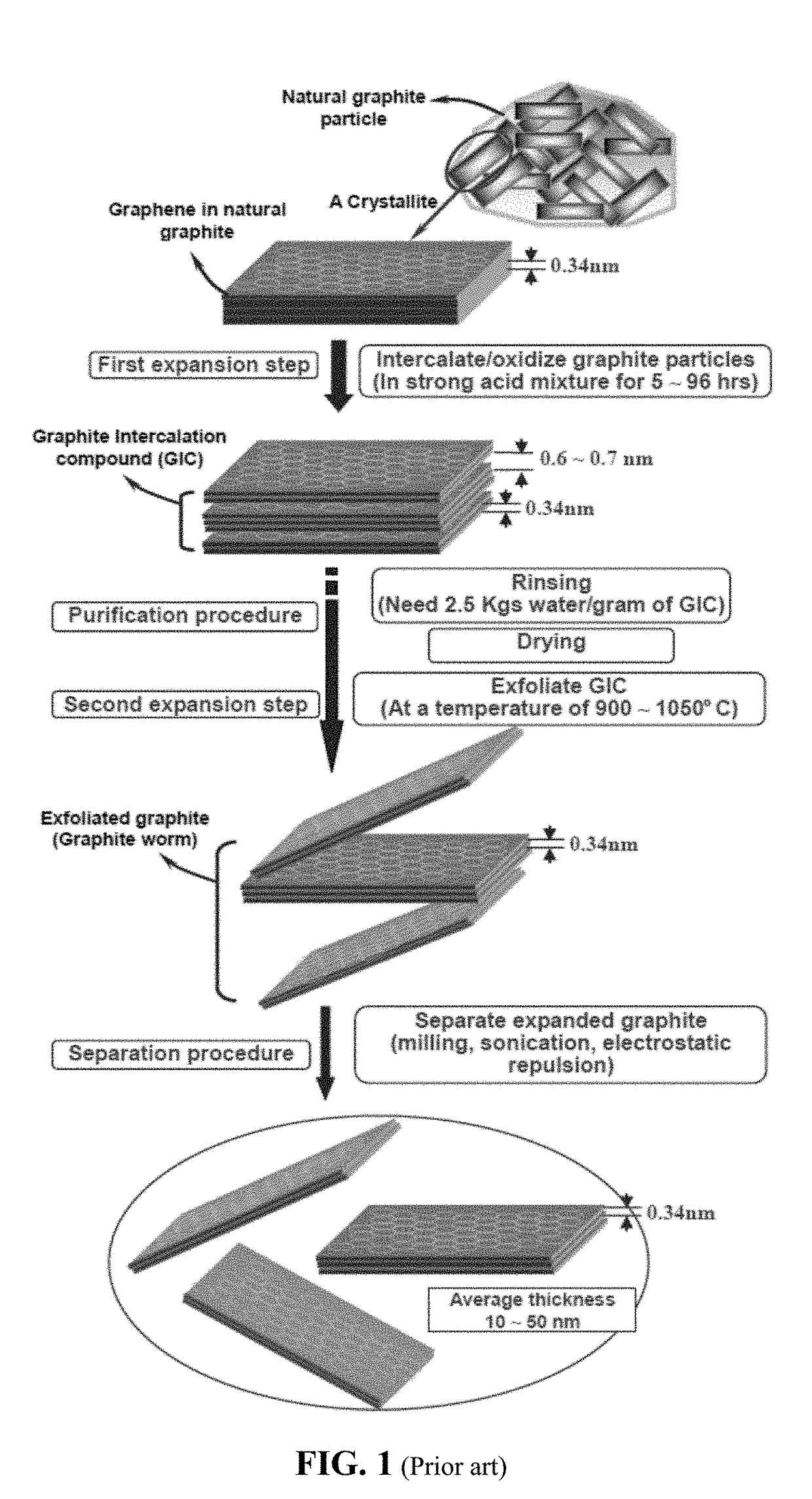

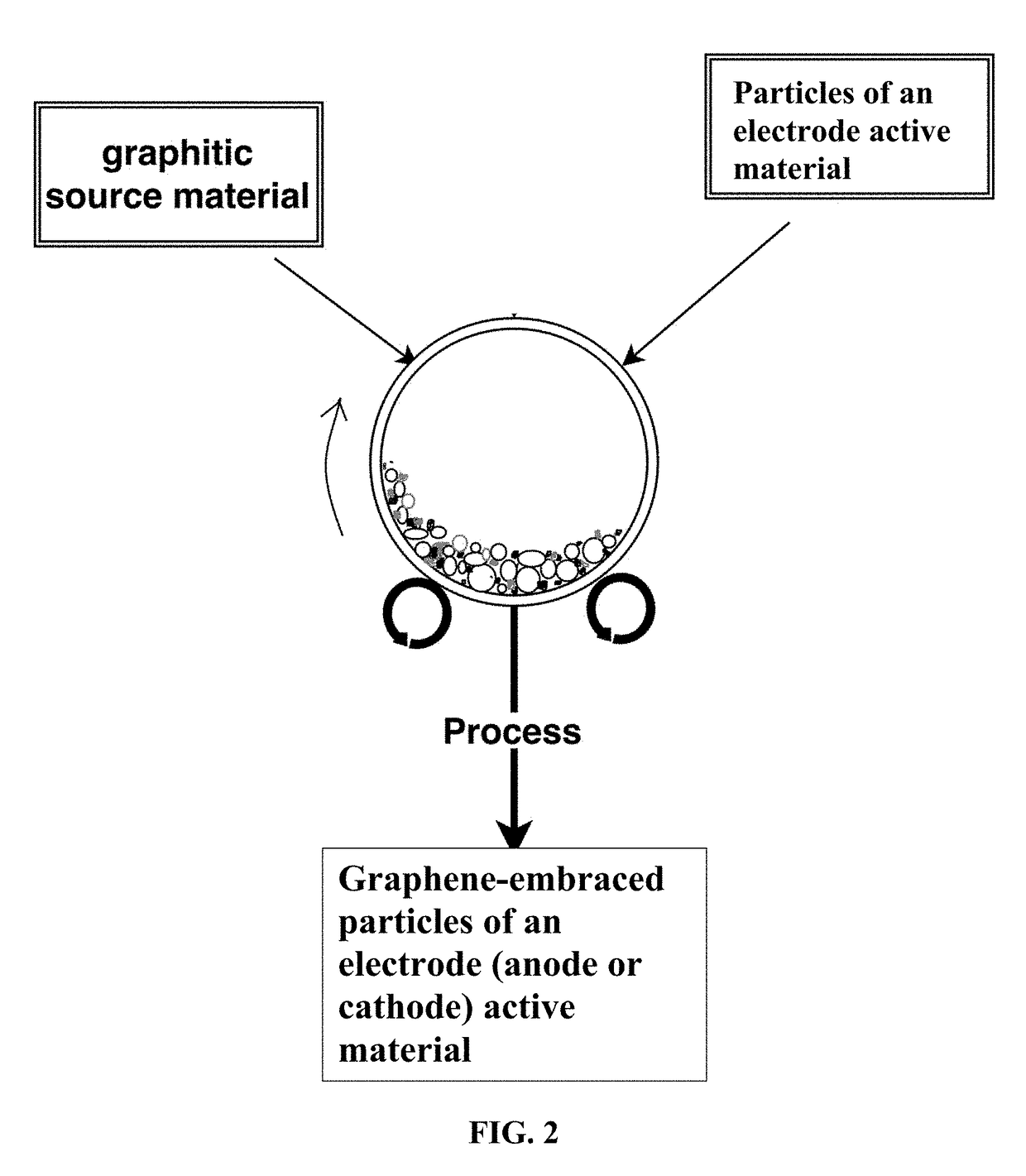

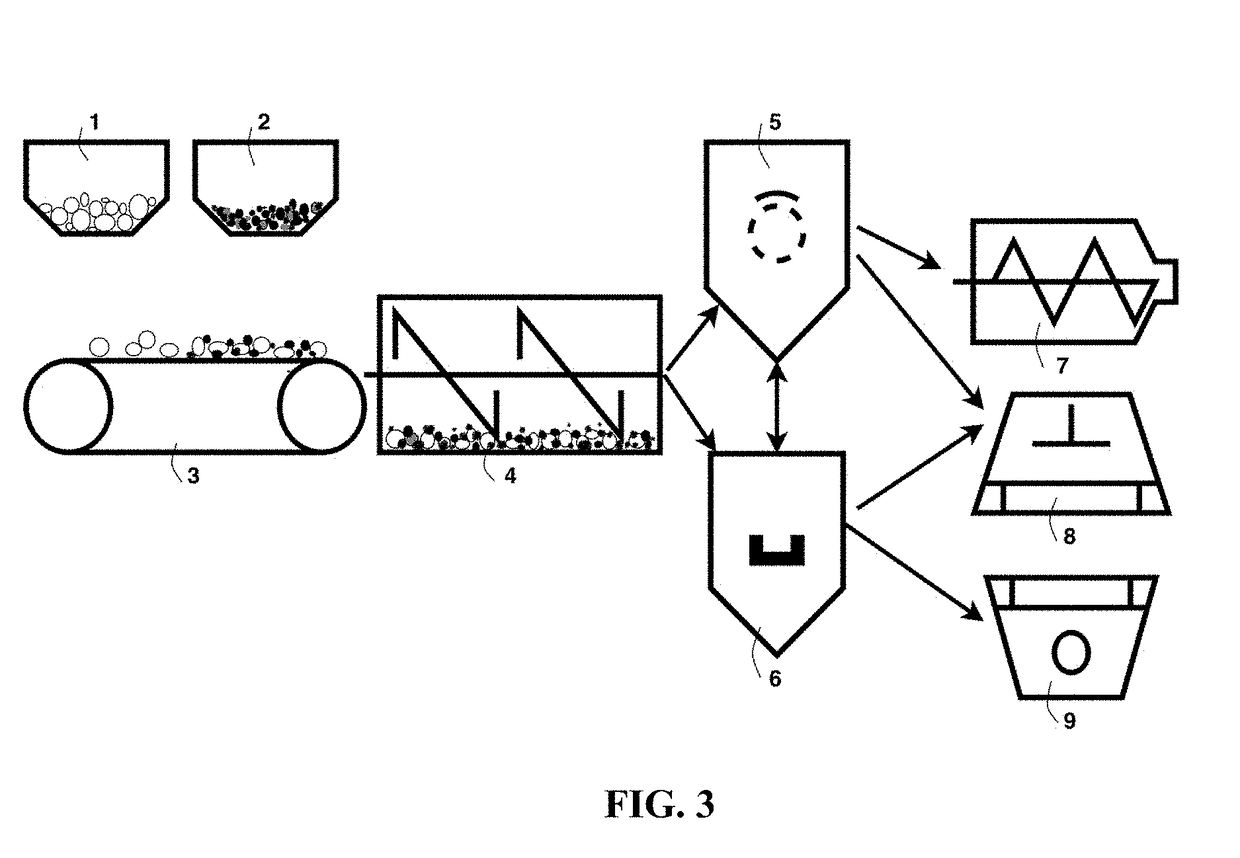

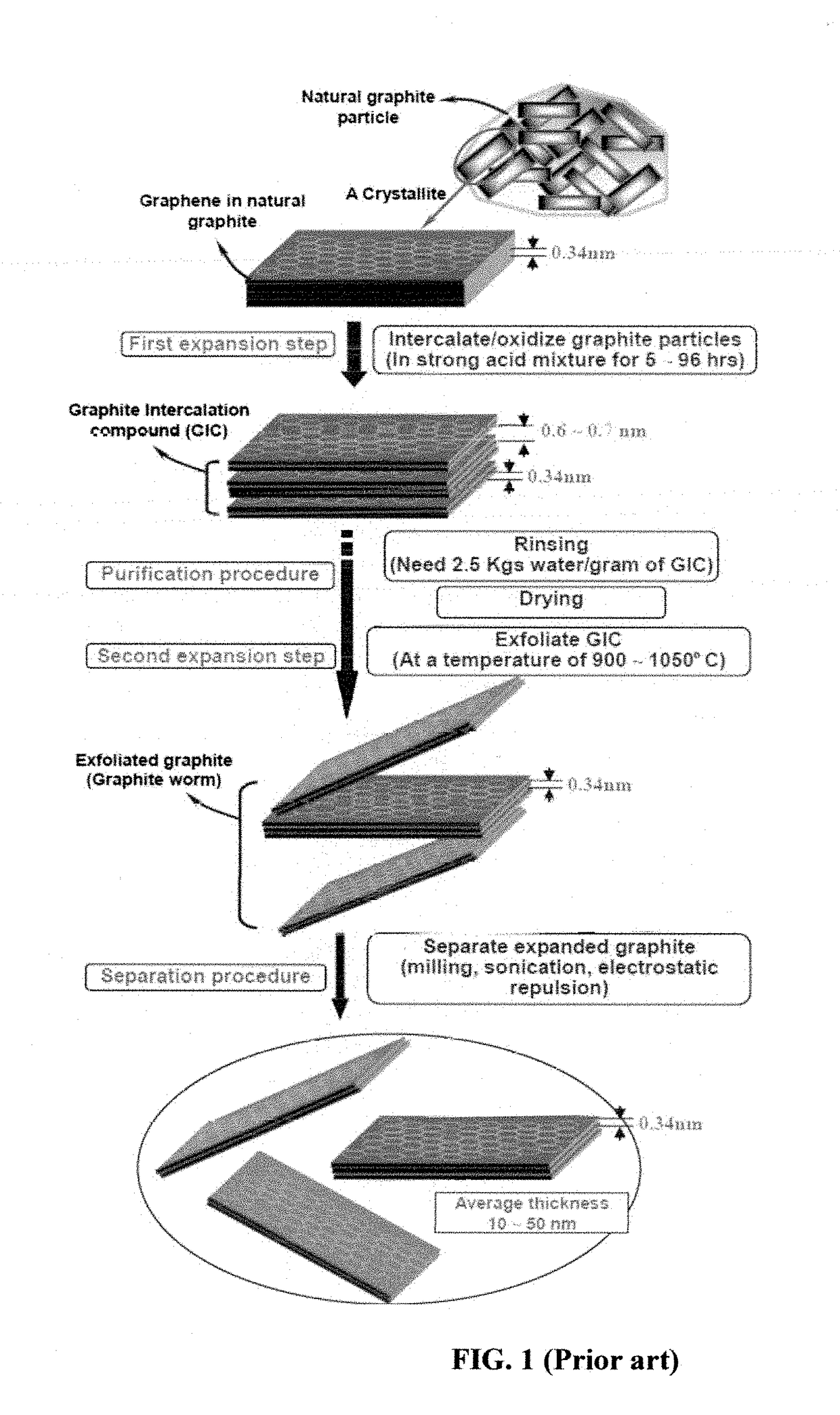

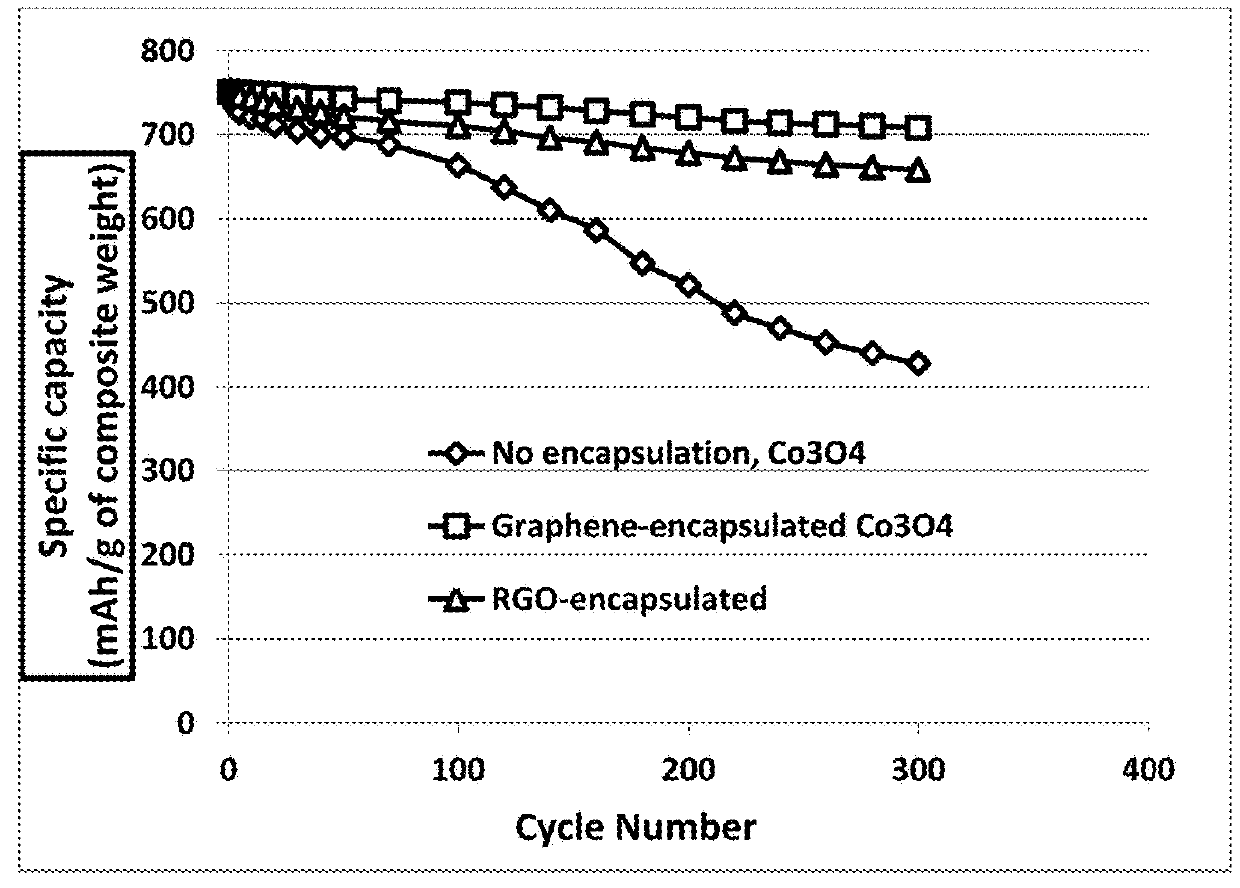

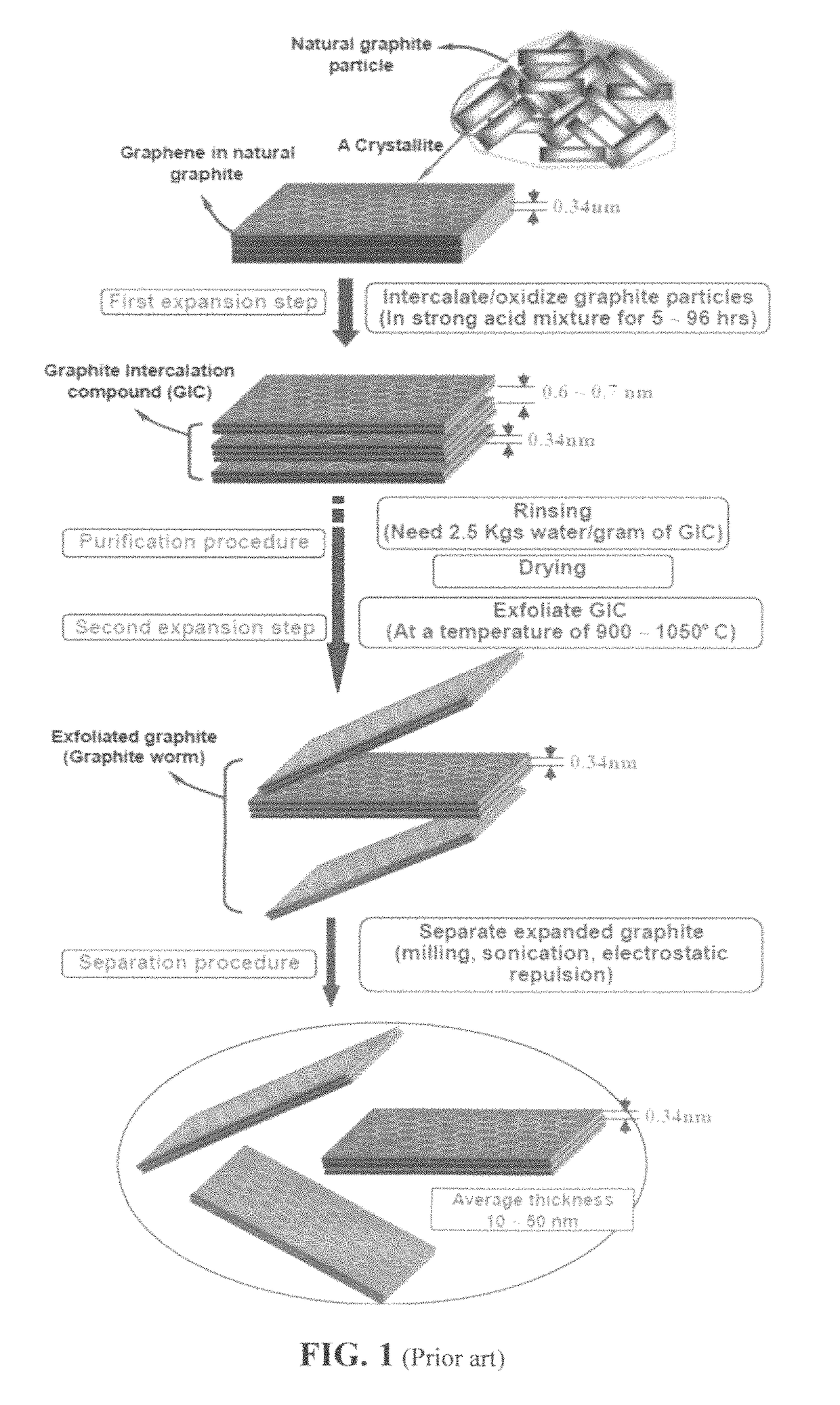

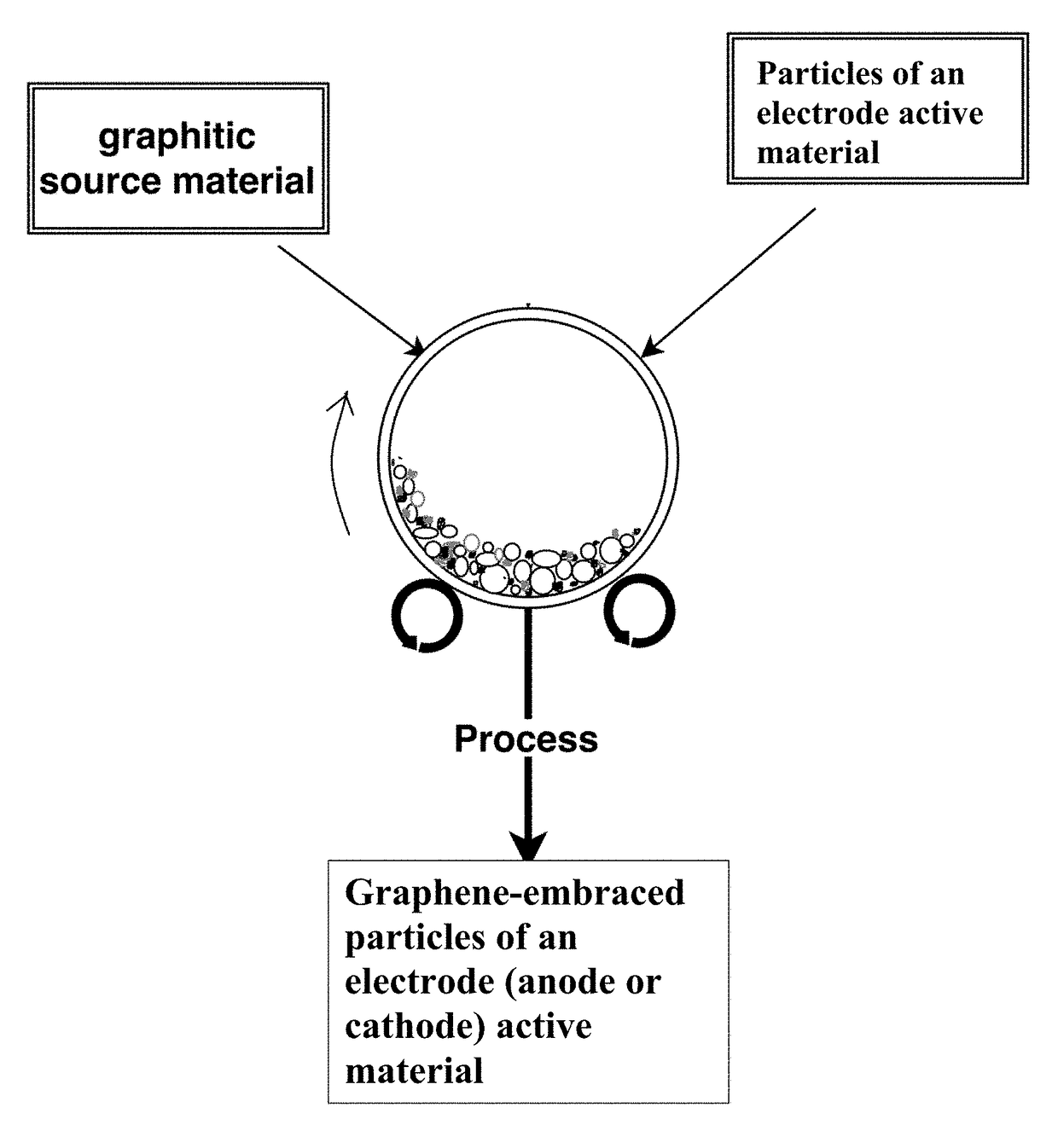

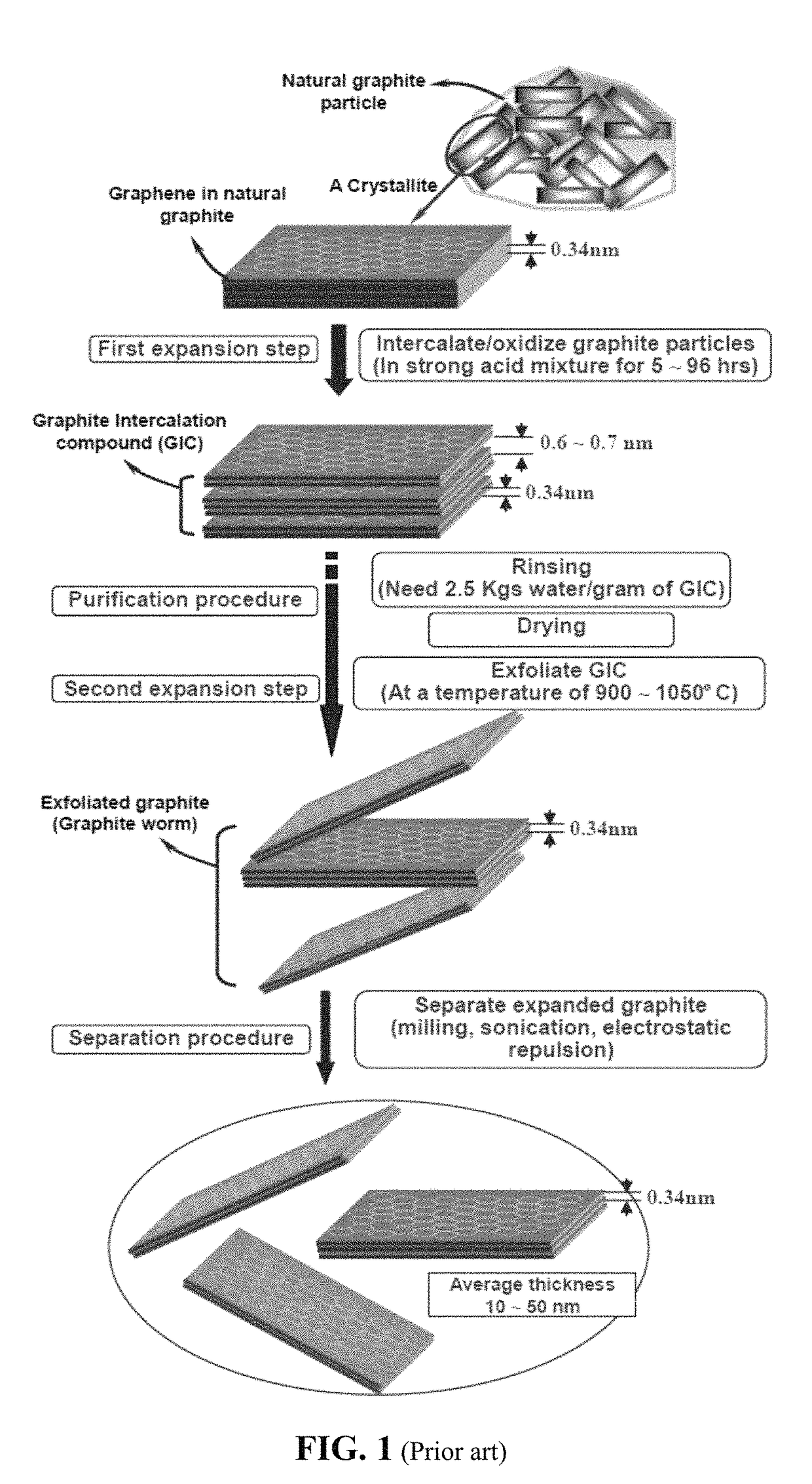

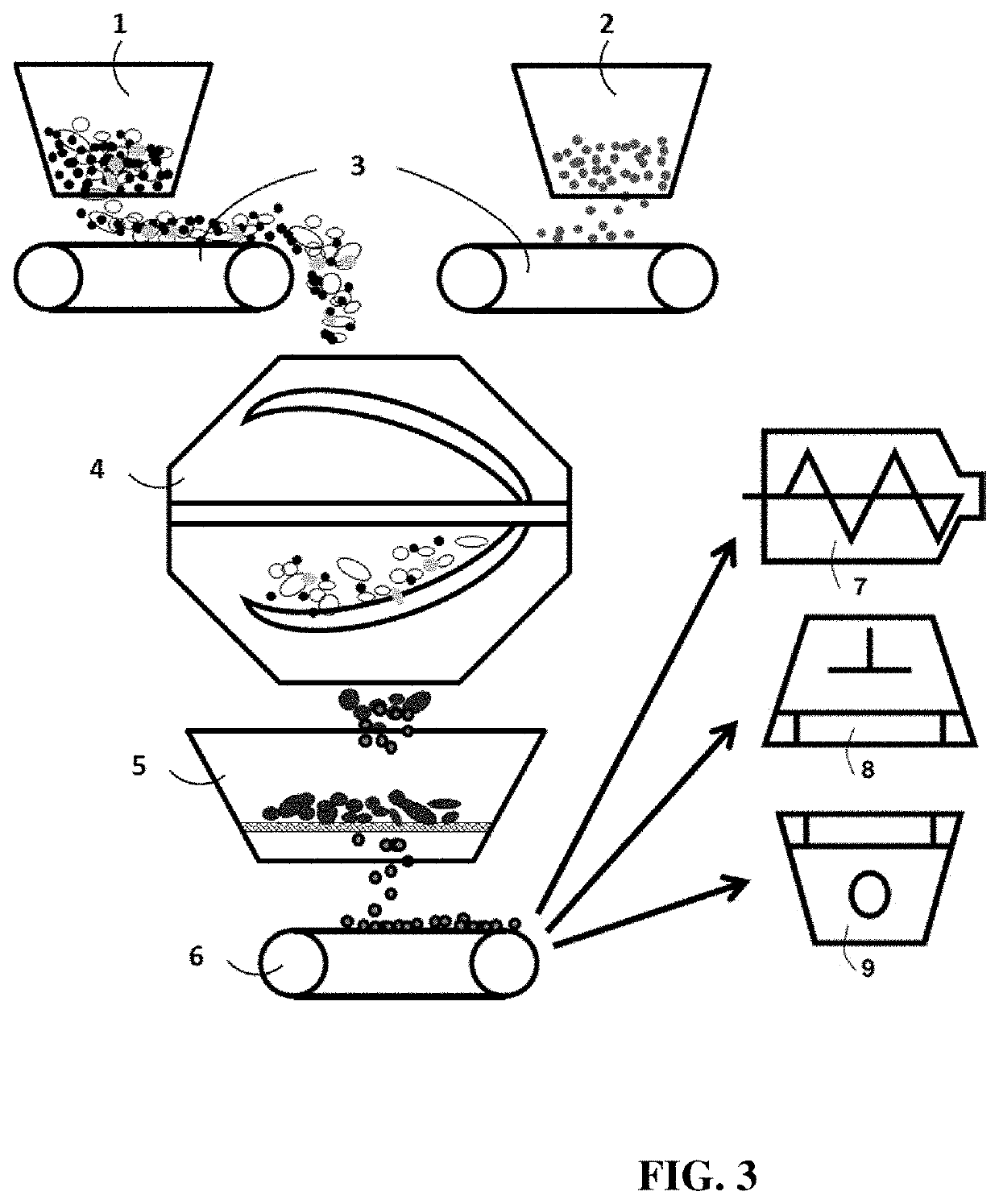

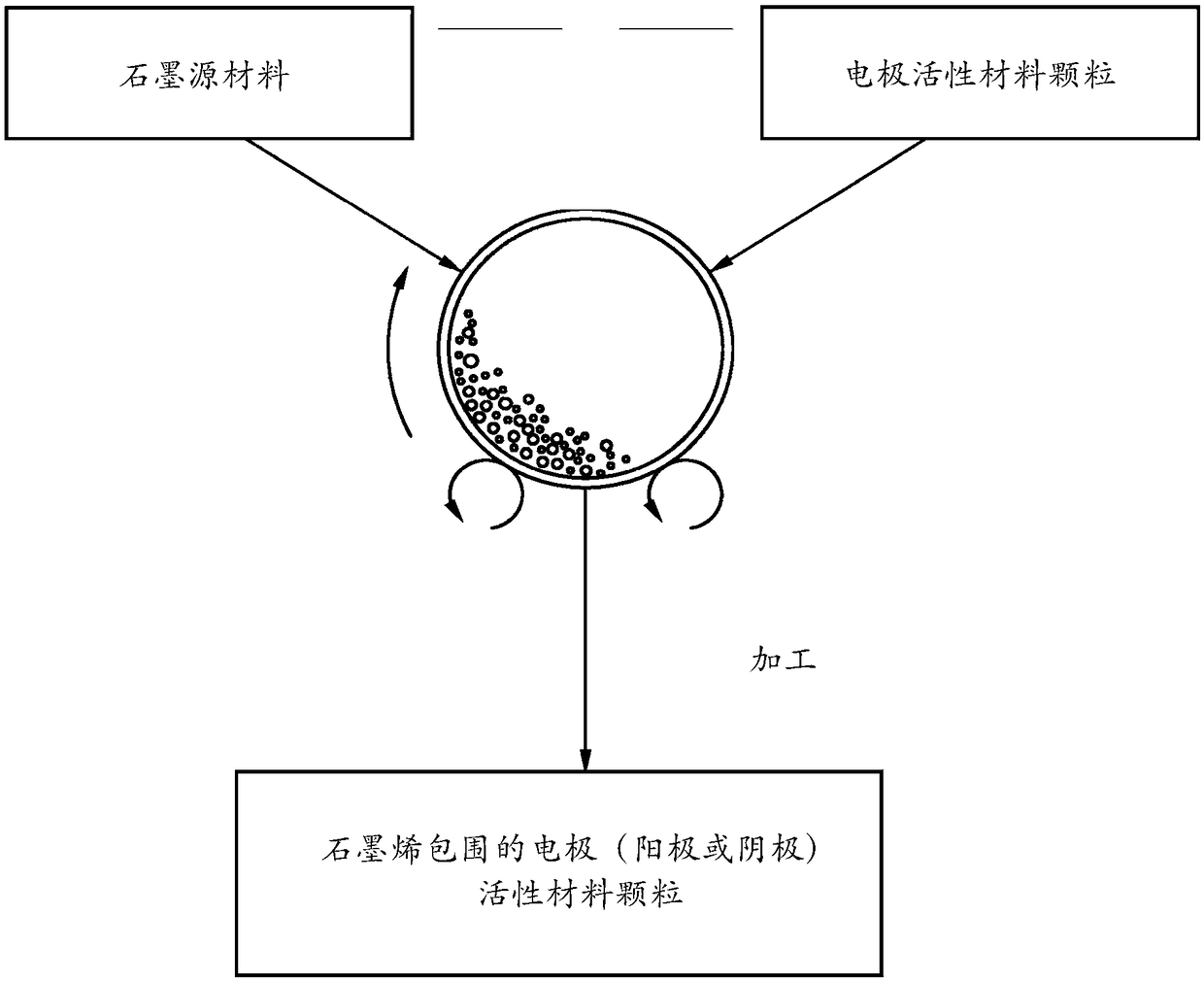

Provided is a simple, fast, scalable, and environmentally benign method of producing graphene-embraced or encapsulated particles of a battery electrode active material directly from a graphitic material, the method comprising: a) mixing graphitic material particles and multiple particles of a solid electrode active material to form a mixture in an impacting chamber of an energy impacting apparatus, wherein the graphitic material has never been intercalated, oxidized, or exfoliated and the chamber contains therein no previously produced graphene sheets and no ball-milling media; b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for transferring graphene sheets from the graphitic material to surfaces of electrode active material particles to produce graphene-embraced electrode active material particles; and c) recovering the particles from the impacting chamber. Also provided is a mass of the graphene-embraced particles, electrode containing such particles, and battery containing this electrode.

Owner:GLOBAL GRAPHENE GRP INC

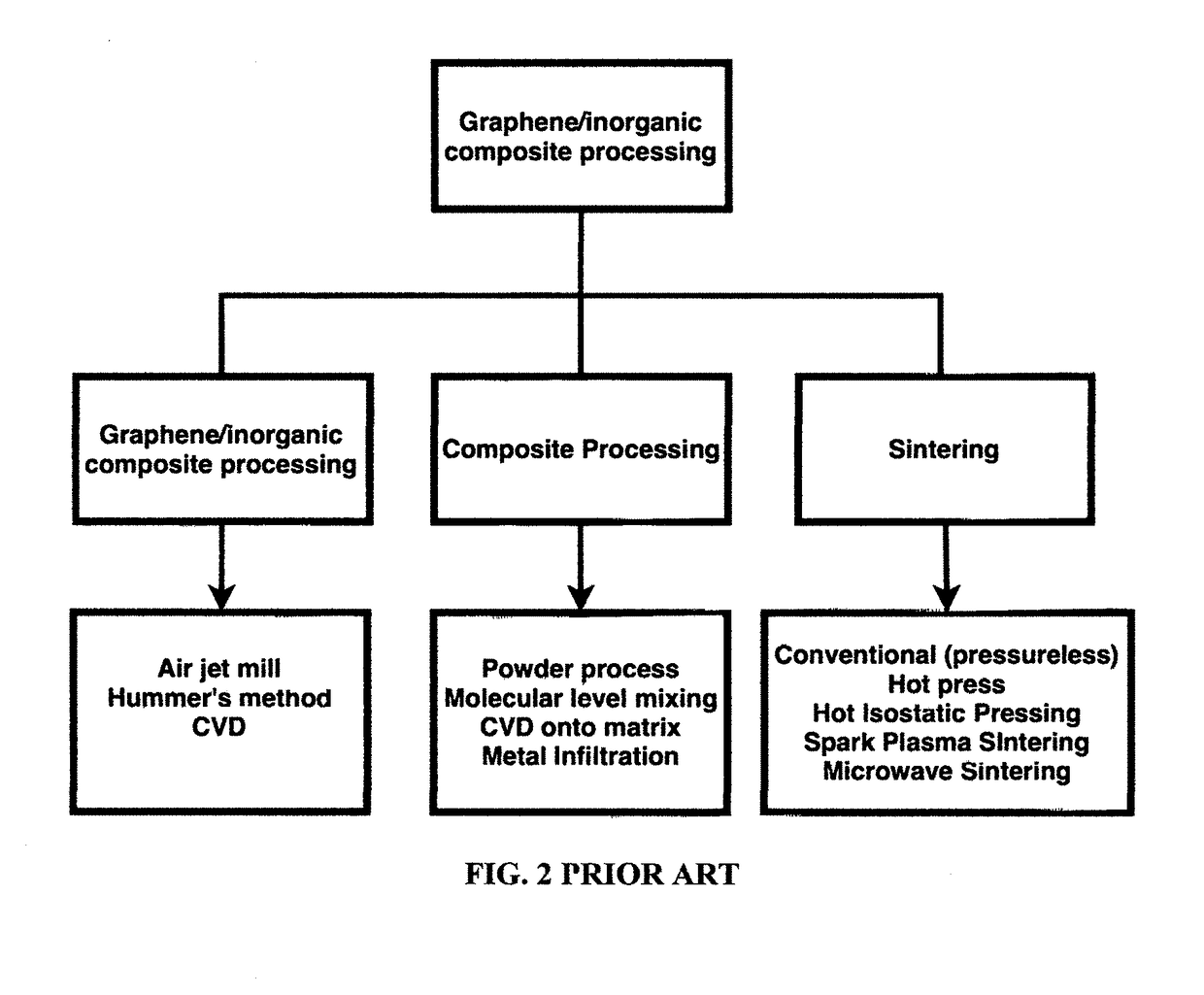

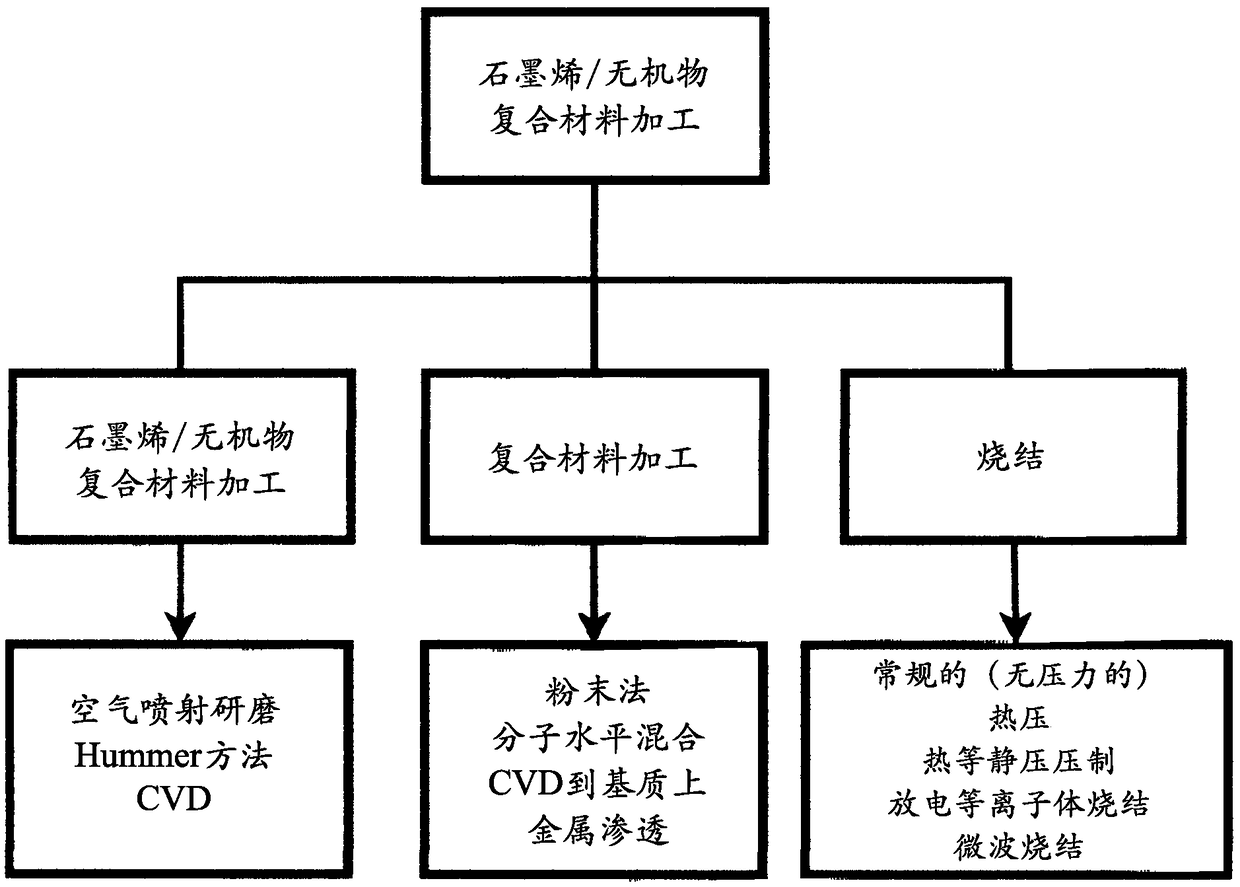

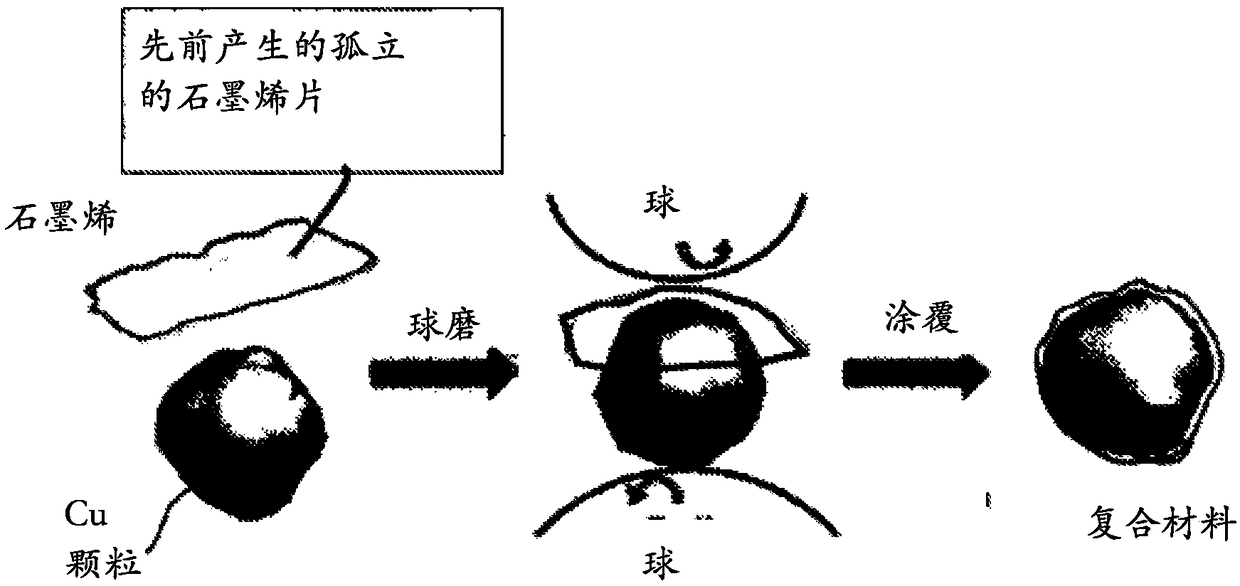

Chemical-free production of graphene-reinforced inorganic matrix composites

ActiveUS20170225233A1Low costAdditive manufacturing apparatusTransportation and packagingInorganic particleGraphene flake

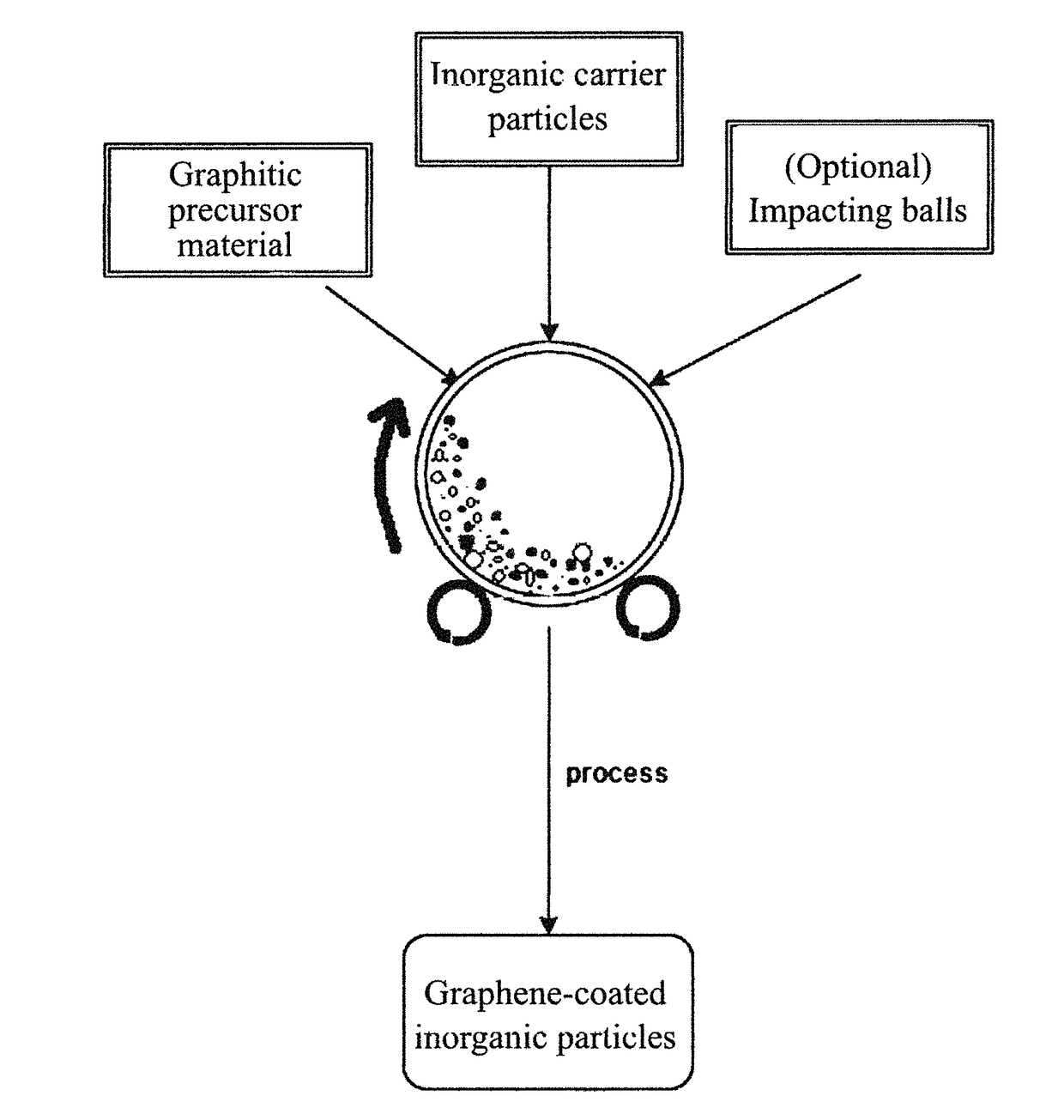

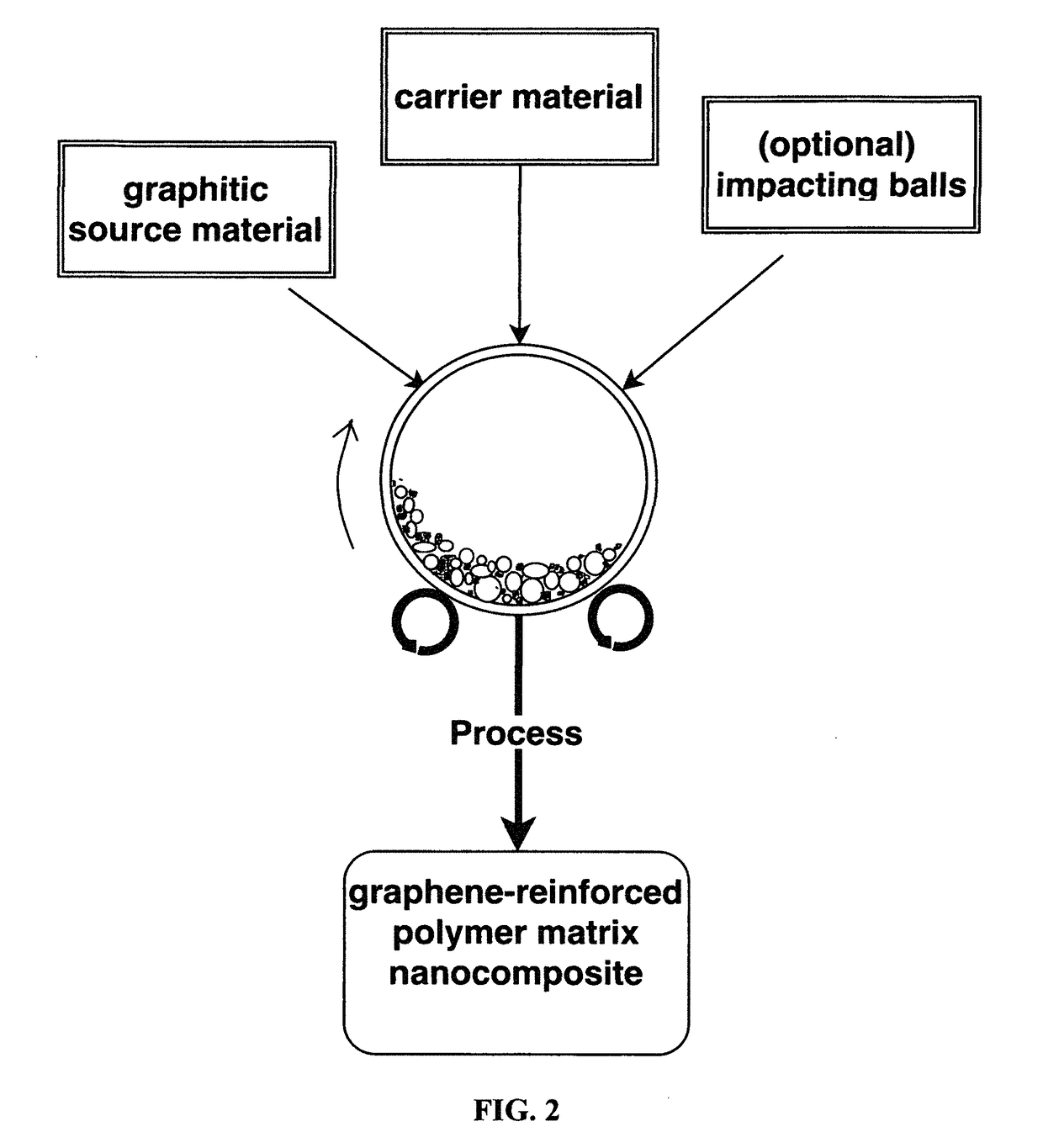

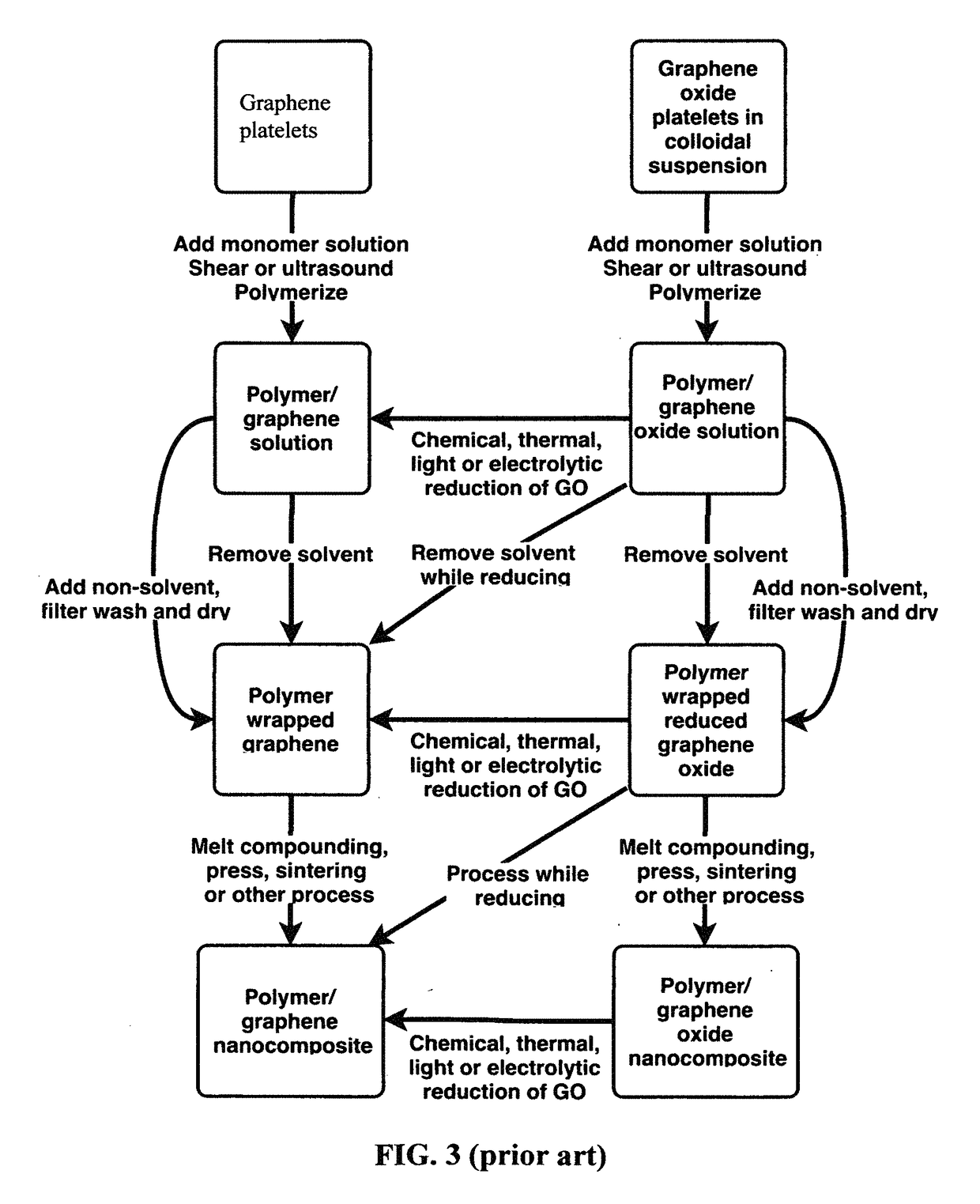

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced inorganic matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of an inorganic solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid inorganic carrier material particles to produce graphene coated or graphene-embedded inorganic particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded inorganic particles into the graphene-reinforced inorganic matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded inorganic particles produced by this method.

Owner:GLOBAL GRAPHENE GRP INC

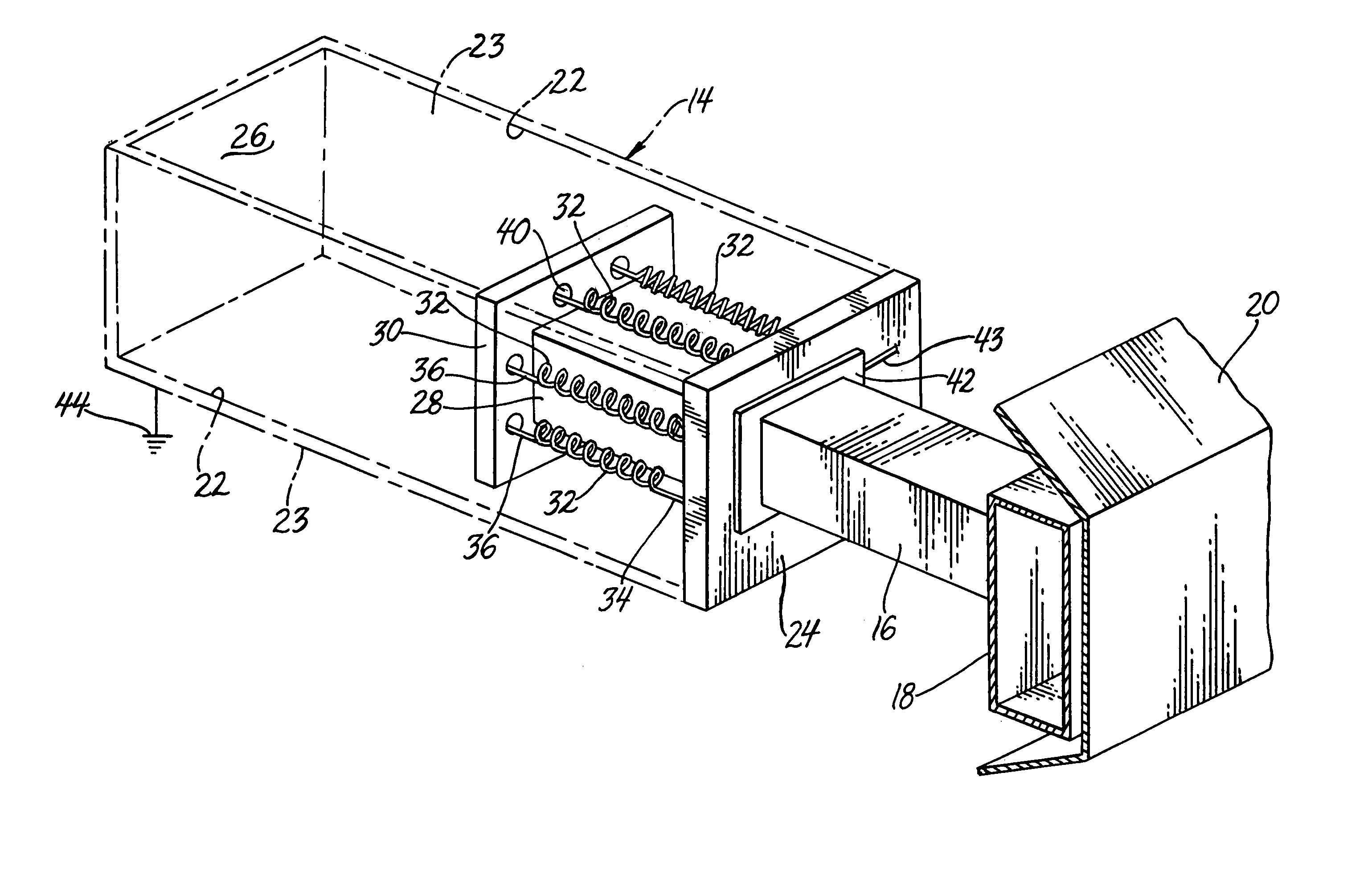

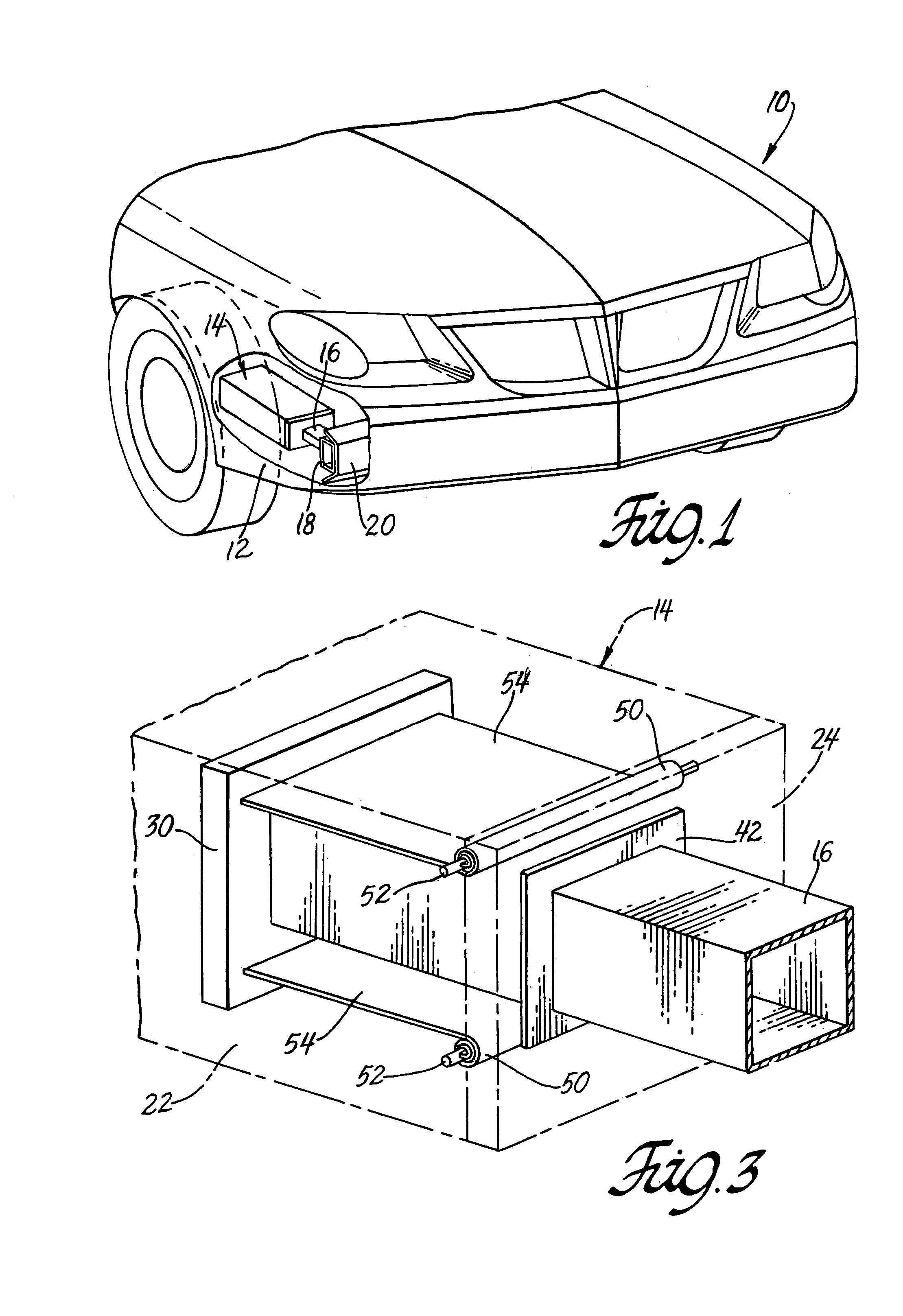

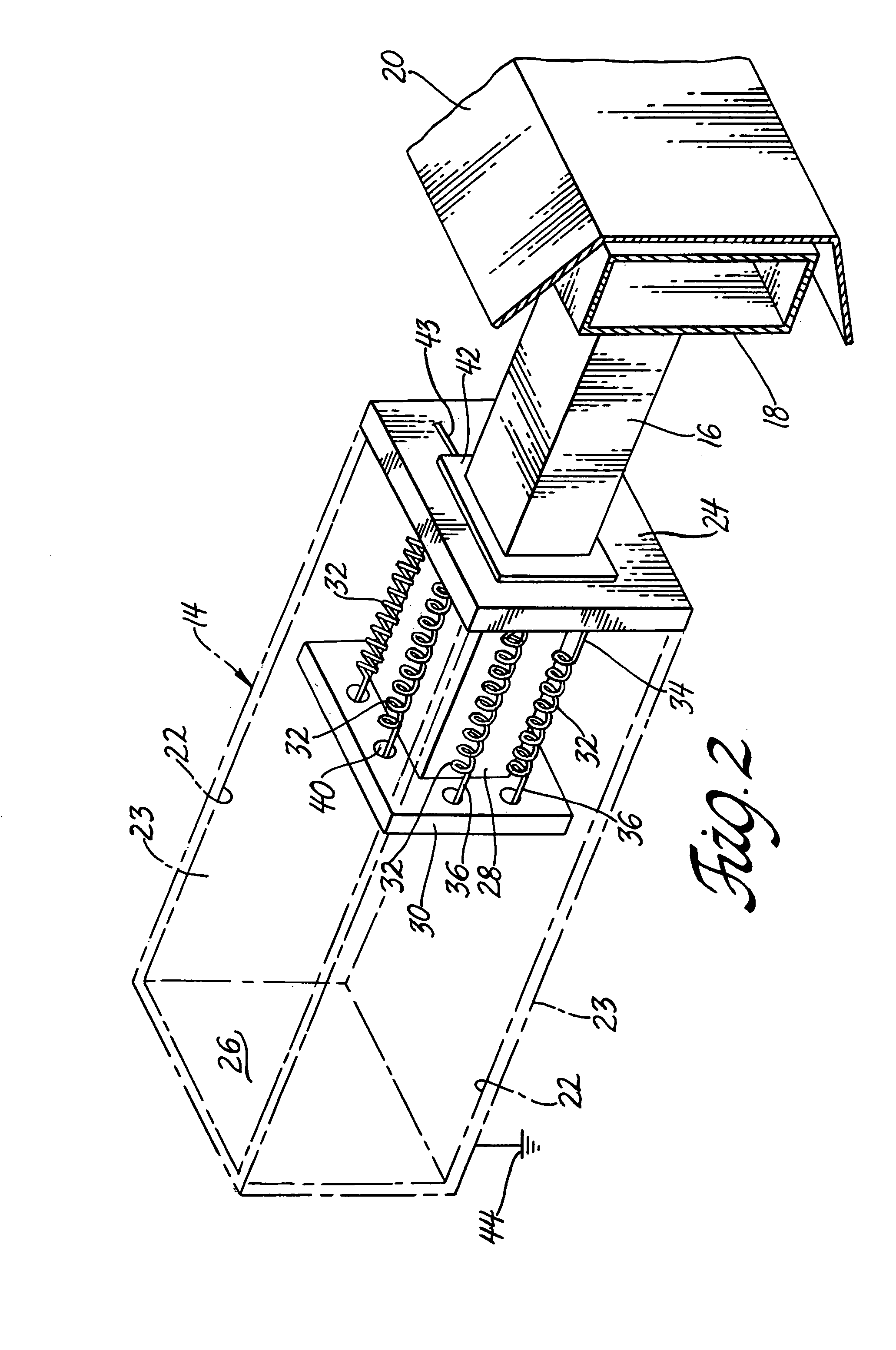

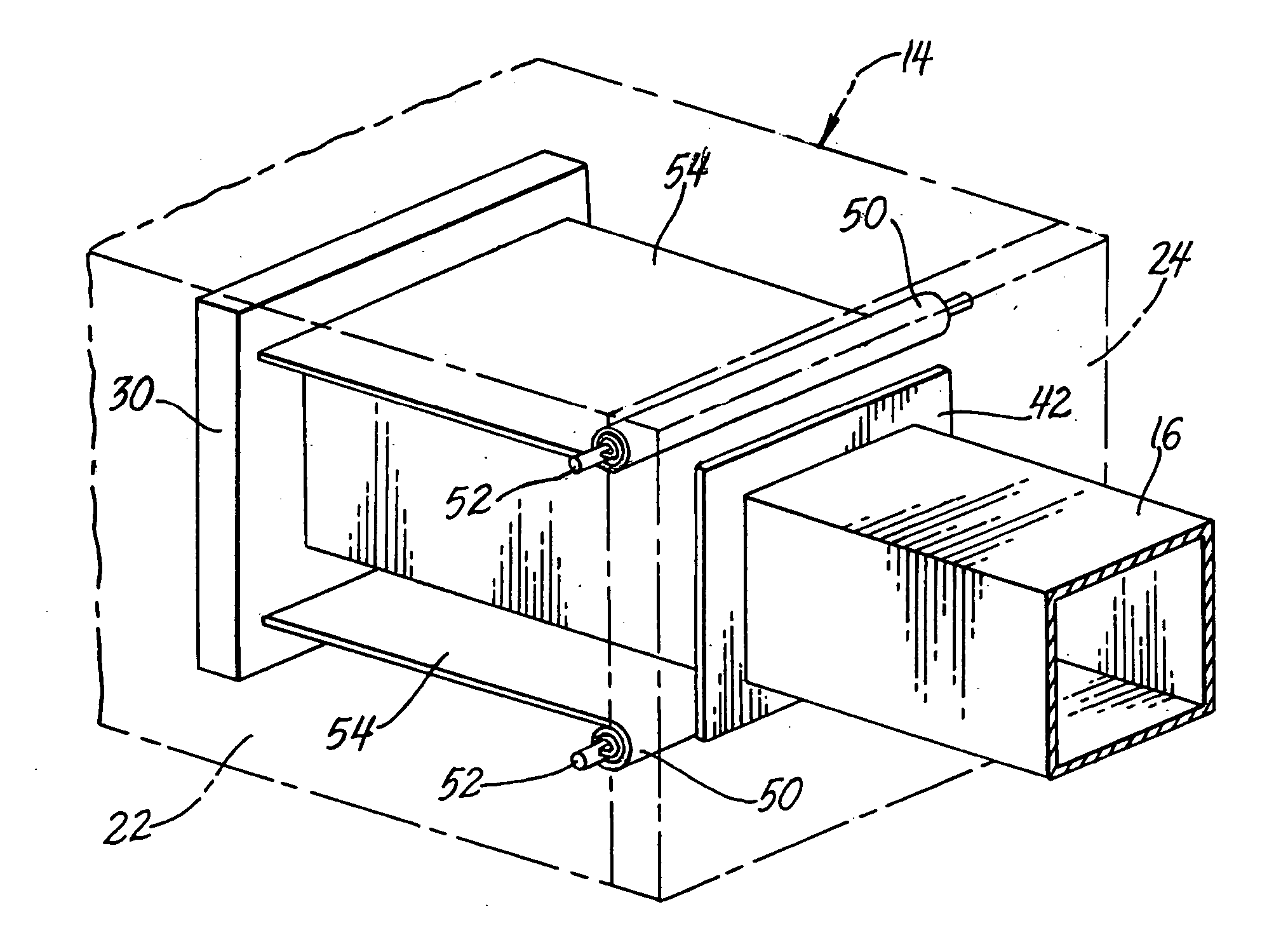

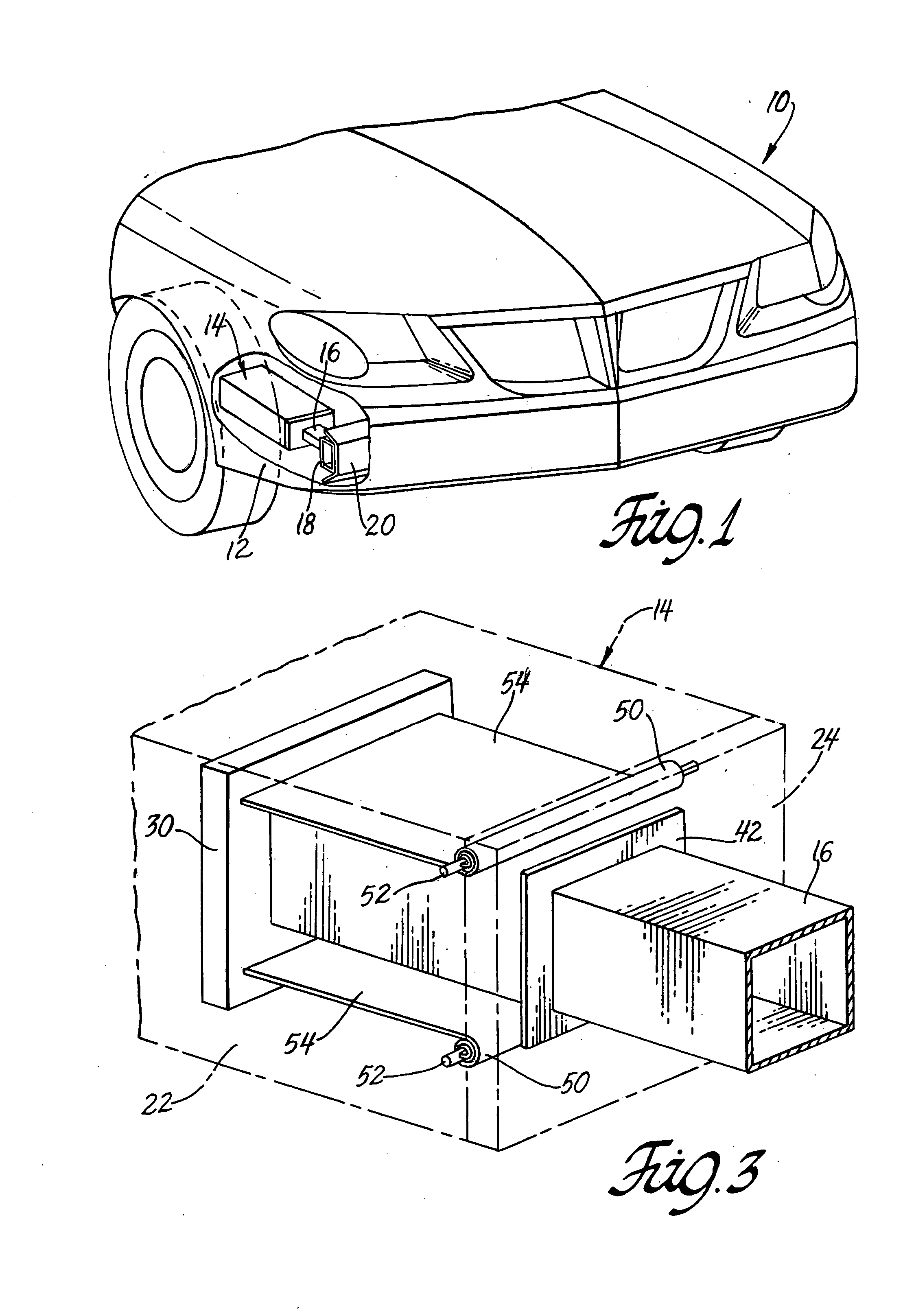

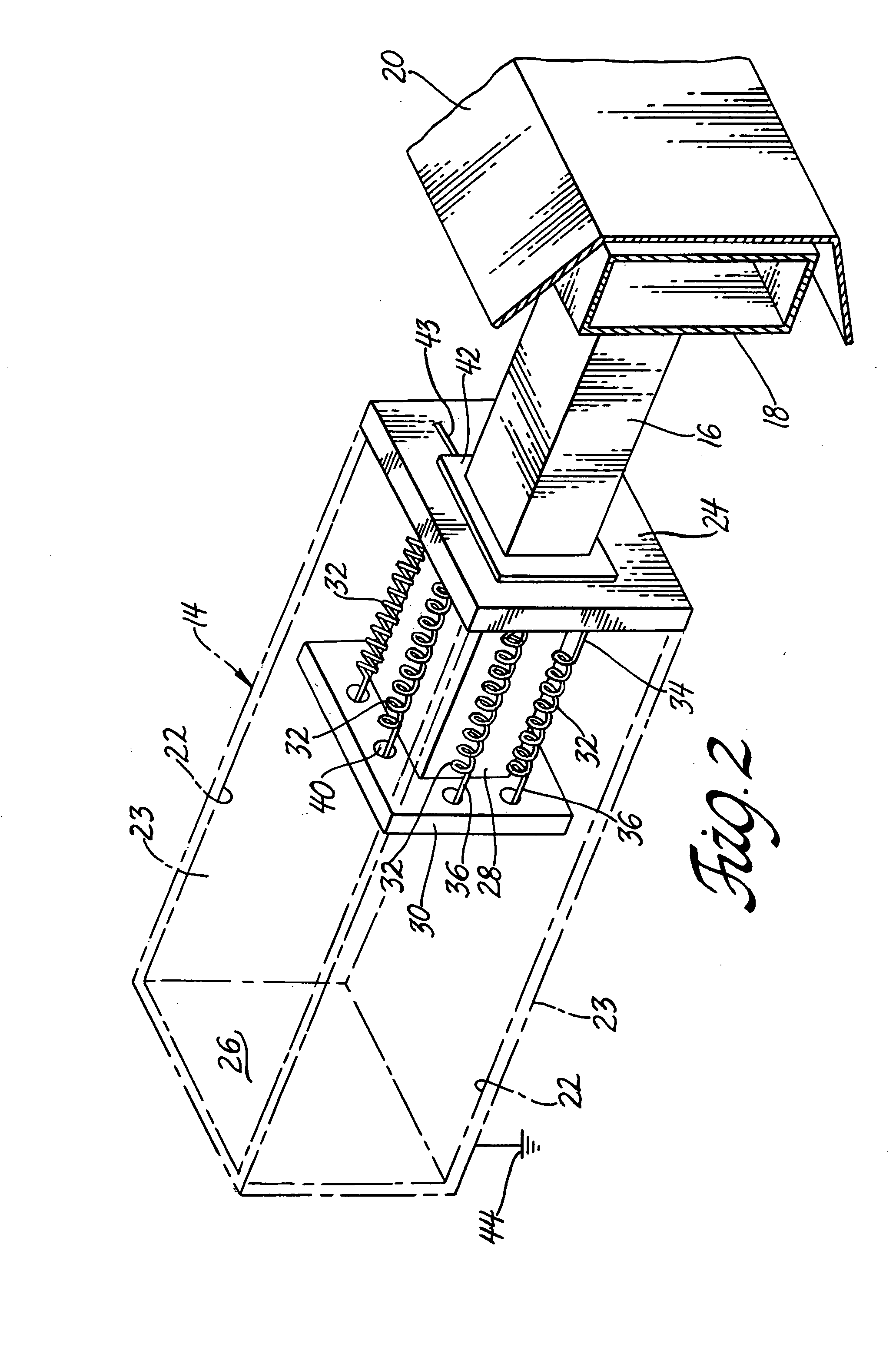

Tunable, healable vehicle impact devices

InactiveUS7029044B2Large energy absorption capacityImprove energy absorptionVehicle seatsPedestrian/occupant safety arrangementLow speedEnergy absorption

Owner:GM GLOBAL TECH OPERATIONS LLC

Tunable, healable vehicle impact devices

ActiveUS20050104391A1Low costLarge energy absorption capacityBumpersShock absorbersLow speedEnergy absorption

An impact absorbing device for a vehicle uses a shape memory material that can be heated to repair deformation from a relatively low speed, low energy impact and its stroking force and energy absorption can be tuned by heating. The shape memory material is suitably used in a crash box having an inserted impact absorbing ram, the box being placed, for example, between a bumper and strong body member. The shape memory material is attached to the box and ram for absorbing energy as the ram is driven into the box. Heating means is provided to repair or tune the shape memory material.

Owner:GM GLOBAL TECH OPERATIONS LLC

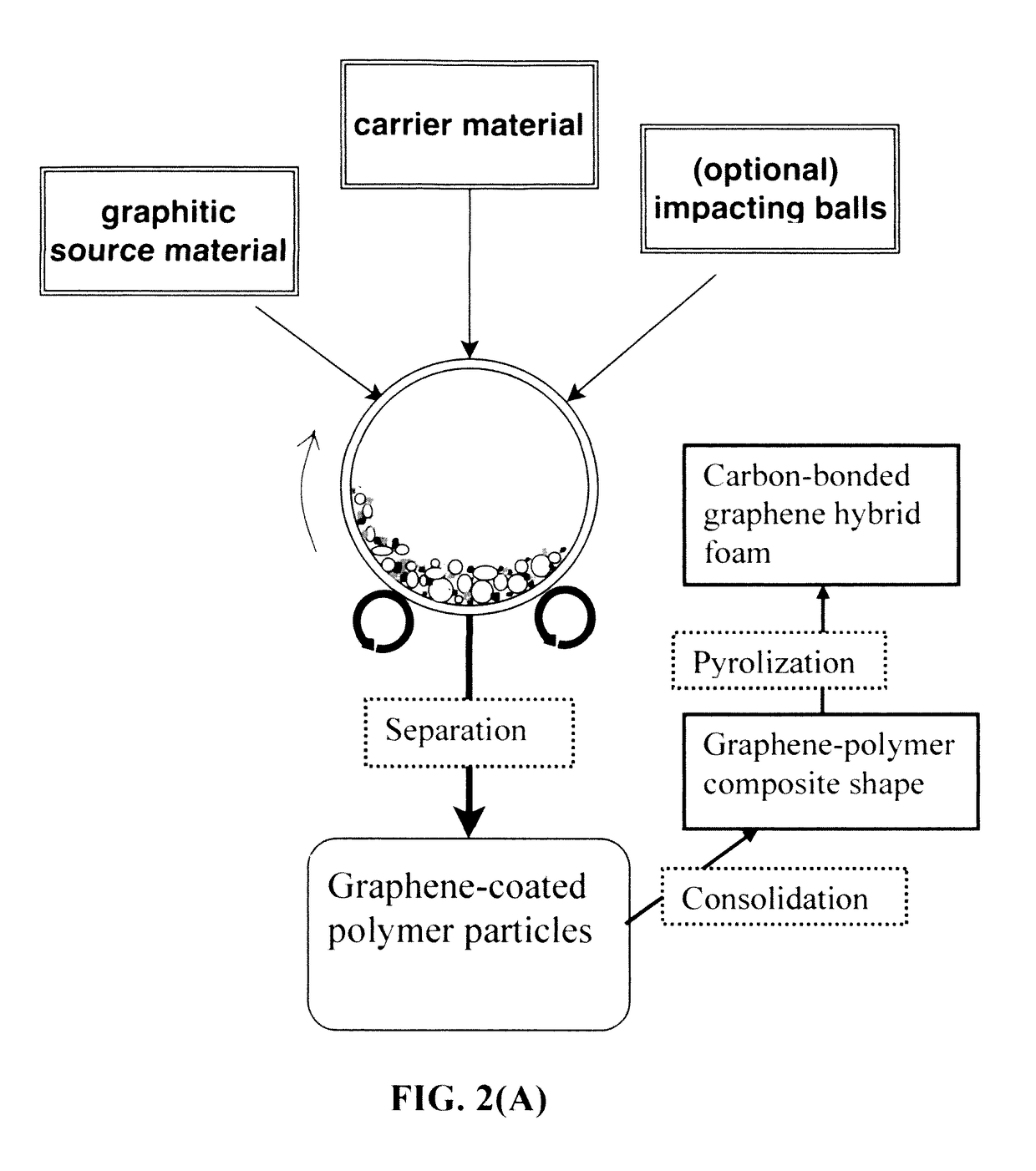

Chemical-free production of 3D graphene-carbon hybrid foam

ActiveUS9597657B1Increase heightReduce yieldCarbon compoundsOther chemical processesEnergy impactGraphite

Provided is a method of producing an integral 3D graphene-carbon hybrid foam, comprising: (a) mixing multiple particles of a graphitic material and multiple particles of a solid polymer carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus to peel off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid polymer carrier material particles to produce graphene-coated polymer particles; (c) recovering the graphene-coated polymer particles from the impacting chamber and consolidating the graphene-coated polymer particles into a desired shape of graphene-polymer composite structure; and (d) pyrolyzing the shape of graphene-polymer composite structure to thermally convert the polymer into carbon or graphite that bonds the graphene sheets to form the integral 3D graphene-carbon hybrid foam.

Owner:GLOBAL GRAPHENE GRP INC

Chemical-free production of graphene-wrapped electrode active material particles for battery applications

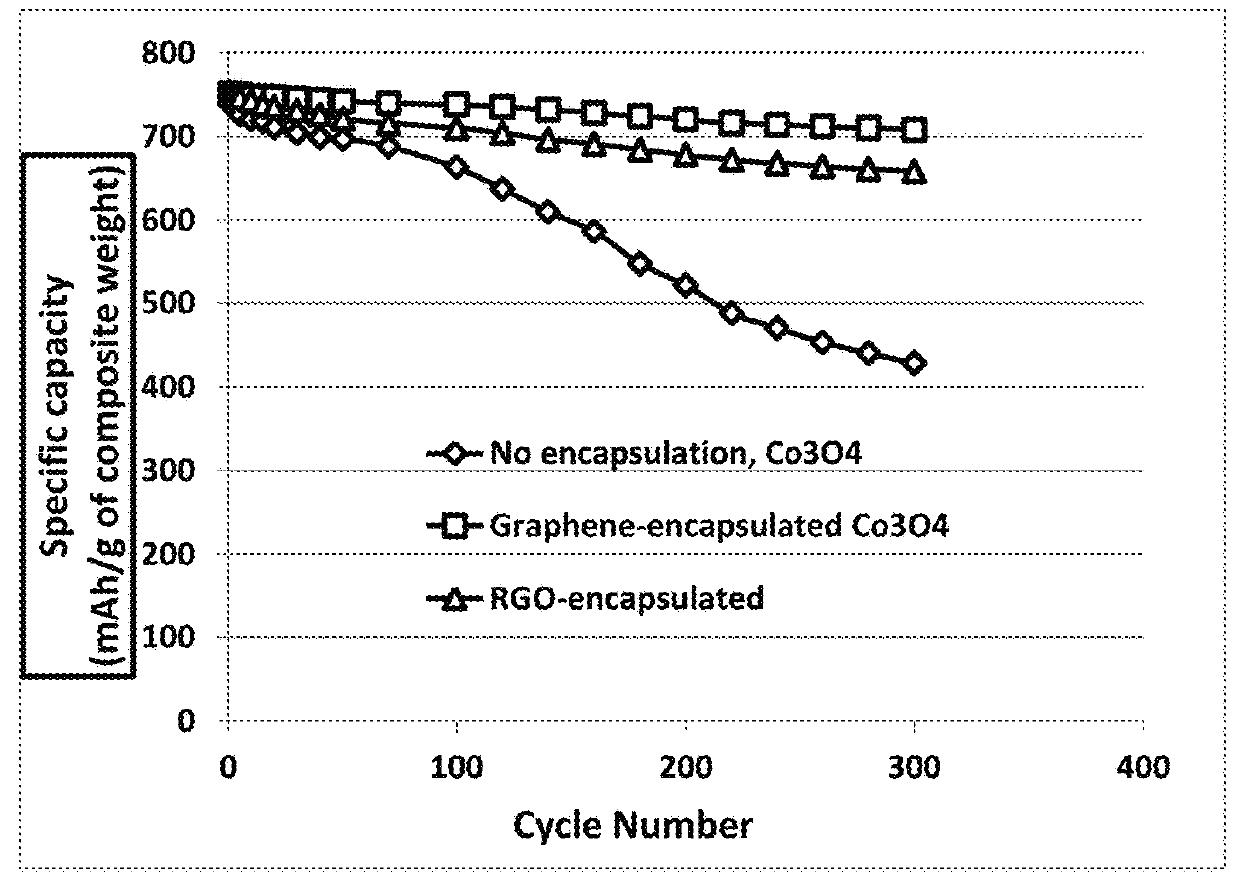

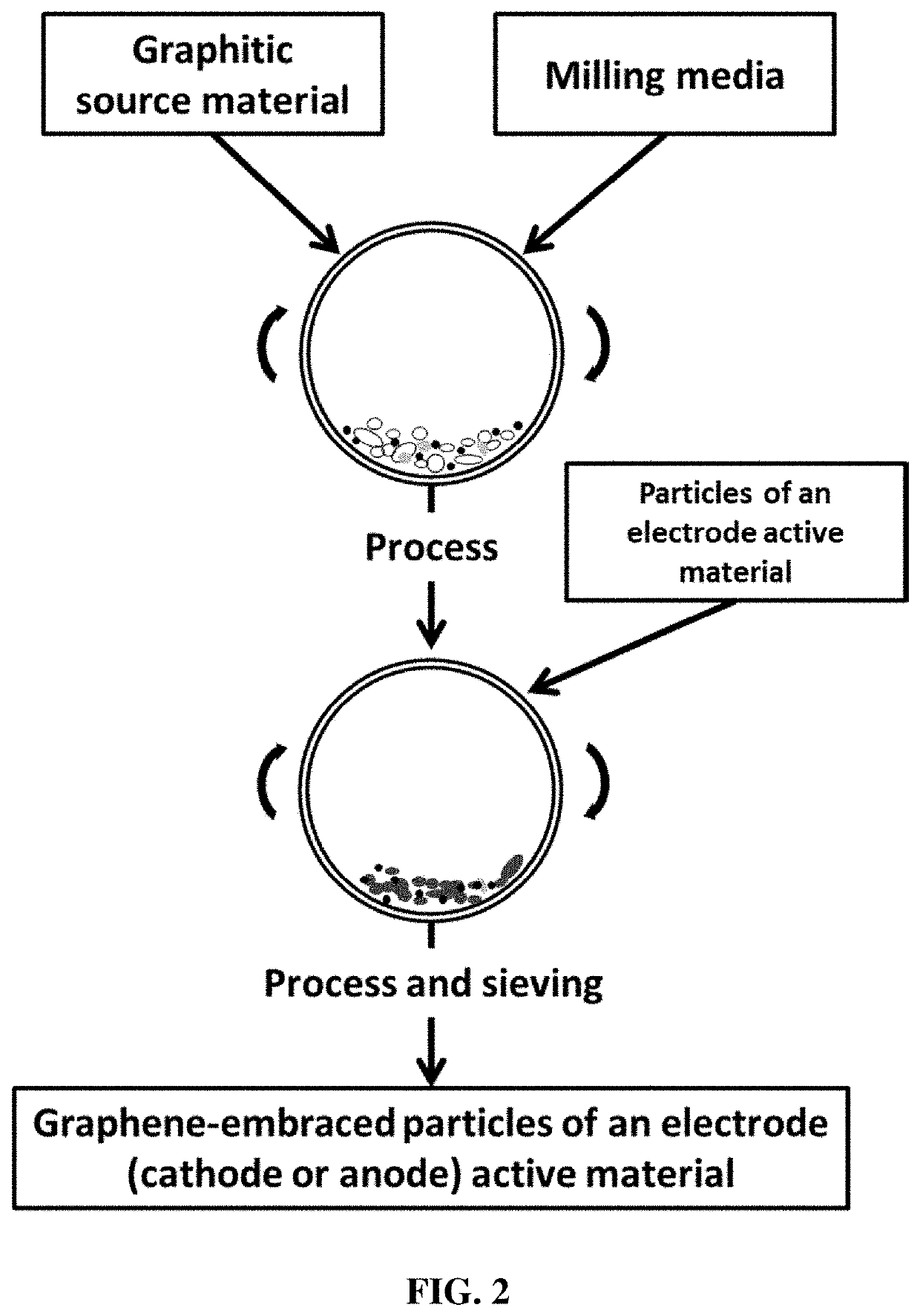

ActiveUS10008723B1Improve mechanical propertiesImprove thermal conductivityCell electrodesGrapheneEnergy impactGraphite

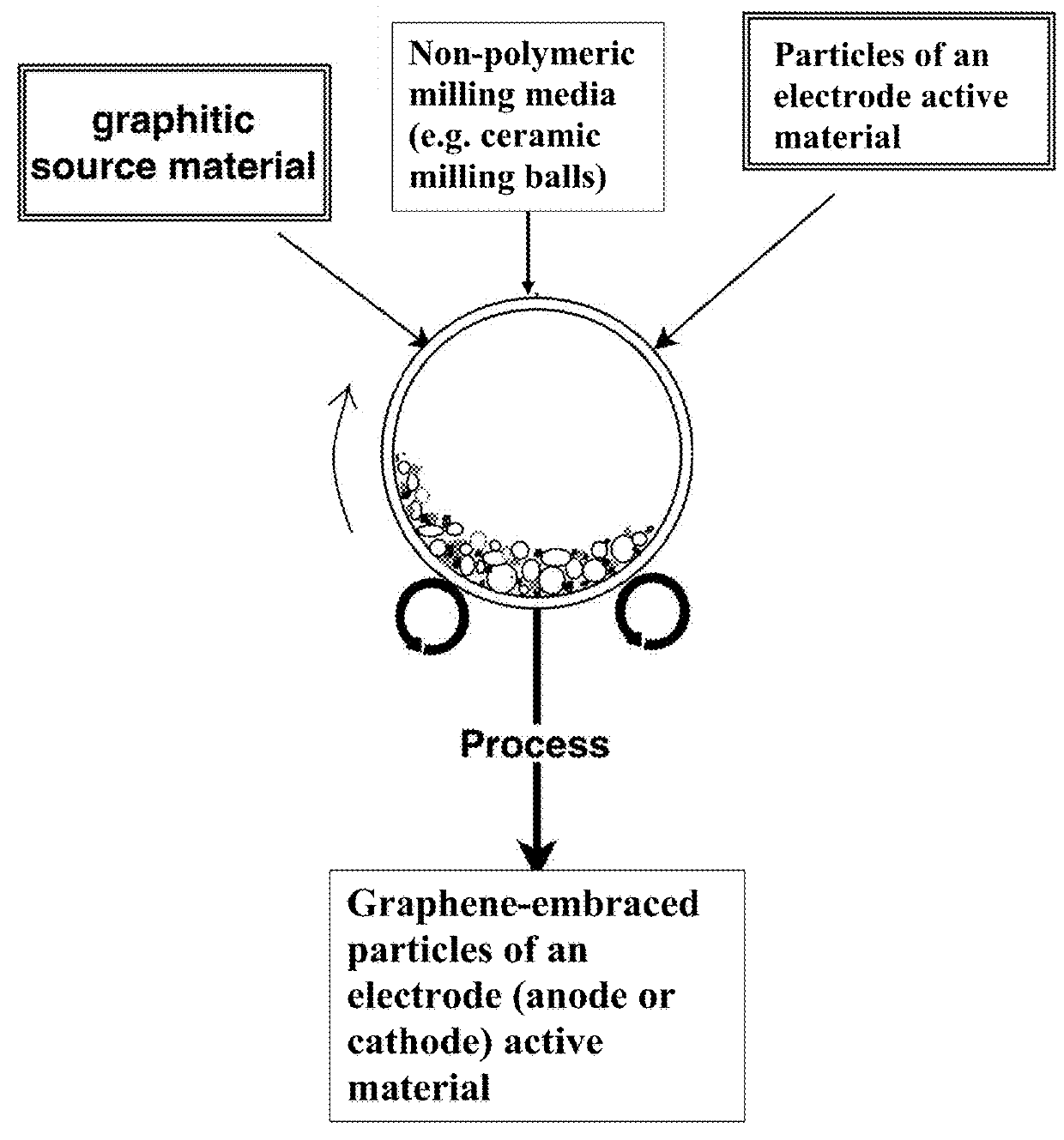

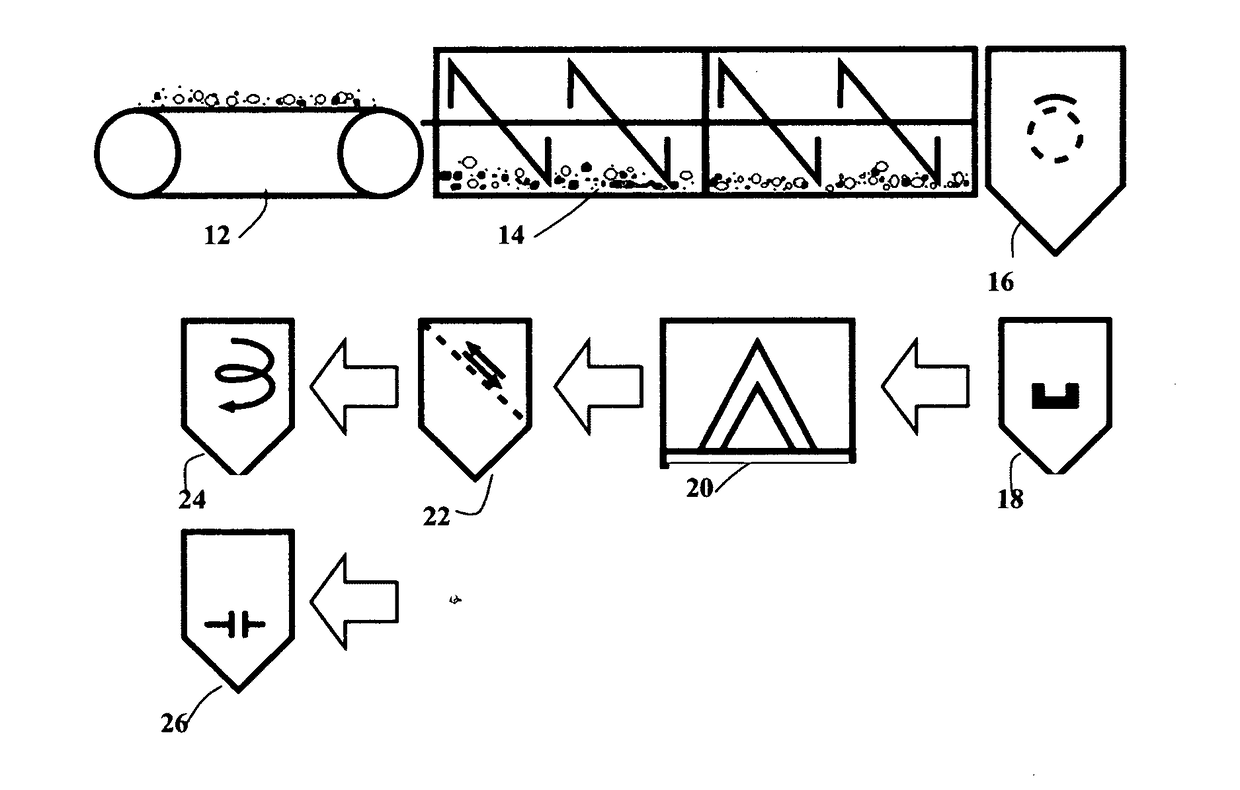

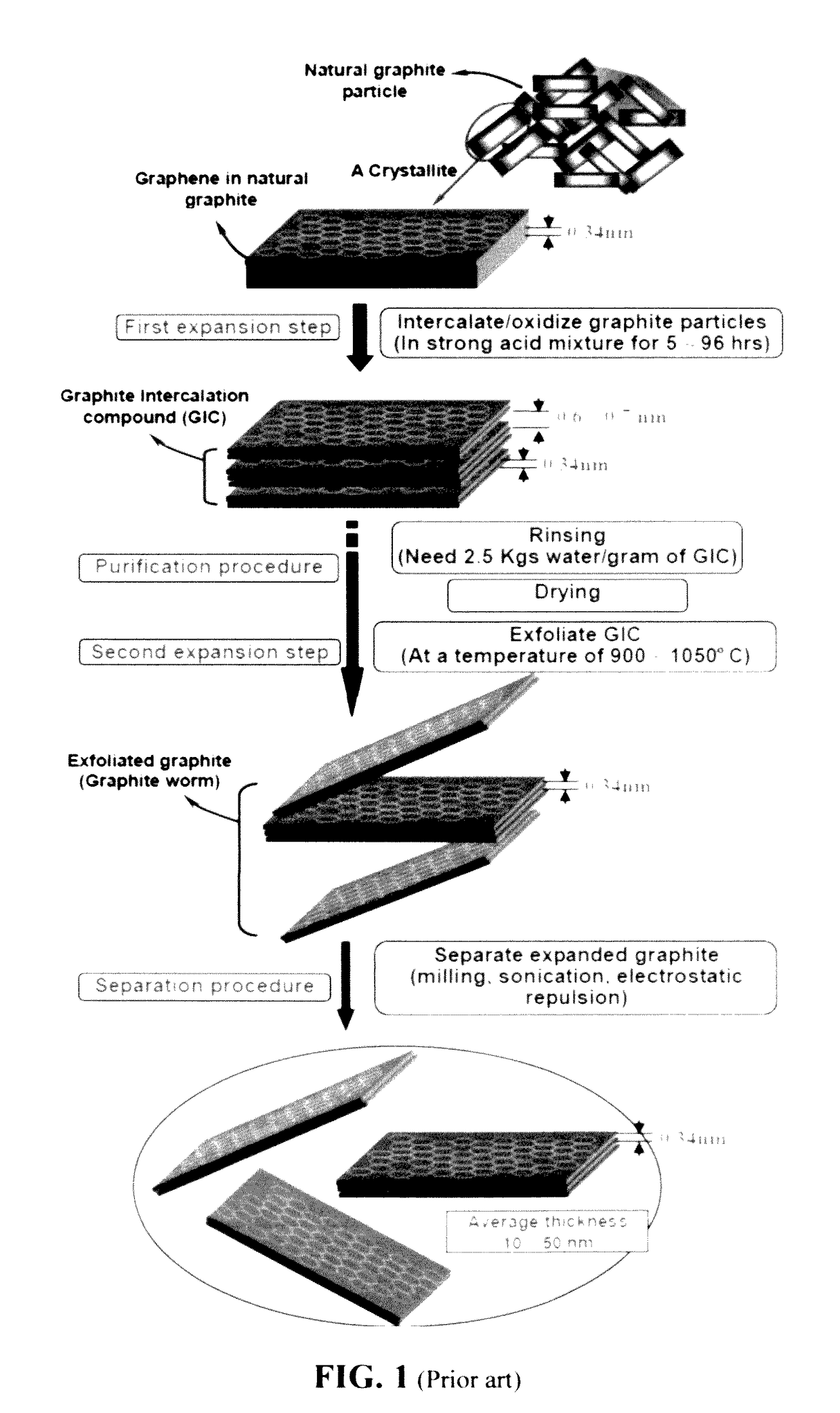

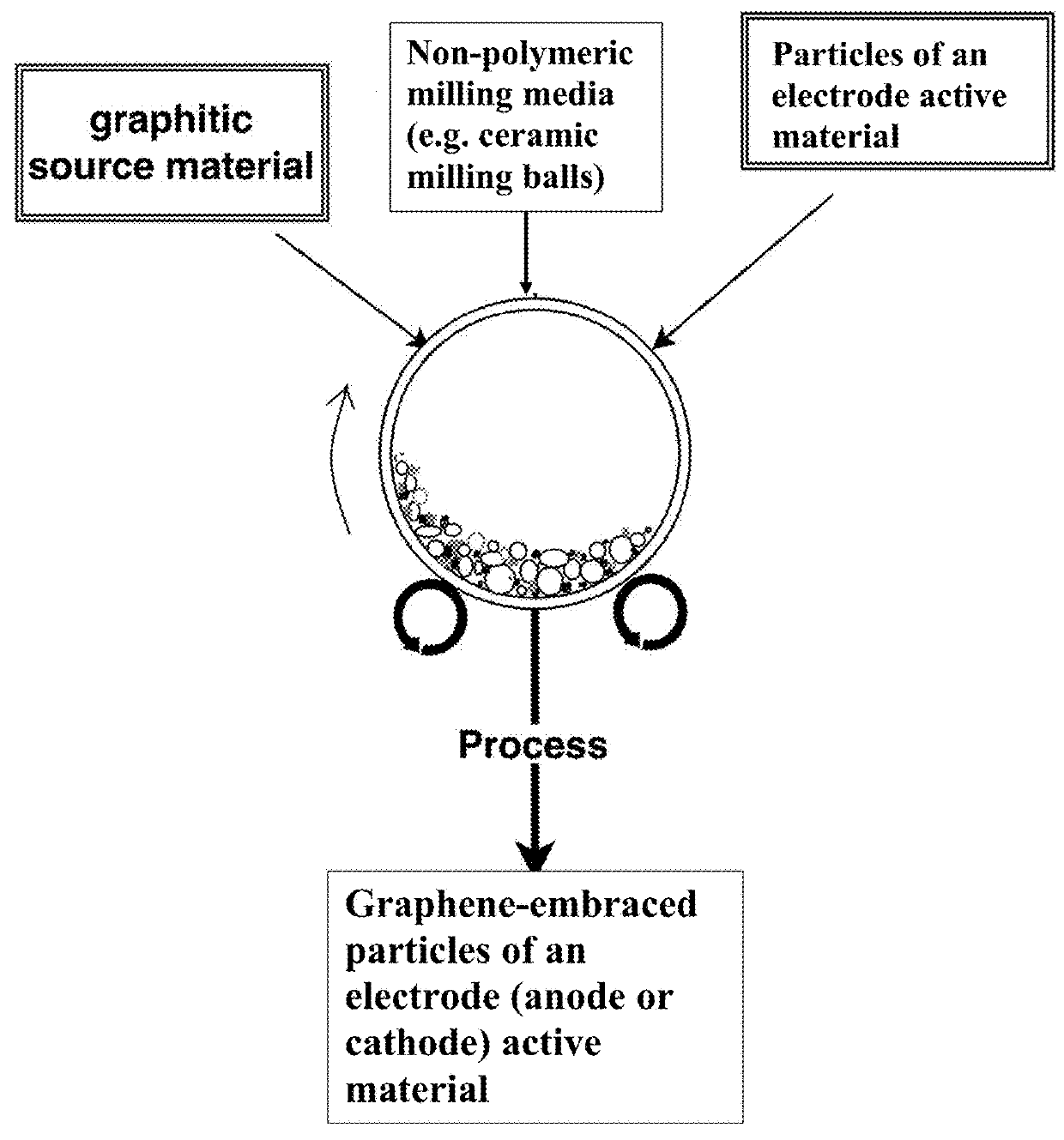

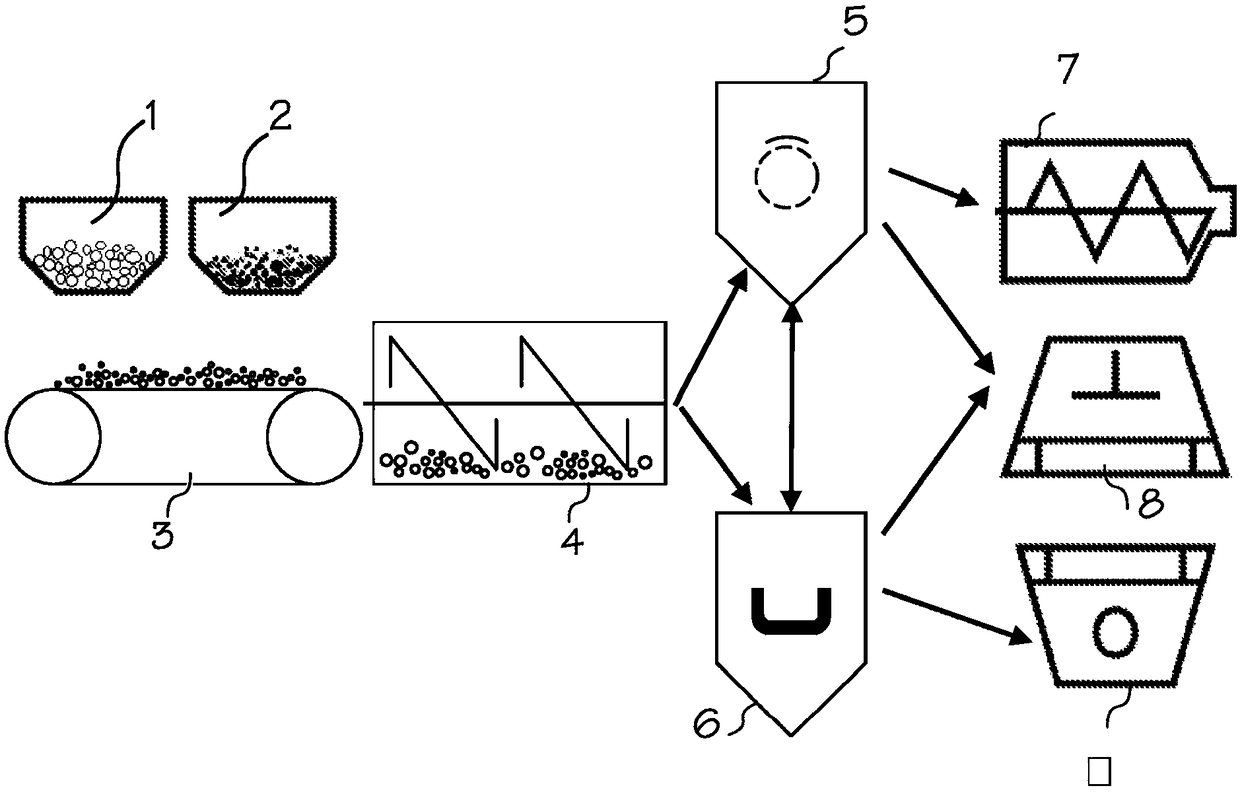

Provided is a simple, fast, scalable, and environmentally benign method of producing graphene-embraced or encapsulated particles of a battery electrode active material directly from a graphitic material, the method comprising: a) mixing graphitic material particles, multiple particles of an electrode active material, and non-polymeric particles of milling media to form a mixture in an impacting chamber, wherein the graphitic material has never been intercalated, oxidized, or exfoliated and the chamber contains therein no previously produced graphene sheets; b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring graphene sheets to surfaces of electrode active material particles to produce graphene-embraced active material particles; and c) recovering the graphene-embraced particles from the impacting chamber. Also provided is a mass of the graphene-embraced particles, electrode containing such particles, and battery containing this electrode.

Owner:GLOBAL GRAPHENE GRP INC

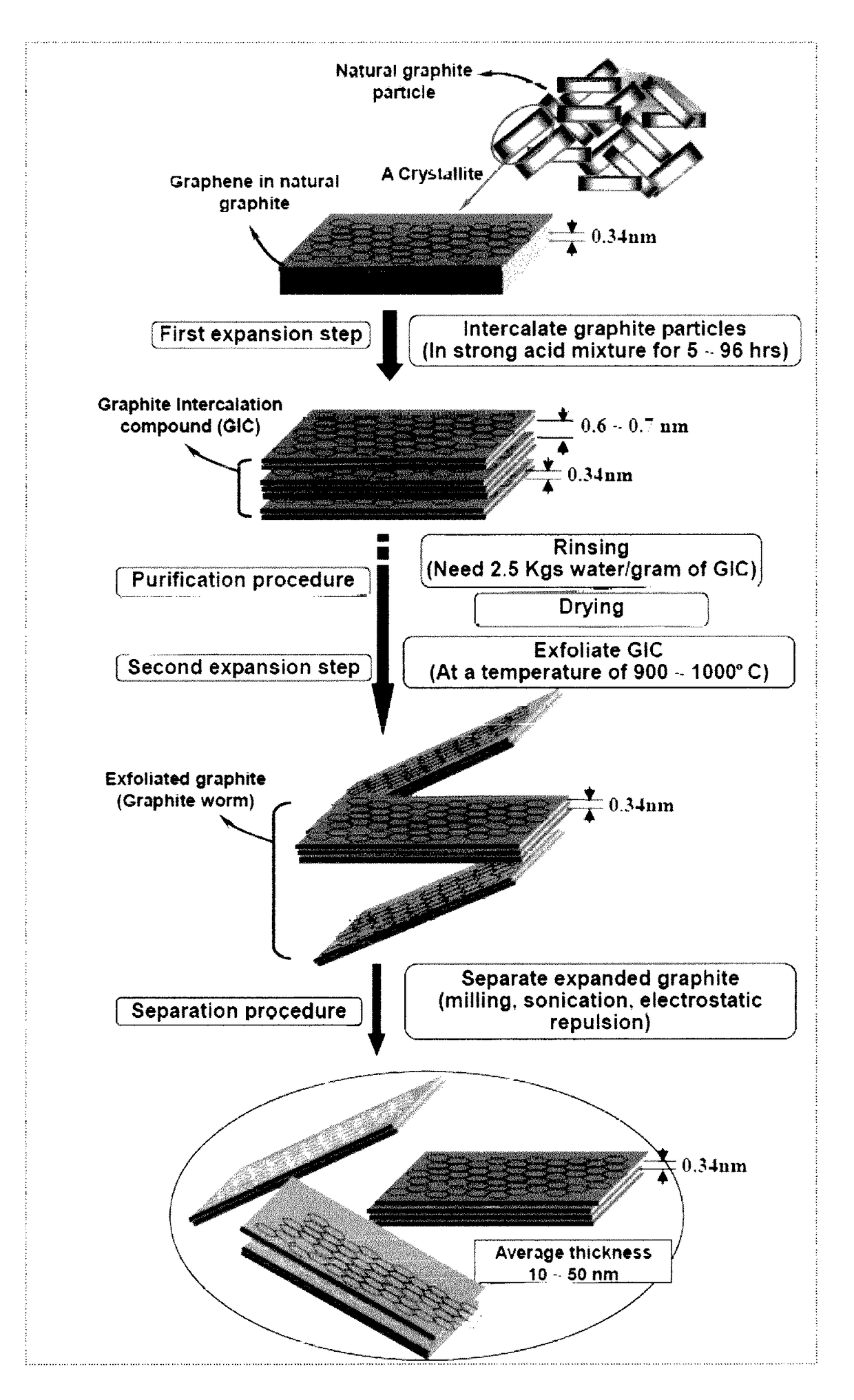

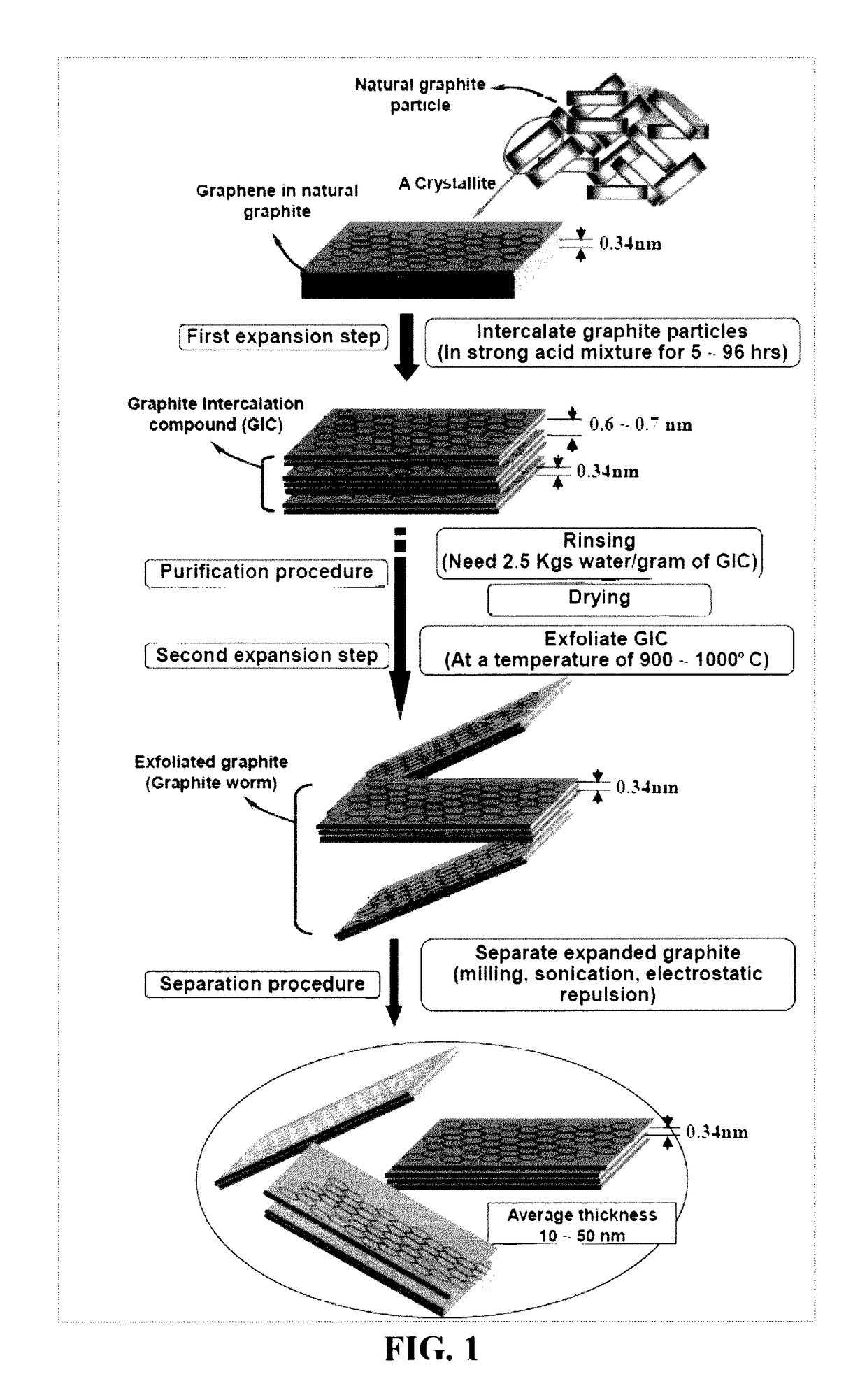

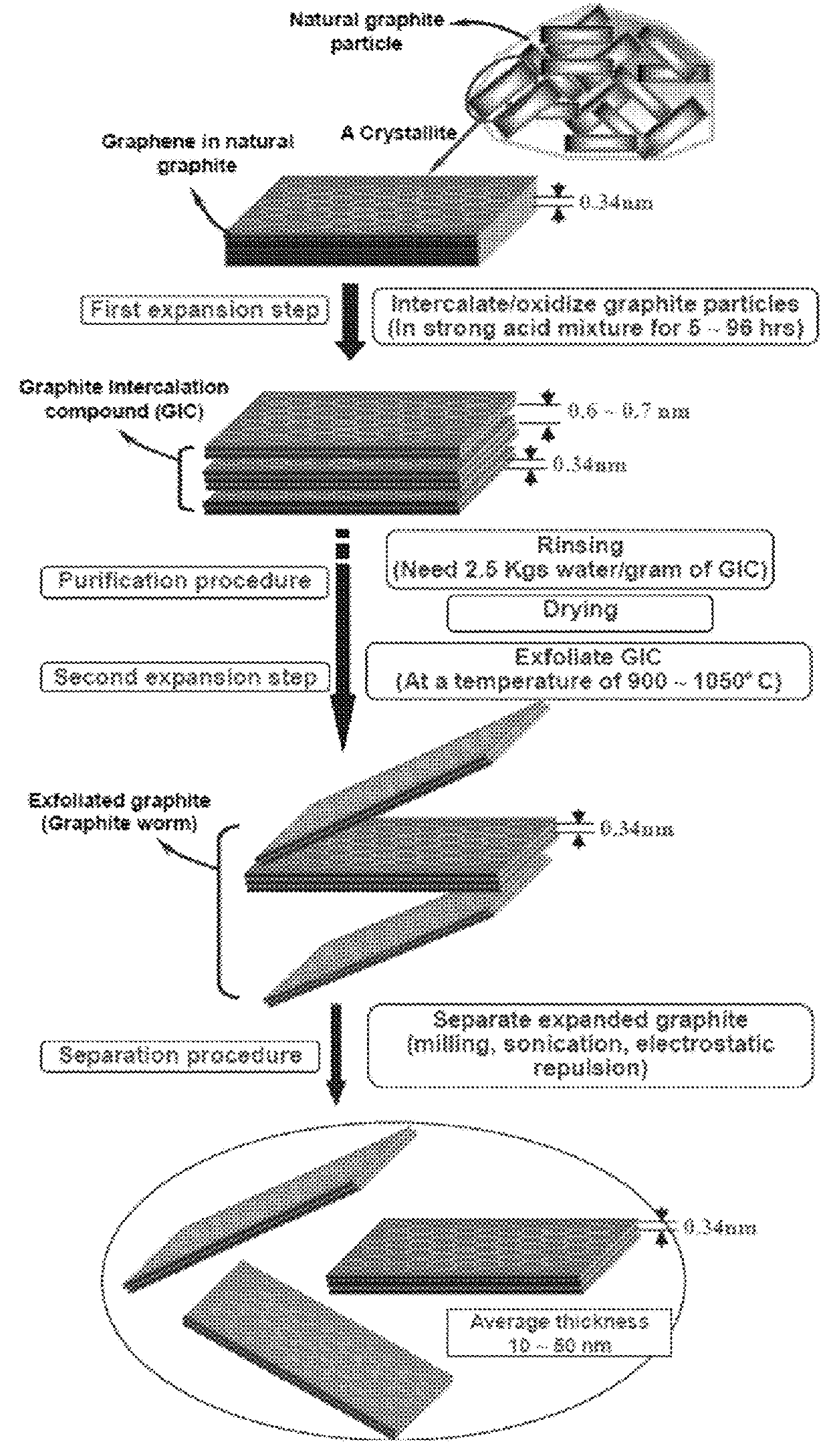

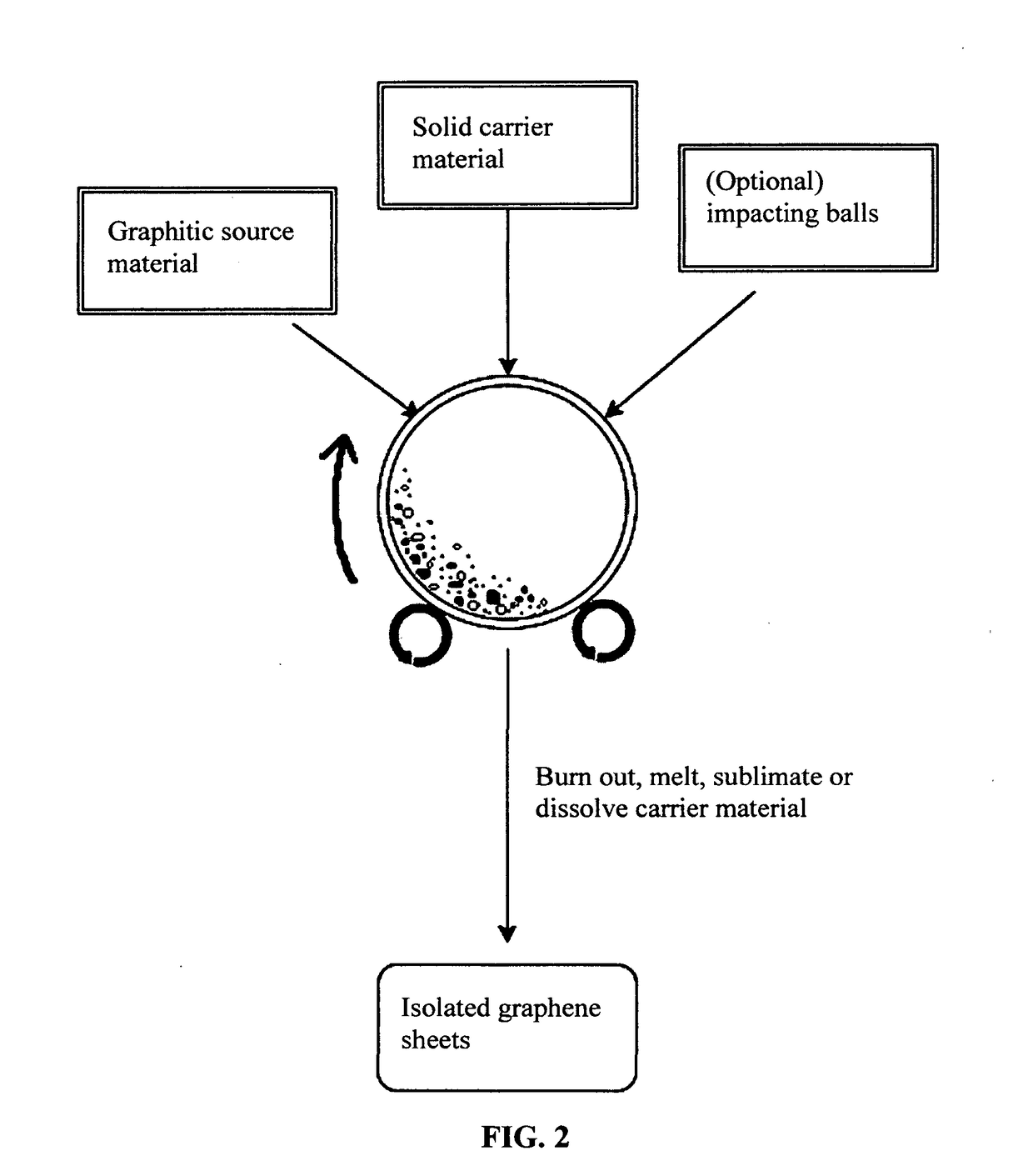

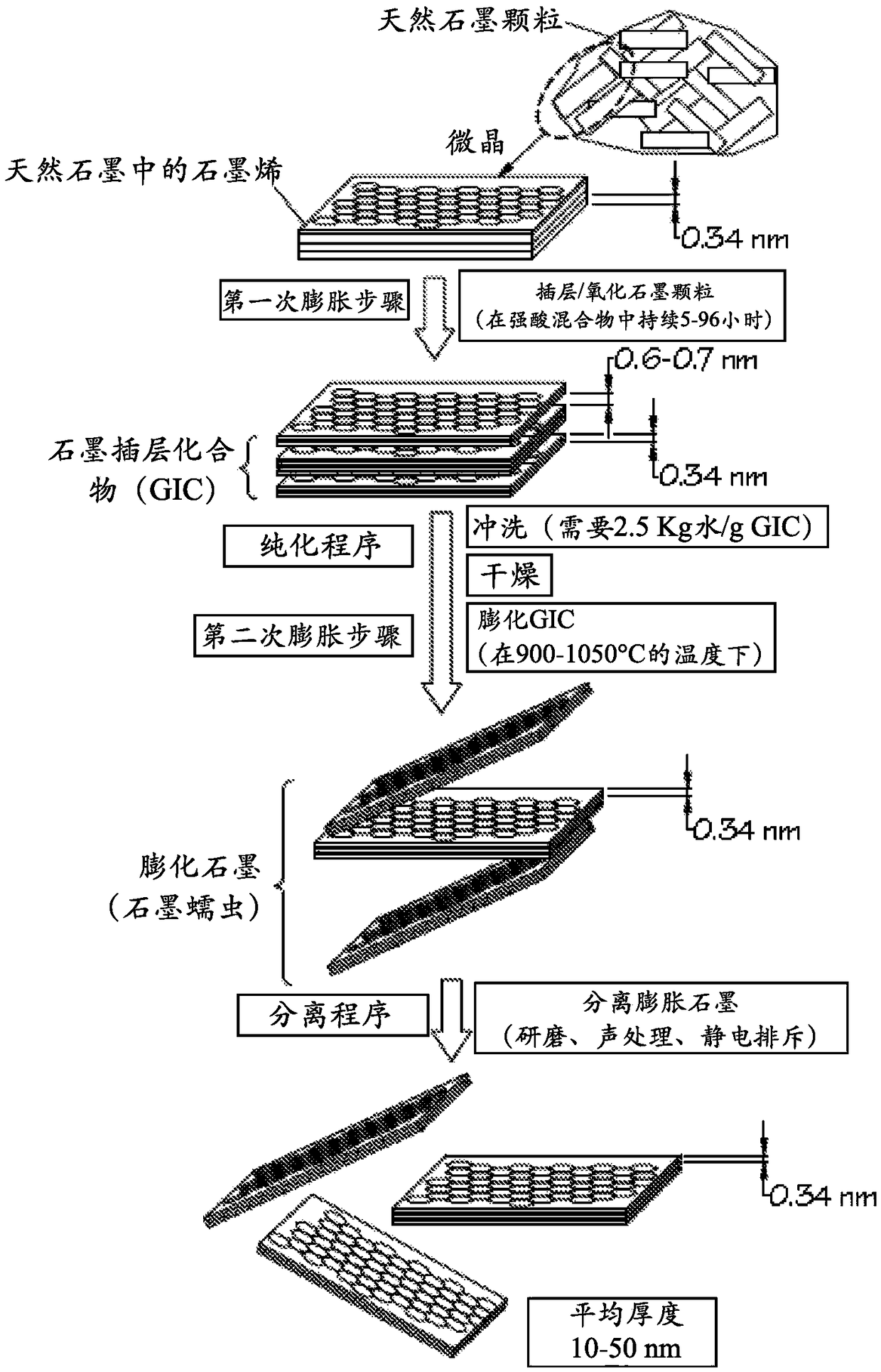

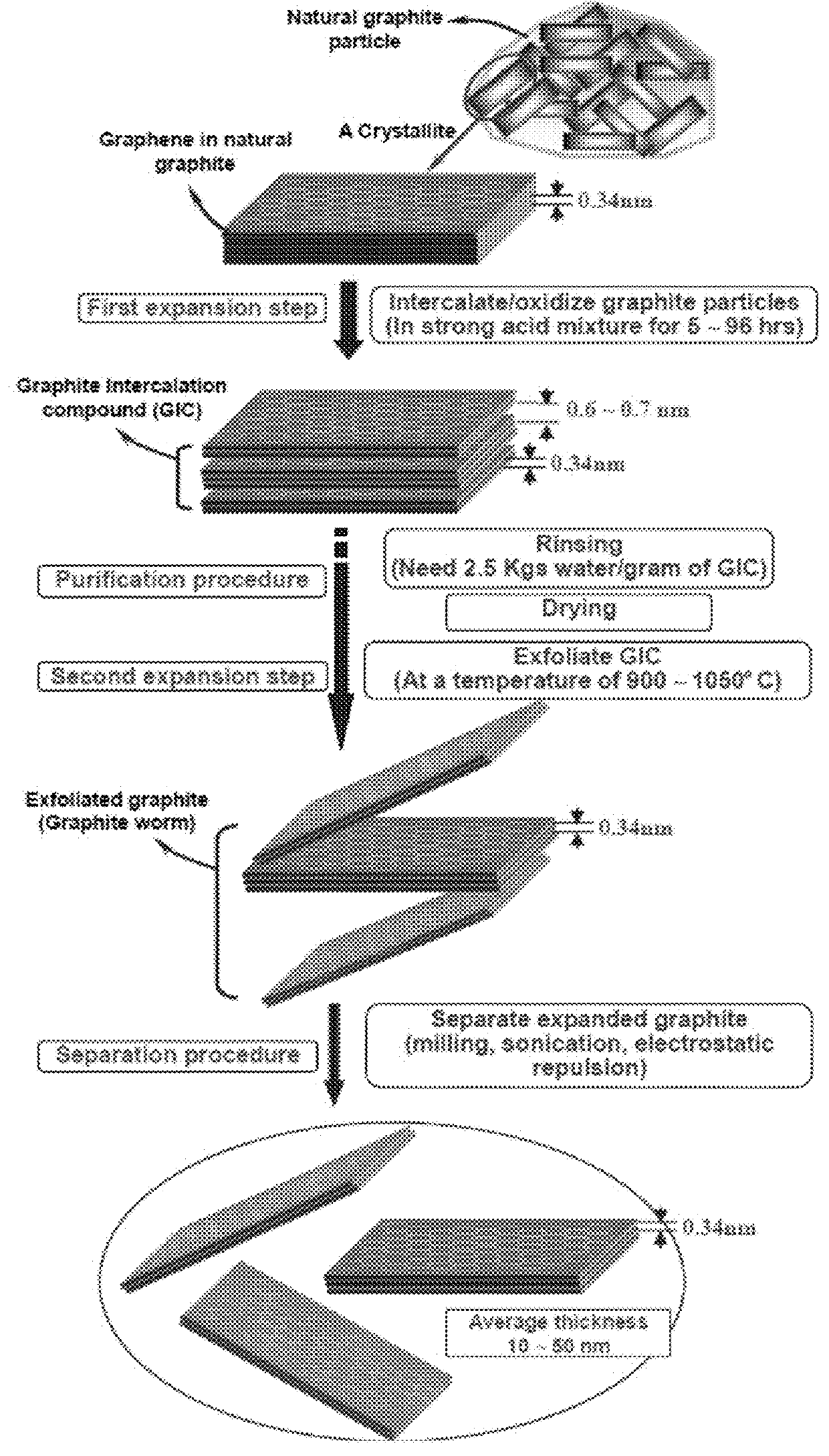

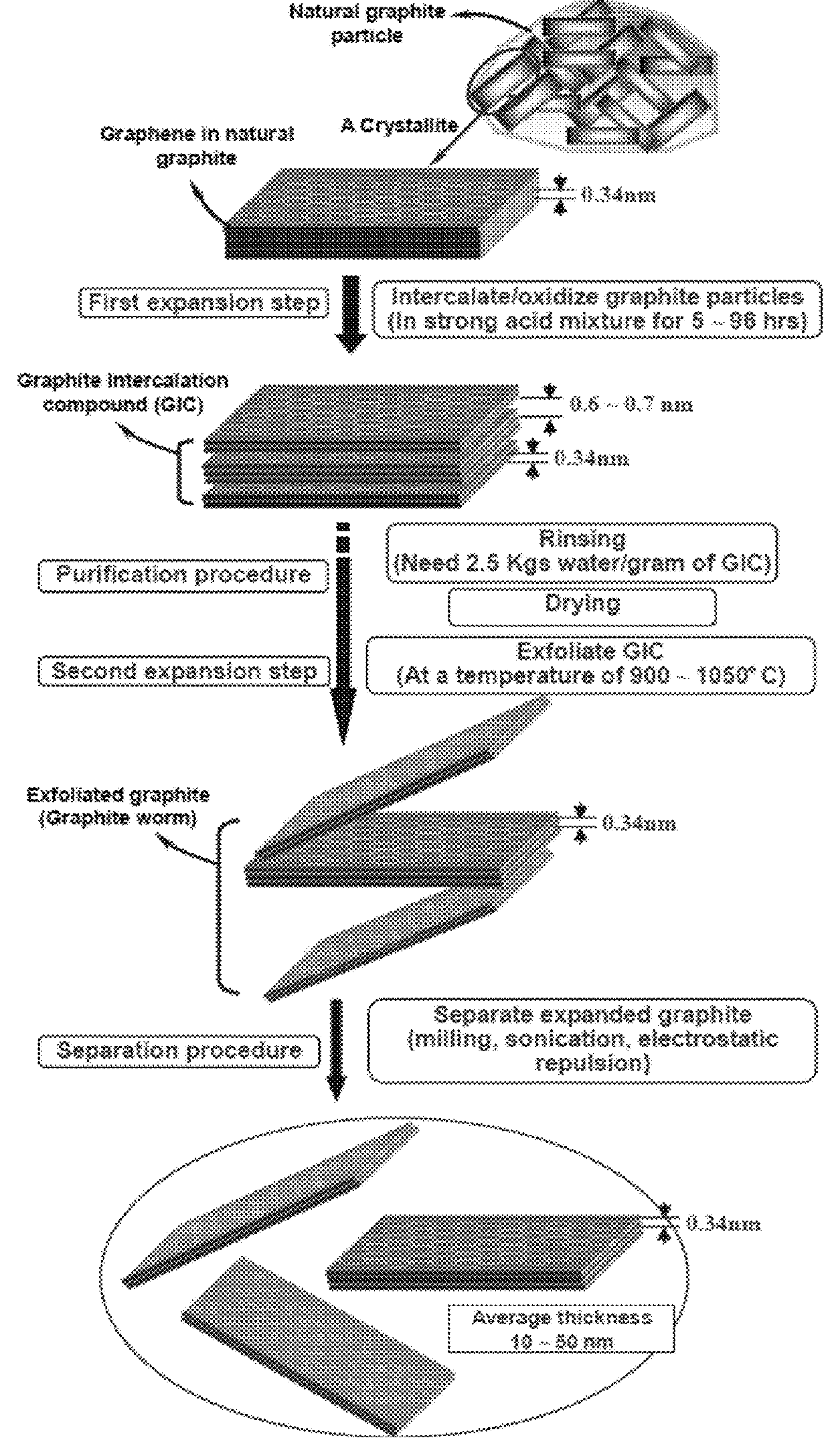

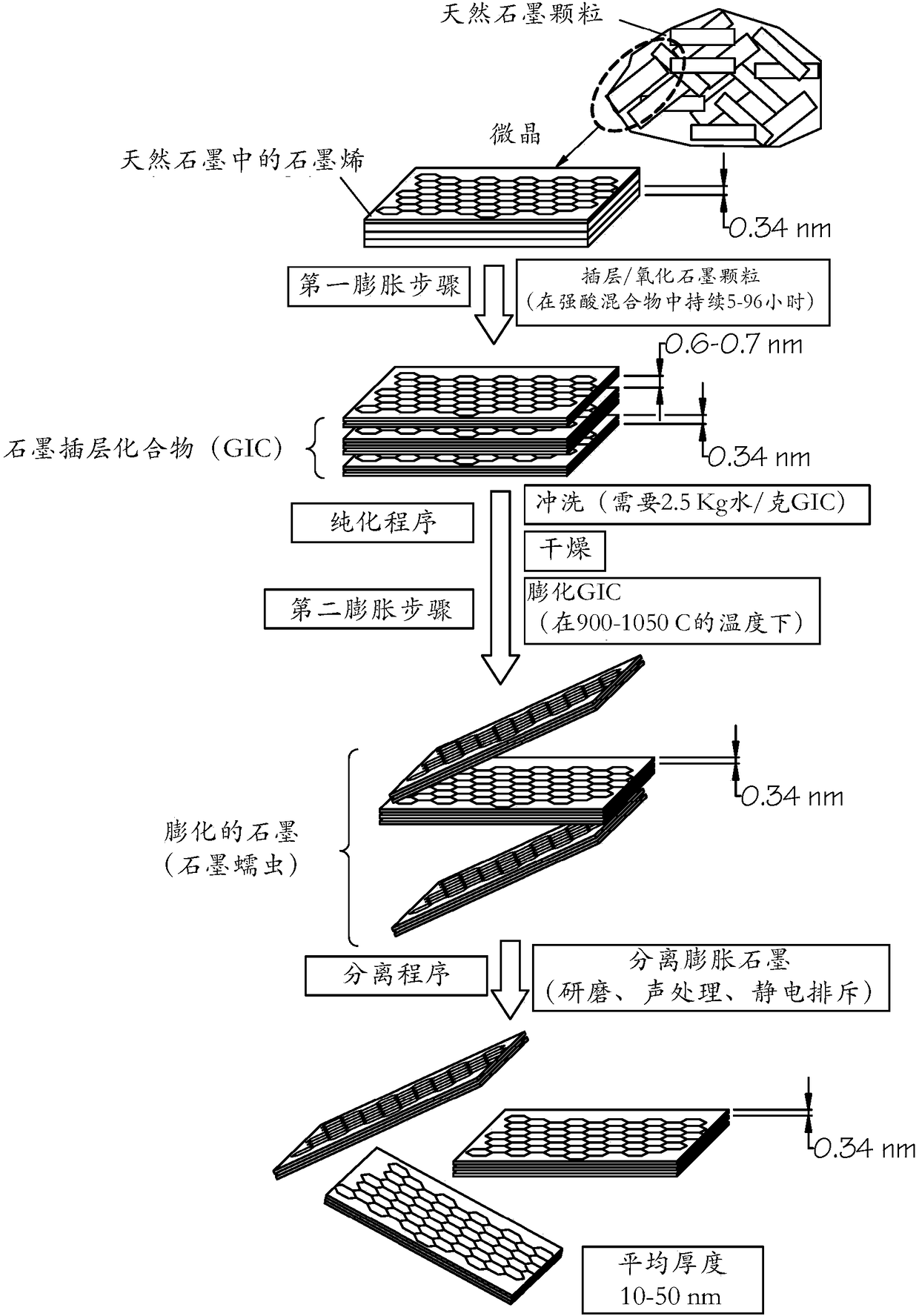

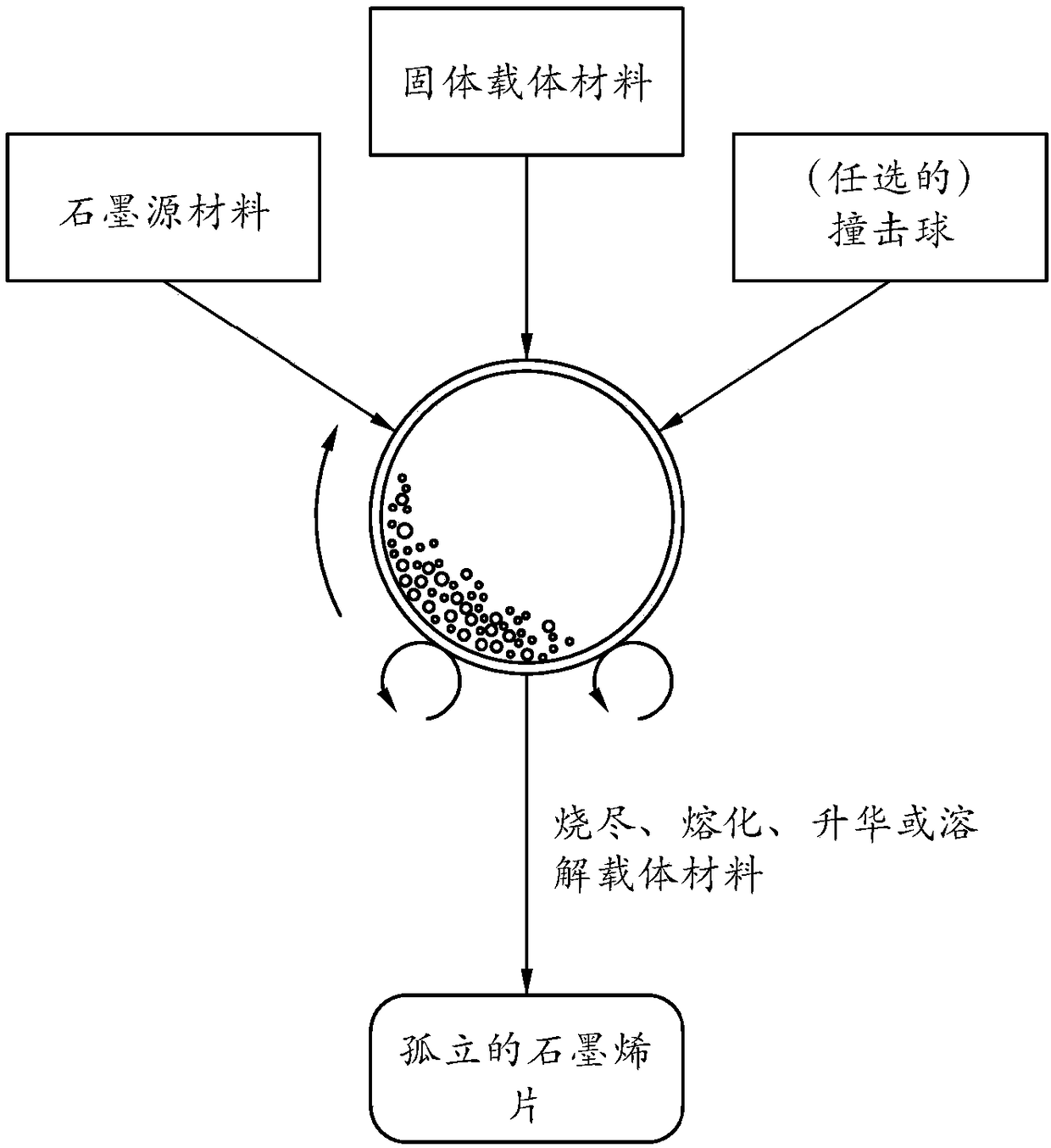

Chemical-free production of graphene materials

A method of producing isolated graphene sheets directly from a graphitic material, comprising: a) mixing multiple particles of a graphitic material and multiple particles of a solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; b) operating the impacting apparatus for peeling off graphene sheets from the graphitic material and transferring these graphene sheets to surfaces of solid carrier material particles to produce graphene-coated solid particles inside the impacting chamber; c) separating the graphene sheets from the solid carrier material particle surfaces to recover isolated graphene sheets. The method enables production of graphene sheets directly from a graphitic material without going through a chemical intercalation or oxidation procedure. The process is fast (hours as opposed to days of conventional processes), has low or no water usage, environmentally benign, cost effective, and highly scalable.

Owner:GLOBAL GRAPHENE GRP INC

Chemical-free production of graphene-reinforced inorganic matrix composites

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced inorganic matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of an inorganic solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid inorganic material particles to produce graphene coated or graphene-embedded inorganic particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded inorganic particles into the graphene-reinforced inorganic matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded inorganic particles produced by this method.

Owner:NANOTEK INSTR

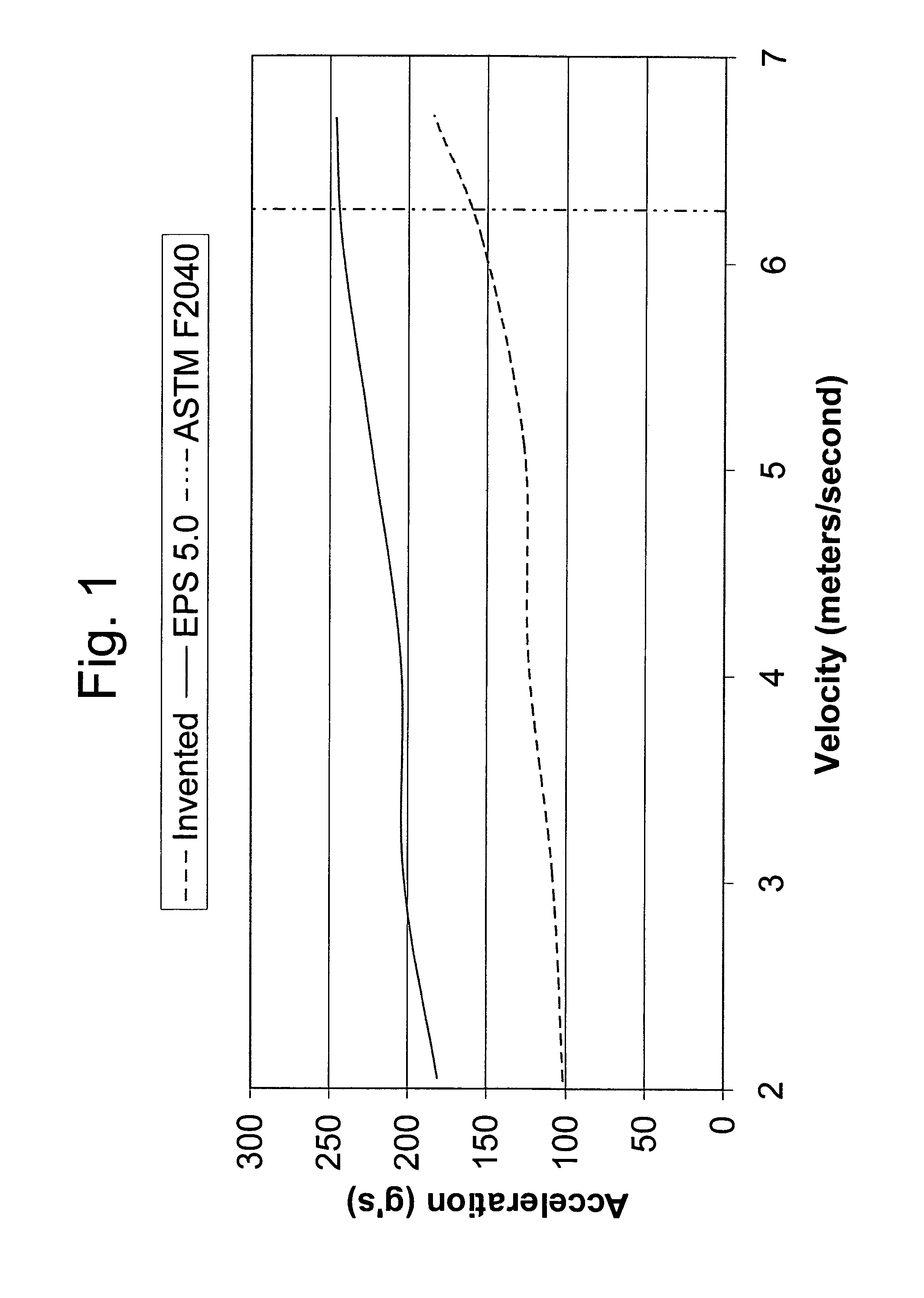

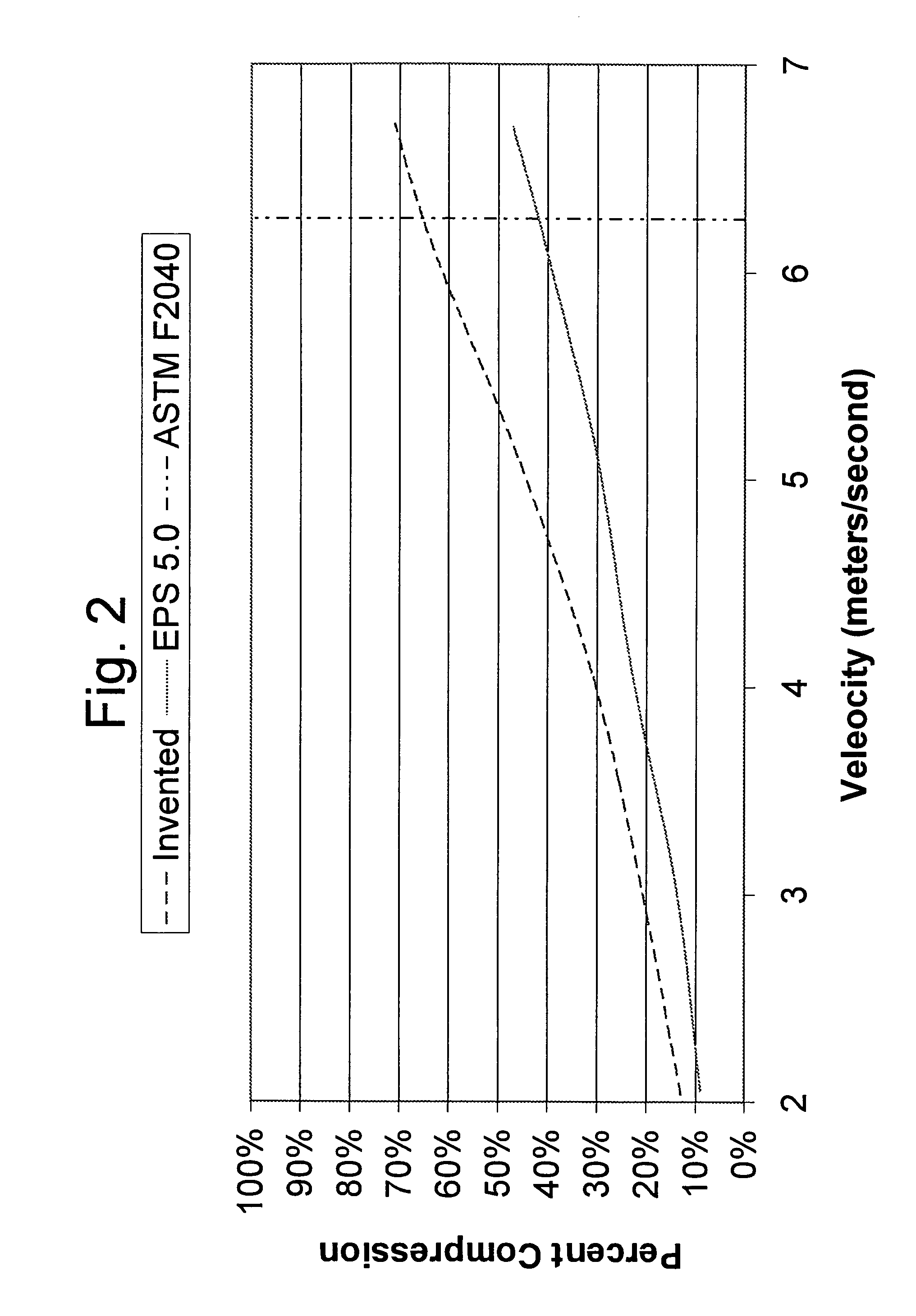

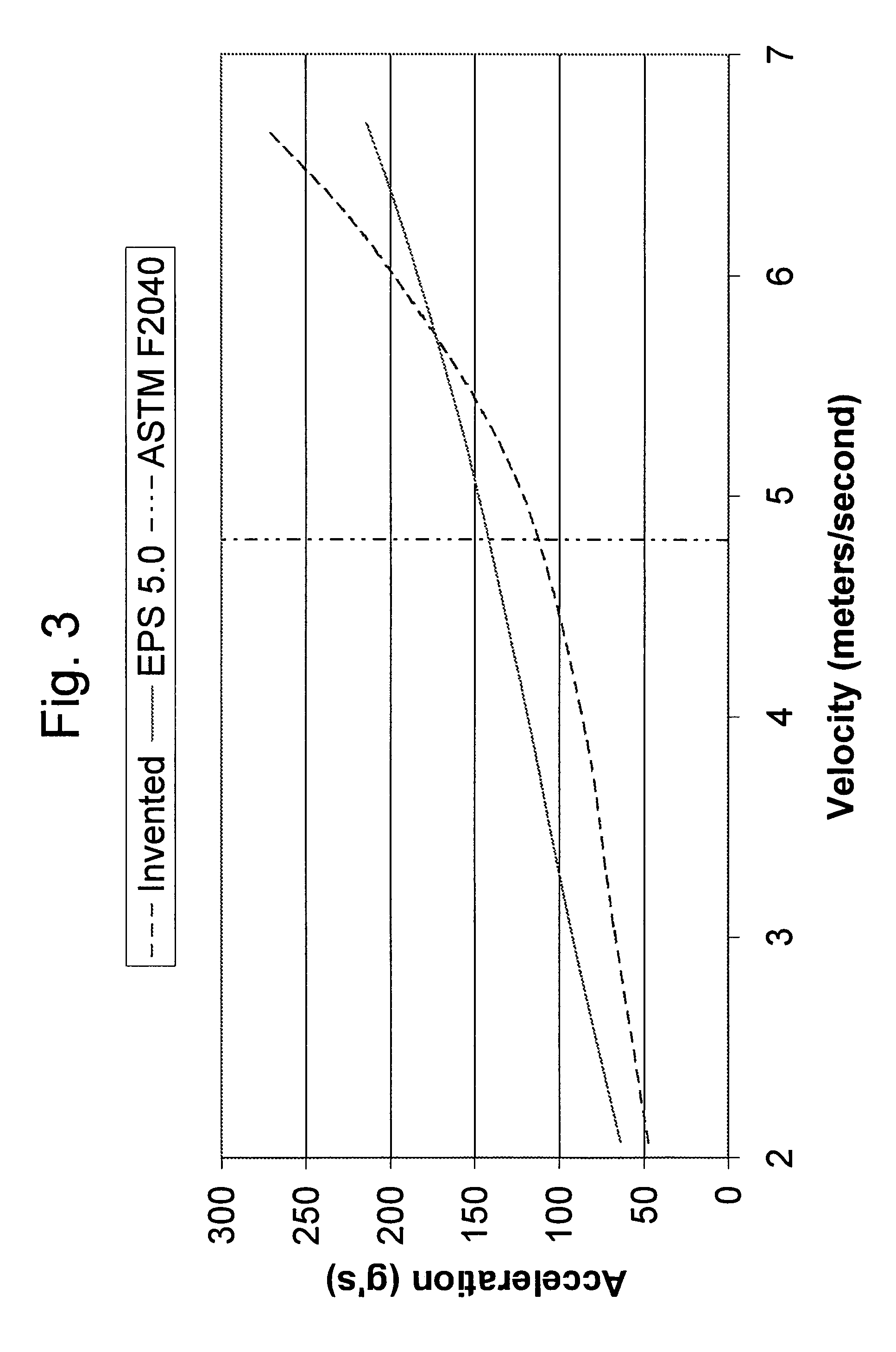

Viscoelastic foam layer and composition

A viscoelastic foam is provided having an amine-based polyol system to impart strength, recoverability and endurance to the foam, and an appropriately selected trifunctional non-amine-based polyol system to provide flexibility to the foam. The combination of amine-based and non amine-based polyols provides a viscoelastic semi-rigid foam with excellent impact and recovery properties, recovering to substantially 100% of its initial volume and shape following an impact, yet with high rigidity and stiffness so that it is effective at absorbing high as well as low-energy impacts. A method of making the above viscoelastic foam is also provided. In a preferred embodiment, the foam is made using an allophanate-modified MDI prepolymer in order to provide the isocyanate in liquid form at standard temperature and pressure in order to simplify the production of the invented viscoelastic foams.

Owner:TEAM WENDY

High performance foam and composite foam structures and processes for making same

InactiveUS20130116354A1Average pressureAverage temperatureLiquid surface applicatorsCoatingsLiquid crystallinePolymer science

Methods are disclosed for making liquid crystalline polymer (LCP) foams and foam structures of various shapes and forms. LCP foams of the invention have a high compression strength suitable for high performance energy-absorption and energy-impact applications and devices.

Owner:BATTELLE MEMORIAL INST

Chemical-Free Production of Graphene-Wrapped Electrode Active Material Particles for Battery Applications

ActiveUS20180183062A1Improve battery performanceImprove conductivityCell electrodesGrapheneEnergy impactGraphite

Provided is a simple, fast, scalable, and environmentally benign method of producing graphene-embraced or encapsulated particles of a battery electrode active material directly from a graphitic material, the method comprising: a) mixing graphitic material particles, multiple particles of an electrode active material, and non-polymeric particles of milling media to form a mixture in an impacting chamber, wherein the graphitic material has never been intercalated, oxidized, or exfoliated and the chamber contains therein no previously produced graphene sheets; b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring graphene sheets to surfaces of electrode active material particles to produce graphene-embraced active material particles; and c) recovering the graphene-embraced particles from the impacting chamber. Also provided is a mass of the graphene-embraced particles, electrode containing such particles, and battery containing this electrode.

Owner:GLOBAL GRAPHENE GRP INC

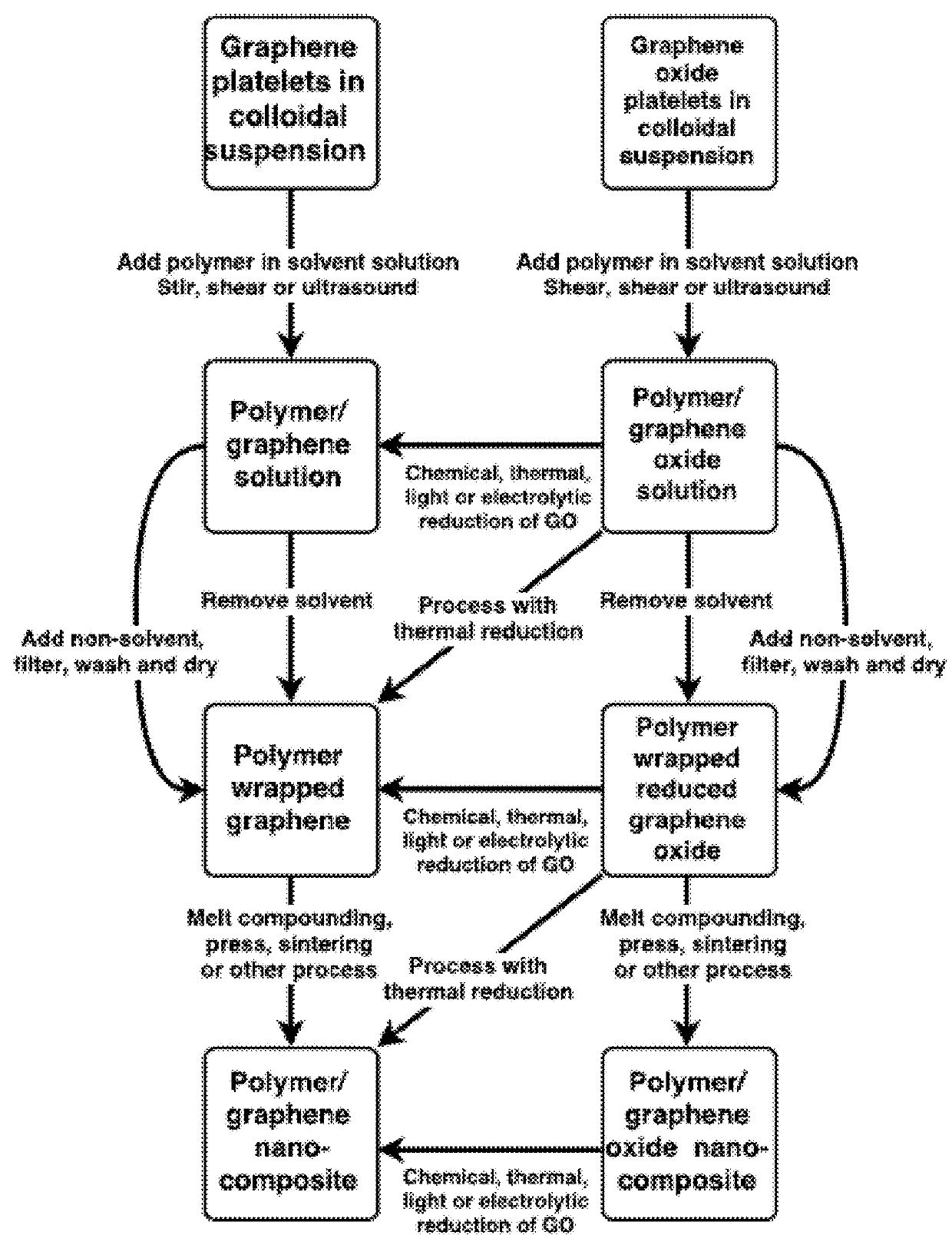

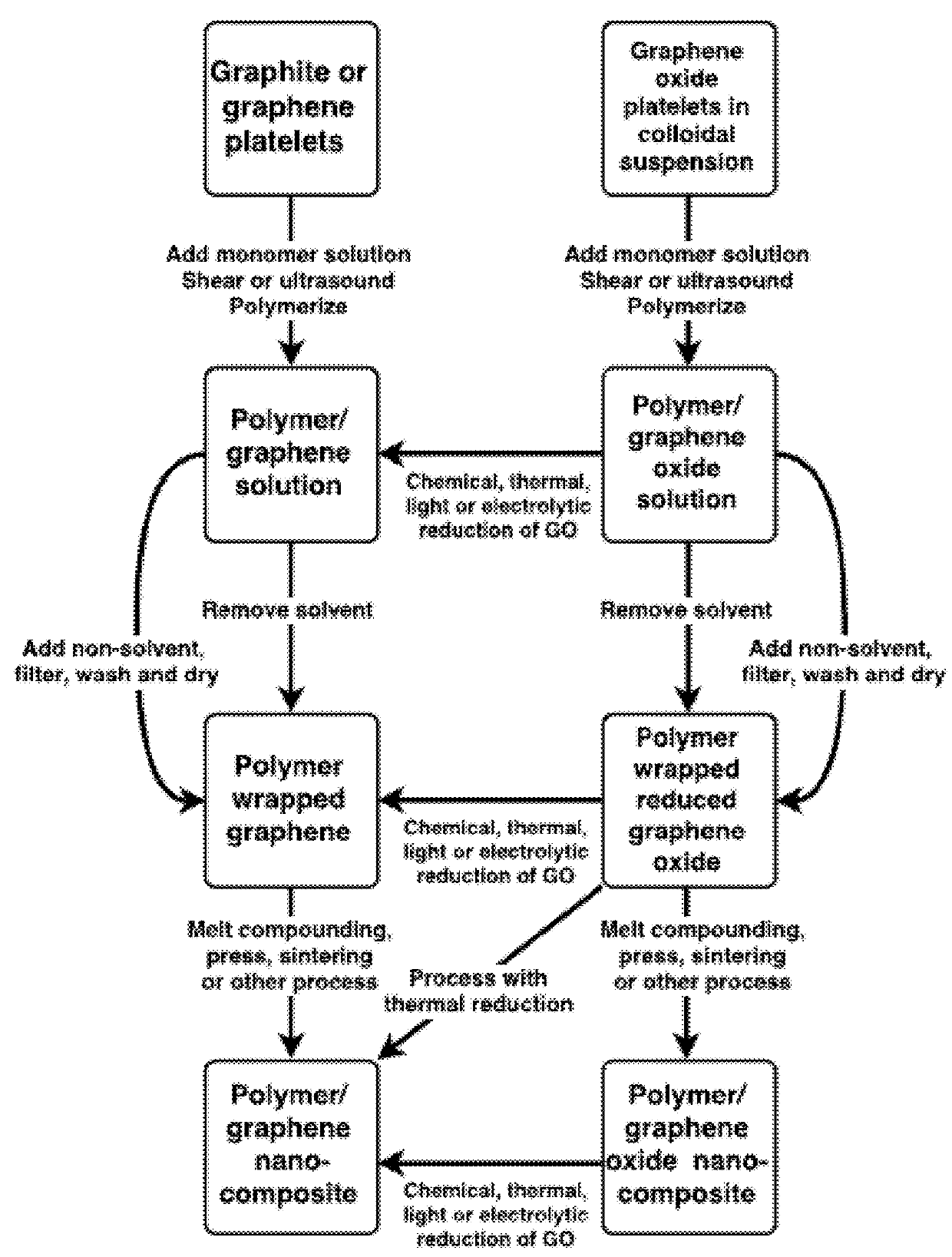

Chemical-free production of graphene-polymer pellets and graphene-polymer nanocomposite products

PendingUS20180272565A1Enhanced interface bindingCost effectiveGrapheneNanotechnologyEnergy impactGraphite

Provided is a method of producing pellets of a graphene-polymer composite, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of a solid polymer carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material particles and transferring the graphene sheets to surfaces of the solid polymer carrier material particles to produce graphene-coated polymer particles inside the impacting chamber; and (c) feeding multiple graphene-coated polymer particles into an extruder to produce filaments of an extruded graphene-polymer composite and operating a cutter or pelletizer to cut the filaments into pellets of graphene-polymer composite. The process is fast (hours as opposed to days of conventional processes), environmentally benign, cost effective, and highly scalable.

Owner:GLOBAL GRAPHENE GRP INC

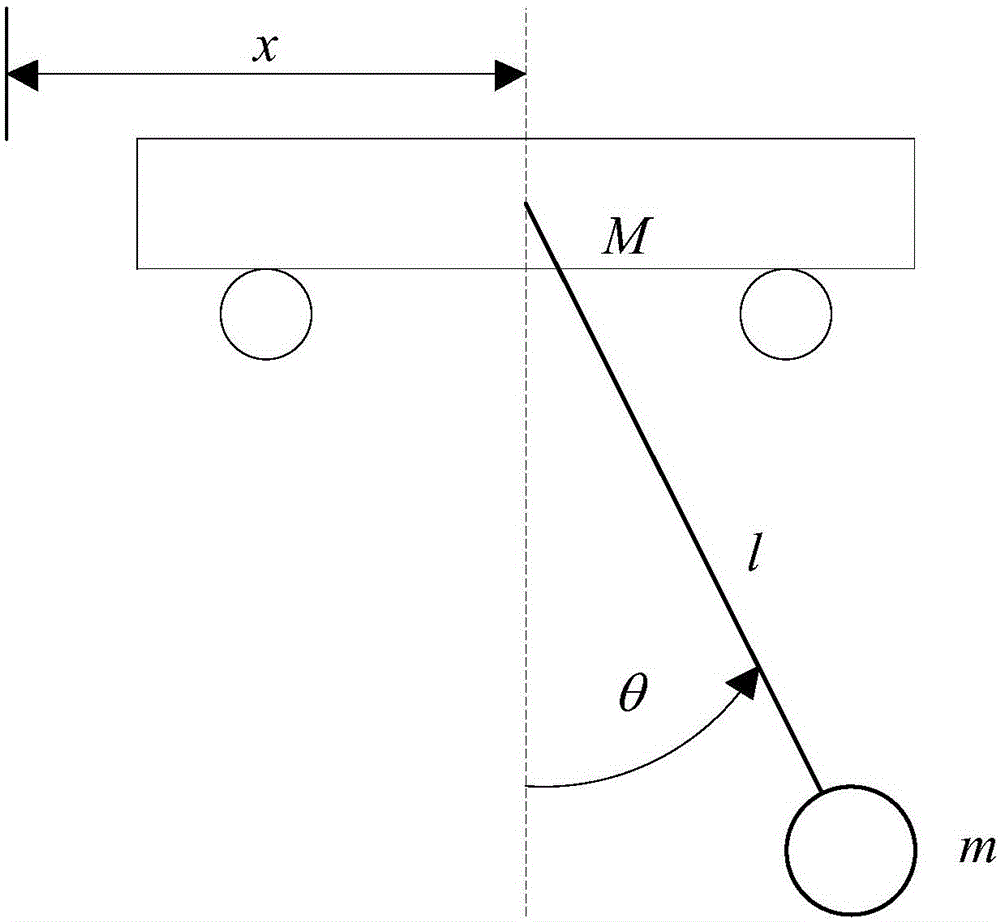

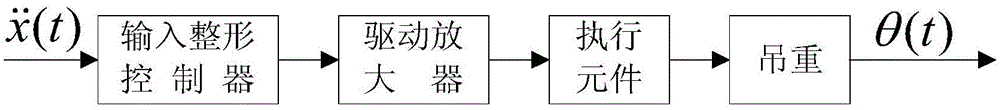

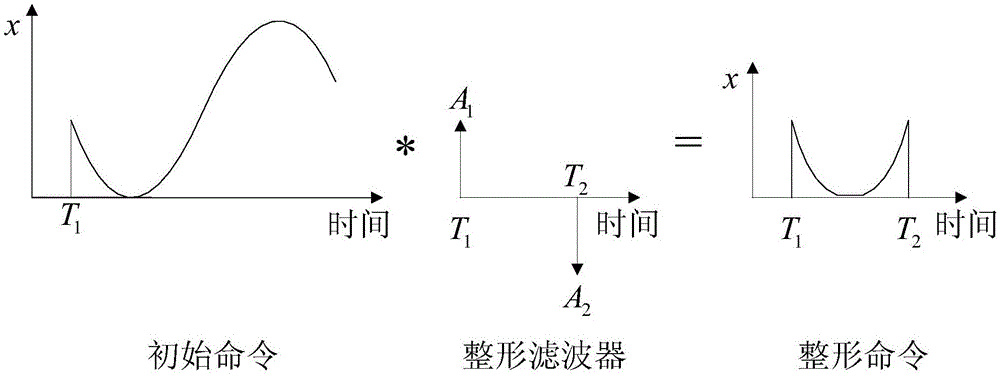

Anti-swing control method for crane

ActiveCN105016210AImprove transport efficiencySuppress energy shockLoad-engaging elementsAcceleration amplitudeControl system

The invention discloses an anti-swing control method for a crane. Acceleration of a sling load of a suspension arm is performed through a cosine function; energy impact caused in the frequent starting and stopping processes of an executing component is restrained; the swing angle theta(t) of the sling load is worked out according to a swing mathematic model B of the swing load of the crane and the acceleration (please see the formula in the description) of the suspension arm; the swing angular speed (please see the formula in the description) of the sling load is obtained through derivation; according to the swing angle theta(t) of the sling load, the swing angular speed (please see the formula in the description) of the sling load, and the remnant swing amplitude computational formula (please see the formula in the description) of the sling load, the input frequency omega<c> of a shaping controller is worked out; according to the speed of the suspension arm operated by a crane operator and the input frequency omega<c> of the shaping controller, the acceleration amplitude A of the crane is worked out; finally, the acceleration (please see the formula in the description) is worked out and input into the shaping controller as an input signal, and a control signal is obtained; and the control signal passes a driving amplification unit and thus can control the executing element, and the remnant swing angle of the sling load can be zero after acceleration of the suspension arm of the crane. The method has the beneficial effects that in a crane control system, swing of the crane is eliminated, energy impact of the executing element is reduced, and the transport efficiency of the crane control system is improved.

Owner:HOHAI UNIV CHANGZHOU

Chemical-free production of graphene-reinforced polymer matrix composites

ActiveUS9926427B2Optimization propertiesOptimize throughputAdditive manufacturing apparatusLiquid surface applicatorsPolymer scienceEnergy impact

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced polymer matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of a solid polymer carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid polymer carrier material particles to produce graphene-coated or graphene-embedded polymer particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded polymer particles into the graphene-reinforced polymer matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded polymer particles produced by this method.

Owner:GLOBAL GRAPHENE GRP INC

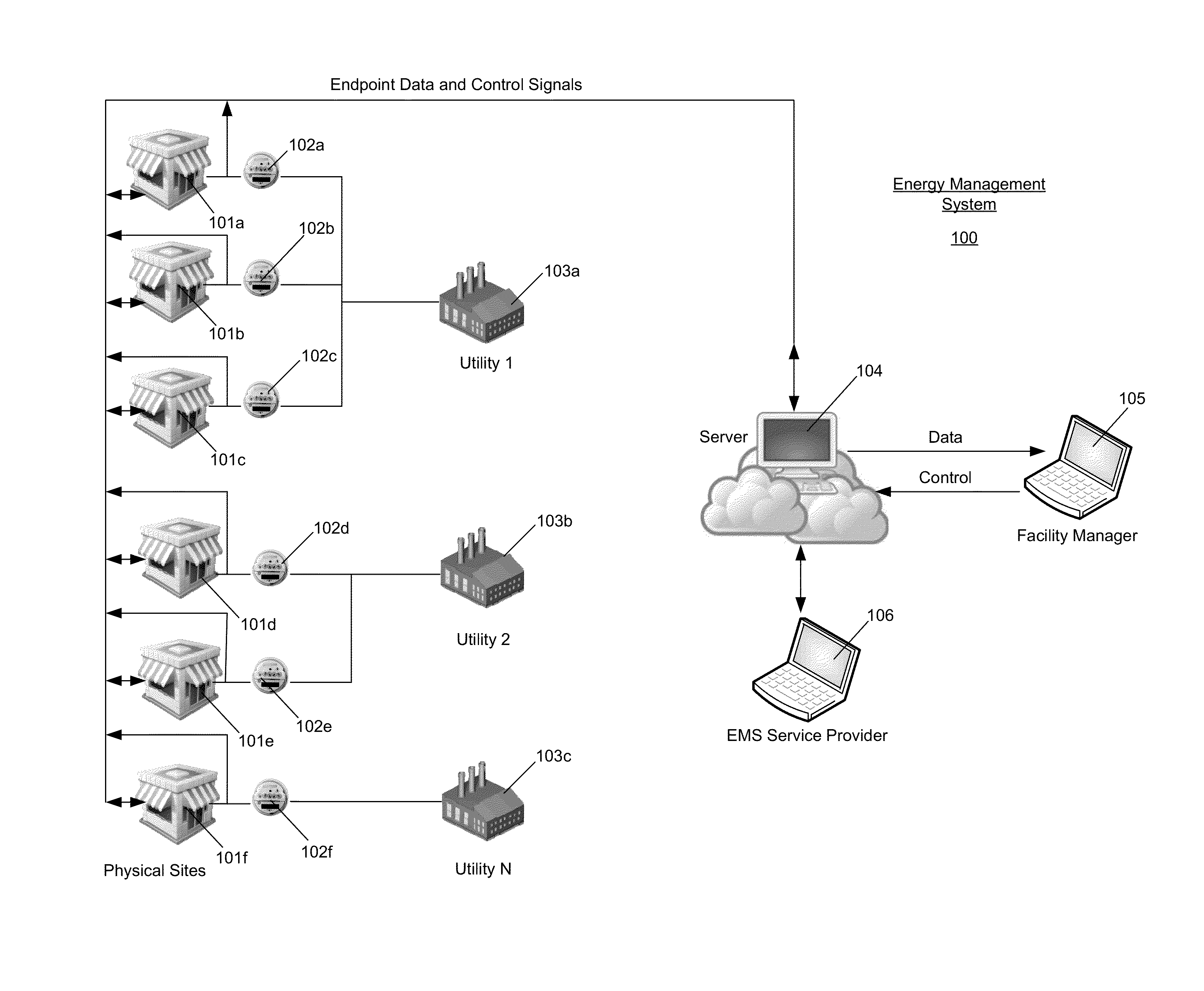

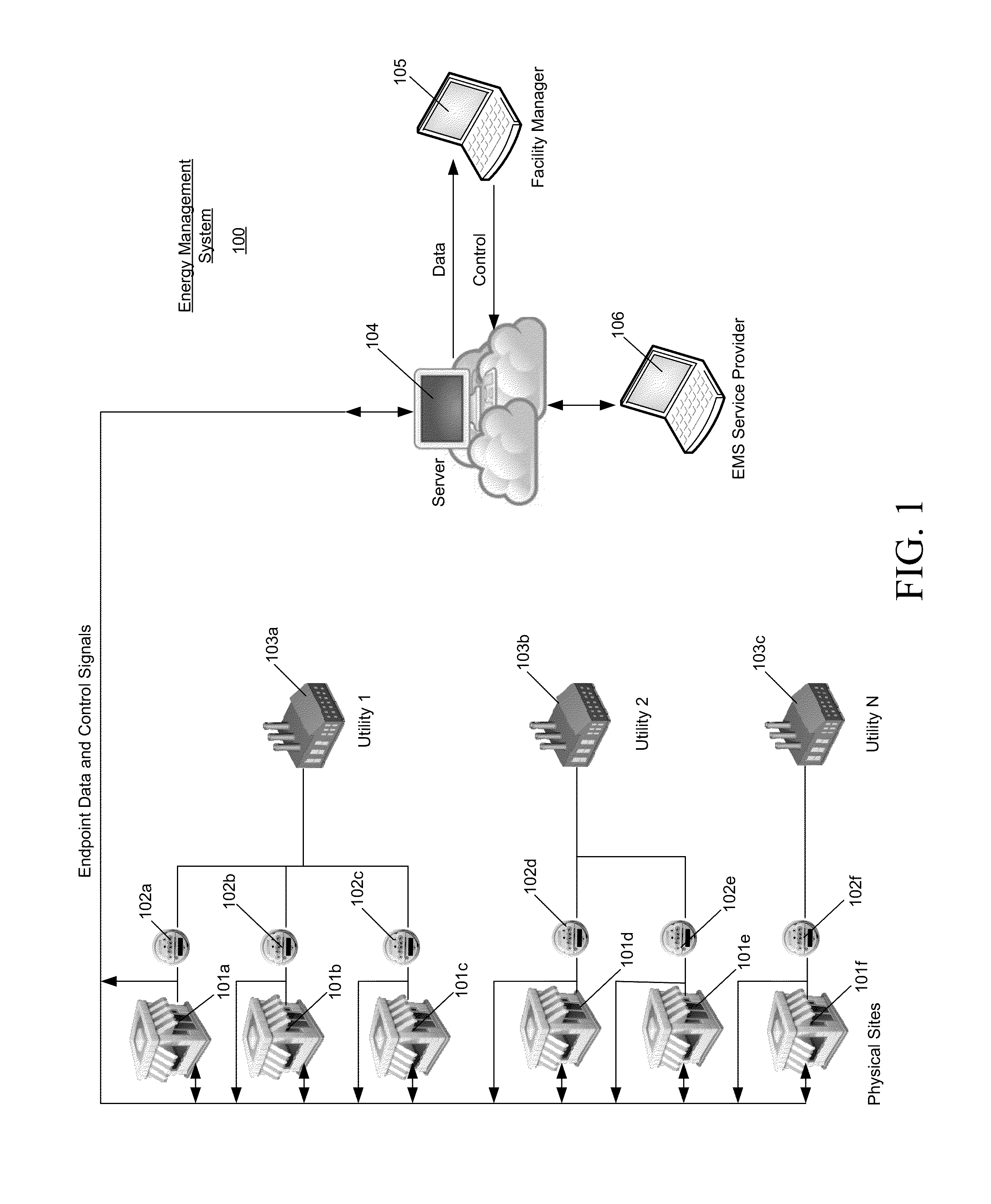

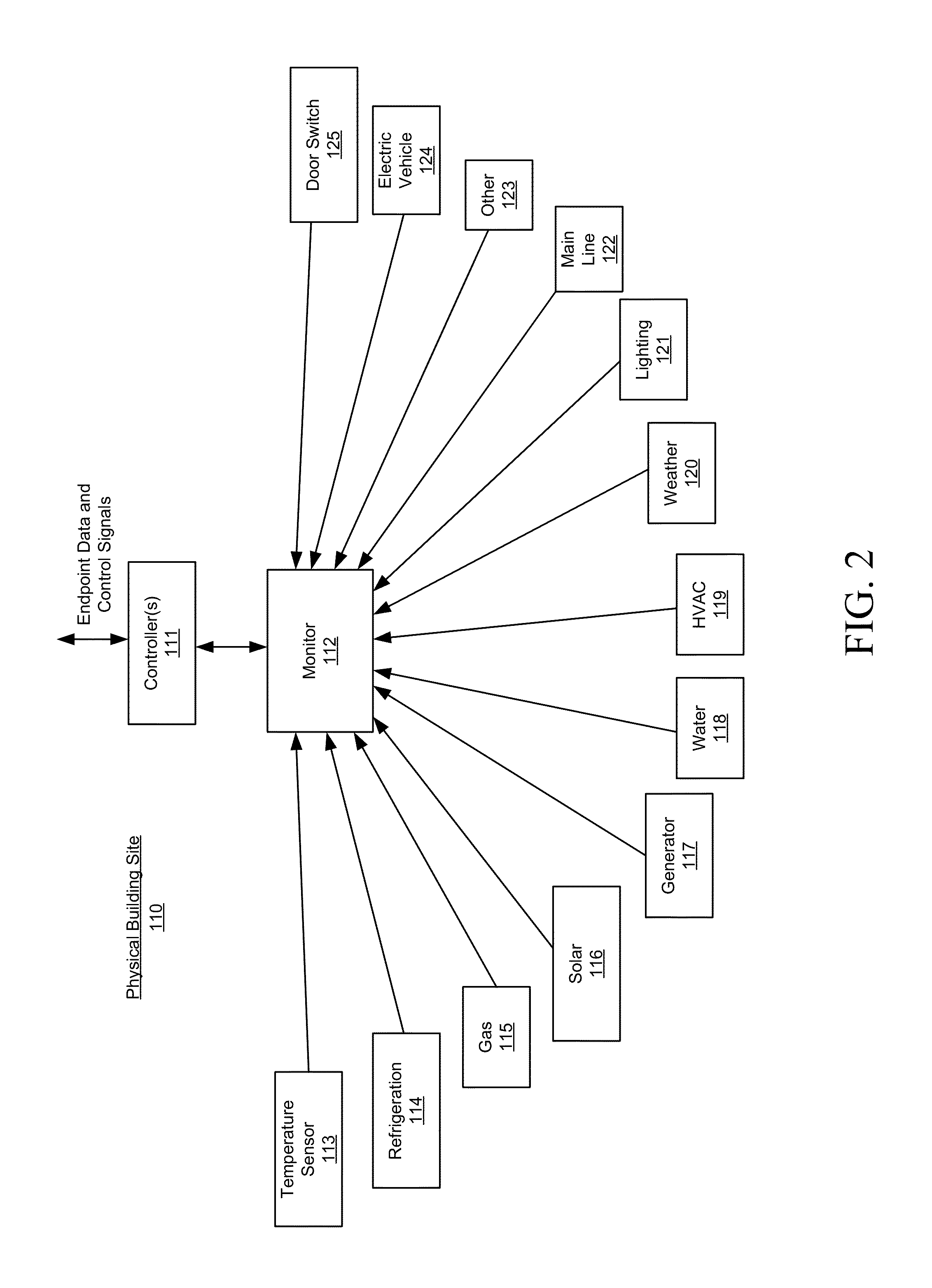

Method and system for tracking project impacts, event impacts, and energy savings

InactiveUS20150032583A1Complete banking machinesMechanical power/torque controlBaseline dataStart time

A method assesses an energy impacting event at a facility using an energy management system. One or more energy consuming endpoints of the facility are sub-metered and data from the sub-metered endpoints is transmitted to the energy management system. A project is created within the EMS by entering project definition attributes including at least a site name, a project name, and a start date. Data from one or more sub-metered channels and a project indicator is displayed. The displayed project indicator is located at a point corresponding to its project start time. A further method tracks the progress of energy saving project at a facility using an energy management system. The project definition attributes further include one or more sub-metered channels, baseline usage data, and an energy related goal. An energy impact value is calculated by subtracting the actual sub-metered usage data from the baseline data and a determination is made whether the energy impact value meets or exceeds the energy goal. The baseline usage data, the energy goal data, the actual sub-metered data, and an indication of whether the energy goal was met are displayed. A further method tracks the financial progress of energy saving project at a facility using an energy management system. The project definition attributes further include one or more capital investment outflow values, a discount rate, and an energy cost rate. Net actual project cash flows and the net project goal cash flows are both plotted against a time scale and periodically displayed. An estimated net present value and net present value are periodically calculated and displayed.

Owner:GRIDPOINT

Chemical-free production of graphene-encapsulated electrode active material particles for battery applications

ActiveUS9899672B2Improve battery performanceImprove conductivityGrapheneNegative electrodesEnergy impactGraphite

Owner:GLOBAL GRAPHENE GRP INC

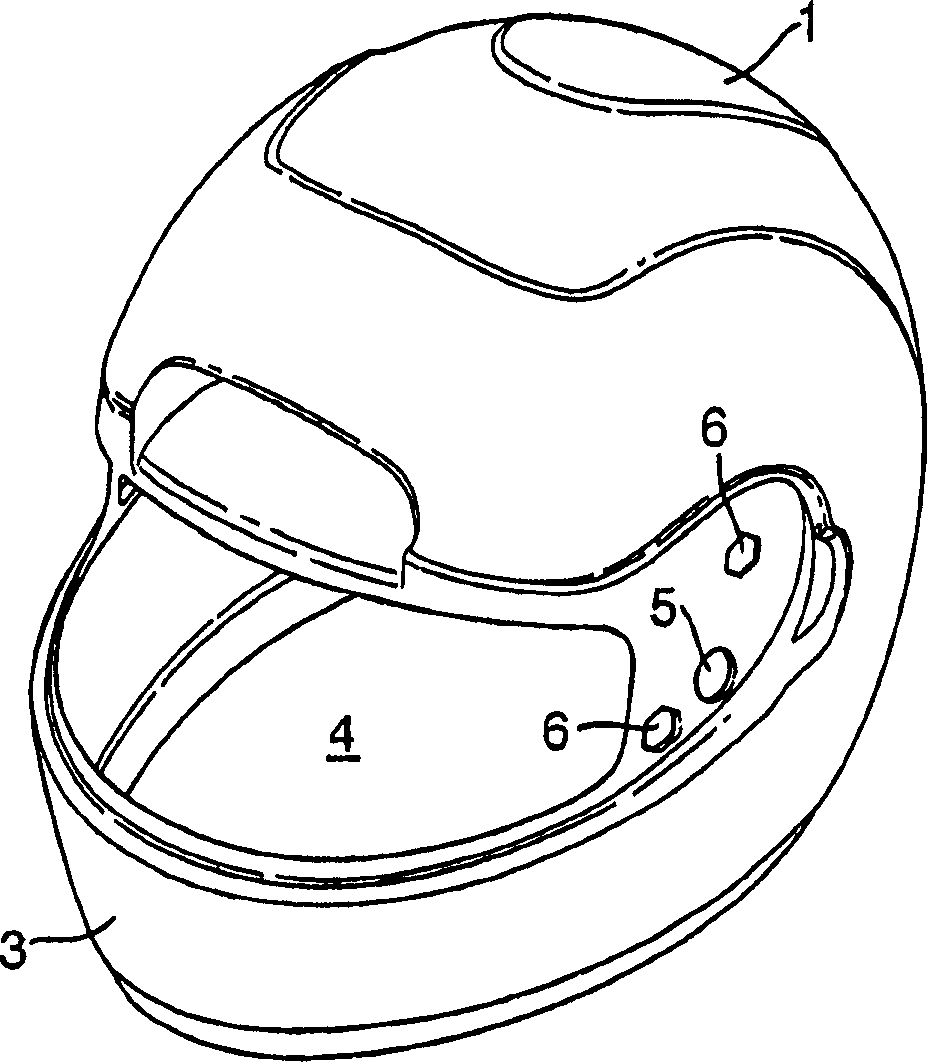

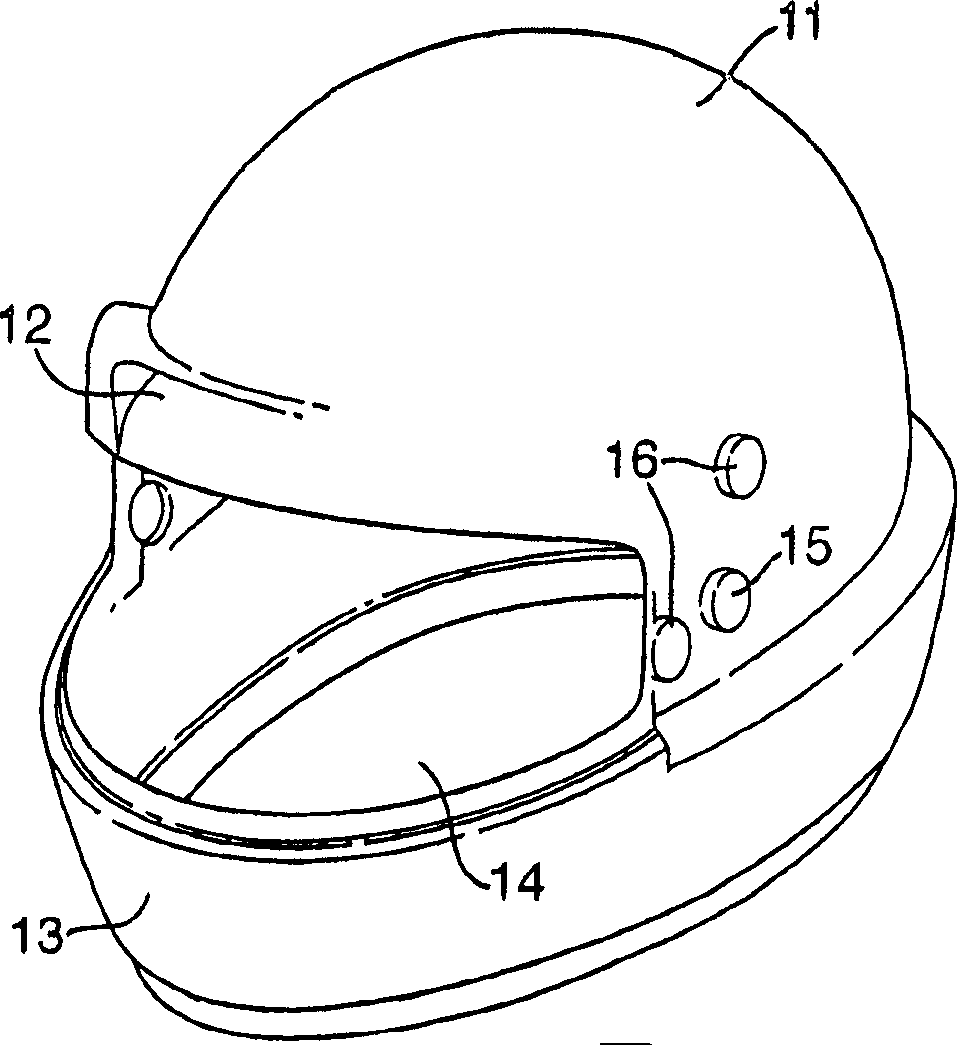

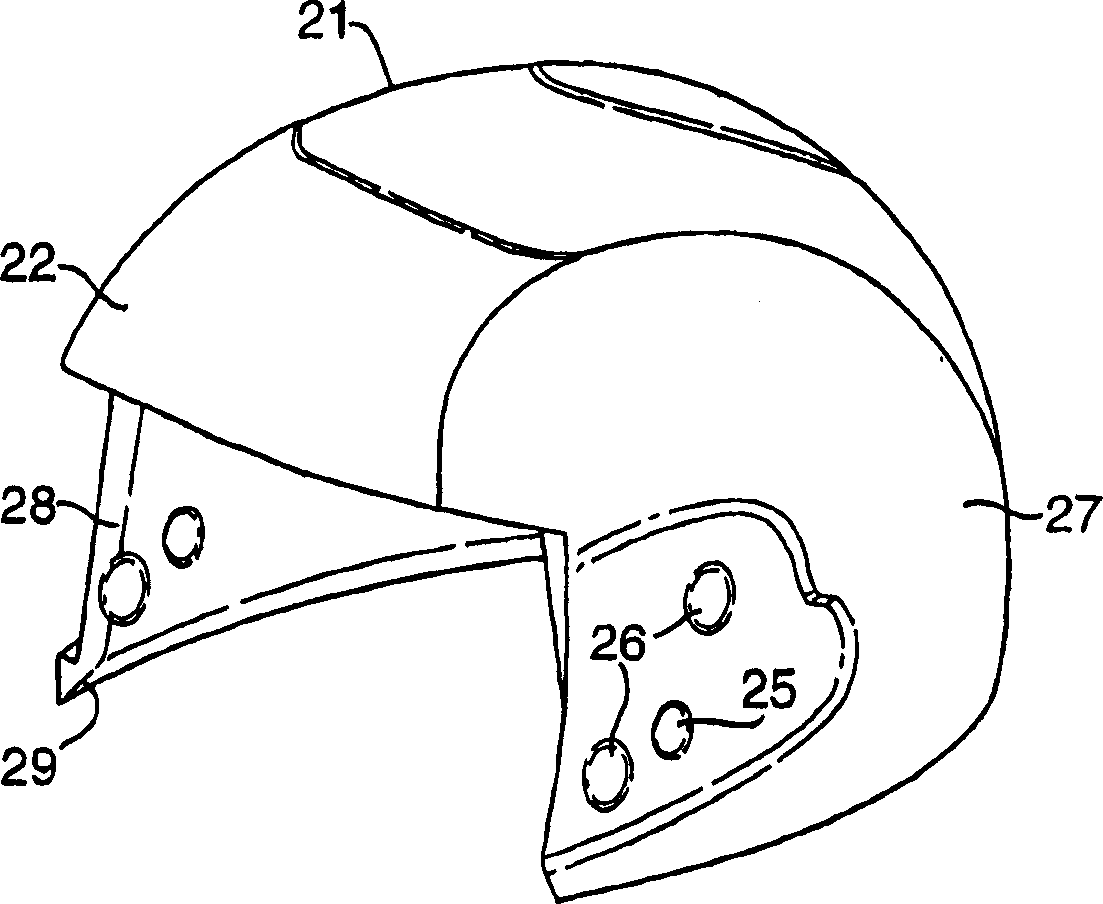

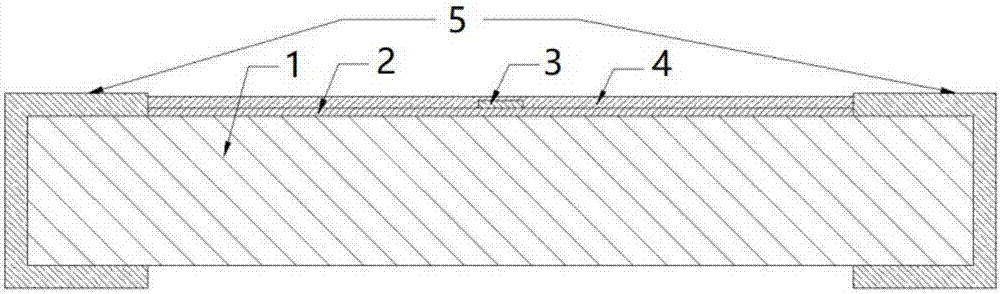

Safety helmets

InactiveCN1812731AReduce the numberSynthetic resin layered productsClothingsEnergy impactEngineering

A low mass safety helmet is provided, containing a sandwich of polymer composite materials to produce an effective means of shock mitigation to a wearer's head. The sandwich comprises an inner and outer layer of fibre reinforced polymer which encapsulates a pre-formed energy dispersive material which is typically a high impact resistant foam. Optionally, on the inside surface of the inner layer which is adjacent to the wearer's head there may also be fitted a comfort liner, manufactured from either a low density impact foam or a material or plastic lattice, to provide comfort to the wearer and protection from low energy impacts. The use of a preformed foam liner in the manufacturing of the helmet allows for accurate dimensional tolerances to be achieved, thus allowing helmets which can meet the requirements for both military and civilian use to be manufactured by mass production techniques.

Owner:QINETIQ LTD

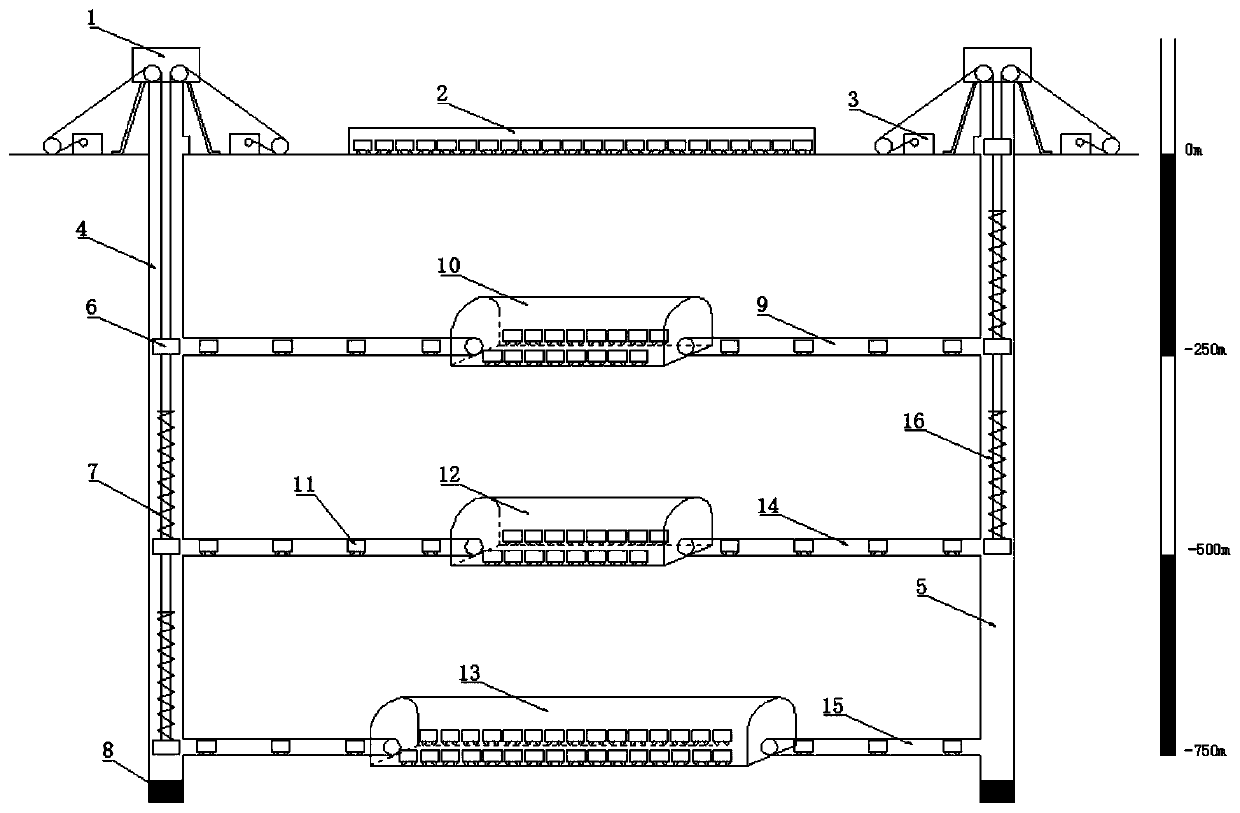

Gradient gravity energy storage system for abandoned mine well shaft and gangue after mining

PendingCN111287918ARealize hierarchical conversionThe principle is simpleMachines/enginesMotorsNew energyMining engineering

The invention discloses a gradient gravity energy storage system for an abandoned mine well shaft and gangue after mining, and provides a more economical new energy storage system and secondary utilization system for the abandoned mine well shaft and the gangue after mining. Based on the specific exploitation situation of an abandoned mine well, abandoned mine well shafts are utilized to serve asenergy storage channels; underground parking lots with different elevations are constructed between a primary well and a secondary well; the number of cage conductors are set according to corresponding elevation difference and the number of parking lots; the number of the cage conductors in a channel on one side is equal to the number of the underground parking lots; and the rising and falling elevation differences between the cage conductors are equal to each other all the time. The system comprises energy storage-release channels transformed by an abandoned primary well and an abandoned secondary well; the upper parts of the channels are out of the ground to connect corresponding equipment; the lower parts are connected with various underground parking lots; various channels are connected to the parking lots by utilizing connecting roadways; when energy is stored, a mine vehicle in a lower-position parking lot is lifted to an upper-position parking lot by a lifting system; and when the energy is released, the mine vehicle in the upper-position parking lot is dropped to the lower-position parking lot. Gradient gravity energy storage and release are realized by controlling the loading capacity of the gangue of the mine vehicle and the transferring amount between the cage conductors in a centralized manner by means of a central control chamber; and in addition, buffering springsare arranged between adjacent cage conductors, so that the energy impact caused by accidental fracture of a steel wire rope is reduced. According to the system, the problem about power energy storageof new energy is solved on the basis of comprehensive utilization of the abandoned mine well shaft and the gangue; and transformation reference is provided for the abandoned well after mining and thewell which is about to be pulled out of production capacity.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

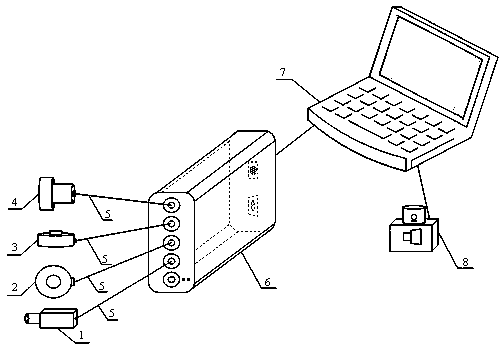

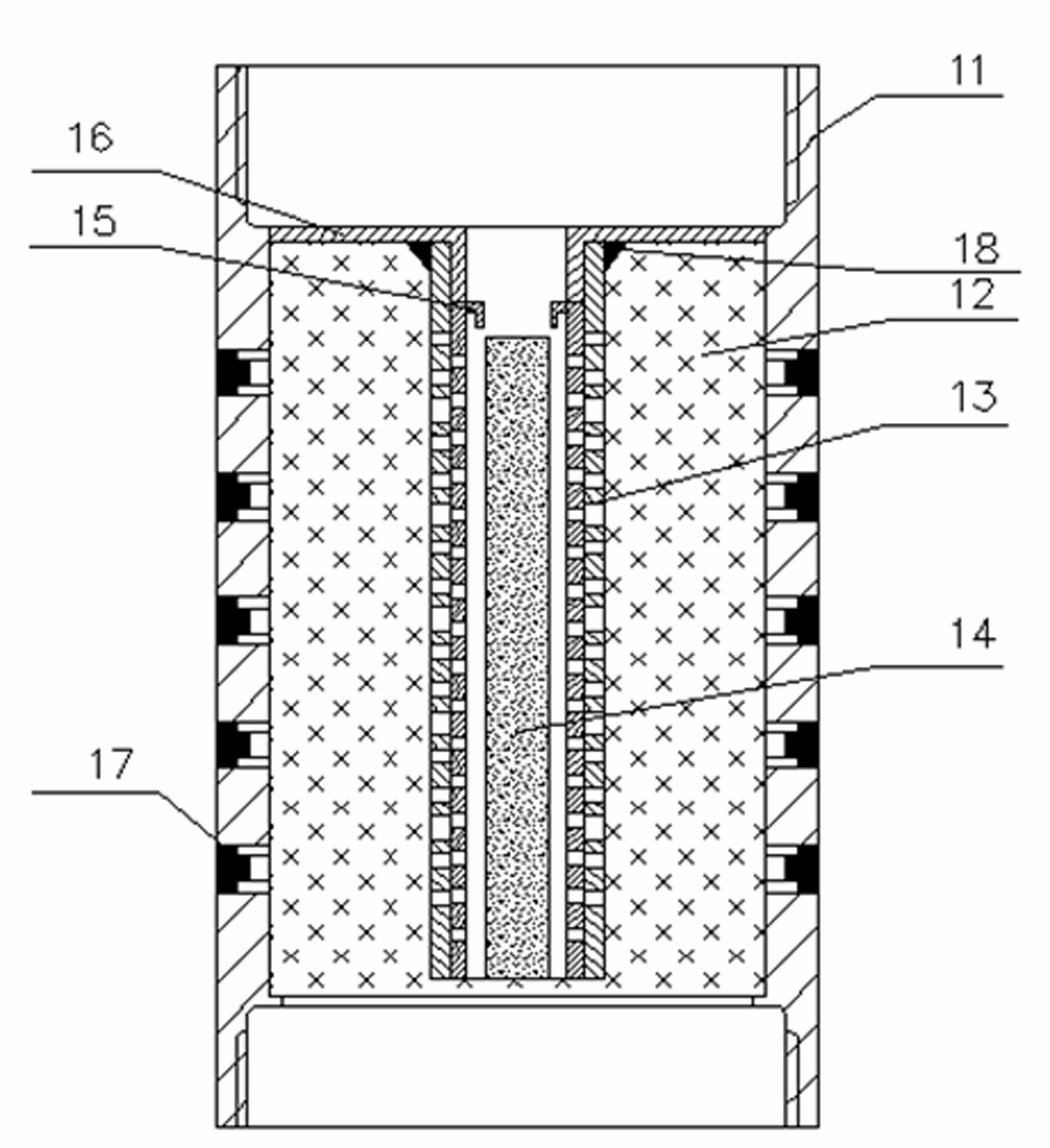

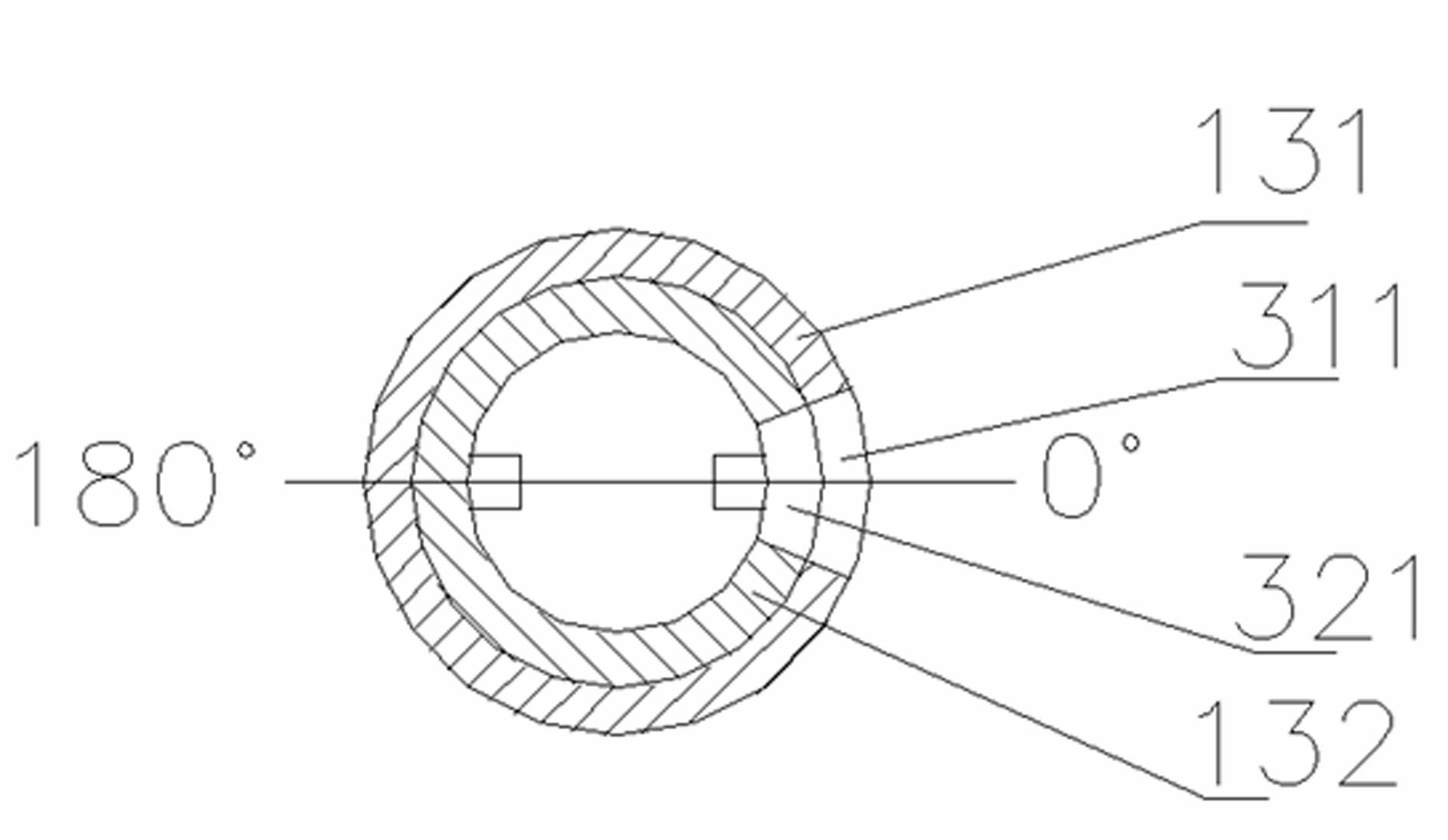

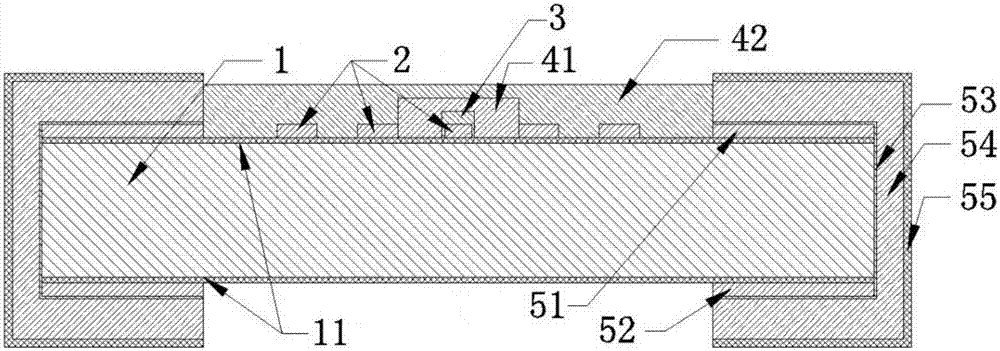

High-voltage circuit breaker mechanical state online monitoring and fault identification device

InactiveCN109164380ANo effect on normal operationJudging performance statusMachine part testingCircuit interrupters testingVibration accelerationEnergy impact

The invention discloses a high-voltage circuit breaker mechanical state online monitoring and fault identification device. The high-voltage circuit breaker mechanical state online monitoring and faultidentification device comprises an image sensor, a hall current sensor, a sound sensor, a vibration acceleration sensor, an acquisition card, an intelligent industrial control monitor and an acousto-optic alarm module; the mechanical parameters of the operating mechanism of the high-voltage circuit breaker in the operation process are synchronously monitored through the four sensors, and then theintelligent industrial control monitor is used for analyzing and processing so as to judge the health grade required by the mechanical state in the operation process of the operation mechanism; the device can achieve rapid analysis of the energy impact, the component movement and the driving state of the operation mechanism in the operation of the circuit breaker, the overall mechanical performance and the running state of the operating mechanism can be judged, and more importantly, the device has no influence on normal operation of the circuit breaker; and the device can be used for solvingthe problem the fault of the high-voltage circuit breaker is difficult to judge only by means of perceptual understanding and experience in the periodic inspection by an operator, so that efficiency is improved, and manpower and material resources are saved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

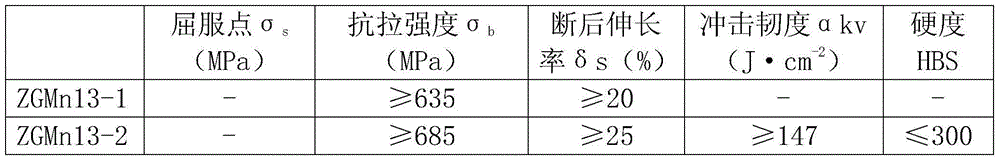

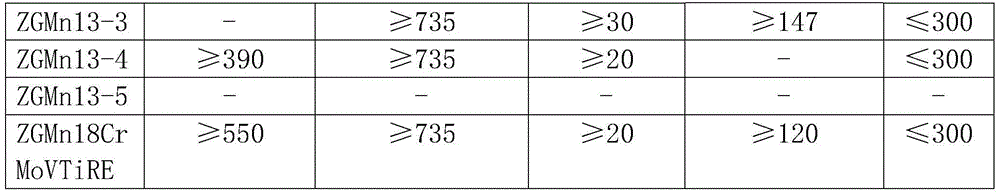

Preparing method of ultrahigh manganese multielement rare earth wear-resisting alloy steel liner plate

The invention relates to a preparing method of an ultrahigh manganese multielement rare earth wear-resisting alloy steel liner plate. The liner plate comprises the following components in percent by mass: 0.9 to 1.4% of C, 16.0 to 19.0% of Mn, smaller than 1.0% of Si, 1.5 to 3.0% of Cr, 0.3 to 1.0% of Mo, 0.2 to 0.5% of V, 0.1 to 0.4% of Ti, smaller than 0.3% of CU, smaller than 0.035% of S, smaller than 0.05% of P, 0.2% of RE and the balance of steel. The preparing method of the liner plate comprises the following steps of: adding into a smelting furnace for smelting and casting the liner plate, placing the liner plate into a thermal processing furnace for normalizing, quenching and tempering; air cooling processing; tempering the air-cooled liner plate at low temperature; performing mechanical performance test, grinding and polishing. The preparing method has the beneficial effects that the alloy steel has the tenacity strength of common high manganese steel, substrate initial hardness is enhanced, the material is fast hardened by small energy impact in use, and achieves a excellent wear-resisting capability, the service life of the product is improved, productivity is improved, production cost is reduced, and resource waste is reduced.

Owner:靖江市玉盛特钢厂

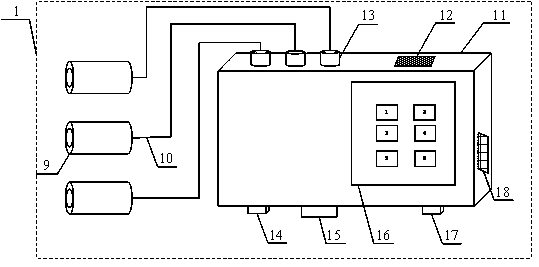

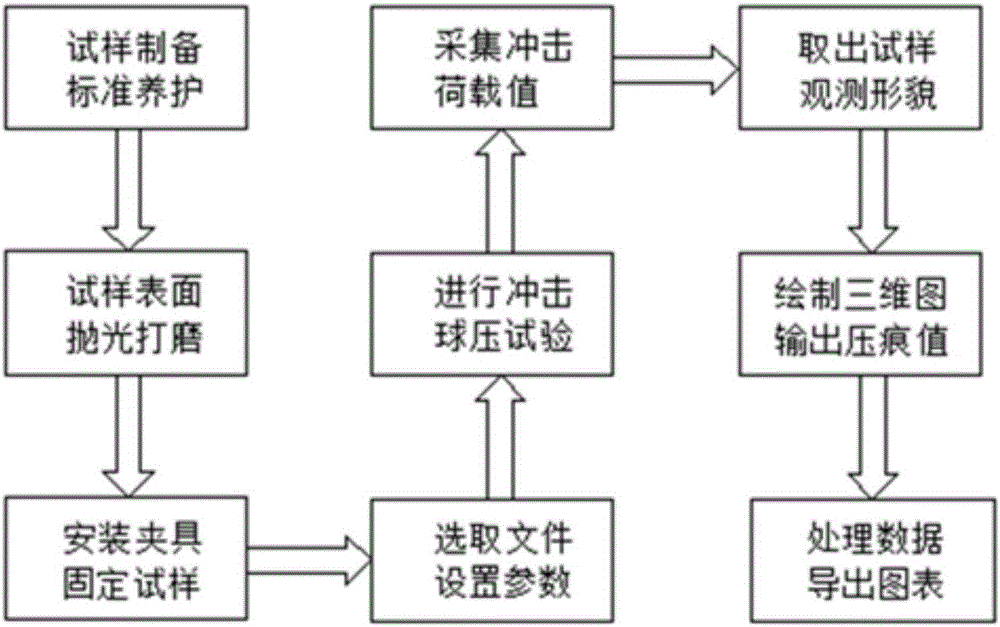

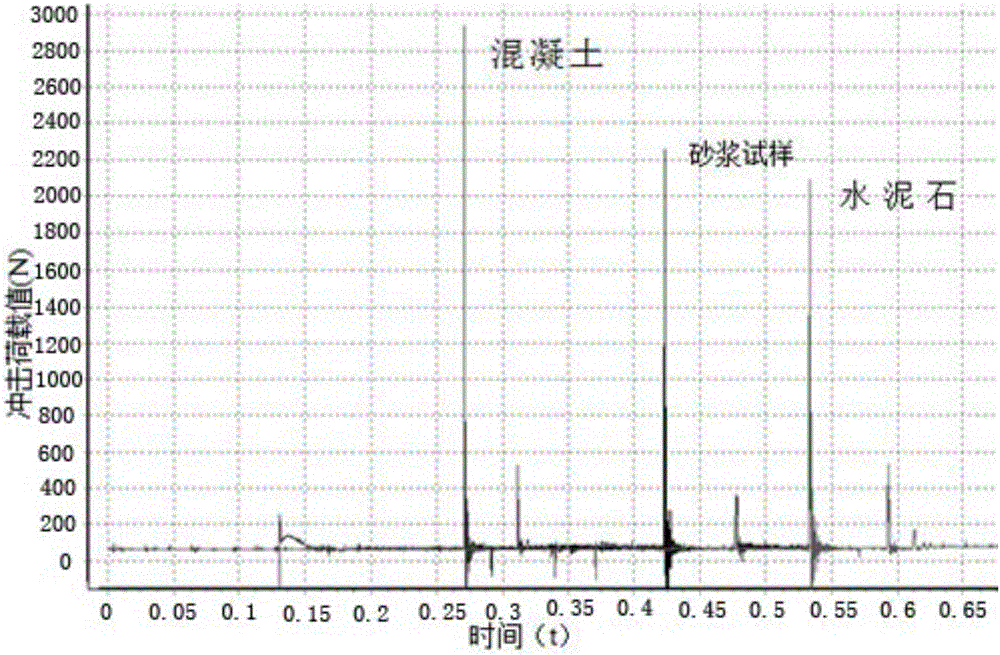

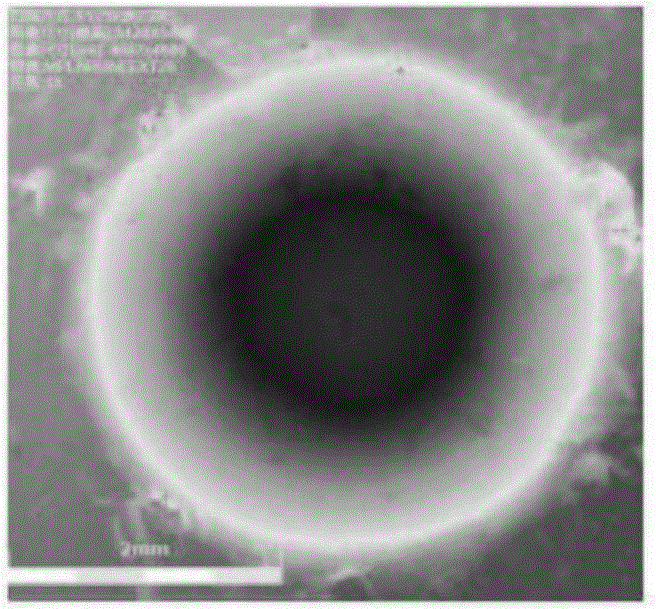

Impacting ball-pressure testing and evaluation method of engineering material

The invention belongs to the technical field of engineering material detection and in particular relates to an impacting ball-pressure testing and evaluation method of an engineering material. An impact load and an impact indentation radius are obtained through an impacting ball-pressure test, so that the plasticity resistance, deformation capability, elasticity recovery capability, surface dynamic elastic modulus and shear modulus of the engineering material are analyzed; the impacting ball-pressure testing and evaluation method comprises four parts including test sample treatment, impacting testing, three-dimensional shape inspection and data processing. Compared with the prior art, the impacting ball-pressure testing method provided by the invention can realize polishing on a test sample needing surface treatment; a self-researched automatic ball-pressure tester can be used for carrying out a small-energy impacting ball-pressure test, and shape changes of the test sample are analyzed by measuring a 3D (Three Dimensional) shape of a surface damaged region of the test sample through utilizing a laser confocal technology; finally, test sample surface mechanical properties including the plasticity resistance, deformation capability, elasticity recovery capability, surface dynamic elastic modulus and shear modulus and the like of the surface of the test sample are analyzed through corresponding software; finally, one set of complete impacting ball-pressure testing method of the engineering material is obtained.

Owner:INNER MONGOLIA UNIV OF TECH

Chemical-free production method of graphene-encapsulated electrode active material particles for battery applications

PendingUS20200266426A1Improve mechanical propertiesImprove thermal conductivityPositive electrodesNon-aqueous electrolyte accumulator electrodesGraphene flakeEnergy impact

Provided is a simple, fast, scalable, and environmentally benign method of producing graphene-embraced particles of a battery electrode active material, comprising: a) mixing graphitic material particles and multiple particles of a milling media to form a mixture in an impacting chamber of an energy impacting apparatus; b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for transferring graphene sheets from the graphitic material to surfaces of milling media particles to produce graphene-embraced milling media particles; c) mixing particles of an active material with graphene-embraced milling media particles in an impacting chamber of an energy impacting apparatus; d) operating the energy impacting apparatus for transferring graphene sheets from the graphene-embraced milling media particles to surfaces of active material particles to produce graphene-embraced electrode active material particles; and e) recovering these graphene-embraced active material particles from the impacting chamber.

Owner:GLOBAL GRAPHENE GRP INC

Positive-pressure blasting device

ActiveCN102536177ASuccessful implementation of fracturing operationsAvoid failureFluid removalCombustionEnergy impact

The invention discloses a positive-pressure blasting device, which solves the problem that ultra-shallow well crustless bomb high-energy gas fracturing cannot be directly realized in the prior art. The positive-pressure blasting device comprises a primer ignition system, a pressure generator and an initiation device. A bridge plug grain is arranged in the central hole of the pressure generator. The upper end of the pressure generator is connected with an ignition joint in a screwing way. The initiation device comprises a pressure initiation joint, a pressure initiation firing pin, a micro initiation core piece and a booster grain, wherein the booster grain, the micro initiation core piece and the pressure initiation firing pin are sequentially arranged in the center of the pressure initiation joint from the bottom to the top. The positive-pressure blasting device has the advantages that the combustion is ensured to be full during ultra-shallow well crustless bomb high-energy gas fracturing, the ultra-shallow well fracturing operation is smoothly realized, the filler is prevented from being discharged out of a hole and being failed, the explosion energy impact waves can decompose petroleum and natural gas hydrate solids into liquid and gas, and the collection and extraction of the generated liquid and gaseous natural gas hydrates are facilitated.

Owner:甘肃兰金民用爆炸高新技术有限责任公司

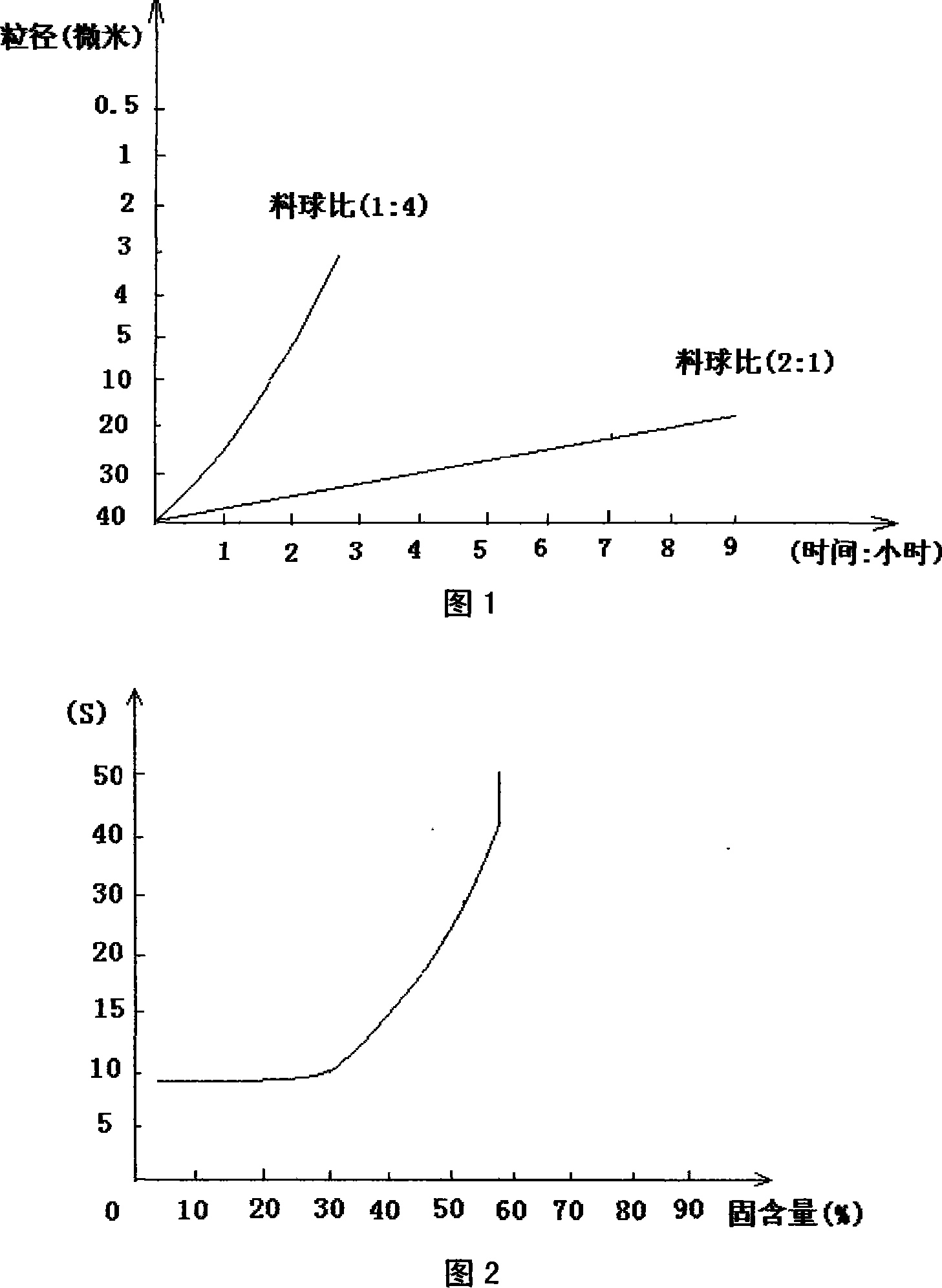

Super-fine smashing method for reduction dye

ActiveCN101230205AReduced pre-dispersion timeReduce the ratioOrganic dyesEnergy impactMixed materials

The invention relates to a super-fine crushing method of vat dye, which is characterized in that the super-fine crushing method comprises the following steps: the vat dye, dispersant and water are added into the ball crusher, to perform the ball milling mixing into pulpy material, and the pulpy material is pre-dispersed; the fluid energy impact and smashing is performed to the mixed material obtained in the first step through a pin mill; the smashed mixed material is added with anti-bubbling agent, and superfine-ground in a bidirectional rotating ball mill. The novel process adopts the process method that according to the particle distribution and the physical property of the pulpy material, the different equipment and process methods are chosen at the different stages to perform the effective grinding to attain the best grinding effect, and a process cycle period has 12-48 hours. The traditional process is that a variety of dye with different structures and performances is ground through the invariable device and process, but the novel process is that aiming at the a variety of dye with different structures and performances, the best grinding process is found through the multivariant devices and processes.

Owner:XUZHOU KAIDA FINE CHEM CO LTD +1

Chemical-free production of graphene-encapsulated electrode active material particles for battery applications

Provided is a simple, fast, scalable, and environmentally benign method of producing graphene-embraced or encapsulated particles of a battery electrode active material directly from a graphitic material, the method comprising: a) mixing graphitic material particles and multiple particles of a solid electrode active material to form a mixture in an impacting chamber of an energy impacting apparatus, wherein the graphitic material has never been intercalated, oxidized, or exfoliated and the chamber contains therein no previously produced graphene sheets and no ball-milling media; b) operating the energy impacting apparatus with a frequency and an intensity to transfer graphene sheets from the graphitic material to surfaces of electrode active material particles to produce graphene-embraced electrode active material particles; and c) recovering the particles from the impacting chamber. Also provided is a mass of the graphene-embraced particles, electrode containing such particles, and battery containing this electrode.

Owner:NANOTEK INSTR

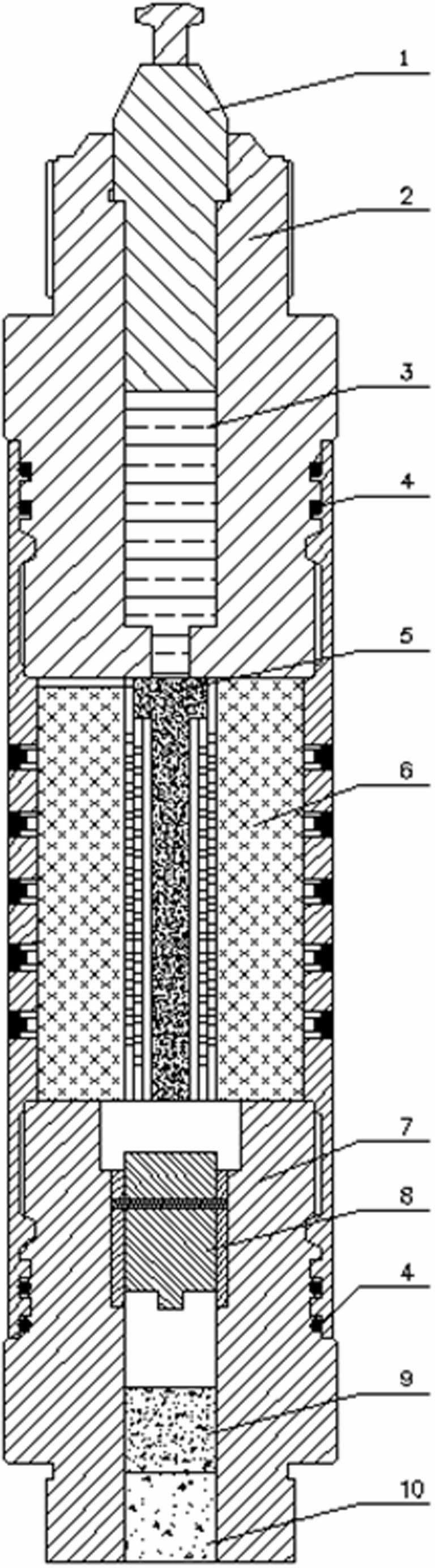

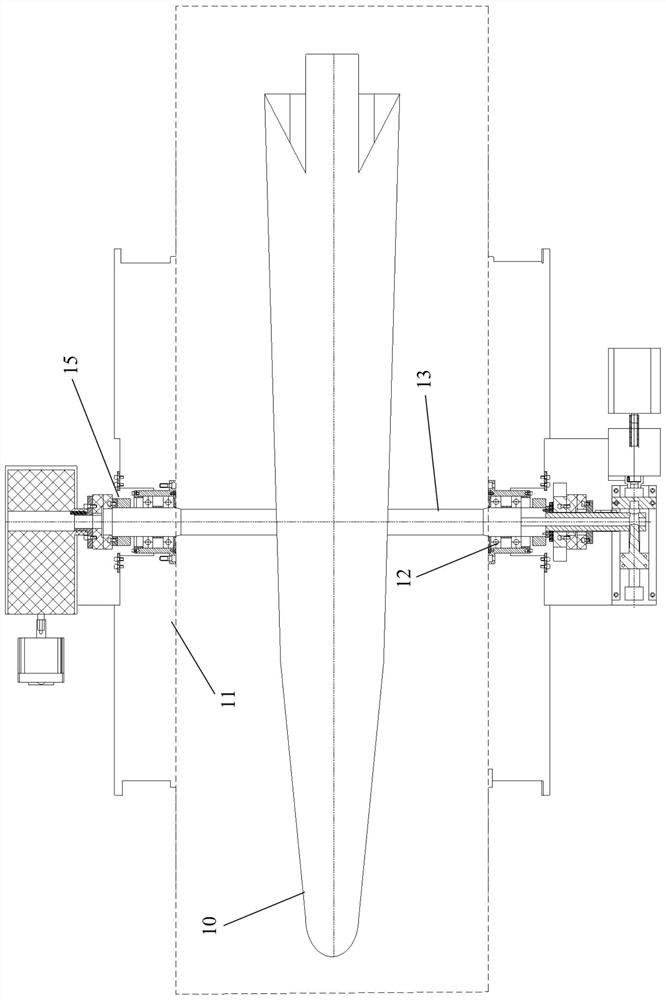

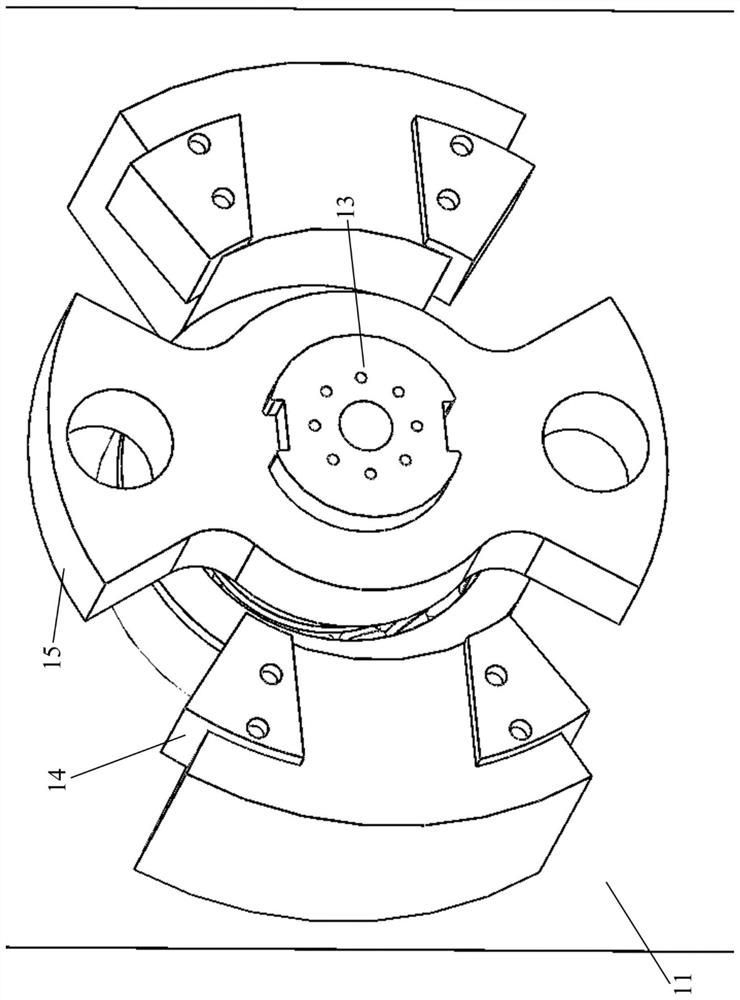

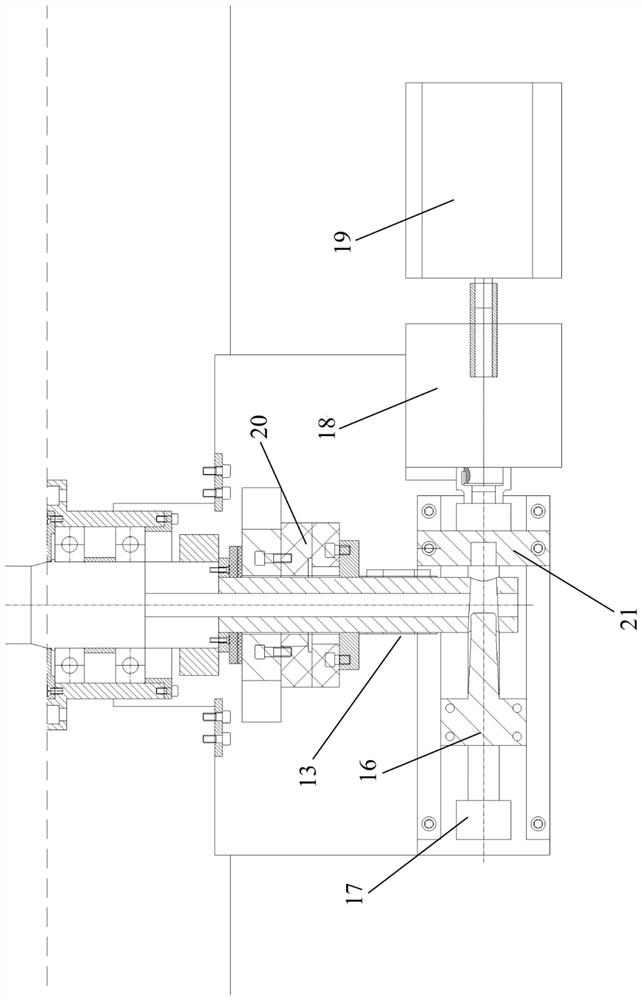

Supersonic wind tunnel model pitching motion protection device

ActiveCN112268676AInjury-free sportsResist short-term strong energy impactAerodynamic testingFlight vehicleHigh energy

The invention discloses a supersonic wind tunnel model pitching motion protection device. The pitching motion protection device comprises a transverse support, the main body of the transverse supportis a tubular support rod, and the tubular support rod penetrates through the mass center of an aircraft model to support the aircraft model on the central axis of a wind tunnel test section; a motionbearing, a mechanical limiting mechanism and an anti-impact conical surface locking mechanism are sequentially installed on the tubular supporting rod extending out of the left side of the transversesupport outside the wind tunnel test section, and a motion bearing, a mechanical limiting mechanism and an emergency forced zero returning mechanism are sequentially installed on the tubular supporting rod extending out of the right side of the transverse support. The pitching motion protection device can provide three-level protection from weak to strong for an aircraft model of a supersonic windtunnel simulation test, has the advantages of being reliable in structure and convenient to control, has the functions of high resistance to high-energy impact, forced zero returning and the like, and can be expanded to be used in supporting model systems on the two sides of a subsonic wind tunnel and a transonic wind tunnel.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

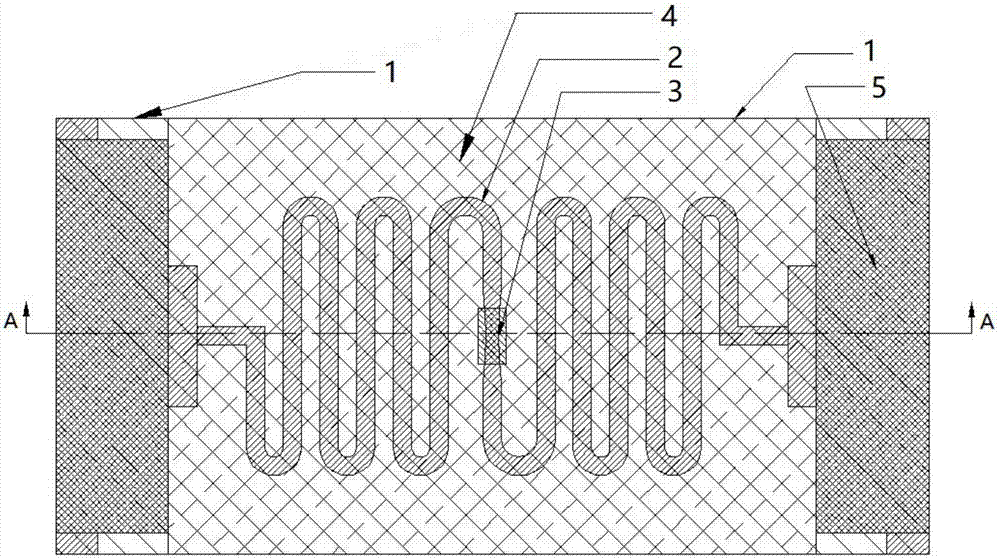

PCB (printed circuit board) matrix fuse and manufacturing method thereof

ActiveCN107464732AImprove breaking capacityImprove anti-surge performanceFuse device manufactureUltrasound attenuationEnergy impact

The invention discloses a PCB (printed circuit board) matrix fuse and a manufacturing method thereof. A PCB substrate is used as a matrix, and is wrapped by flame-retardant arc-extinguishing glue; an effect point part of a melt layer on the upper surface of the PCB substrate is wrapped by a melting supporter; the melting supporter is wrapped by an arc extinguishing protection layer prepared from the flame-retardant arc-extinguishing glue, so that the effect point part, which is easy to fuse, on the melt layer is completely wrapped in the flame-retardant arc-extinguishing glue, and the flame-retardant arc-extinguishing glue is provided with an arc extinguishing layer of a three-dimensional elastic structure and a nanofiller; in case of high current and high voltage in the fuse, a breaking arc generates plasmas which are outwards splashed; the arc extinguishing layer can absorb a large amount of heat and bear energy impact of the plasmas; the nanofiller absorbs a large amount of heat and is partially decomposed, thus generating flame-retardant arc-extinguishing gas which accelerates attenuation of short circuit current to finally extinguish the arc; the breaking capacity is improved, and the surge resisting capacity is also improved. The manufacturing method is mature in process; for a small-sized fuse with high surge resistance and high breaking capacity, the manufacturing method is relatively low in cost.

Owner:NANJING SART SCI & TECH DEV

Low-temperature laser spot impact welding driven without contact

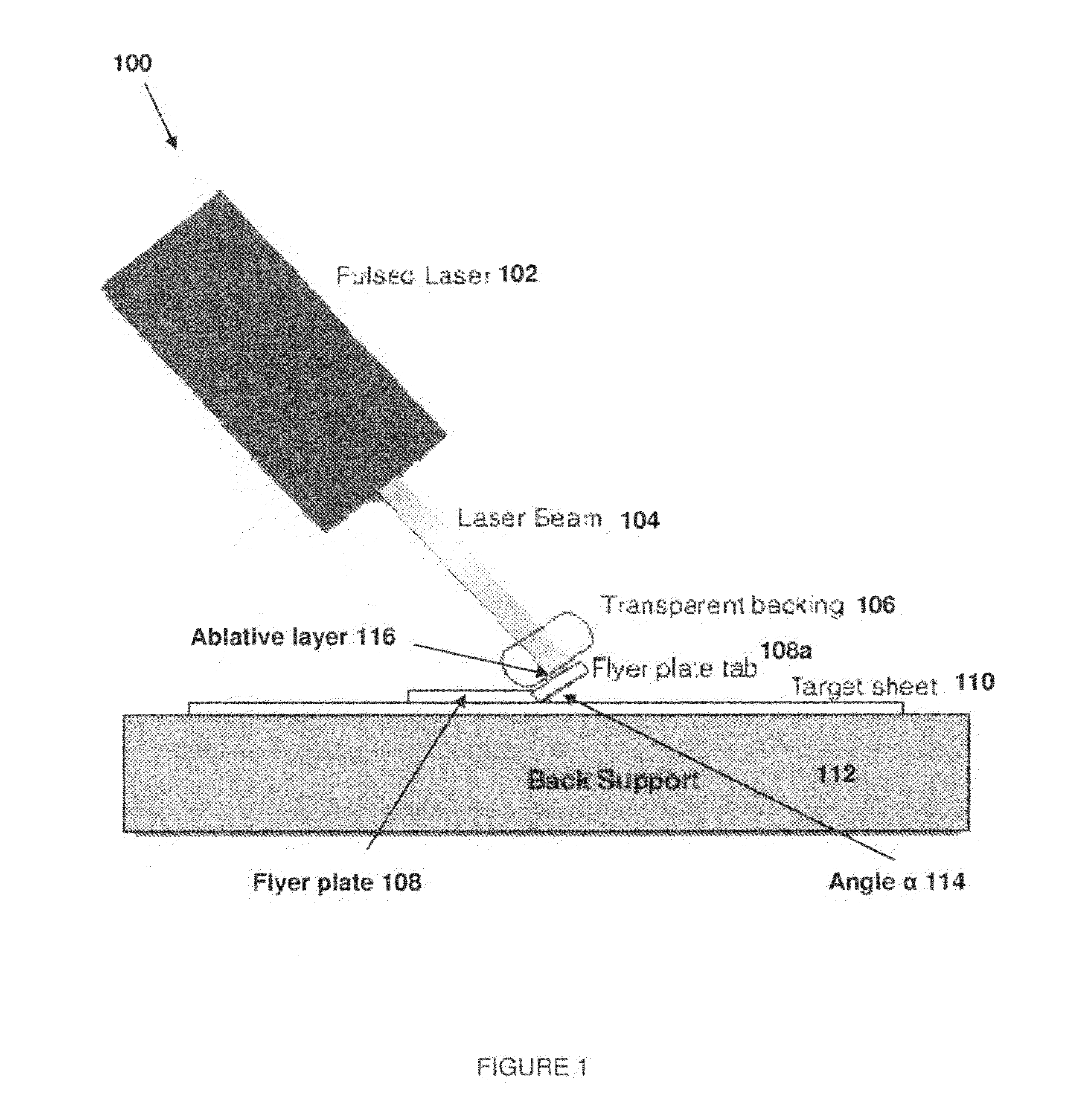

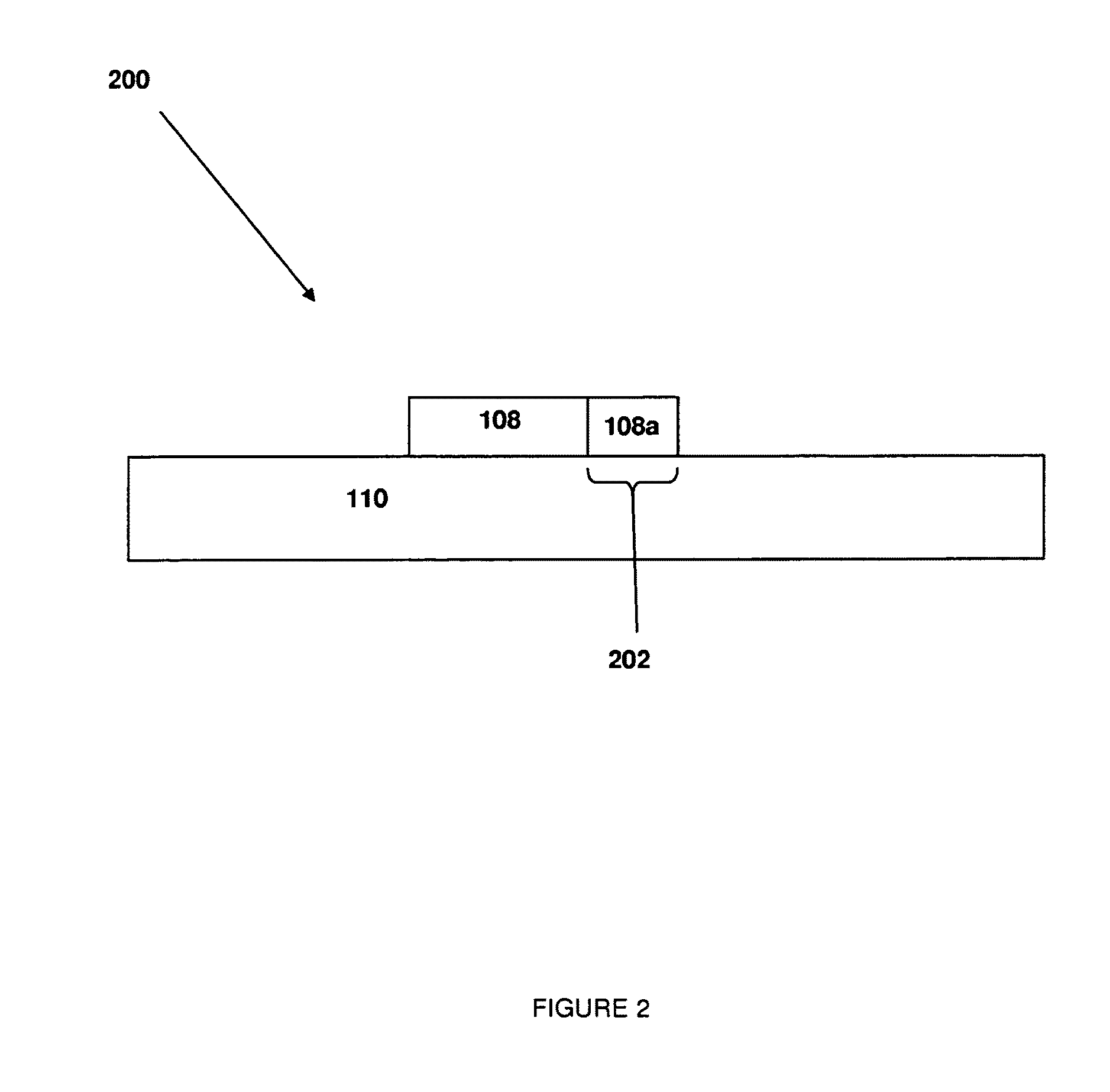

ActiveUS8084710B2Absorbs optical energyEasily ablatedDomestic vesselsMetal working apparatusEnergy impactEngineering

A laser, aimed at a flyer plate tab, causes optical energy to be directed at the tab, specifically, at a top surface thereof. Energy impacting the tab accelerates the tab out of an initial bent position, straightening it into an impact with a target sheet. The impact occurs in excess of 100 m / s, resulting in a metallurgical bond between the tab and the target sheet. The laser preferably strikes the top surface in a normal direction, based upon an initial angularity of the tab relative to the target. The laser emission, preferably in the range of 1 to 100 Joules delivered in a microsecond, may be augmented by an ablative layer on the top surface or a transparent covering on the top surface that reacts against the expanding gas from ablative activity on the top surface. The weld is formed without physical contact between the welding device and the tab.

Owner:THE OHIO STATES UNIV

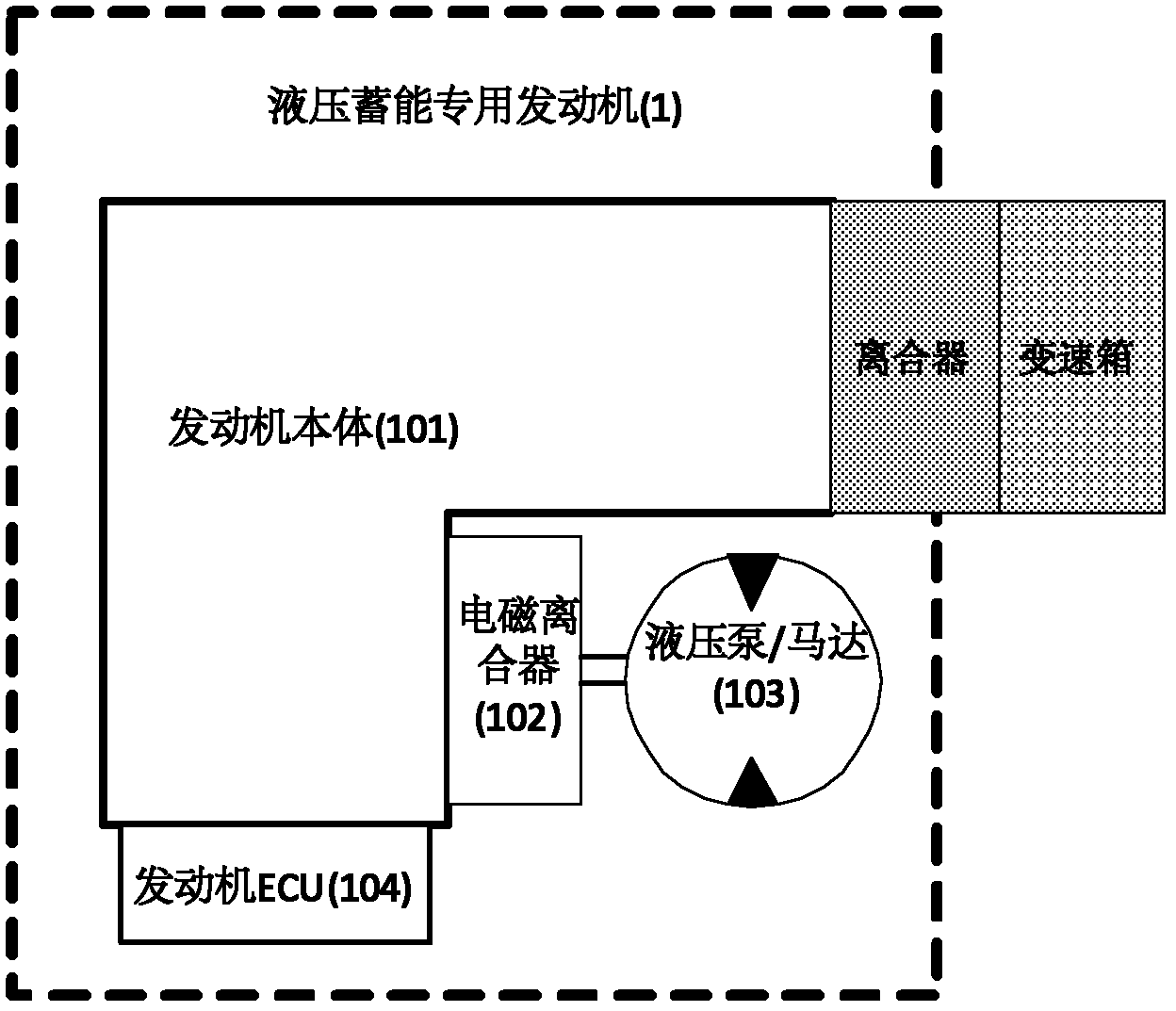

System and method for providing hydraulic energy-accumulation hybrid power

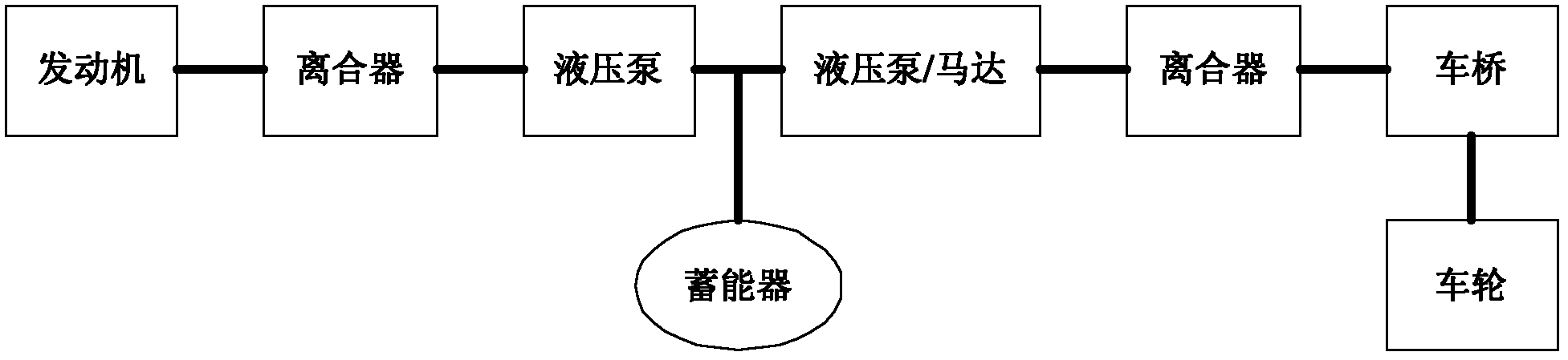

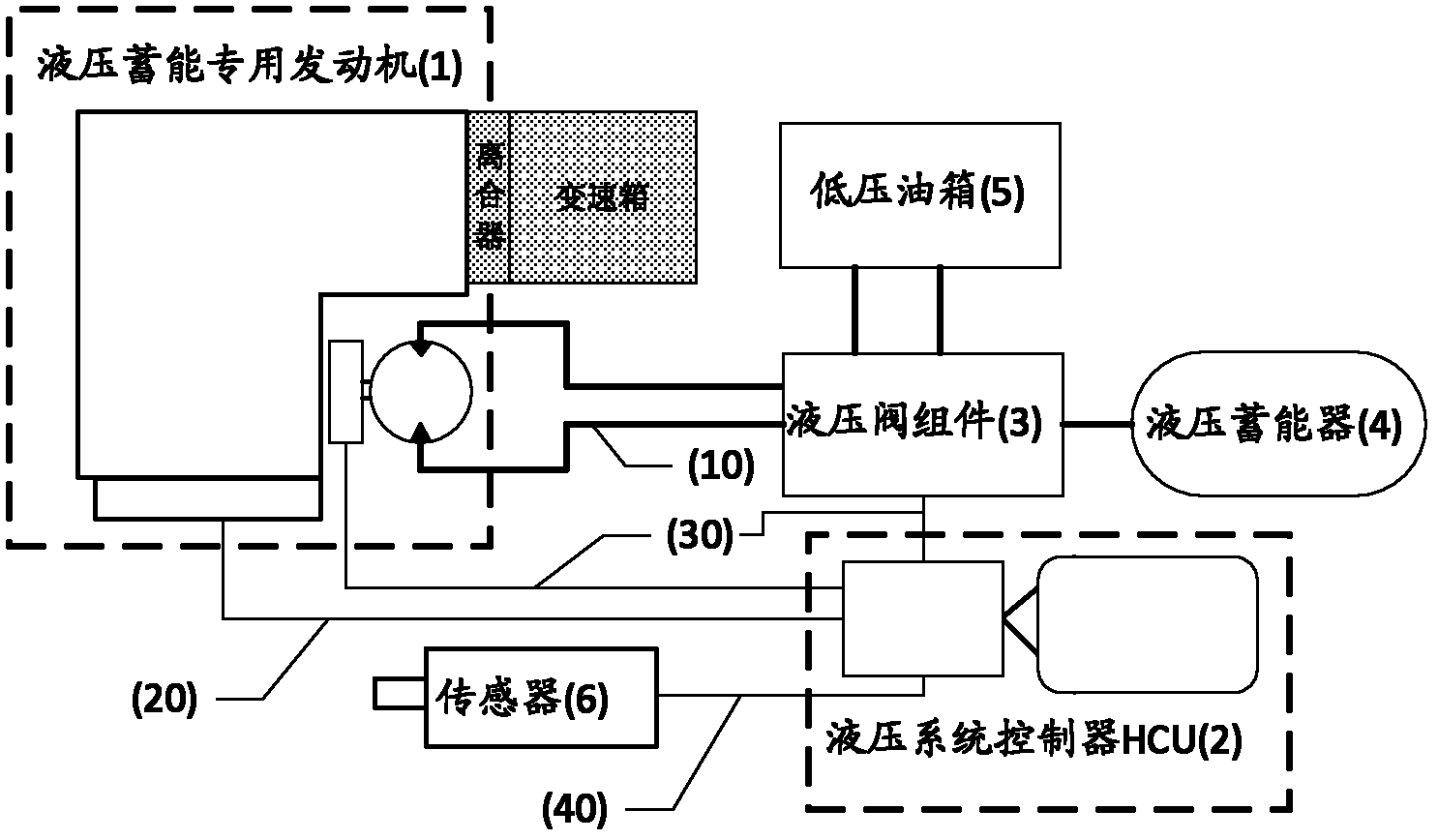

ActiveCN102616125ASave energyDoes not affect operationGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingLiquid mediumHydraulic pump

The invention discloses a system and a method for providing hydraulic energy-accumulation hybrid power. In the system disclosed by the invention, an engine is interacted with a hydraulic pump / motor through a special clutch for engines, and outputs power to a gearbox through an external clutch. In the process of car braking, the engine drives the hydraulic pump / motor to rotate through the special clutch so as to convert the mechanical energy of the hydraulic pump / motor into the pressure energy of a liquid medium, and stores the liquid medium with the power energy into a hydraulic energy accumulator, thereby achieving an effect of energy recovery; and in the process of car starting or accelerating, the liquid medium with the power energy impacts the hydraulic pump / motor to rotate, the hydraulic pump / motor converts the power energy into mechanical energy and outputs the mechanical energy to the engine by the special clutch, and the engine drives a car to go forward through the external clutch, thereby achieving an effect of energy regeneration. The method disclosed by the invention comprises the steps of judging the state of a car according to acquired car information and then carrying out corresponding control on the system, thereby achieving the purpose of energy recovery or regeneration.

Owner:WEICHAI POWER CO LTD

Chemical-free production of graphene materials

ActiveCN108430642AImprove conductivityHigh thermal conductivityMaterial nanotechnologyGrapheneGraphene flakeEnergy impact

A method of producing isolated graphene sheets directly from a graphitic material, comprising: a) mixing multiple particles of a graphitic material and multiple particles of a solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; b) operating the impacting apparatus for peeling off graphene sheets from the graphitic material and transferring these graphene sheets to surfaces of solid carrier material particles to produce graphene-coated solid particles inside the impacting chamber; c) separating the graphene sheet from the solid carrier material particle surfaces to recover isolated graphene sheets. The method enables production of graphene sheets directly from a graphitic material without going through a chemical intercalation or oxidation procedure. The process is fast (hours as opposed to days of conventional processes), has low or no water usage, environmentally benign, cost effective, and highly scalable.

Owner:NANOTEK INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com